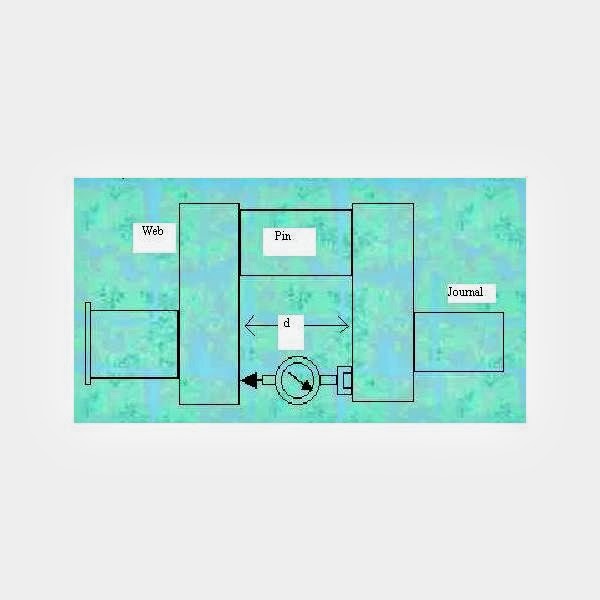

Crankshaft Deflection Measurement Procedure . crankshaft deflection measuring positions. the measurement principle is that curvature of the crankshaft, due to height/. Remove any dirt or debris from the journal surface using a clean cloth. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. crankshaft deflection measurement procedure. >these are generally taken using a spring loaded dial gauge. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the.

from www.marinesite.info

>these are generally taken using a spring loaded dial gauge. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. the measurement principle is that curvature of the crankshaft, due to height/. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. crankshaft deflection measurement procedure. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. Remove any dirt or debris from the journal surface using a clean cloth. crankshaft deflection measuring positions.

Simple Explanation Of Crankshaft Deflections, Measurement Procedure, Readings,Curves

Crankshaft Deflection Measurement Procedure this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. crankshaft deflection measurement procedure. >these are generally taken using a spring loaded dial gauge. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. crankshaft deflection measuring positions. Remove any dirt or debris from the journal surface using a clean cloth. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. the measurement principle is that curvature of the crankshaft, due to height/.

From www.youtube.com

Crankshaft Deflection Measurement in Commercial Ships YouTube Crankshaft Deflection Measurement Procedure this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. Remove any dirt or debris from the journal surface using a clean cloth. crankshaft deflection measurement procedure. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation. Crankshaft Deflection Measurement Procedure.

From www.scribd.com

Crankshaft Deflection Crankshaft Deflection Measurement Procedure To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of. Crankshaft Deflection Measurement Procedure.

From www.scribd.com

March 11, 2016 News Hound Engine Crankshaft Deflection Measurement PDF Bearing (Mechanical Crankshaft Deflection Measurement Procedure crankshaft deflection measuring positions. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in. Crankshaft Deflection Measurement Procedure.

From www.marineengineersknowledge.com

Crankshaft Deflections Measurement Marine engineers knowledge Crankshaft Deflection Measurement Procedure the measurement principle is that curvature of the crankshaft, due to height/. Remove any dirt or debris from the journal surface using a clean cloth. crankshaft deflection measurement procedure. >these are generally taken using a spring loaded dial gauge. crankshaft deflection measuring positions. To determine the crank deflection, the crankshaft must always be rotated in such a. Crankshaft Deflection Measurement Procedure.

From vdocuments.mx

Crank Shaft & Its Deflection Measurement [PDF Document] Crankshaft Deflection Measurement Procedure crankshaft deflection measuring positions. crankshaft deflection measurement procedure. Remove any dirt or debris from the journal surface using a clean cloth. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction. Crankshaft Deflection Measurement Procedure.

From telegra.ph

Crankshaft Deflection Measurement Telegraph Crankshaft Deflection Measurement Procedure crankshaft deflection measurement procedure. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. crankshaft deflection measuring positions. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. the measurement principle is that curvature of the crankshaft, due. Crankshaft Deflection Measurement Procedure.

From motionicsllcblog.wordpress.com

How to Measure Crankshaft Deflection Motionics Blog Crankshaft Deflection Measurement Procedure To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. Remove any dirt or debris from the journal surface using a clean cloth. the measurement principle is that. Crankshaft Deflection Measurement Procedure.

From www.scribd.com

Simple Explanation of Crankshaft Deflections, Measurement Procedure, Readings, Curves Crankshaft Deflection Measurement Procedure the measurement principle is that curvature of the crankshaft, due to height/. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. crankshaft deflection measurement procedure. Remove any dirt or debris from the journal surface using a clean cloth. >these are generally taken using a spring loaded dial gauge.. Crankshaft Deflection Measurement Procedure.

