Zinc Nickel Plating Vs Cadmium Plating . It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. This article will explain cadmium and zinc plating, including their advantages and particular applications. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. And what must be the. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used.

from exoetuuqc.blob.core.windows.net

Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. This article will explain cadmium and zinc plating, including their advantages and particular applications. And what must be the.

Zinc Nickel Vs Cadmium Plating at Dianne Witham blog

Zinc Nickel Plating Vs Cadmium Plating A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. And what must be the. This article will explain cadmium and zinc plating, including their advantages and particular applications. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. Their reduced environmental impact compared to cadmium plating. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. It also offers excellent corrosion resistance and ductility.

From exoetuuqc.blob.core.windows.net

Zinc Nickel Vs Cadmium Plating at Dianne Witham blog Zinc Nickel Plating Vs Cadmium Plating It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. And what must be the. This article will explain cadmium and zinc plating, including their advantages and particular applications. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. Zinc nickel and cadmium plating are popular. Zinc Nickel Plating Vs Cadmium Plating.

From www.youtube.com

Zinc Plating vs ZincNickel Plating YouTube Zinc Nickel Plating Vs Cadmium Plating It also offers excellent corrosion resistance and ductility. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. And what must be the. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications.. Zinc Nickel Plating Vs Cadmium Plating.

From hxezxewfq.blob.core.windows.net

Mechanical Zinc Plating Vs. Electroplating at Margie Gaulke blog Zinc Nickel Plating Vs Cadmium Plating It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. And what must be the. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. This article will explain cadmium. Zinc Nickel Plating Vs Cadmium Plating.

From www.jmplating.com

Zinc Nickel — J&M Plating Zinc Nickel Plating Vs Cadmium Plating In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. And what must be the. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. Their reduced environmental impact compared to cadmium plating. It also offers excellent corrosion resistance and ductility. This article will explain cadmium. Zinc Nickel Plating Vs Cadmium Plating.

From exoetuuqc.blob.core.windows.net

Zinc Nickel Vs Cadmium Plating at Dianne Witham blog Zinc Nickel Plating Vs Cadmium Plating It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. A 0.3 millimeter thick deposit can resist over 500 hours. Zinc Nickel Plating Vs Cadmium Plating.

From www.iqsdirectory.com

Types of Metal Plating Metal, Types, Applications, and Benefits Zinc Nickel Plating Vs Cadmium Plating Their reduced environmental impact compared to cadmium plating. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. It also offers. Zinc Nickel Plating Vs Cadmium Plating.

From kcjplating.com

Zinc Nickel Plating Services Corrosion Resistance KCJ Zinc Nickel Plating Vs Cadmium Plating Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. It also offers excellent corrosion resistance and ductility. This article will explain cadmium and zinc plating, including their advantages and particular applications. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains. Zinc Nickel Plating Vs Cadmium Plating.

From blog.thepipingmart.com

Tin Plating vs Zinc Plating What's the Difference Zinc Nickel Plating Vs Cadmium Plating Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. This article will explain cadmium and zinc plating, including their advantages and particular applications. And what must be the. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. Their reduced environmental impact compared to cadmium. Zinc Nickel Plating Vs Cadmium Plating.

From jsamc2.com

Zinc Nickel Plating JSA Metal Finishing Supplier Zinc Nickel Plating Vs Cadmium Plating It also offers excellent corrosion resistance and ductility. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. Their reduced environmental impact compared. Zinc Nickel Plating Vs Cadmium Plating.

From www.ecwilliams.co.uk

What is Zinc Nickel Plating? EC Williams Your Guide To Electroplating Zinc Nickel Plating Vs Cadmium Plating Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. It also offers excellent corrosion resistance and ductility. And what must be the. Their reduced environmental impact compared to cadmium plating. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its. Zinc Nickel Plating Vs Cadmium Plating.

From exoetuuqc.blob.core.windows.net

Zinc Nickel Vs Cadmium Plating at Dianne Witham blog Zinc Nickel Plating Vs Cadmium Plating A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. This article will explain cadmium and zinc plating, including their advantages. Zinc Nickel Plating Vs Cadmium Plating.

