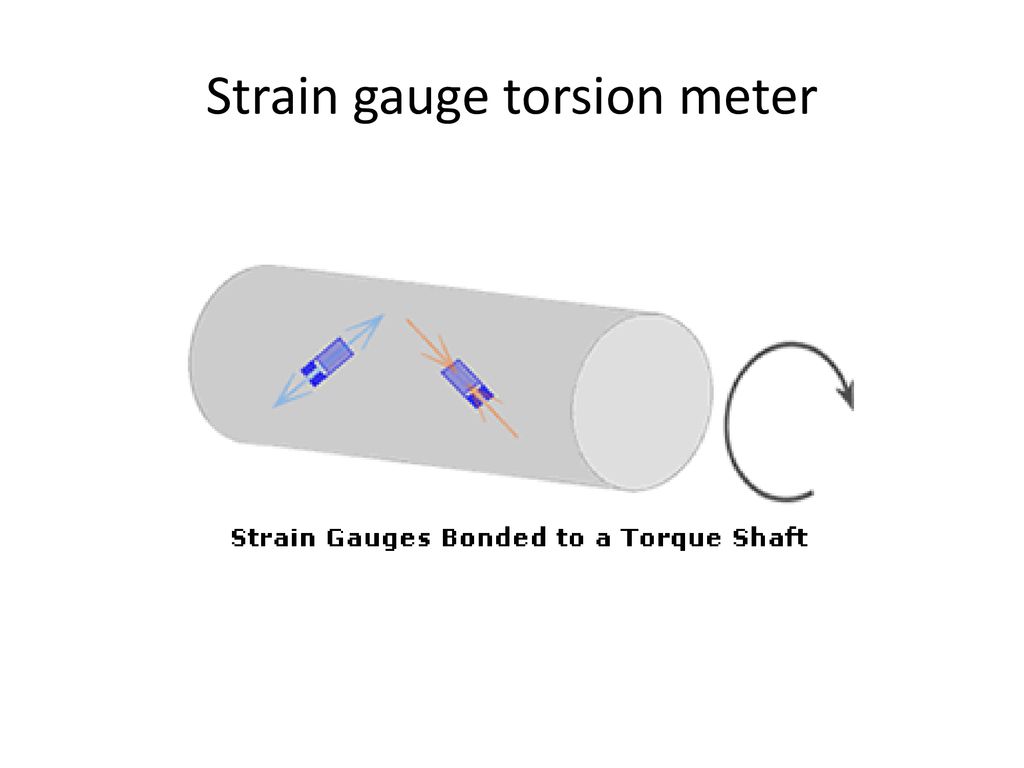

Measurement Of Torque Using Strain Gauge . This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. At its most basic form, a strain gage converts a change in dimension to a change in electrical resistance. A strain gage works to measure the amount of strain on a given object. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. Strain is commonly measured by a strain gage (sometimes written as “strain gauge”).

from atelier-yuwa.ciao.jp

At its most basic form, a strain gage converts a change in dimension to a change in electrical resistance. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. A strain gage works to measure the amount of strain on a given object.

Strain Gauge Torque Measurement atelieryuwa.ciao.jp

Measurement Of Torque Using Strain Gauge At its most basic form, a strain gage converts a change in dimension to a change in electrical resistance. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. At its most basic form, a strain gage converts a change in dimension to a change in electrical resistance. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. A strain gage works to measure the amount of strain on a given object. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material.

From www.youtube.com

Strain Measurement using Strain Gauges YouTube Measurement Of Torque Using Strain Gauge Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). The strain. Measurement Of Torque Using Strain Gauge.

From www.michsci.com

What is a Strain Gauge and How Does it Work? Michigan Scientific Measurement Of Torque Using Strain Gauge In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. The ratio of mechanical strain to electrical resistance is what is known as the. Measurement Of Torque Using Strain Gauge.

From www.mdpi.com

Sensors Free FullText A High Performance Torque Sensor for Milling Measurement Of Torque Using Strain Gauge To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. This article explains. Measurement Of Torque Using Strain Gauge.