From www.youtube.com

How to Measure Crankshaft Deflection YouTube Crankshaft Deflection Measurement Procedure crankshaft deflection measuring positions. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. the measurement principle is that curvature of the crankshaft, due to height/. . Crankshaft Deflection Measurement Procedure.

From www.marineengineersknowledge.com

Crankshaft Deflections Measurement Marine engineers knowledge Crankshaft Deflection Measurement Procedure To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of. Crankshaft Deflection Measurement Procedure.

From www.marineengineersknowledge.com

Crankshaft Deflections Measurement Marine engineers knowledge Crankshaft Deflection Measurement Procedure the measurement principle is that curvature of the crankshaft, due to height/. Remove any dirt or debris from the journal surface using a clean cloth. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. To determine the crank deflection, the crankshaft must always be rotated in such a way. Crankshaft Deflection Measurement Procedure.

From motionics.com

How to Measure Crankshaft Deflection Motionics LLC Crankshaft Deflection Measurement Procedure the measurement principle is that curvature of the crankshaft, due to height/. Remove any dirt or debris from the journal surface using a clean cloth. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. crankshaft deflection measurement procedure. To determine the crank deflection, the crankshaft must always. Crankshaft Deflection Measurement Procedure.

From dokumen.tips

(PDF) Crank Shaft & Its Deflection Measurement DOKUMEN.TIPS Crankshaft Deflection Measurement Procedure crankshaft deflection measurement procedure. crankshaft deflection measuring positions. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. the measurement principle is that curvature of the crankshaft, due to height/. the straight gauge is merely a dial reading inside micrometer used to measure the variation in. Crankshaft Deflection Measurement Procedure.

From www.youtube.com

Crankshaft Deflection Measurement procedure YouTube Crankshaft Deflection Measurement Procedure crankshaft deflection measuring positions. the measurement principle is that curvature of the crankshaft, due to height/. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. . Crankshaft Deflection Measurement Procedure.

From www.youtube.com

Measuring Procedure of Crank Deflection Yanmar Diesel Engine Generator Criteria & Allowable Crankshaft Deflection Measurement Procedure this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. the measurement principle is that curvature of the crankshaft, due to height/. crankshaft deflection measuring positions. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. crankshaft deflection. Crankshaft Deflection Measurement Procedure.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Crankshaft Deflection Measurement Procedure >these are generally taken using a spring loaded dial gauge. crankshaft deflection measuring positions. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. Remove any dirt or debris from the journal surface using a clean cloth. To determine the crank deflection, the crankshaft must always be rotated in. Crankshaft Deflection Measurement Procedure.

From www.iims.org.uk

Engine Crankshaft Deflection Measurement Guide IIMS Crankshaft Deflection Measurement Procedure crankshaft deflection measurement procedure. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. >these are generally taken using a spring loaded dial gauge. Remove any dirt or. Crankshaft Deflection Measurement Procedure.

From www.scribd.com

Crank Deflections A5.05. 02.02.01.00 Inspection / Measuring Engine Technology Internal Crankshaft Deflection Measurement Procedure this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. crankshaft deflection measurement procedure. crankshaft deflection measuring positions. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. >these are generally taken using a spring loaded dial gauge. Remove. Crankshaft Deflection Measurement Procedure.

From www.iims.org.uk

Engine Crankshaft Deflection Measurement Guide IIMS Crankshaft Deflection Measurement Procedure this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. Remove any dirt or debris from the journal surface using a clean cloth. >these are generally taken using a spring loaded dial gauge. crankshaft deflection measurement procedure. crankshaft deflection measuring positions. To determine the crank deflection, the crankshaft. Crankshaft Deflection Measurement Procedure.

From www.iims.org.uk

Engine Crankshaft Deflection Measurement Guide IIMS Crankshaft Deflection Measurement Procedure crankshaft deflection measurement procedure. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the. Crankshaft Deflection Measurement Procedure.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Crankshaft Deflection Measurement Procedure >these are generally taken using a spring loaded dial gauge. crankshaft deflection measurement procedure. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. Remove any dirt or debris from the journal surface using a clean cloth. the straight gauge is merely a dial reading inside micrometer used. Crankshaft Deflection Measurement Procedure.

From www.scribd.com

Engine Crankshaft Deflection Measurement Guide IIMS PDF Bearing (Mechanical) Internal Crankshaft Deflection Measurement Procedure the measurement principle is that curvature of the crankshaft, due to height/. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. Remove any dirt or debris from the journal surface using a clean cloth. the straight gauge is merely a dial reading inside micrometer used to measure. Crankshaft Deflection Measurement Procedure.

