Plastic Injection Molding Ribs . Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. Ribs are thin support features frequently found in plastic injection moulded part designs. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Discover the essential rib design principles for maximizing part strength in plastic injection molding. They are often used strategically to replace thick wall. One of the ways to strengthen a part is by adding one or more “ribs” to the design. They are often used strategically to. Plastic ribs design plays an important role in the success of injection molded parts. Effectively designed ribs enhance material usage, structural integrity, quality and part. Ribs are thin support features frequently found in plastic injection moulded part designs. Learn how ribs are used in. Ribs are thin protrusions that extend perpendicular.

from www.reddit.com

Ribs are thin support features frequently found in plastic injection moulded part designs. One of the ways to strengthen a part is by adding one or more “ribs” to the design. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Effectively designed ribs enhance material usage, structural integrity, quality and part. Learn how ribs are used in. They are often used strategically to. They are often used strategically to replace thick wall. Ribs are thin protrusions that extend perpendicular. Plastic ribs design plays an important role in the success of injection molded parts. Discover the essential rib design principles for maximizing part strength in plastic injection molding.

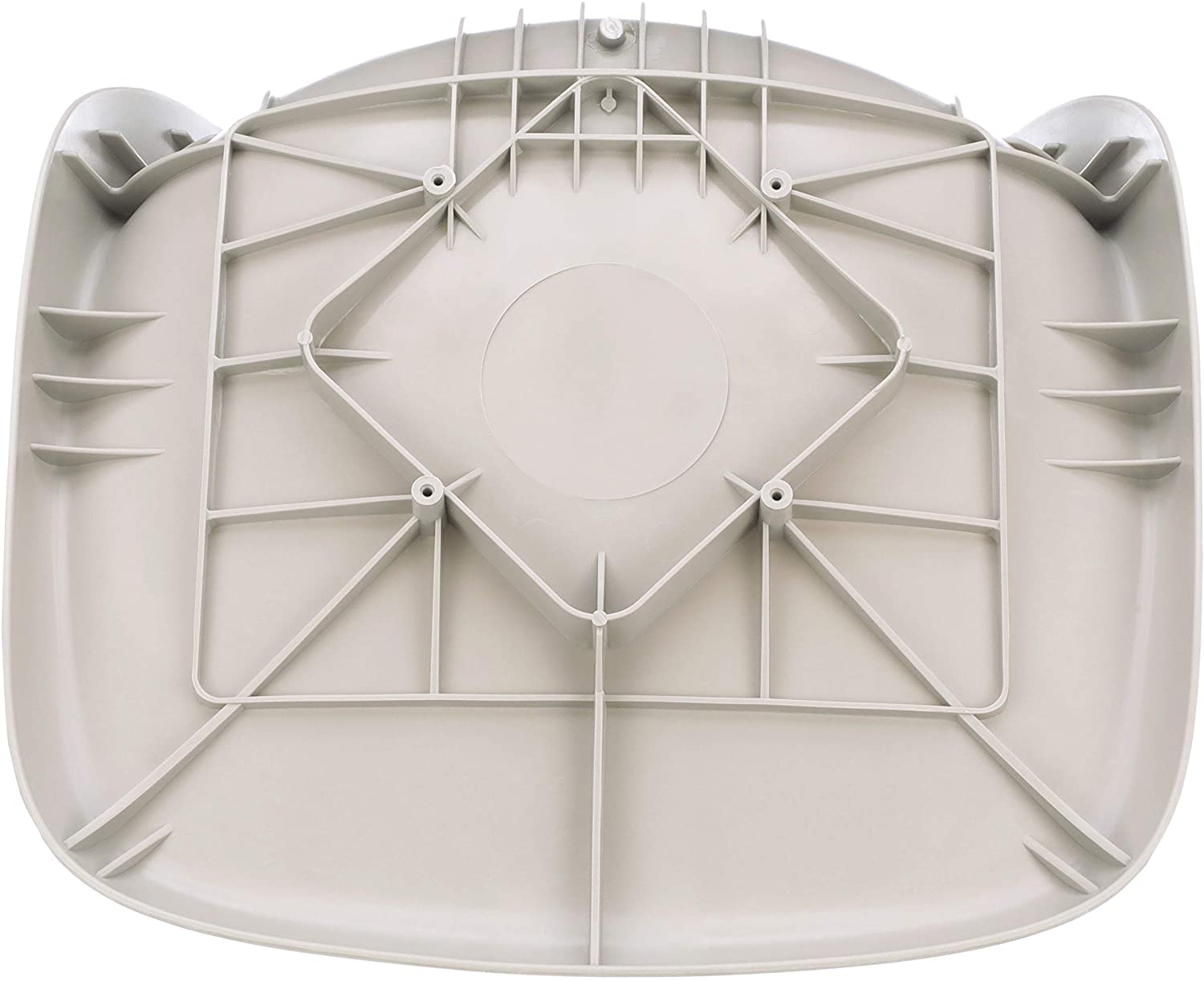

Any resources to design rib grids for injection molding? r/IndustrialDesign

Plastic Injection Molding Ribs Ribs are thin support features frequently found in plastic injection moulded part designs. Discover the essential rib design principles for maximizing part strength in plastic injection molding. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin support features frequently found in plastic injection moulded part designs. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. They are often used strategically to replace thick wall. Plastic ribs design plays an important role in the success of injection molded parts. Ribs are thin protrusions that extend perpendicular. They are often used strategically to. Learn how ribs are used in. Effectively designed ribs enhance material usage, structural integrity, quality and part. One of the ways to strengthen a part is by adding one or more “ribs” to the design.

From www.plasticmold.net

Rib Design Injection Molding, Best No. 1 Rib Design in Mold Plastic Injection Molding Ribs They are often used strategically to. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin support features frequently found in plastic injection moulded part designs. Learn how ribs are used in. Plastic ribs design plays an important role in the success of injection molded parts. Our helpful design aid demonstrates part features that. Plastic Injection Molding Ribs.

From www.rapiddirect.com

Add Crush Ribs in Injection Molded Parts rapiddirect Plastic Injection Molding Ribs Discover the essential rib design principles for maximizing part strength in plastic injection molding. Learn how ribs are used in. Ribs are thin support features frequently found in plastic injection moulded part designs. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of. Plastic Injection Molding Ribs.

From www.pinterest.es

