Pump Motor Shaft Couplings . Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. Its primary function is to transmit. Application considerations when selecting a coupling include: Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Transmit required torque at given speed (s) fit to pump and driver shaft. The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Motor, engine) to the shaft of the pump itself. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems.

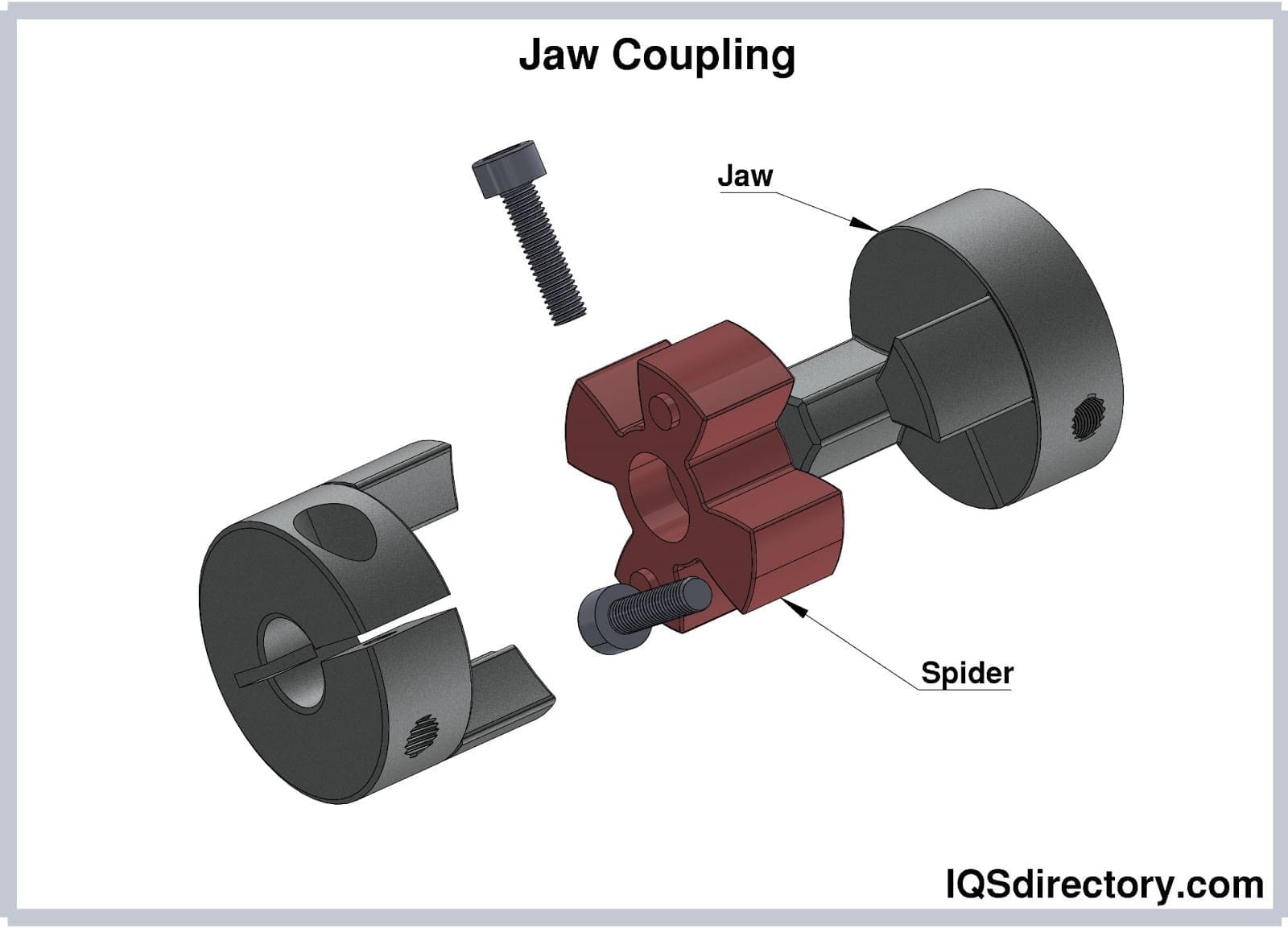

from www.iqsdirectory.com

In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Its primary function is to transmit. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Motor, engine) to the shaft of the pump itself. Application considerations when selecting a coupling include: The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems.

Shaft Coupling What Is It? How Is it Used? Types Of, Roles

Pump Motor Shaft Couplings In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. Motor, engine) to the shaft of the pump itself. The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Transmit required torque at given speed (s) fit to pump and driver shaft. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Its primary function is to transmit. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Application considerations when selecting a coupling include: Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems.

