Riser Types In Casting . a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. riser can supply feed metal. design riser (or feeder): If one would draw a line separating the casting section to be fed by a riser and the section to be fed. The most basic categorization of risers is made into closed and open risers (fig. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. Closed risers (also referred to as blind risers) are connected to. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. A combination of shape and formulation have an important effect on the efficiency of the riser’s.

from www.zhycasting.com

the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. A combination of shape and formulation have an important effect on the efficiency of the riser’s. Closed risers (also referred to as blind risers) are connected to. design riser (or feeder): The most basic categorization of risers is made into closed and open risers (fig. riser can supply feed metal. If one would draw a line separating the casting section to be fed by a riser and the section to be fed. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper.

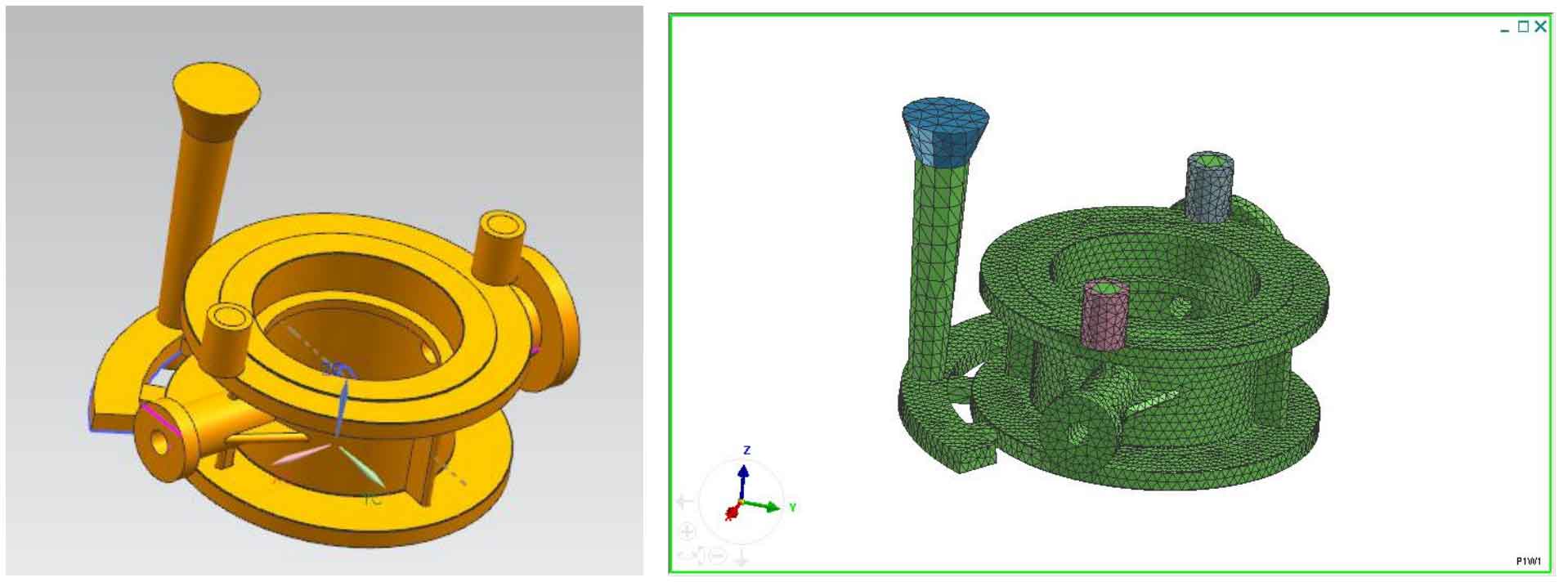

Design of riser for lost foam casting process of cast steel valve body

Riser Types In Casting riser can supply feed metal. If one would draw a line separating the casting section to be fed by a riser and the section to be fed. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. Closed risers (also referred to as blind risers) are connected to. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. The most basic categorization of risers is made into closed and open risers (fig. design riser (or feeder): A combination of shape and formulation have an important effect on the efficiency of the riser’s. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. riser can supply feed metal.

From www.scribd.com

Lecture 03Risers and Riser Design Casting (Metalworking) Amorphous Riser Types In Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. The most basic categorization of risers is made into closed and open risers (fig. A combination of shape and formulation have an important effect on the efficiency of the riser’s. riser can supply feed metal. design riser. Riser Types In Casting.

