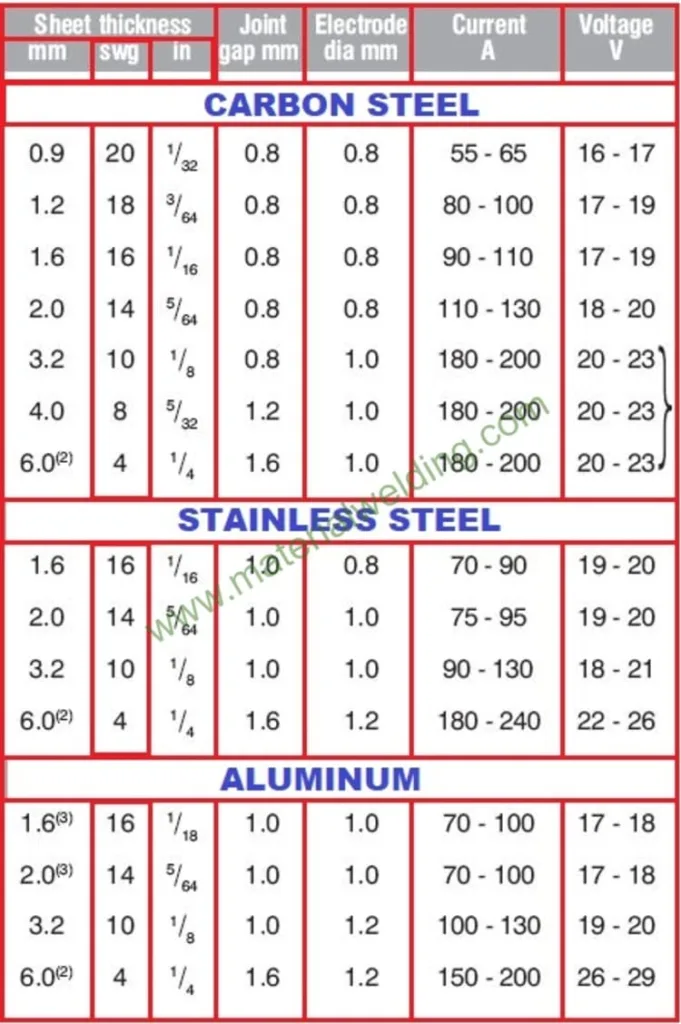

Metal Thickness Chart Mig Welder . For thicker metals, mig can struggle due to its lower. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. As a guideline, each.001 inch of material thickness requires 1 amp of output: There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully. Select proper wire size according to amperage. Since you don't want to change. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. .125 inch = 125 amps. Every welding machine has one.

from materialwelding.com

Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Every welding machine has one. Select proper wire size according to amperage. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. For thicker metals, mig can struggle due to its lower. As a guideline, each.001 inch of material thickness requires 1 amp of output: There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. .125 inch = 125 amps. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully. Since you don't want to change.

MIG welding sheet metal settings with Charts (with PDF)

Metal Thickness Chart Mig Welder Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: For thicker metals, mig can struggle due to its lower. Every welding machine has one. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. As a guideline, each.001 inch of material thickness requires 1 amp of output: Since you don't want to change. Select proper wire size according to amperage. .125 inch = 125 amps. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully.

From weldguru.com

How To MIG Weld Aluminum Beginners Guide (with Chart) Metal Thickness Chart Mig Welder For thicker metals, mig can struggle due to its lower. Select proper wire size according to amperage. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and. Metal Thickness Chart Mig Welder.

From www.instructables.com

Basics of MIG Welding 17 Steps (with Pictures) Instructables Metal Thickness Chart Mig Welder Every welding machine has one. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. The chart tells you what amperage to use for what thickness. Metal Thickness Chart Mig Welder.

From weldingmastermind.com

A MIG Welding Amps to Metal Thickness Chart Welding Mastermind Metal Thickness Chart Mig Welder .125 inch = 125 amps. Every welding machine has one. For thicker metals, mig can struggle due to its lower. Since you don't want to change. Select proper wire size according to amperage. As a guideline, each.001 inch of material thickness requires 1 amp of output: We will explain how mig deals with sheet metal, medium or hobbyist steel, and. Metal Thickness Chart Mig Welder.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Metal Thickness Chart Mig Welder .125 inch = 125 amps. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Since you don't want to change. For thicker metals, mig can struggle due to its lower. As a guideline, each.001 inch of material thickness requires 1 amp of output: The chart tells you. Metal Thickness Chart Mig Welder.

