What Are The Different Types Of Plastic Extrusion . The process requires careful control of temperature, speed, and pressure. The material is then heated until it melts, turning into a liquefied form. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. Plastic extrusion is a vital process in the manufacturing industry. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The four major processes are. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. Plastic extrusion has different processes for different applications. four types of plastic extrusion processes. The process involves feeding plastic material pellets into an extruder. what is plastic extrusion?

from www.slideserve.com

Plastic extrusion has different processes for different applications. The material is then heated until it melts, turning into a liquefied form. The process involves feeding plastic material pellets into an extruder. The process requires careful control of temperature, speed, and pressure. The four major processes are. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. Plastic extrusion is a vital process in the manufacturing industry. four types of plastic extrusion processes.

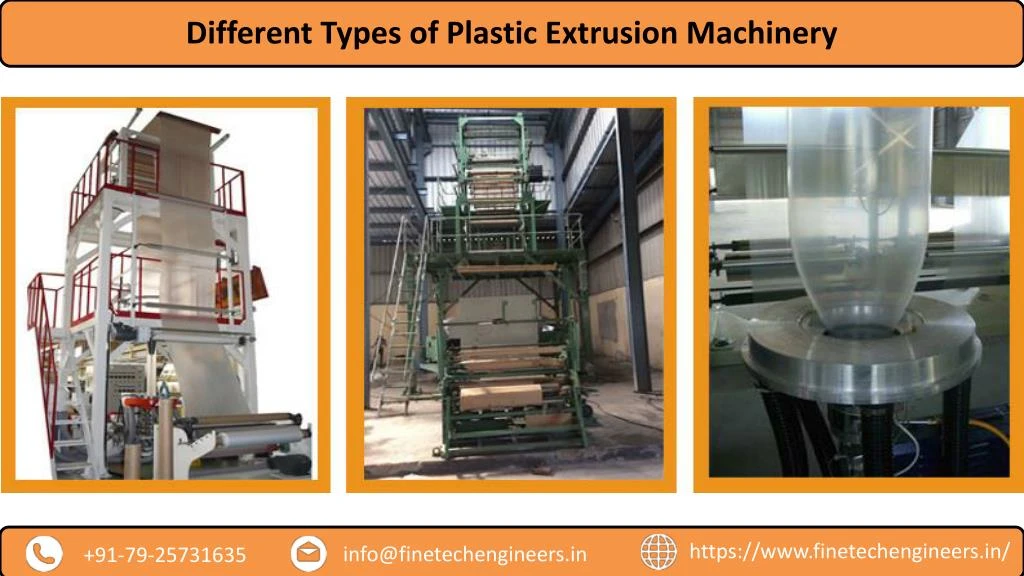

PPT Different Types of Plastic Extrusion Machinery PowerPoint

What Are The Different Types Of Plastic Extrusion what is plastic extrusion? four types of plastic extrusion processes. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The material is then heated until it melts, turning into a liquefied form. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Plastic extrusion has different processes for different applications. The process requires careful control of temperature, speed, and pressure. Plastic extrusion is a vital process in the manufacturing industry. The four major processes are. The process involves feeding plastic material pellets into an extruder. what is plastic extrusion?

From www.iqsdirectory.com

Plastic Extrusion Manufacturers Suppliers IQS Directory What Are The Different Types Of Plastic Extrusion plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. The process requires careful control of temperature, speed, and pressure. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The four major processes are. four types of plastic extrusion processes. Plastic extrusion is. What Are The Different Types Of Plastic Extrusion.

From www.opusplastics.com

Types of Plastic Extrusion Processes Opus Plastics What Are The Different Types Of Plastic Extrusion The four major processes are. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The process involves feeding plastic material pellets into an extruder. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. Plastic extrusion has different processes. What Are The Different Types Of Plastic Extrusion.

From www.essaii.com

What is a plastic extrusion process in a stepbystep guide? What Are The Different Types Of Plastic Extrusion This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The four major processes are. The process requires careful control of temperature, speed, and pressure. The material is then heated until it melts, turning into a liquefied form. Plastic extrusion has different processes for different applications. what is. What Are The Different Types Of Plastic Extrusion.

From theecohub.com

Understanding The 7 Types Of Plastic The Eco Hub What Are The Different Types Of Plastic Extrusion The four major processes are. four types of plastic extrusion processes. The process requires careful control of temperature, speed, and pressure. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process involves feeding plastic material pellets into an extruder. The material is then heated until it melts, turning into a liquefied. What Are The Different Types Of Plastic Extrusion.

From blog.thepipingmart.com

Types and Uses of Extrusion What Are The Different Types Of Plastic Extrusion The four major processes are. The process requires careful control of temperature, speed, and pressure. The process involves feeding plastic material pellets into an extruder. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Plastic extrusion is a vital process in the manufacturing industry. The material is then. What Are The Different Types Of Plastic Extrusion.