From www.slideserve.com

PPT FUNDAMENTALS OF METAL CASTING PowerPoint Presentation, free Riser Types In Casting Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. The most basic categorization of risers is made into closed and open risers (fig. riser can supply feed metal. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. If. Riser Types In Casting.

From thegraduateengineer.com

What Is A Riser In Casting? The Graduate Engineer Materials Riser Types In Casting riser can supply feed metal. Closed risers (also referred to as blind risers) are connected to. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. Riser design involves optimizing. Riser Types In Casting.

From www.youtube.com

Gating System Parts in Casting Process [Pattern, Mold, Gate, Sprue Riser Types In Casting design riser (or feeder): The most basic categorization of risers is made into closed and open risers (fig. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. the. Riser Types In Casting.

From www.hrmetalcasting.com

About metal casting iron casting steel casting riser Riser Types In Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper.. Riser Types In Casting.

From www.youtube.com

Casting Riser Design YouTube Riser Types In Casting a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. riser can supply feed metal. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release. Riser Types In Casting.

From journals.sagepub.com

Design of a gate system and riser optimization for turbine housing and Riser Types In Casting Closed risers (also referred to as blind risers) are connected to. design riser (or feeder): The most basic categorization of risers is made into closed and open risers (fig. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the. Riser Types In Casting.

From www.slideserve.com

PPT Chapter 11 Fundamentals of Casting PowerPoint Presentation, free Riser Types In Casting A combination of shape and formulation have an important effect on the efficiency of the riser’s. riser can supply feed metal. If one would draw a line separating the casting section to be fed by a riser and the section to be fed. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases. Riser Types In Casting.

From www.vrogue.co

Riser Casting vrogue.co Riser Types In Casting A combination of shape and formulation have an important effect on the efficiency of the riser’s. riser can supply feed metal. The most basic categorization of risers is made into closed and open risers (fig. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. Closed risers (also. Riser Types In Casting.

From www.sputtertargets.net

An Introduction to Metal Casting Process Stanford Advanced Materials Riser Types In Casting a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. Closed risers (also referred to as blind risers) are connected to. The most basic categorization of risers is made into closed. Riser Types In Casting.

From www.researchgate.net

Casting yields for different riser types. Download Scientific Diagram Riser Types In Casting riser can supply feed metal. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. A combination of shape and formulation have an important effect on the efficiency of the riser’s. If one would draw a line separating the casting section to be fed by a riser and the section to. Riser Types In Casting.

From www.youtube.com

Riser Design Metal Casting Production Process 1 YouTube Riser Types In Casting design riser (or feeder): a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. riser can supply feed metal. the three ways that risers should be designed for. Riser Types In Casting.

From www.zhycasting.com

Design of riser for lost foam casting process of cast steel valve body Riser Types In Casting If one would draw a line separating the casting section to be fed by a riser and the section to be fed. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. The most basic categorization of risers is made into closed and open risers (fig. a riser (also called a. Riser Types In Casting.

From www.youtube.com

Metal casting riser design calculation Riser design example problems Riser Types In Casting Closed risers (also referred to as blind risers) are connected to. design riser (or feeder): Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. If one would draw a. Riser Types In Casting.

From www.youtube.com

Casting 07 Riser Design Part I YouTube Riser Types In Casting The most basic categorization of risers is made into closed and open risers (fig. riser can supply feed metal. Closed risers (also referred to as blind risers) are connected to. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. design riser (or feeder): a riser. Riser Types In Casting.

From www.learnpick.in

Riser Design In Casting Notes LearnPick India Riser Types In Casting Closed risers (also referred to as blind risers) are connected to. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. If one would draw a line separating the casting section. Riser Types In Casting.

From www.studypool.com

SOLUTION Principle of getting riser in casting Studypool Riser Types In Casting The most basic categorization of risers is made into closed and open risers (fig. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. design riser (or feeder): riser. Riser Types In Casting.

From www.mech4study.com

Types of Casting in Manufacturing Mech4study Riser Types In Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. The most basic categorization of risers is made into closed and open risers (fig. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. a riser (also called a “feeder”). Riser Types In Casting.

From www.learnpick.in

Riser Design In Casting Notes LearnPick India Riser Types In Casting If one would draw a line separating the casting section to be fed by a riser and the section to be fed. A combination of shape and formulation have an important effect on the efficiency of the riser’s. The most basic categorization of risers is made into closed and open risers (fig. design riser (or feeder): riser can. Riser Types In Casting.