injection mold boss in corner Google Search Injection moulding, Plastic moulding, Plastic design Plastic Injection Molding Ribs They are often used strategically to. Learn how ribs are used in. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. Ribs are thin support features frequently found in plastic injection moulded part designs. If they’re properly designed for manufacturing,. Plastic Injection Molding Ribs.

From www.pinterest.ca

Plastic Injection Molding Parts Design Guideline 模具, 教材 Plastic Injection Molding Ribs Ribs are thin support features frequently found in plastic injection moulded part designs. Learn how ribs are used in. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the ways to strengthen a part is by adding one or more “ribs”. Plastic Injection Molding Ribs.

From www.moldplasticinjection.com

Plastic Injection Molding Guide Best Design Tips On How To Avoid Common Mistakes In Injection Plastic Injection Molding Ribs Plastic ribs design plays an important role in the success of injection molded parts. Ribs are thin protrusions that extend perpendicular. Effectively designed ribs enhance material usage, structural integrity, quality and part. Learn how ribs are used in. Discover the essential rib design principles for maximizing part strength in plastic injection molding. One of the ways to strengthen a part. Plastic Injection Molding Ribs.

From www.youtube.com

Designing of Plastic Products for Injection Moulding Rib Thickness and Sink Mark YouTube Plastic Injection Molding Ribs They are often used strategically to. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. They are often used strategically to replace thick wall. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Effectively. Plastic Injection Molding Ribs.

From milesproducts.com

Gas Assisted Plastic Injection Molding Miles Products Plastic Injection Molding Ribs One of the ways to strengthen a part is by adding one or more “ribs” to the design. They are often used strategically to. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations. Plastic Injection Molding Ribs.

From www.hollyplasticparts.com

A Completely Plastic Part Design Guide for Injection Molding Holly Parts Plastic Injection Molding Ribs If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Effectively designed ribs enhance material usage, structural integrity, quality and part. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin protrusions that extend perpendicular. They are often used strategically to replace thick wall. Our helpful design aid demonstrates part features. Plastic Injection Molding Ribs.

From onearmy.github.io

Tips on injection mouldmaking · Precious Plastic Toolbox Plastic Injection Molding Ribs They are often used strategically to. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin support features frequently found in plastic injection moulded part designs. Effectively designed ribs enhance material usage, structural integrity, quality and. Plastic Injection Molding Ribs.

From www.youtube.com

Fantastic Plastic 19 Ribs on Curved Surfaces SOLIDWORKS YouTube Plastic Injection Molding Ribs Ribs are thin support features frequently found in plastic injection moulded part designs. Plastic ribs design plays an important role in the success of injection molded parts. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Effectively designed ribs enhance material usage, structural integrity, quality and part. They are often used. Plastic Injection Molding Ribs.