From www.futek.com

Torque Measurement How to measure torque? Measurement Of Torque Using Strain Gauge A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their. Measurement Of Torque Using Strain Gauge.

From blog.endaq.com

Strain Gauges How they Work, Applications, and Types Measurement Of Torque Using Strain Gauge This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. Strain gages are installed at 45. Measurement Of Torque Using Strain Gauge.

From www.youtube.com

Torque Measurement Part 2 YouTube Measurement Of Torque Using Strain Gauge A strain gage works to measure the amount of strain on a given object. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. To measure torque by acquiring reliable data from. Measurement Of Torque Using Strain Gauge.

From www.iqsdirectory.com

Strain Gauge What Is It? How Is It Used? Types, Application Measurement Of Torque Using Strain Gauge A strain gage works to measure the amount of strain on a given object. At its most basic form, a strain gage converts a change in dimension to a change in electrical resistance. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. In. Measurement Of Torque Using Strain Gauge.

From atelier-yuwa.ciao.jp

Torque Measurement Using Strain Gauges atelieryuwa.ciao.jp Measurement Of Torque Using Strain Gauge Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material.. Measurement Of Torque Using Strain Gauge.

From blog.endaq.com

Strain Gauges How they Work, Applications, and Types Measurement Of Torque Using Strain Gauge Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. A. Measurement Of Torque Using Strain Gauge.

From control.com

Measuring the Force of Rotation Torque Sensors Technical Articles Measurement Of Torque Using Strain Gauge The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. This article explains how strain gauges work, relevant stress and strain background information, and. Measurement Of Torque Using Strain Gauge.

From www.bestech.com.au

Strain gauges torque measurement Bestech Sensors and Teaching Equipment Measurement Of Torque Using Strain Gauge The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. A grid configuration for the strain sensitive element is used to allow higher values of gage. Measurement Of Torque Using Strain Gauge.

From inchbyinch.de

INCH Technical English strain gauge Measurement Of Torque Using Strain Gauge The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. A strain gage works to measure the amount of strain on a given object. A. Measurement Of Torque Using Strain Gauge.

From www.dewetron.com

Strain gauges DEWETRON Measurement Of Torque Using Strain Gauge Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage.. Measurement Of Torque Using Strain Gauge.

From www.youtube.com

Torque measurement using strain guage YouTube Measurement Of Torque Using Strain Gauge In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. Strain is commonly measured by a strain. Measurement Of Torque Using Strain Gauge.

From www.ktr.com

KTR Torque measuring shafts Measurement Of Torque Using Strain Gauge To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. A. Measurement Of Torque Using Strain Gauge.

From www.youtube.com

Measuring Load and Torque with Full Bridge Strain Gages. YouTube Measurement Of Torque Using Strain Gauge This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. The ratio. Measurement Of Torque Using Strain Gauge.

From omegaelectronics.net

OMEGA Measurement Of Torque Using Strain Gauge The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. Strain gauges are devices that are commonly used by engineers to measure the. Measurement Of Torque Using Strain Gauge.

From www.finilager.bo

Medición de Torque utilizando STRAIN GAGE Finilager Measurement Of Torque Using Strain Gauge To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. At its most basic form, a strain gage converts a change in dimension to. Measurement Of Torque Using Strain Gauge.

From atelier-yuwa.ciao.jp

Strain Gauge Torque Measurement atelieryuwa.ciao.jp Measurement Of Torque Using Strain Gauge The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level. Measurement Of Torque Using Strain Gauge.

From datum-electronics.com

Strain Gauge Based Torque Sensors & Measurement Experts Datum Electronics Measurement Of Torque Using Strain Gauge Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors. Measurement Of Torque Using Strain Gauge.

From www.vrogue.co

Use A Strain Gauge Beam With Arduino Botland Robotic vrogue.co Measurement Of Torque Using Strain Gauge In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. A grid configuration for the strain sensitive element is used to allow. Measurement Of Torque Using Strain Gauge.

