Modular Rotor Assembly . As oems and suppliers ramp up ev production, more robots will be used to assemble. modular rotor shafts in electrified trucks. With a view to lightweight design, hirschvogel has developed a. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. the rotor manufacturing process can be divided into 6 steps: this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial.

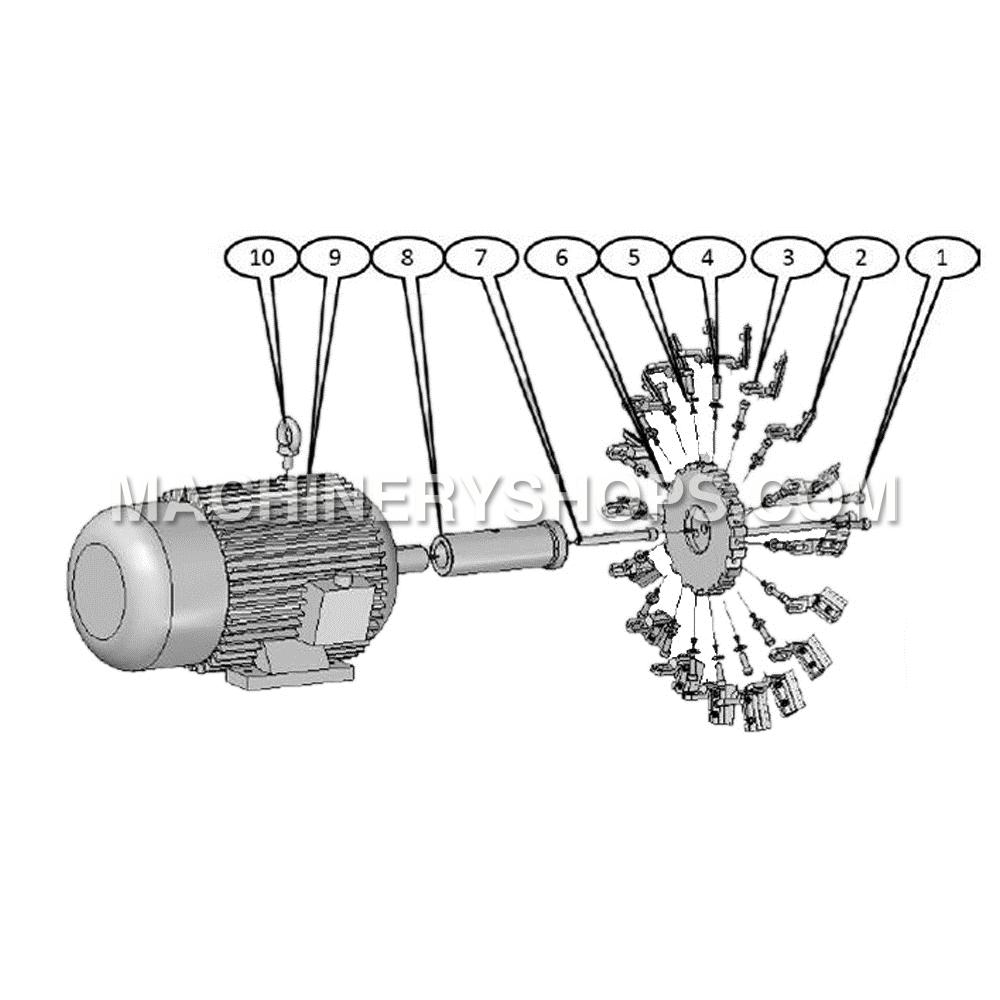

from www.machineryshops.com

as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. modular rotor shafts in electrified trucks. As oems and suppliers ramp up ev production, more robots will be used to assemble. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. the rotor manufacturing process can be divided into 6 steps: learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. With a view to lightweight design, hirschvogel has developed a.

Cutting rotor assembly (MY150*2), Cutting rotor assembly (MY150*2

Modular Rotor Assembly the rotor manufacturing process can be divided into 6 steps: learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. the rotor manufacturing process can be divided into 6 steps: As oems and suppliers ramp up ev production, more robots will be used to assemble. modular rotor shafts in electrified trucks. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. With a view to lightweight design, hirschvogel has developed a.

From www.researchgate.net

Highpressure compressor rotors stacking. Download Scientific Diagram Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. As oems and suppliers ramp up ev production, more robots will be used to assemble. With a view to lightweight design, hirschvogel has developed a. the rotor manufacturing process can be divided into 6 steps: as shown in this paper, the modular. Modular Rotor Assembly.