From www.zhycasting.com

Riser design of casting process for cast steel joint ZHY Casting Riser Types In Casting The most basic categorization of risers is made into closed and open risers (fig. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. design riser (or feeder): Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. A combination. Riser Types In Casting.

From www.youtube.com

Casting Riser and riser design Last Sec (6) YouTube Riser Types In Casting a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. design riser (or feeder): riser can supply feed metal. the three ways that risers should be designed for. Riser Types In Casting.

From www.youtube.com

Casting Process Riser Design YouTube Riser Types In Casting A combination of shape and formulation have an important effect on the efficiency of the riser’s. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. design riser (or feeder):. Riser Types In Casting.

From www.zhycasting.com

Effect of different riser height on casting defect distribution of Riser Types In Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. If one would draw a line separating the casting section to be fed by a riser and the section to be fed. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during. Riser Types In Casting.

From www.sefunm.com

What is Riser Sleeve? What is the Function of the Riser Sleeve? Knowledge Riser Types In Casting Closed risers (also referred to as blind risers) are connected to. design riser (or feeder): A combination of shape and formulation have an important effect on the efficiency of the riser’s. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. The most basic categorization of risers is made into closed. Riser Types In Casting.

From www.youtube.com

Riser Design Metal casting YouTube Riser Types In Casting Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. design riser (or feeder): the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. riser can supply feed metal. a riser (also called a “feeder”) attaches to the. Riser Types In Casting.

From www.mechgrace.com

Riser In Casting Types Diagram Design Riser In Gating System Riser Types In Casting Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. A combination of shape and formulation have an important effect on the efficiency of the riser’s. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. The most basic categorization of. Riser Types In Casting.

From www.mdpi.com

Metals Free FullText Heating System for Riser Size Minimizing in Riser Types In Casting Closed risers (also referred to as blind risers) are connected to. If one would draw a line separating the casting section to be fed by a riser and the section to be fed. A combination of shape and formulation have an important effect on the efficiency of the riser’s. The most basic categorization of risers is made into closed and. Riser Types In Casting.

From en-academic.com

Riser (casting) Riser Types In Casting riser can supply feed metal. Closed risers (also referred to as blind risers) are connected to. design riser (or feeder): Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. If one would draw a line separating the casting section to be fed by a riser and the section to. Riser Types In Casting.

From www.sefunm.com

Types of Risers in Casting Knowledge Cangzhou Sefu Ceramic New Riser Types In Casting Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. design riser (or feeder): If one would draw a line separating the casting section to be fed by a riser and the section to be fed. a riser (also called a “feeder”) attaches to the mold at the point of. Riser Types In Casting.

From thors.com

Gating and Risering Basics Course Riser Types In Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper.. Riser Types In Casting.

From www.zhycasting.com

Riser design of gating system for steel castings ZHY Casting Riser Types In Casting design riser (or feeder): If one would draw a line separating the casting section to be fed by a riser and the section to be fed. riser can supply feed metal. a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during. Riser Types In Casting.

From www.zhycasting.com

Design of riser in sand casting ZHY Casting Riser Types In Casting The most basic categorization of risers is made into closed and open risers (fig. riser can supply feed metal. Riser design involves optimizing size, position, and shape to compensate for metal shrinkage and release gases during casting. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. Closed. Riser Types In Casting.

From thelibraryofmanufacturing.com

The Metal Casting Operation Riser Types In Casting design riser (or feeder): A combination of shape and formulation have an important effect on the efficiency of the riser’s. riser can supply feed metal. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. Riser design involves optimizing size, position, and shape to compensate for metal. Riser Types In Casting.

From www.mdpi.com

Metals Free FullText Heating System for Riser Size Minimizing in Riser Types In Casting a riser (also called a “feeder”) attaches to the mold at the point of molten metal entry, to prevent cavities from forming due to shrinkage during solidification because the last point to solidify is outside the mold proper. The most basic categorization of risers is made into closed and open risers (fig. riser can supply feed metal. Closed. Riser Types In Casting.

From www.youtube.com

CASTING (TYPES OF RISER AND DESIGN OF RISER) YouTube Riser Types In Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. riser can supply feed metal. If one would draw a line separating the casting section to be fed by a riser and the section to be fed. A combination of shape and formulation have an important effect on. Riser Types In Casting.