What Is Hydrostatic Testing . Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines. Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Find out the procedures, advantages, limitations, and alternatives of this testing method. This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems.

from www.meyernow.com

Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines. This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Find out the procedures, advantages, limitations, and alternatives of this testing method.

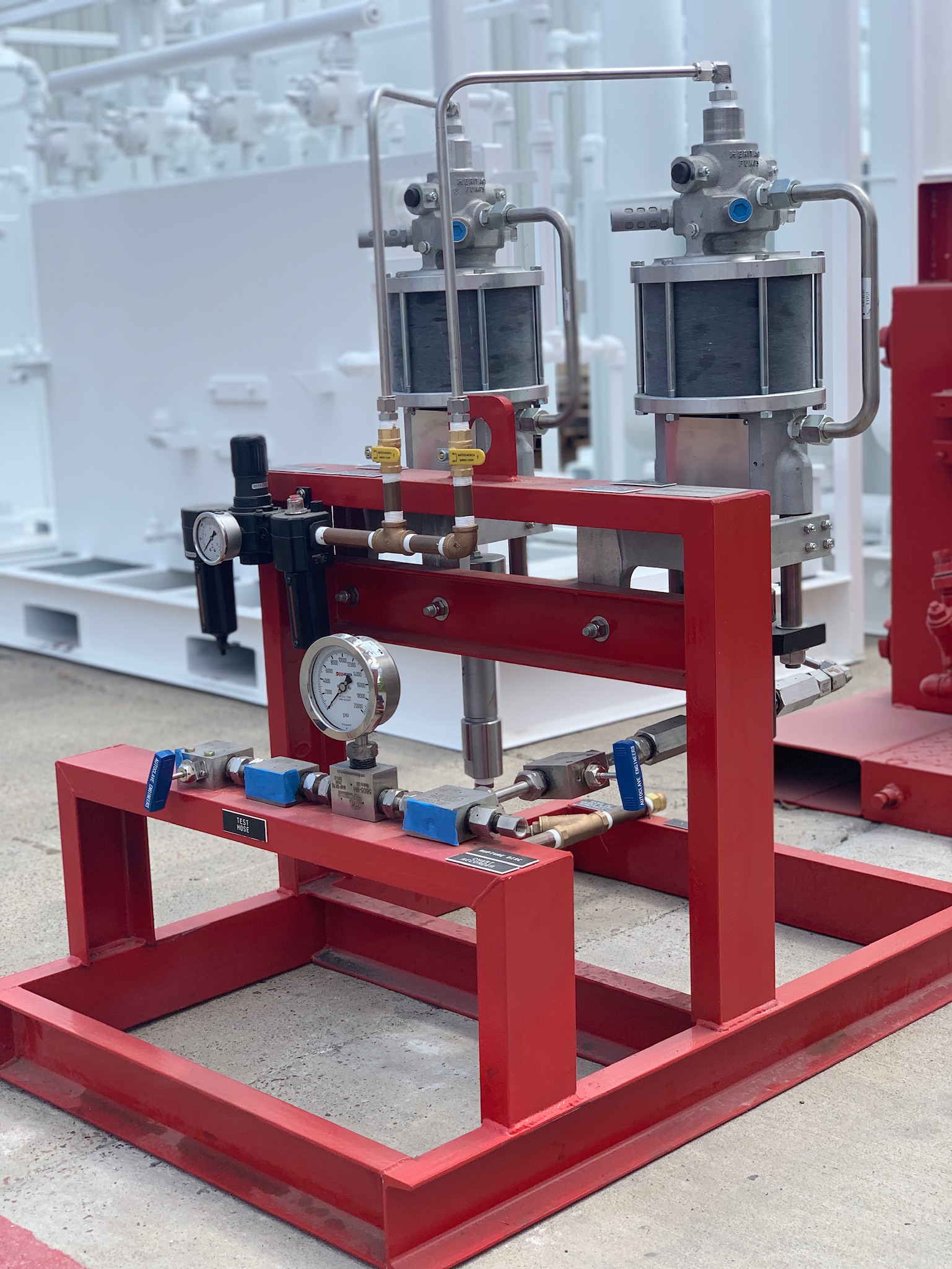

Hydrostatic Pressure Testing Equipment Hydrostatic Valve Testing

What Is Hydrostatic Testing Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems. Find out the procedures, advantages, limitations, and alternatives of this testing method. Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines.