From makemoneywelding.com

Important MIG Welder Settings You Need to Know (with Chart) Metal Thickness Chart Mig Welder Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Every welding machine has one. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: There are various criteria to consider when setting your mig weld. Metal Thickness Chart Mig Welder.

From weldguru.com

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru Metal Thickness Chart Mig Welder We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Since you don't want to change. .125 inch = 125 amps. For thicker. Metal Thickness Chart Mig Welder.

From brandonkss.github.io

Mig Welding Settings Chart Metal Thickness Chart Mig Welder .125 inch = 125 amps. For thicker metals, mig can struggle due to its lower. Every welding machine has one. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas,. Metal Thickness Chart Mig Welder.

From brandonkss.github.io

Mig Welding Settings Chart Metal Thickness Chart Mig Welder Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. As a guideline, each.001 inch of material thickness requires 1 amp of output: For thicker metals, mig can struggle due to its lower. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick. Metal Thickness Chart Mig Welder.

From www.homedepot.com

How to MIG Weld The Home Depot Metal Thickness Chart Mig Welder .125 inch = 125 amps. Since you don't want to change. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Select proper wire size according to amperage. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will. Metal Thickness Chart Mig Welder.

From mavink.com

Mig Welding Guide Chart Metal Thickness Chart Mig Welder Every welding machine has one. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. .125 inch = 125 amps. There are various. Metal Thickness Chart Mig Welder.

From mollypickering.z19.web.core.windows.net

Metal Thickness Stick Welding Amperage Chart Metal Thickness Chart Mig Welder The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. For thicker metals, mig can struggle due to its lower. .125 inch = 125 amps. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld. Metal Thickness Chart Mig Welder.

From weldingdirect.com

MIG Welding Wire Output Amperage & Selection Chart Metal Thickness Chart Mig Welder Select proper wire size according to amperage. As a guideline, each.001 inch of material thickness requires 1 amp of output: Every welding machine has one. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. The chart tells you what amperage to use for what thickness and even. Metal Thickness Chart Mig Welder.

From joshuawest.z13.web.core.windows.net

Mig Welder Chart Settings Metal Thickness Chart Mig Welder .125 inch = 125 amps. Select proper wire size according to amperage. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. As a guideline, each.001 inch of material thickness requires 1 amp of output: Here is a chart that summarizes the mig welding amps according to the. Metal Thickness Chart Mig Welder.

From weldingmastermind.com

A MIG Welding Amps to Metal Thickness Chart Welding Mastermind Metal Thickness Chart Mig Welder For thicker metals, mig can struggle due to its lower. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. As a guideline, each.001 inch of material thickness requires 1 amp of output: Select proper wire size according to amperage. The chart tells you what amperage to use. Metal Thickness Chart Mig Welder.

From studylibrarywulf.z19.web.core.windows.net

Welding Amps Metal Thickness Chart Metal Thickness Chart Mig Welder Select proper wire size according to amperage. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: .125 inch = 125 amps. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. As a guideline, each.001. Metal Thickness Chart Mig Welder.

From mavink.com

Welding Chart For Mig Welding Metal Thickness Chart Mig Welder As a guideline, each.001 inch of material thickness requires 1 amp of output: Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully.. Metal Thickness Chart Mig Welder.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Metal Thickness Chart Mig Welder Since you don't want to change. For thicker metals, mig can struggle due to its lower. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to. Metal Thickness Chart Mig Welder.

From joshuawest.z13.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Metal Thickness Chart Mig Welder There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. As a guideline, each.001 inch of material thickness requires 1 amp of output: We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully.. Metal Thickness Chart Mig Welder.

From americanprime.com.br

TIG Welding Amp Charts PDF Welding Construction, 45 OFF Metal Thickness Chart Mig Welder There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully. For thicker metals, mig can struggle due to its lower. Every welding machine. Metal Thickness Chart Mig Welder.

From www.scribd.com

242 MIG Settings Chart PDF Metalworking Metals Metal Thickness Chart Mig Welder Since you don't want to change. Select proper wire size according to amperage. .125 inch = 125 amps. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. For thicker metals, mig can struggle due to its lower. We will explain how mig deals with sheet metal, medium. Metal Thickness Chart Mig Welder.