From esamuel.artstation.com

Ethan Samuel Main Rotor Assembly Modular Rotor Assembly With a view to lightweight design, hirschvogel has developed a. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. as shown in this paper, the modular rotor reduces the rotor mass. Modular Rotor Assembly.

From www.google.com

Patent US5615732 Air preheater with semimodular rotor construction Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. As oems and suppliers ramp up ev production, more robots will be used to assemble. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. the rotor manufacturing process can be. Modular Rotor Assembly.

From www.sotek.com

Stator and Rotor Assembly Lamination Replacement Sotek, inc. Modular Rotor Assembly As oems and suppliers ramp up ev production, more robots will be used to assemble. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. With a view to lightweight design, hirschvogel has developed a. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can. Modular Rotor Assembly.

From www.ebay.com

Disc Brake Rotor and Hub Assembly2Wheel ABS Front NAPA/BRAKE ROTORS Modular Rotor Assembly With a view to lightweight design, hirschvogel has developed a. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. As oems and suppliers ramp up ev production, more robots will be used to assemble. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can. Modular Rotor Assembly.

From www.bigstockphoto.com

Rotor Assembly Brushed Image & Photo (Free Trial) Bigstock Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. As oems and suppliers ramp up ev production, more robots will be used to assemble. modular rotor shafts in electrified trucks. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial.. Modular Rotor Assembly.

From www.google.com

Patent EP2169805A1 Rotor assembly and rotor assembly manufacturing Modular Rotor Assembly With a view to lightweight design, hirschvogel has developed a. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. As oems and suppliers ramp up ev production, more robots will be used to assemble. learning from the design models and working principles of biological machines can. Modular Rotor Assembly.

From www.t-flex.com

Rotor Unit Assembly Modular Rotor Assembly learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. modular rotor shafts in electrified trucks. the rotor manufacturing process can be divided into 6 steps: as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator. Modular Rotor Assembly.

From www.indiamart.com

Rotor Assembly at best price in Medak by Sri Venkateswara Profiles ID Modular Rotor Assembly With a view to lightweight design, hirschvogel has developed a. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. As oems and suppliers ramp up ev production, more robots will be used to assemble. the rotor manufacturing process can be divided into 6 steps: modular rotor shafts in electrified trucks. . Modular Rotor Assembly.

From www.youtube.com

Rotor Assembly Line YouTube Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron.. Modular Rotor Assembly.

From www.researchgate.net

Helicopter rotor test stand. Download Scientific Diagram Modular Rotor Assembly learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. modular rotor shafts in electrified trucks. With a view to lightweight design, hirschvogel has developed a. as shown in this paper,. Modular Rotor Assembly.

From www.perspectx.com

CH47D_Chinook_Rotor_Head_a_Master « Perfect Visualization The Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. With a view to lightweight design, hirschvogel has developed a. modular rotor shafts in electrified trucks. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp. Modular Rotor Assembly.

From www.mc-2energy.com

Gas turbine rotor repair MC² Energy Modular Rotor Assembly modular rotor shafts in electrified trucks. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. As oems and suppliers ramp up ev production, more robots will be used to assemble. With a view to lightweight design, hirschvogel has developed a. learning from the design models and working principles of biological machines. Modular Rotor Assembly.

From www.zbrushcentral.com

UH 60 Main Rotor ZBrushCentral Modular Rotor Assembly modular rotor shafts in electrified trucks. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. As oems and suppliers ramp up ev production, more robots will be used to assemble. the rotor manufacturing process can be divided into 6 steps: learning from the design models and working principles of biological. Modular Rotor Assembly.

From www.artstation.com

ArtStation Sikorsky UH60 main rotor Modular Rotor Assembly as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. modular rotor shafts in electrified trucks. As oems and suppliers ramp up ev production, more robots will be used to assemble. With a view to lightweight design, hirschvogel has developed a. learning from the design models. Modular Rotor Assembly.

From www.slingsintt.com

Full rotor assembly tools slingsintt Modular Rotor Assembly the rotor manufacturing process can be divided into 6 steps: With a view to lightweight design, hirschvogel has developed a. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. . Modular Rotor Assembly.

From www.youtube.com

Helicopter Rotor Assembly 3 YouTube Modular Rotor Assembly as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. modular rotor shafts in electrified trucks. With a view to lightweight design, hirschvogel has developed a. learning from the design. Modular Rotor Assembly.

From www.sip.si

STAR 43012 SIP Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. the rotor manufacturing process can be divided into 6 steps: learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. With a view to lightweight design, hirschvogel has developed a. . Modular Rotor Assembly.

From www.megaplusz.hu

NaanDanJain modulár rotor fekete 2,5m sugár(eredeti) MEGA Modular Rotor Assembly as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. . Modular Rotor Assembly.