From medium.com

What are Ribs & Gussets in Injection Molding? by Jaycon Systems Jaycon Systems Medium Plastic Injection Molding Ribs Ribs are thin support features frequently found in plastic injection moulded part designs. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the ways to. Plastic Injection Molding Ribs.

From www.youtube.com

Injection Molding 101 Ribs & Gussets YouTube Plastic Injection Molding Ribs Learn how ribs are used in. Effectively designed ribs enhance material usage, structural integrity, quality and part. Ribs are thin protrusions that extend perpendicular. They are often used strategically to. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin support. Plastic Injection Molding Ribs.

From 3space.com

Injection Molding Rib Design 3 Space Plastic Injection Molding Ribs Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin protrusions that extend perpendicular. Discover the essential rib design principles for maximizing part strength in plastic injection molding. One of the ways to strengthen a part is by adding one or. Plastic Injection Molding Ribs.

From exycomuqe.blob.core.windows.net

Plastic Injection Molding Tolerances at Susan Murrin blog Plastic Injection Molding Ribs Effectively designed ribs enhance material usage, structural integrity, quality and part. One of the ways to strengthen a part is by adding one or more “ribs” to the design. They are often used strategically to replace thick wall. They are often used strategically to. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses,. Plastic Injection Molding Ribs.

From www.youtube.com

ribs in Functional Plastic Part YouTube Plastic Injection Molding Ribs Ribs are thin support features frequently found in plastic injection moulded part designs. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. Ribs are thin protrusions that extend perpendicular. They are often used strategically to replace thick wall. Learn how. Plastic Injection Molding Ribs.

From di1vc2liilbw2.cloudfront.net

What is injection molding? Hubs Plastic Injection Molding Ribs Effectively designed ribs enhance material usage, structural integrity, quality and part. They are often used strategically to. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Plastic ribs design plays an important role in the success of injection molded parts. Our helpful design aid demonstrates part features that are too thin. Plastic Injection Molding Ribs.

From www.hollyplasticparts.com

A Completely Plastic Part Design Guide for Injection Molding Holly Parts Plastic Injection Molding Ribs Plastic ribs design plays an important role in the success of injection molded parts. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Ribs are thin protrusions that extend perpendicular. Ribs are thin support features frequently found in plastic injection moulded part designs. They are often used strategically to replace thick. Plastic Injection Molding Ribs.

From www.reddit.com

Any resources to design rib grids for injection molding? r/IndustrialDesign Plastic Injection Molding Ribs Learn how ribs are used in. They are often used strategically to. Effectively designed ribs enhance material usage, structural integrity, quality and part. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin protrusions that extend perpendicular. Ribs are thin support features frequently found in plastic injection moulded part designs. They are often used. Plastic Injection Molding Ribs.

From www.cadrex.com

Plastic Injection Molding Design Tips Cadrex Plastic Injection Molding Ribs Effectively designed ribs enhance material usage, structural integrity, quality and part. Ribs are thin protrusions that extend perpendicular. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Discover the essential rib design principles for maximizing part strength in plastic injection molding. Plastic ribs design plays an important role in the success. Plastic Injection Molding Ribs.

From read.nxtbook.com

Plastic Part Design To Use Ribs or Not to Use Ribs That is the Question Plastic Injection Molding Ribs Ribs are thin protrusions that extend perpendicular. Discover the essential rib design principles for maximizing part strength in plastic injection molding. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the ways to strengthen a part is by adding one or. Plastic Injection Molding Ribs.

From www.rodongroup.com

Understanding Plastic Injection Molding Volumes The Rodon Group® Plastic Injection Molding Ribs They are often used strategically to. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. Effectively designed ribs enhance material usage, structural integrity, quality and part. One of the ways to strengthen a part is by adding one or more. Plastic Injection Molding Ribs.

From read.nxtbook.com

Plastic Part Design To Use Ribs or Not to Use Ribs That is the Question Plastic Injection Molding Ribs One of the ways to strengthen a part is by adding one or more “ribs” to the design. Effectively designed ribs enhance material usage, structural integrity, quality and part. Learn how ribs are used in. Ribs are thin protrusions that extend perpendicular. They are often used strategically to replace thick wall. Discover the essential rib design principles for maximizing part. Plastic Injection Molding Ribs.