From giohcijhl.blob.core.windows.net

Motor Shaft Couplings at Dolly Price blog Pump Motor Shaft Couplings Application considerations when selecting a coupling include: Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. The primary role of a coupling is to join the rotating. Pump Motor Shaft Couplings.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Pump Motor Shaft Couplings Application considerations when selecting a coupling include: Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. The primary role of a coupling is to. Pump Motor Shaft Couplings.

From www.amazon.com

RuggedMade Steel Motor Shaft Coupling, 3/4" Inch Bore, 15/8" OD, 3 Pump Motor Shaft Couplings Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Transmit required torque at given speed (s) fit to pump and. Pump Motor Shaft Couplings.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Pump Motor Shaft Couplings The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. A pump coupling is a mechanical device used to connect two. Pump Motor Shaft Couplings.

From fixmachinedehartpips.z21.web.core.windows.net

Coupling For Hydraulic Pump Pump Motor Shaft Couplings A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Coupling the driving and driven shafts would be simple if they were. Pump Motor Shaft Couplings.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Pump Motor Shaft Couplings A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Transmit required torque at given speed (s) fit to pump and driver shaft. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. In the. Pump Motor Shaft Couplings.

From www.grainger.com

RULAND MANUFACTURING 1 Piece Clamp 1/2 in Bore Dia. 303 Stainless Steel Pump Motor Shaft Couplings Motor, engine) to the shaft of the pump itself. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Application considerations when selecting a coupling include: Pump couplings connect the pump shaft. Pump Motor Shaft Couplings.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Pump Motor Shaft Couplings In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Application considerations when selecting a coupling include: The primary role of a coupling is to join the rotating pump shaft to the. Pump Motor Shaft Couplings.

From giohcijhl.blob.core.windows.net

Motor Shaft Couplings at Dolly Price blog Pump Motor Shaft Couplings A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Pump couplings connect the pump shaft and motor shaft together in order. Pump Motor Shaft Couplings.

From klaeflhwp.blob.core.windows.net

Types Of Pump Coupling at Duane Stuart blog Pump Motor Shaft Couplings Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Coupling the driving and driven shafts would be simple if they were perfectly aligned,. Pump Motor Shaft Couplings.

From www.amazon.ca

11/2" to 1" Inch Bore Engine Motor Drive Shaft Coupling Flexible L100 Pump Motor Shaft Couplings Motor, engine) to the shaft of the pump itself. Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. The shaft coupling is the connecting element between. Pump Motor Shaft Couplings.

From mavink.com

Pump Coupling Types Pump Motor Shaft Couplings Application considerations when selecting a coupling include: Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Jaw, wrap, sleeve, tire, grid, gear and disc are. Pump Motor Shaft Couplings.

From www.idealvac.com

Ideal Vacuum Motor Shaft Coupling Kit for Edwards E2M30, E2M28, E2M18 Pump Motor Shaft Couplings Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Its primary function is to transmit. The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. A pump. Pump Motor Shaft Couplings.

From mechstuff.com

What are Couplings? Types of Couplings and their application MechStuff Pump Motor Shaft Couplings A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Transmit required torque at given speed (s) fit to pump and driver shaft. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the. Pump Motor Shaft Couplings.

From www.youtube.com

KTR couplings for PumpMotor applications YouTube Pump Motor Shaft Couplings Its primary function is to transmit. Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Transmit required torque at given speed (s) fit to pump and driver shaft. Motor, engine) to the shaft of the pump itself. Application considerations when selecting a coupling include: Pump. Pump Motor Shaft Couplings.

From www.flowfitonline.com

"Petrol Engine Drive Coupling, Motor Half, For Group 1 Pump To 3/4 Pump Motor Shaft Couplings Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Shaft couplings play an important role in pump application scenarios and are primarily used. Pump Motor Shaft Couplings.

From akita-mitsubishi.co.jp

Industrial Mechanical Power Transmission Industrial Rigid Couplings 1 Pump Motor Shaft Couplings Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Jaw, wrap, sleeve, tire, grid, gear and disc are all. Pump Motor Shaft Couplings.

From www.mrosupply.com

The Main Types of Shaft Couplings and their Applications Pump Motor Shaft Couplings The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Motor, engine) to the shaft of the pump itself. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most. Pump Motor Shaft Couplings.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Pump Motor Shaft Couplings Transmit required torque at given speed (s) fit to pump and driver shaft. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Application considerations when selecting a coupling include: Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. The primary. Pump Motor Shaft Couplings.