From www.iqsdirectory.com

Plastic Trim Types, Extrusion Methods, Applications, and Benefits What Are The Different Types Of Plastic Extrusion The process requires careful control of temperature, speed, and pressure. The material is then heated until it melts, turning into a liquefied form. what is plastic extrusion? components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The four major processes are. This process starts by feeding plastic material (pellets, granules, flakes or. What Are The Different Types Of Plastic Extrusion.

From cmppin.com

What are the 2 types of Extrusion Blow Moulding Machines? Central What Are The Different Types Of Plastic Extrusion The material is then heated until it melts, turning into a liquefied form. what is plastic extrusion? Plastic extrusion has different processes for different applications. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The four major processes are. Plastic extrusion is a vital process in the. What Are The Different Types Of Plastic Extrusion.

From www.researchgate.net

Schematic diagrams of three different extrusion forming of plastic What Are The Different Types Of Plastic Extrusion The material is then heated until it melts, turning into a liquefied form. what is plastic extrusion? The four major processes are. Plastic extrusion has different processes for different applications. four types of plastic extrusion processes. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. components of. What Are The Different Types Of Plastic Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Are The Different Types Of Plastic Extrusion what is plastic extrusion? The process involves feeding plastic material pellets into an extruder. four types of plastic extrusion processes. The material is then heated until it melts, turning into a liquefied form. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. components of a. What Are The Different Types Of Plastic Extrusion.

From www.pinterest.com

Types of Plastic Extrusion Processes Extrusion, Types of plastics What Are The Different Types Of Plastic Extrusion This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. four types of plastic extrusion processes. The material is then heated until it melts, turning into a liquefied form. The four major processes are. Plastic extrusion has different processes for different applications. what is plastic extrusion? . What Are The Different Types Of Plastic Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Are The Different Types Of Plastic Extrusion plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The four major processes are. The process requires careful control of temperature, speed, and pressure. This process starts by feeding plastic material (pellets, granules, flakes. What Are The Different Types Of Plastic Extrusion.

From www.kemalmfg.com

Plastic Extrusion Guide What Are The Different Types Of Plastic Extrusion The material is then heated until it melts, turning into a liquefied form. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. what is plastic extrusion? four types of plastic extrusion processes. Plastic extrusion has different processes for different applications. The four major processes are. . What Are The Different Types Of Plastic Extrusion.

From www.dragonmetal.com.au

Key Types of Plastic Extrusion Materials What Are The Different Types Of Plastic Extrusion The material is then heated until it melts, turning into a liquefied form. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The four major processes are. The process requires careful control of temperature, speed, and pressure. Plastic extrusion is a vital process in the manufacturing industry. The process involves feeding plastic material. What Are The Different Types Of Plastic Extrusion.

From engineeringlearner.com

Types of Extrusion Process Working, Advantages & Disadvantages What Are The Different Types Of Plastic Extrusion This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is then heated until it melts, turning into a liquefied form. what is plastic extrusion? four types of plastic extrusion processes. The four major processes are. The process involves feeding plastic material pellets into an. What Are The Different Types Of Plastic Extrusion.

From sunriseplastic.com.pk

Sunrise Plastic Industries Extrusion blow Moulding What Are The Different Types Of Plastic Extrusion The four major processes are. The process involves feeding plastic material pellets into an extruder. The process requires careful control of temperature, speed, and pressure. Plastic extrusion is a vital process in the manufacturing industry. The material is then heated until it melts, turning into a liquefied form. Plastic extrusion has different processes for different applications. components of a. What Are The Different Types Of Plastic Extrusion.

From pri-plastics.com

Understanding Plastic Extrusion Plastics Resources Inc. What Are The Different Types Of Plastic Extrusion plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process requires careful control of temperature, speed, and pressure. The process involves feeding plastic material pellets into an extruder. what is plastic extrusion?. What Are The Different Types Of Plastic Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Are The Different Types Of Plastic Extrusion components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. The process requires careful control of temperature, speed, and pressure. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. Plastic extrusion has different processes for different applications. four types of plastic extrusion processes.. What Are The Different Types Of Plastic Extrusion.

From en.lesso.com

Learn the Concept and Process of Plastic Pipe Extrusion LESSO Blog What Are The Different Types Of Plastic Extrusion Plastic extrusion is a vital process in the manufacturing industry. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The process requires careful control of temperature, speed, and pressure. The process involves feeding plastic material pellets into an extruder. four types of plastic extrusion processes. plastic. What Are The Different Types Of Plastic Extrusion.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics What Are The Different Types Of Plastic Extrusion The four major processes are. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. The process involves feeding plastic material pellets into an extruder. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Plastic extrusion is a vital. What Are The Different Types Of Plastic Extrusion.

From www.slideserve.com

PPT Different Types of Plastic Extrusion Machinery PowerPoint What Are The Different Types Of Plastic Extrusion The material is then heated until it melts, turning into a liquefied form. four types of plastic extrusion processes. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder.. What Are The Different Types Of Plastic Extrusion.

From www.sukoptfe.com

News Types of Plastic Extrusion Process What Are The Different Types Of Plastic Extrusion Plastic extrusion is a vital process in the manufacturing industry. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. four types of plastic extrusion processes. The process involves feeding plastic material pellets into an extruder. components of a plastic extruder include a screw, barrel, heaters, cooling. What Are The Different Types Of Plastic Extrusion.