From ims-tex.com

Plastic Design for Injection Molding Plastic Injection Molding Ribs If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. They are often used strategically to replace thick wall. Learn how ribs are used in. Discover the essential rib design principles for maximizing part strength in plastic injection molding. They are often used strategically to. Effectively designed ribs enhance material usage, structural integrity, quality and part. Ribs. Plastic Injection Molding Ribs.

From www.deepmould.net

Injection Molded Plastic Part Design Guidelines Knowledge Deep Mould Co.,Ltd Plastic Injection Molding Ribs Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Plastic ribs design plays an important role in the success of injection molded. Plastic Injection Molding Ribs.

From 3space.com

Injection Molding Rib Design 3 Space Plastic Injection Molding Ribs One of the ways to strengthen a part is by adding one or more “ribs” to the design. They are often used strategically to. Learn how ribs are used in. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin protrusions that extend perpendicular. They are often used strategically to replace thick wall. Plastic. Plastic Injection Molding Ribs.

From www.3dhubs.com

How to design parts for Injection Molding 3D Hubs Plastic Injection Molding Ribs They are often used strategically to replace thick wall. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin support features frequently found in plastic injection moulded part designs. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be. Plastic Injection Molding Ribs.

From www.myplasticmold.com

A Whole Guide For Plastic Injection Mold Plastic Injection Molding Ribs Ribs are thin protrusions that extend perpendicular. They are often used strategically to. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Discover the essential rib design principles for maximizing part strength in plastic injection molding. If they’re. Plastic Injection Molding Ribs.

From hlhrapid.com

Injection Moulding Design Guide How to Design Plastic Parts Plastic Injection Molding Ribs Plastic ribs design plays an important role in the success of injection molded parts. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Our helpful design aid demonstrates part features that are too thin or too thick, bad. Plastic Injection Molding Ribs.

From madeproducts.uk

How to Design for Injection Moulding MADE Products Plastic Injection Molding Ribs They are often used strategically to. One of the ways to strengthen a part is by adding one or more “ribs” to the design. Ribs are thin protrusions that extend perpendicular. They are often used strategically to replace thick wall. Effectively designed ribs enhance material usage, structural integrity, quality and part. Plastic ribs design plays an important role in the. Plastic Injection Molding Ribs.

From ims-tex.com

Injection Molding Wall Thickness For Plastic Manufacturing Integrated Molding Solutions Plastic Injection Molding Ribs Plastic ribs design plays an important role in the success of injection molded parts. Discover the essential rib design principles for maximizing part strength in plastic injection molding. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Ribs are thin support features frequently found in plastic injection moulded part designs. They are often used strategically to.. Plastic Injection Molding Ribs.

From www.upminc.com

Using Crush Ribs in Injection Molded Parts Universal Plastic Mold Plastic Injection Molding Ribs Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. They are often used strategically to. Ribs are thin support features frequently found in plastic injection moulded part designs. Effectively designed ribs enhance material usage, structural integrity, quality and part. Learn. Plastic Injection Molding Ribs.

From capablemachining.com

Designing Ribs For Injection Molded Plastic Components Plastic Injection Molding Ribs Plastic ribs design plays an important role in the success of injection molded parts. Ribs are thin support features frequently found in plastic injection moulded part designs. If they’re properly designed for manufacturing, they improve the molten plastic’s flow into. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs,. Plastic Injection Molding Ribs.

From medium.com

Engineering Guidelines to Designing Plastic Parts for Injection Molding Plastic Injection Molding Ribs Discover the essential rib design principles for maximizing part strength in plastic injection molding. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing. Ribs are thin support features frequently found in plastic injection moulded part designs. One of the ways. Plastic Injection Molding Ribs.

From www.plastopialtd.com

Ribs Design for Injection Molding Plastopia Plastic Injection Molding Ribs They are often used strategically to. Ribs are thin protrusions that extend perpendicular. Ribs are thin support features frequently found in plastic injection moulded part designs. Plastic ribs design plays an important role in the success of injection molded parts. They are often used strategically to replace thick wall. If they’re properly designed for manufacturing, they improve the molten plastic’s. Plastic Injection Molding Ribs.

From www.plastopialtd.com

Ribs Design for Injection Molding Plastopia Plastic Injection Molding Ribs Effectively designed ribs enhance material usage, structural integrity, quality and part. They are often used strategically to replace thick wall. Ribs are thin support features frequently found in plastic injection moulded part designs. Ribs are thin protrusions that extend perpendicular. Our helpful design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs,. Plastic Injection Molding Ribs.