From baco-iraq.com

Inspection & NDT & Hydrostatic Test BACO What Is Hydrostatic Testing Find out the procedures, advantages, limitations, and alternatives of this testing method. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines. Hydrostatic pressure testing is a process that uses pressure to. What Is Hydrostatic Testing.

From www.indepth.ie

Hydrostatic Pressure Testing Cavan InDepth Water Management What Is Hydrostatic Testing Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the. What Is Hydrostatic Testing.

From www.ralstoninst.com

What is Hydrostatic Pressure Testing? Ralston Instruments What Is Hydrostatic Testing This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health.. What Is Hydrostatic Testing.

From www.ralstoninst.com

What is Hydrostatic Pressure Testing? Ralston Instruments What Is Hydrostatic Testing Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure. What Is Hydrostatic Testing.

From axenics.com

What You Need to Know About DOT Hydrostatic Testing Axenics What Is Hydrostatic Testing Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Find out the procedures, advantages, limitations, and alternatives of this testing method. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to. What Is Hydrostatic Testing.

From www.ceasefireme.com

What is Hydrostatic Testing of Fire Extinguisher CeaseFire What Is Hydrostatic Testing Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic testing is a leak testing method performed in. What Is Hydrostatic Testing.

From complete.maexproit.com

What Is Hydrostatic Testing Of A Boiler? Weekly Boiler Tips with What Is Hydrostatic Testing Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Find out the procedures, advantages, limitations, and alternatives of this testing method. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will. What Is Hydrostatic Testing.

From www.mechanical-knowledge.com

HYDROSTATIC TESTING PROCEDURE AND TYPES What Is Hydrostatic Testing Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Find out the procedures, advantages, limitations, and alternatives of this testing method. Learn how the asme hydrostatic test assesses the integrity and. What Is Hydrostatic Testing.

From www.ralstoninst.com

What is Hydrostatic Pressure Testing? Ralston Instruments What Is Hydrostatic Testing Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems,. What Is Hydrostatic Testing.

From hsewatch.com

Importance Of Hydrostatic Testing In Fire Extinguisher Cylinders What Is Hydrostatic Testing Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Proper execution of hydrostatic. What Is Hydrostatic Testing.

From coastalchem.com

Hydrostatic Testing Coastal Chemical What Is Hydrostatic Testing Find out the procedures, advantages, limitations, and alternatives of this testing method. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Hydrostatic. What Is Hydrostatic Testing.

From www.precgroup.com

Hydrostatic Testing What is it, how does it work, and what are the What Is Hydrostatic Testing Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Hydrostatic testing is a method used to ensure the. What Is Hydrostatic Testing.

From alamoplumbingsolutions.com

Hydrostatic Testing Alamo Plumbing Solutions What Is Hydrostatic Testing Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid. What Is Hydrostatic Testing.

From www.youtube.com

What is Hydrostatic Testing? YouTube What Is Hydrostatic Testing Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to. What Is Hydrostatic Testing.

From ricehydro.com

Hydrostatic Test Pumps What Is Hydrostatic Testing Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Find out the procedures, advantages, limitations, and alternatives of this testing method. Learn how hydrostatic pressure testing works, why it is important,. What Is Hydrostatic Testing.

From www.meyernow.com

Hydrostatic Pressure Testing Equipment Hydrostatic Valve Testing What Is Hydrostatic Testing Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems. Learn how the. What Is Hydrostatic Testing.

From www.vrogue.co

What Is Hydrostatic Testing Sapphire Gas Solutions vrogue.co What Is Hydrostatic Testing Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems. Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Learn how hydrostatic. What Is Hydrostatic Testing.

From www.mcwaneductile.com

How to Successfully Prepare and Complete a Hydrostatic Test McWane What Is Hydrostatic Testing This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they. What Is Hydrostatic Testing.

From alamoplumbingsolutions.com

Hydrostatic Testing Alamo Plumbing Solutions What Is Hydrostatic Testing Find out the procedures, advantages, limitations, and alternatives of this testing method. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. This technique involves applying water pressure to these vessels to check for leaks and. What Is Hydrostatic Testing.

From www.sapphiregassolutions.com

What Is Hydrostatic Testing? Sapphire Gas Solutions What Is Hydrostatic Testing Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a method used to ensure the. What Is Hydrostatic Testing.