From rb-hardware.com

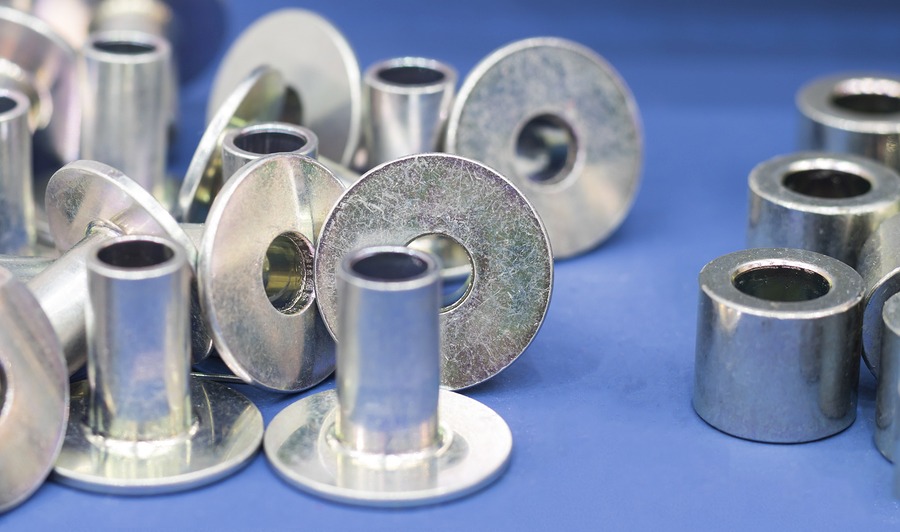

Common Surface Treatments (Electroplating) Rainbow Hardware Zinc Nickel Plating Vs Cadmium Plating This article will explain cadmium and zinc plating, including their advantages and particular applications. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. Their reduced environmental impact compared to cadmium plating. It also offers excellent corrosion resistance and. Zinc Nickel Plating Vs Cadmium Plating.

From chemresearchco.com

Difference Between Cadmium and Zinc Nickel Plating Zinc Nickel Plating Vs Cadmium Plating Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. And what must be the. It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. This article will explain cadmium. Zinc Nickel Plating Vs Cadmium Plating.

From www.peregrinemetalfinishing.com

Which One is Best for Your Industry ZincNickel Plating vs. Standard Zinc Nickel Plating Vs Cadmium Plating This article will explain cadmium and zinc plating, including their advantages and particular applications. It also offers excellent corrosion resistance and ductility. And what must be the. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting. Zinc Nickel Plating Vs Cadmium Plating.

From www.youtube.com

【Zinc plating, Nickel plating, Chromium plating】What's the difference Zinc Nickel Plating Vs Cadmium Plating In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. This article will explain cadmium and zinc plating, including their advantages and particular applications. Their reduced environmental impact compared to cadmium plating. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and. Zinc Nickel Plating Vs Cadmium Plating.

From www.akjia.com

The Comprehensive Guide to Zinc Nickel Plating vs. Zinc Plating Zinc Nickel Plating Vs Cadmium Plating Their reduced environmental impact compared to cadmium plating. This article will explain cadmium and zinc plating, including their advantages and particular applications. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and. Zinc Nickel Plating Vs Cadmium Plating.

From glecoplating.com

Nickel vs Zinc Plating Which One Should You Choose? Gleco Plating Zinc Nickel Plating Vs Cadmium Plating In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. This article will explain cadmium and zinc plating, including their advantages and particular applications. And what must be the. It also offers excellent corrosion resistance and ductility. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing. Zinc Nickel Plating Vs Cadmium Plating.

From craftercornerindia.blogspot.com

Electroplating Nickel And Its History Zinc Nickel Plating Vs Cadmium Plating This article will explain cadmium and zinc plating, including their advantages and particular applications. And what must be the. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. A 0.3 millimeter thick deposit can resist over 500. Zinc Nickel Plating Vs Cadmium Plating.

From blog.thepipingmart.com

Zinc Plating vs Cadmium Plating What's the Difference Zinc Nickel Plating Vs Cadmium Plating Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. And what must be the. It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its. Zinc Nickel Plating Vs Cadmium Plating.

From blog.thepipingmart.com

Nickel Plating vs Cadmium Plating What's the Difference Zinc Nickel Plating Vs Cadmium Plating A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. It also offers excellent corrosion resistance and ductility. Their reduced environmental. Zinc Nickel Plating Vs Cadmium Plating.

From wilsongarner.com

ZincNickel Plating for Fasteners What to Know WilsonGarner Zinc Nickel Plating Vs Cadmium Plating Their reduced environmental impact compared to cadmium plating. It also offers excellent corrosion resistance and ductility. This article will explain cadmium and zinc plating, including their advantages and particular applications. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. Zinc nickel and cadmium plating are popular metal coatings used in various. Zinc Nickel Plating Vs Cadmium Plating.