From www.oceanproperty.co.th

MIG Welder Settings Explained (with Chart) Weld Guru, 49 OFF Metal Thickness Chart Mig Welder Select proper wire size according to amperage. As a guideline, each.001 inch of material thickness requires 1 amp of output: Since you don't want to change. .125 inch = 125 amps. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. We will explain how mig deals with. Metal Thickness Chart Mig Welder.

From gowelding.org

How To Set Up a MIG Welder Welder Settings, Gasses and Electrodes Metal Thickness Chart Mig Welder For thicker metals, mig can struggle due to its lower. Since you don't want to change. Every welding machine has one. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding. Metal Thickness Chart Mig Welder.

From mavink.com

Welding Chart For Mig Welding Metal Thickness Chart Mig Welder .125 inch = 125 amps. Select proper wire size according to amperage. Every welding machine has one. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully. For thicker metals, mig can struggle due to its lower. As a guideline, each.001 inch of material thickness. Metal Thickness Chart Mig Welder.

From learningtrommler.z1.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Metal Thickness Chart Mig Welder Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. For thicker metals, mig can struggle due to its lower. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. As a guideline, each.001 inch of. Metal Thickness Chart Mig Welder.

From joshuawest.z13.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Metal Thickness Chart Mig Welder As a guideline, each.001 inch of material thickness requires 1 amp of output: The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. For thicker metals, mig can struggle due to its lower. Find below the mig welding sheet metal settings chart which displays the recommended settings for. Metal Thickness Chart Mig Welder.

From app.aws.org

MIG settings for welding different thickness mild steel Metal Thickness Chart Mig Welder Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Select proper wire size according to amperage. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will need to weld them successfully. Here is a chart that summarizes. Metal Thickness Chart Mig Welder.

From materialwelding.com

MIG welding sheet metal settings with Charts (with PDF) Metal Thickness Chart Mig Welder Select proper wire size according to amperage. .125 inch = 125 amps. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. Every welding machine has. Metal Thickness Chart Mig Welder.

From aaronconnolly.z19.web.core.windows.net

Aluminium Mig Welding Parameters Metal Thickness Chart Mig Welder Since you don't want to change. Select proper wire size according to amperage. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. .125 inch = 125 amps. For thicker metals, mig can struggle due to its lower. Find below the mig welding sheet metal settings chart which. Metal Thickness Chart Mig Welder.

From www.pinnaxis.com

A MIG Welding Amps To Metal Thickness Chart Welding, 52 OFF Metal Thickness Chart Mig Welder Since you don't want to change. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. For thicker metals, mig can struggle due to its lower.. Metal Thickness Chart Mig Welder.

From brandonkss.github.io

Mig Welding Settings Chart Metal Thickness Chart Mig Welder Every welding machine has one. Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: As a guideline, each.001 inch of material thickness requires 1 amp of output: For thicker metals, mig can struggle due to its lower. Select proper wire size according to amperage. Find below the. Metal Thickness Chart Mig Welder.

From weldguru.com

How to Weld Stainless Steel A Complete Guide Metal Thickness Chart Mig Welder For thicker metals, mig can struggle due to its lower. Since you don't want to change. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Every welding machine has one. The chart tells you what amperage to use for what thickness and even tells you what maximum. Metal Thickness Chart Mig Welder.

From mollypickering.z19.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Metal Thickness Chart Mig Welder For thicker metals, mig can struggle due to its lower. Select proper wire size according to amperage. .125 inch = 125 amps. Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. As a guideline, each.001 inch of material thickness requires 1 amp of output: We will explain. Metal Thickness Chart Mig Welder.

From mollypickering.z19.web.core.windows.net

Mig Welding Amps To Metal Thickness Chart Metal Thickness Chart Mig Welder Here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Find below the mig welding sheet metal settings chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. As a guideline, each.001 inch of material thickness requires 1 amp of output: There are various. Metal Thickness Chart Mig Welder.

From mavink.com

Welding Thickness Chart Metal Thickness Chart Mig Welder .125 inch = 125 amps. As a guideline, each.001 inch of material thickness requires 1 amp of output: The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. We will explain how mig deals with sheet metal, medium or hobbyist steel, and thick plates and what you will. Metal Thickness Chart Mig Welder.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Metal Thickness Chart Mig Welder The chart tells you what amperage to use for what thickness and even tells you what maximum thickness your welder can accommodate. For thicker metals, mig can struggle due to its lower. Select proper wire size according to amperage. Every welding machine has one. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness,. Metal Thickness Chart Mig Welder.