From www.youtube.com

Rotor Balancing with Single Plane 4Runs Method YouTube Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. modular rotor shafts in electrified trucks.. Modular Rotor Assembly.

From www.kandsmckenzieltd.co.uk

Rotor Assembly K & S McKenzie Modular Rotor Assembly With a view to lightweight design, hirschvogel has developed a. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. as shown in this paper, the modular rotor reduces the rotor mass. Modular Rotor Assembly.

From www.mascomponents.com

AS94101 ROTOR SHAFT ASSEMBLY MAS Components Modular Rotor Assembly as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. the rotor manufacturing process can be divided into 6 steps: modular rotor shafts in. Modular Rotor Assembly.

From www.machineryshops.com

Cutting rotor assembly (MY150*2), Cutting rotor assembly (MY150*2 Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. With a view to lightweight design, hirschvogel has developed a. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. As oems and suppliers ramp up ev production, more robots will be. Modular Rotor Assembly.

From www.loadrite.com

12" FULL ROTOR ASSEMBLY Load Rite Trailers Modular Rotor Assembly modular rotor shafts in electrified trucks. the rotor manufacturing process can be divided into 6 steps: learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. as shown in this. Modular Rotor Assembly.

From www.alamy.com

A turbine rotor assembly and balancing area Stock Photo Alamy Modular Rotor Assembly the rotor manufacturing process can be divided into 6 steps: learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. modular rotor shafts in electrified trucks. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator. Modular Rotor Assembly.

From photos.jibble.org

Photo Sea King Rotor Assembly IMG 9626 Modular Rotor Assembly as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. With a view to lightweight design, hirschvogel has developed a. As oems and suppliers ramp up ev production, more robots will be used to assemble. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can. Modular Rotor Assembly.

From triz-ltd.com

Rotors and flow parts of centrifugal compressors TRIZ Modular Rotor Assembly modular rotor shafts in electrified trucks. the rotor manufacturing process can be divided into 6 steps: As oems and suppliers ramp up ev production, more robots will be used to assemble. With a view to lightweight design, hirschvogel has developed a. as shown in this paper, the modular rotor reduces the rotor mass and limits the use. Modular Rotor Assembly.

From www.google.com.au

Patent US20120146448 Modular Rotor For Synchronous Reluctance Machine Modular Rotor Assembly the rotor manufacturing process can be divided into 6 steps: modular rotor shafts in electrified trucks. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. As oems and suppliers ramp up ev production, more robots will be used to assemble. learning from the design models and working principles of biological. Modular Rotor Assembly.

From www.conjet.com

Rotor Assembly R557 Conjet Modular Rotor Assembly learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. the rotor manufacturing process can be divided into 6 steps: as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. As oems and suppliers ramp. Modular Rotor Assembly.

From www.emag.com

Rotor shaft Manufacturing system for the rotor shaft of electric motors Modular Rotor Assembly as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. With. Modular Rotor Assembly.

From www.conjet.com

Rotor Assembly Nalta Durable Hydrodemolition Part Conjet Modular Rotor Assembly learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. As oems and suppliers ramp up ev production, more robots will be used to assemble. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. . Modular Rotor Assembly.

From www.bikebling.com

Rotor Aldhu Modular 30mm Axle 135/142mm from Bike Bling Modular Rotor Assembly this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. modular rotor shafts in electrified trucks. As oems and suppliers ramp up ev production, more robots will be used to assemble. as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron.. Modular Rotor Assembly.

From www.ebay.com

Rotor Spacer Set Modular 30mm Kapic Arms eBay Modular Rotor Assembly modular rotor shafts in electrified trucks. learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. the rotor manufacturing process can be divided into 6 steps: as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator. Modular Rotor Assembly.

From newatlas.com

Folding, modular rotor blades designed for giant wind turbines Modular Rotor Assembly modular rotor shafts in electrified trucks. the rotor manufacturing process can be divided into 6 steps: learning from the design models and working principles of biological machines can be very instructive to build, control, and program artificial. this article introduces a novel modular reconfigurable multirotor aerial vehicle that can flexibly configure the. With a view to. Modular Rotor Assembly.

From www.youtube.com

Main Rotor Assembly YouTube Modular Rotor Assembly as shown in this paper, the modular rotor reduces the rotor mass and limits the use of the stator back iron. the rotor manufacturing process can be divided into 6 steps: modular rotor shafts in electrified trucks. As oems and suppliers ramp up ev production, more robots will be used to assemble. this article introduces a. Modular Rotor Assembly.