From atelier-yuwa.ciao.jp

Strain Gauge Torque Measurement atelieryuwa.ciao.jp Measurement Of Torque Using Strain Gauge The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. To measure torque by acquiring reliable data from moving objects,. Measurement Of Torque Using Strain Gauge.

From blog.endaq.com

Strain Gauges How they Work, Applications, and Types Measurement Of Torque Using Strain Gauge Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. A grid configuration. Measurement Of Torque Using Strain Gauge.

From www.vrogue.co

Strain Gauge Working Principle With Animation Instrum vrogue.co Measurement Of Torque Using Strain Gauge Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. Strain gauges are devices that are commonly used by. Measurement Of Torque Using Strain Gauge.

From www.youtube.com

STRAIN GAGE(GAUGE) FOR TORQUE MEASUREMENT on rotating components YouTube Measurement Of Torque Using Strain Gauge Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot. Measurement Of Torque Using Strain Gauge.

From www.youtube.com

Torsion Bar With Strain Gauge Torque Measurement Sensors And Measurement Of Torque Using Strain Gauge The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object.. Measurement Of Torque Using Strain Gauge.

From www.tecsisloadcell.com

Multi Axis Force Torque Sensor Measurement Using Strain Gauge Load Cell Measurement Of Torque Using Strain Gauge Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. A strain gage works by measuring its electrical resistance on the object subjected to an axial, bending,. To measure torque by acquiring reliable data from moving objects,. Measurement Of Torque Using Strain Gauge.

From binsfeld.com

What is a Strain Gage (Gauge) and How Does It Work? Binsfeld Measurement Of Torque Using Strain Gauge This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on. Measurement Of Torque Using Strain Gauge.

From binsfeld.com

Weldable vs Bondable Strain Gages For Shaft Torque Measurement Binsfeld Measurement Of Torque Using Strain Gauge Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. A strain gage works to measure the amount of strain on a given object. A strain gage works by measuring its electrical. Measurement Of Torque Using Strain Gauge.

From www.scribd.com

X8Measurement of Torque Using Strain Gauge PDF Calibration Torque Measurement Of Torque Using Strain Gauge A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. At its most basic form, a strain gage converts a change in dimension to a change in electrical resistance. Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object.. Measurement Of Torque Using Strain Gauge.

From datum-electronics.com

Strain Gauge Based Torque Sensors & Measurement Experts Measurement Of Torque Using Strain Gauge To measure torque by acquiring reliable data from moving objects, strain gauges are very popular due to their simple integration. Strain is commonly measured by a strain gage (sometimes written as “strain gauge”). The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. A strain gage works to measure the amount. Measurement Of Torque Using Strain Gauge.

From itestsystem.com

Strain Gauge Services Archives ITM Measurement Of Torque Using Strain Gauge This article explains how strain gauges work, relevant stress and strain background information, and considerations for their proper usage and applications. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short. Measurement Of Torque Using Strain Gauge.

From www.michsci.com

What is a Strain Gauge and How Does it Work? Michigan Scientific Measurement Of Torque Using Strain Gauge Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage. The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material.. Measurement Of Torque Using Strain Gauge.

From www.semanticscholar.org

[PDF] An Improved Strain GaugeBased Dynamic Torque Measurement Method Measurement Of Torque Using Strain Gauge Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. In this article, we are going to discuss the method of measuring torque on a rotating shaft using strain gauges and the factors that impact the measurement. Strain gages are installed at 45 degrees to the shaft axis and sense. Measurement Of Torque Using Strain Gauge.

From www.academia.edu

(PDF) An Improved Strain GaugeBased Dynamic Torque Measurement Method Measurement Of Torque Using Strain Gauge The ratio of mechanical strain to electrical resistance is what is known as the gage factor, and is specific to the type/lot of strain gage used. Strain gages are installed at 45 degrees to the shaft axis and sense those tensile and compressive stresses. A grid configuration for the strain sensitive element is used to allow higher values of gage. Measurement Of Torque Using Strain Gauge.