From en.lesso.com

Learn the Concept and Process of Plastic Pipe Extrusion LESSO Blog What Are The Different Types Of Plastic Extrusion four types of plastic extrusion processes. The four major processes are. what is plastic extrusion? This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Plastic extrusion is a vital process in the manufacturing industry. components of a plastic extruder include a screw, barrel, heaters, cooling. What Are The Different Types Of Plastic Extrusion.

From www.mech4study.com

Extrusion Process Working, Types, Application, Advantages and What Are The Different Types Of Plastic Extrusion what is plastic extrusion? four types of plastic extrusion processes. Plastic extrusion has different processes for different applications. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. The process requires careful control of temperature, speed, and pressure. components of a plastic extruder include a screw, barrel, heaters,. What Are The Different Types Of Plastic Extrusion.

From www.iqsdirectory.com

Plastic Rods Definition, Types, Applications, and Benefits What Are The Different Types Of Plastic Extrusion The four major processes are. Plastic extrusion has different processes for different applications. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The process requires careful control of temperature, speed, and pressure. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die.. What Are The Different Types Of Plastic Extrusion.

From www.hardwareinterviews.fyi

Basics of Plastic Extrusion 2 by beechiaseed Consumer Hardware What Are The Different Types Of Plastic Extrusion four types of plastic extrusion processes. Plastic extrusion has different processes for different applications. The process involves feeding plastic material pellets into an extruder. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. what is plastic extrusion? components of a plastic extruder include a screw, barrel, heaters,. What Are The Different Types Of Plastic Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Are The Different Types Of Plastic Extrusion plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Plastic extrusion is a vital process in the manufacturing industry. what is plastic extrusion? The four major processes are.. What Are The Different Types Of Plastic Extrusion.

From www.youtube.com

Basic Of Extrusion Process I Type of extrusion technique YouTube What Are The Different Types Of Plastic Extrusion The four major processes are. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. The material is then heated until it melts, turning into a liquefied form. The process involves feeding plastic material pellets into an extruder. This process starts by feeding plastic material (pellets, granules, flakes or powders) from. What Are The Different Types Of Plastic Extrusion.

From dxorsyqnq.blob.core.windows.net

Pvc Extrusion Hcl at Robert Gonzales blog What Are The Different Types Of Plastic Extrusion The process involves feeding plastic material pellets into an extruder. The material is then heated until it melts, turning into a liquefied form. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder.. What Are The Different Types Of Plastic Extrusion.

From plastic-extrusionmachines.com

Types of Plastic Extrusion Processes & Material Selection Plastic What Are The Different Types Of Plastic Extrusion The four major processes are. The process requires careful control of temperature, speed, and pressure. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. components of a plastic extruder include a screw, barrel, heaters, cooling fans, and a die. four types of plastic extrusion processes. The. What Are The Different Types Of Plastic Extrusion.

From mechanicstips.blogspot.com

Plastic Extrusion MechanicsTips What Are The Different Types Of Plastic Extrusion The process involves feeding plastic material pellets into an extruder. what is plastic extrusion? The process requires careful control of temperature, speed, and pressure. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Plastic extrusion has different processes for different applications. The four major processes are. . What Are The Different Types Of Plastic Extrusion.

From www.opusplastics.com

What is Plastic Extrusion? Process Guide Opus Plastics What Are The Different Types Of Plastic Extrusion The process requires careful control of temperature, speed, and pressure. The material is then heated until it melts, turning into a liquefied form. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. The process involves feeding plastic material pellets into an extruder. Plastic extrusion is a vital process in the. What Are The Different Types Of Plastic Extrusion.

From www.inpvc.com

News Understanding Plastic Extrusion What Are The Different Types Of Plastic Extrusion what is plastic extrusion? The process requires careful control of temperature, speed, and pressure. four types of plastic extrusion processes. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. Plastic extrusion has different processes for different applications. The four major processes are. Plastic extrusion is a vital process. What Are The Different Types Of Plastic Extrusion.

From www.dwplastics.co.uk

Plastic Extrusion Profiles D W Plastics What Are The Different Types Of Plastic Extrusion The process involves feeding plastic material pellets into an extruder. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. Plastic extrusion is a vital process in the manufacturing industry. The four major processes are. Plastic extrusion has different processes for different applications. four types of plastic extrusion. What Are The Different Types Of Plastic Extrusion.

From technologystudent.com

Extrusion of Plastics What Are The Different Types Of Plastic Extrusion The four major processes are. The process requires careful control of temperature, speed, and pressure. Plastic extrusion is a vital process in the manufacturing industry. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. four types of plastic extrusion processes. This process starts by feeding plastic material (pellets, granules,. What Are The Different Types Of Plastic Extrusion.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process What Are The Different Types Of Plastic Extrusion Plastic extrusion is a vital process in the manufacturing industry. Plastic extrusion has different processes for different applications. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. four. What Are The Different Types Of Plastic Extrusion.