From www.ralstoninst.com

What is Hydrostatic Pressure Testing? Ralston Instruments What Is Hydrostatic Testing Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Find out the procedures, advantages, limitations, and alternatives of this testing method. Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines. Hydrostatic testing is a technique used to. What Is Hydrostatic Testing.

From www.indiamart.com

Cylinder Hydrostatic Testing, Cylinder Testing Work, सिलेंडर टेस्टिंग What Is Hydrostatic Testing Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Hydrostatic testing is a leak. What Is Hydrostatic Testing.

From www.gz-supplies.com

HYDROSTATIC TESTING GZ Industrial Supplies What Is Hydrostatic Testing Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Find out the procedures, advantages, limitations, and alternatives of this testing method. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. This technique involves applying water pressure to these vessels to. What Is Hydrostatic Testing.

From www.hoseshop.com

What Is OnSite Hydrostatic Pressure Testing? What Is Hydrostatic Testing Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Find out the procedures,. What Is Hydrostatic Testing.

From blog.koorsen.com

What is Hydrostatic Testing of Portable ABC Fire Extinguishers? What Is Hydrostatic Testing Learn the definition, procedure, equipment, and asme standards for hydrostatic testing of pipelines. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a technique used to verify the durability and. What Is Hydrostatic Testing.

From www.petrosync.com

Hydrostatic Testing Procedures and Methodologies What Is Hydrostatic Testing Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders, plumbing systems, and pipelines. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content. What Is Hydrostatic Testing.

From www.vrogue.co

What Is Hydrostatic Pipeline Pressure Testing Ant Hir vrogue.co What Is Hydrostatic Testing Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Learn the definition,. What Is Hydrostatic Testing.

From www.britewater.ie

Hydrostatic PE Pipeline Pressure Testing Type 2 Britewater What Is Hydrostatic Testing This technique involves applying water pressure to these vessels to check for leaks and assess their strength, helping to identify any weaknesses before they become problems. Find out the procedures, advantages, limitations, and alternatives of this testing method. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Learn how the asme hydrostatic test. What Is Hydrostatic Testing.

From aibusinesspro.com

Hydrostatic Testing What It Is and How Important It Is AI Business Pro What Is Hydrostatic Testing Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Hydrostatic testing is. What Is Hydrostatic Testing.

From www.desertdivers.com

Ensuring Safety The Importance Of Hydrostatic Testing For Scuba Tanks What Is Hydrostatic Testing Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by. What Is Hydrostatic Testing.

From www.youtube.com

Hydrostatic Testing How to Pressure Testing Hydro Test YouTube What Is Hydrostatic Testing Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Hydrostatic pressure testing is a process that uses pressure to measure the strength and stability of pipelines or pressurized vessels. Find out the procedures, advantages, limitations, and alternatives of this testing method. Learn how hydrostatic pressure testing works, why it is important,. What Is Hydrostatic Testing.

From www.zerust.com

Corrosion Solutions for Hydrostatic Testing ZERUST®/EXCOR® What Is Hydrostatic Testing Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Find out the procedures, advantages, limitations, and alternatives of this testing method. Learn how hydrostatic pressure testing works, why it is important,. What Is Hydrostatic Testing.

From blog.qrfs.com

What is Hydrostatic Testing of a Building’s Fire Protection System? What Is Hydrostatic Testing Find out the procedures, advantages, limitations, and alternatives of this testing method. Proper execution of hydrostatic testing protects not only infrastructure, but also the environment and public health. Hydrostatic testing is a leak testing method performed in liquid and gas pipelines before the first content throughput. Hydrostatic pressure testing is a process that uses pressure to measure the strength and. What Is Hydrostatic Testing.

From scdiving.com

Tank Hydrostatic Testing Services What Is Hydrostatic Testing Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a technique used to verify the durability and soundness of piping systems, boilers, gas cylinders, and pressure vessels by filling them with liquid and applying pressure to simulate the pressure they will experience during operation. Learn the definition, procedure,. What Is Hydrostatic Testing.

From www.superterry.com

What is a Hydrostatic Test? Terry's Plumbing What Is Hydrostatic Testing Learn how the asme hydrostatic test assesses the integrity and strength of pressure vessels by applying controlled internal pressure using water. Learn how hydrostatic pressure testing works, why it is important, and what standards and regulations apply to it. Hydrostatic testing is a method used to ensure the safety and structural integrity of pressure vessels like storage tanks, gas cylinders,. What Is Hydrostatic Testing.