From kcjplating.com

Nickel Plating vs. Zinc Plating KC Jones Plating Zinc Nickel Plating Vs Cadmium Plating A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. This article will explain cadmium and zinc plating, including their advantages and particular applications. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the. Zinc Nickel Plating Vs Cadmium Plating.

From twbfinishing.co.uk

Zinc Nickel Plating TWB Finishing Zinc Nickel Plating Vs Cadmium Plating Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. Their reduced environmental impact compared to cadmium plating. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. In the manufacturing industry, zinc. Zinc Nickel Plating Vs Cadmium Plating.

From www.ecwilliams.co.uk

What is Zinc Nickel Plating? EC Williams Your Guide To Electroplating Zinc Nickel Plating Vs Cadmium Plating It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. And what must be the. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. Zinc nickel and cadmium plating are popular metal. Zinc Nickel Plating Vs Cadmium Plating.

From exoetuuqc.blob.core.windows.net

Zinc Nickel Vs Cadmium Plating at Dianne Witham blog Zinc Nickel Plating Vs Cadmium Plating And what must be the. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. It also offers excellent corrosion resistance and ductility. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc. Zinc Nickel Plating Vs Cadmium Plating.

From blog.thepipingmart.com

Zinc Nickel Plating vs Cadmium Plating What's the Difference Zinc Nickel Plating Vs Cadmium Plating Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. This article will explain cadmium and zinc plating, including their advantages and particular applications. It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are. Zinc Nickel Plating Vs Cadmium Plating.

From d-bplating.com

ZincNickel Plating D&B Plating Zinc Nickel Plating Vs Cadmium Plating And what must be the. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. Their reduced environmental impact compared to cadmium plating. This article will explain cadmium and zinc plating, including their advantages and particular applications. In the. Zinc Nickel Plating Vs Cadmium Plating.

From www.youtube.com

ZInc Plating Hardware with Caswell Electroplating Copy Cad Zinc Plating Zinc Nickel Plating Vs Cadmium Plating It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. And what must be the. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it. Zinc Nickel Plating Vs Cadmium Plating.

From pediaa.com

Difference Between Cadmium Plating and Zinc Plating Zinc Nickel Plating Vs Cadmium Plating And what must be the. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. Their reduced environmental impact compared to cadmium plating.. Zinc Nickel Plating Vs Cadmium Plating.

From blog.thepipingmart.com

Zinc vs. Nickel Plating What's the Difference Zinc Nickel Plating Vs Cadmium Plating A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. It also offers excellent corrosion resistance and ductility. And what must. Zinc Nickel Plating Vs Cadmium Plating.

From www.differencebetween.com

Difference Between Zinc and Nickel Plating Compare the Difference Zinc Nickel Plating Vs Cadmium Plating Their reduced environmental impact compared to cadmium plating. And what must be the. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. This article will explain cadmium and zinc plating, including their advantages and particular applications. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing. Zinc Nickel Plating Vs Cadmium Plating.

From www.pioneermetal.com

Zinc Plating vs. Zinc Flake Coating Processes Explained Zinc Nickel Plating Vs Cadmium Plating A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. Their reduced environmental impact compared to cadmium plating. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. And what must. Zinc Nickel Plating Vs Cadmium Plating.

From www.scribd.com

Cadmium vs. Zinc Zinc Metallurgy Zinc Nickel Plating Vs Cadmium Plating This article will explain cadmium and zinc plating, including their advantages and particular applications. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by. Zinc Nickel Plating Vs Cadmium Plating.

From caswellcanada.ca

Plug N' Plate Zinc Plating Kit Caswell Canada Zinc Nickel Plating Vs Cadmium Plating A 0.3 millimeter thick deposit can resist over 500 hours of salt spray before exhibiting any sign of rust, and it retains its shape much more effectively than zinc by itself. And what must be the. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. It also offers excellent corrosion resistance and ductility.. Zinc Nickel Plating Vs Cadmium Plating.

From blog.thepipingmart.com

Zinc Plating vs Black Oxide What's the Difference Zinc Nickel Plating Vs Cadmium Plating And what must be the. Zinc nickel and cadmium plating are popular metal coatings used in various engineering and manufacturing applications. It also offers excellent corrosion resistance and ductility. Their reduced environmental impact compared to cadmium plating. In the manufacturing industry, zinc plating, cadmium plating, chromium plating and nickel plating are the most widely used. This article will explain cadmium. Zinc Nickel Plating Vs Cadmium Plating.