From www.scribd.com

Deflection measurement in Crankshaft PDF Crankshaft Deflection Measurement Procedure the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. crankshaft deflection measurement procedure. the measurement principle is that curvature of the crankshaft, due to height/. Remove any dirt or debris from the journal surface using a clean cloth. >these are generally taken using a spring loaded dial gauge.. Crankshaft Deflection Measurement Procedure.

From mirmarine.net

MirMarine Crankshaft procedures for Inspection and Calibration Crankshaft Deflection Measurement Procedure Remove any dirt or debris from the journal surface using a clean cloth. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. crankshaft deflection measuring positions. . Crankshaft Deflection Measurement Procedure.

From www.vrogue.co

Simple Explanation Of Crankshaft Deflections Measurem vrogue.co Crankshaft Deflection Measurement Procedure crankshaft deflection measurement procedure. Remove any dirt or debris from the journal surface using a clean cloth. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. >these are generally. Crankshaft Deflection Measurement Procedure.

From www.vrogue.co

Simple Explanation Of Crankshaft Deflections Measurem vrogue.co Crankshaft Deflection Measurement Procedure Remove any dirt or debris from the journal surface using a clean cloth. the measurement principle is that curvature of the crankshaft, due to height/. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. crankshaft deflection measurement procedure. this comprehensive guide will delve into the intricacies of. Crankshaft Deflection Measurement Procedure.

From www.iims.org.uk

Engine Crankshaft Deflection Measurement Guide IIMS Crankshaft Deflection Measurement Procedure Remove any dirt or debris from the journal surface using a clean cloth. crankshaft deflection measuring positions. crankshaft deflection measurement procedure. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction. Crankshaft Deflection Measurement Procedure.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Crankshaft Deflection Measurement Procedure Remove any dirt or debris from the journal surface using a clean cloth. >these are generally taken using a spring loaded dial gauge. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction. Crankshaft Deflection Measurement Procedure.

From www.marinesite.info

Simple Explanation Of Crankshaft Deflections, Measurement Procedure, Readings,Curves Crankshaft Deflection Measurement Procedure crankshaft deflection measurement procedure. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the. Crankshaft Deflection Measurement Procedure.

From marineandoffshoreinsight.com

Guide On How To Take Crankshaft Deflection Marine And Offshore Insight Crankshaft Deflection Measurement Procedure To determine the crank deflection, the crankshaft must always be rotated in such a way that, regardless of the engine’s normal rotation direction, the flywheel 1 and pinion 2 of the turning gear rotate in the direction indicated by the arrow. Remove any dirt or debris from the journal surface using a clean cloth. crankshaft deflection measuring positions. . Crankshaft Deflection Measurement Procedure.

From www.scribd.com

Crankshaft Deflection Measurement PDF Transportation Engineering Components Crankshaft Deflection Measurement Procedure >these are generally taken using a spring loaded dial gauge. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. crankshaft deflection measurement procedure. crankshaft deflection measuring positions. the measurement principle is that curvature of the crankshaft, due to height/. Remove any dirt or debris from the journal. Crankshaft Deflection Measurement Procedure.

From www.youtube.com

HOW DO THEY DO.. HOW TO MEASURE CRANKSHAFT DEFLECTION ON GENERATOR ONBOARD SHIPS... YouTube Crankshaft Deflection Measurement Procedure this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. crankshaft deflection measurement procedure. crankshaft deflection measuring positions. Remove any dirt or debris from the journal surface using a clean cloth. >these are generally taken using a spring loaded dial gauge. the measurement principle is that curvature. Crankshaft Deflection Measurement Procedure.

From themachine.science

Mastering Crankshaft Deflection A Comprehensive Guide Crankshaft Deflection Measurement Procedure Remove any dirt or debris from the journal surface using a clean cloth. crankshaft deflection measuring positions. crankshaft deflection measurement procedure. >these are generally taken using a spring loaded dial gauge. this comprehensive guide will delve into the intricacies of crankshaft deflection, providing you with a deep understanding of the. the measurement principle is that curvature. Crankshaft Deflection Measurement Procedure.

From marineandoffshoreinsight.com

Guide On How To Take Crankshaft Deflection Marine And Offshore Insight Crankshaft Deflection Measurement Procedure the measurement principle is that curvature of the crankshaft, due to height/. Remove any dirt or debris from the journal surface using a clean cloth. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. crankshaft deflection measurement procedure. crankshaft deflection measuring positions. this comprehensive guide will. Crankshaft Deflection Measurement Procedure.

From planm8.io

How to Conduct a Crankshaft Deflection Measurement Crankshaft Deflection Measurement Procedure Remove any dirt or debris from the journal surface using a clean cloth. >these are generally taken using a spring loaded dial gauge. crankshaft deflection measurement procedure. the straight gauge is merely a dial reading inside micrometer used to measure the variation in the distance. To determine the crank deflection, the crankshaft must always be rotated in such. Crankshaft Deflection Measurement Procedure.