From www.theengineerspost.com

13 Types of Coupling Definition, Drawings, Uses & (PDF) Pump Motor Shaft Couplings The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Application considerations when selecting a coupling include: Coupling. Pump Motor Shaft Couplings.

From cimotransmission.en.made-in-china.com

Hydraulic Pump Motor Coupling Nm Flexible Rubber Shaft Coupling China Pump Motor Shaft Couplings The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Transmit required torque at given speed (s) fit to pump and driver shaft. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in. Pump Motor Shaft Couplings.

From www.amazon.com

RuggedMade Steel Splined Motor Shaft Coupling, 13/8" Inch Bore, 2" OD Pump Motor Shaft Couplings Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Motor, engine) to the shaft of the pump itself. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. Transmit required torque at given speed (s) fit. Pump Motor Shaft Couplings.

From giohcijhl.blob.core.windows.net

Motor Shaft Couplings at Dolly Price blog Pump Motor Shaft Couplings Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. Its primary function is to transmit. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Motor, engine) to the shaft of the pump. Pump Motor Shaft Couplings.

From www.zeushydratech.com

DCND108B OMT Drive Coupling, Motor Half, 11kw (42mm, 12mm key) Zeus Pump Motor Shaft Couplings The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. A pump coupling is a mechanical device used to connect. Pump Motor Shaft Couplings.

From engineeringlearn.com

Types of Mechanical Coupling and Their Uses [with Pictures Pump Motor Shaft Couplings The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Transmit required torque at given speed (s) fit to pump and driver shaft. Its primary function is to transmit. Application considerations when selecting a coupling include: The primary role of a coupling is to join the rotating pump shaft to the drive shaft of. Pump Motor Shaft Couplings.

From rsvautomotive.co.uk

Business & Industrial 1" Bore Steel Shaft Coupler 4" Long Hydraulic Pump Motor Shaft Couplings Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. Application considerations when selecting a coupling include: Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. The shaft coupling is the connecting element between the. Pump Motor Shaft Couplings.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Pump Motor Shaft Couplings Application considerations when selecting a coupling include: The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power to the pump. Motor, engine) to the shaft of the pump itself. Transmit required torque at given speed (s) fit to pump and driver shaft. Jaw,. Pump Motor Shaft Couplings.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Pump Motor Shaft Couplings In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Application considerations when selecting a coupling include: Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Transmit required torque at given speed (s). Pump Motor Shaft Couplings.

From www.linkedin.com

Mechanical Engineering Learn on LinkedIn Shaft Coupling Definition Pump Motor Shaft Couplings Transmit required torque at given speed (s) fit to pump and driver shaft. Its primary function is to transmit. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent. Pump Motor Shaft Couplings.

From www.linquip.com

What Are The Different Types of Pump Couplings? Linquip Pump Motor Shaft Couplings Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Transmit required torque at given speed (s) fit to pump and driver shaft. Application considerations when selecting a coupling include: The primary role of a coupling is to join the rotating pump shaft to the drive shaft of. Pump Motor Shaft Couplings.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Pump Motor Shaft Couplings Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. The primary role of a coupling is to join the rotating pump shaft to. Pump Motor Shaft Couplings.

From issuu.com

Flexible coupling selection for improved pump and motor efficiency and Pump Motor Shaft Couplings Application considerations when selecting a coupling include: A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. The primary role of a coupling is to join the rotating pump shaft to the drive shaft of the motor, which allows it to efficiently transmit power. Pump Motor Shaft Couplings.

From www.northerntool.com

Standard Half Coupling — 3/4in. Size Northern Tool Pump Motor Shaft Couplings Application considerations when selecting a coupling include: The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump. Pump Motor Shaft Couplings.

From www.amazon.com

RuggedMade Steel Splined Motor Shaft Coupling, 1" Inch Bore, 11/2" OD Pump Motor Shaft Couplings Application considerations when selecting a coupling include: Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Its primary function is to transmit. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Motor, engine) to the shaft of the. Pump Motor Shaft Couplings.

From engineeringlearn.com

Shaft Coupling Definition, Types, Uses, Working Principle & Advantages Pump Motor Shaft Couplings Coupling the driving and driven shafts would be simple if they were perfectly aligned, machines did not vibrate and the shafts never actually moved. Its primary function is to transmit. In the real world of power transmission, however, a flexible coupling can accommodate for the flaws and dynamics inherent in most systems. Motor, engine) to the shaft of the pump. Pump Motor Shaft Couplings.