Electrochemical Etching Acid . Electrochemical marking and etching are done exclusively on conductive metal surfaces. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Wet chemical and electrochemical etching processes, fig.

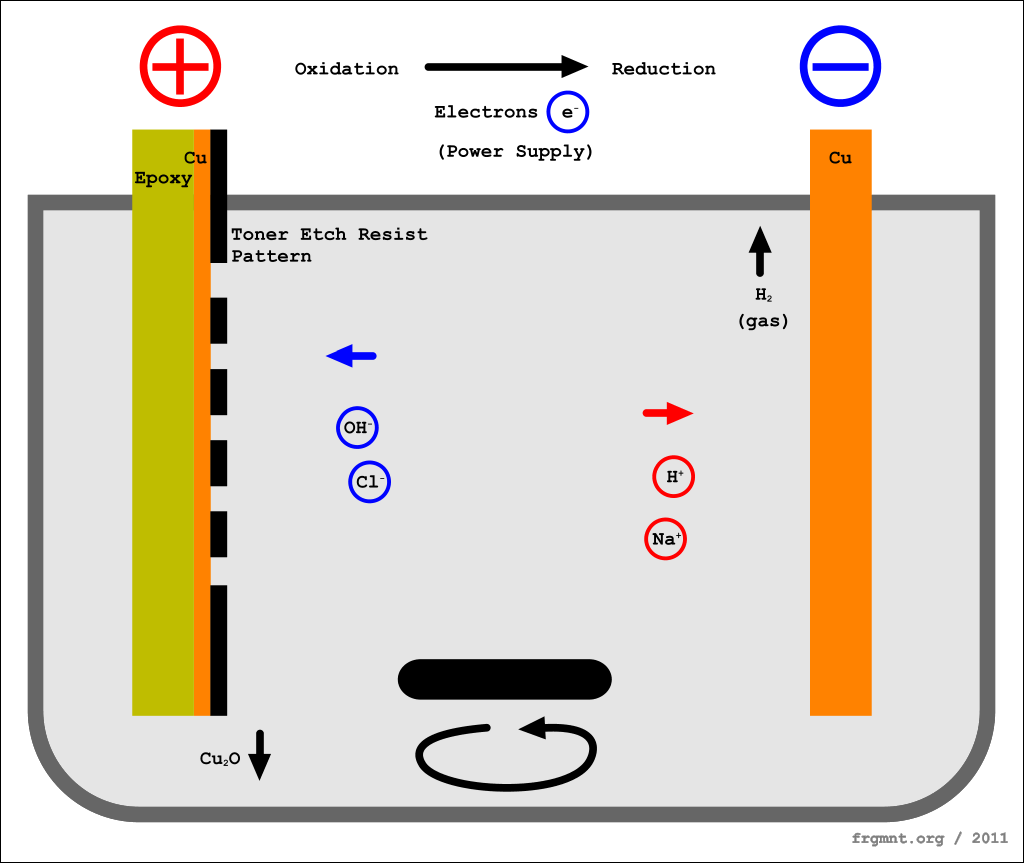

from frgmnt.org

The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. Electrochemical marking and etching are done exclusively on conductive metal surfaces. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Wet chemical and electrochemical etching processes, fig. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid.

Electrochemical Etching « frgmnt org

Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Electrochemical marking and etching are done exclusively on conductive metal surfaces. Wet chemical and electrochemical etching processes, fig. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Electrochemical Etching Acid Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. Wet chemical and electrochemical etching processes, fig. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions,. Electrochemical Etching Acid.

From www.iqsdirectory.com

Acid Etching Acid Types, Metal Types, Applications, and Benefits Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Electrochemical marking and etching are done exclusively on conductive metal surfaces. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical. Electrochemical Etching Acid.

From www.researchgate.net

illustrates the schematic diagram of photoelectrochemical etching Electrochemical Etching Acid Electrochemical marking and etching are done exclusively on conductive metal surfaces. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The electrochemical. Electrochemical Etching Acid.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Electrochemical Etching Acid The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. Electrochemical marking and etching are done exclusively on conductive metal surfaces. A marking head is used to. Electrochemical Etching Acid.

From www.researchgate.net

The electrochemical etching cell setup a schematic diagram b real photo Electrochemical Etching Acid Wet chemical and electrochemical etching processes, fig. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The wet etch process can be described by three basic steps (1) diffusion of the liquid. Electrochemical Etching Acid.

From www.researchgate.net

(a) Schematic diagram of an electrochemical etching setup for preparing Electrochemical Etching Acid Electrochemical marking and etching are done exclusively on conductive metal surfaces. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etch process can be described by three basic steps (1) diffusion of. Electrochemical Etching Acid.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. Electrochemical marking and etching are done exclusively on conductive metal surfaces. A marking head is used to release a weak current to the metal surface. Electrochemical Etching Acid.

From www.researchgate.net

Schematic representation of the electrochemical etching setup Electrochemical Etching Acid The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. Wet chemical and electrochemical etching processes, fig. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure. Electrochemical Etching Acid.

From www.iqsdirectory.com

Acid Etching Acid Types, Metal Types, Applications, and Benefits Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. Electrochemical marking and etching are done exclusively on conductive metal surfaces. The wet etch process can. Electrochemical Etching Acid.

From www.researchgate.net

The electrochemical etching process (A) and obtaining the electrical Electrochemical Etching Acid A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions,. Electrochemical Etching Acid.

From www.researchgate.net

The electrochemical etching system. Download Scientific Diagram Electrochemical Etching Acid The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. A marking head is used to release a weak current to the metal surface through a marking. Electrochemical Etching Acid.

From www.researchgate.net

Illustration of the electrochemical etching process. Download Electrochemical Etching Acid The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. Electrochemical marking and etching are done exclusively on conductive metal surfaces. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet. Electrochemical Etching Acid.

From www.sifarplaccati.it

Etching Primer Phosphoric Acid sifarplaccati.it Electrochemical Etching Acid Wet chemical and electrochemical etching processes, fig. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. Electrochemical marking and etching are done exclusively on conductive metal surfaces. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etching of gan,. Electrochemical Etching Acid.

From www.metaletching.org

Stainless Steel Etching Companies Services Electrochemical Etching Acid A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. Wet chemical and electrochemical etching processes, fig. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Electrochemical marking and etching are done exclusively on conductive. Electrochemical Etching Acid.

From pubs.rsc.org

Analysis of the nGaN electrochemical etching process and its mechanism Electrochemical Etching Acid Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. Wet chemical and electrochemical etching processes, fig. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to. Electrochemical Etching Acid.

From www.researchgate.net

Schematic of the DCetching process of aluminum foil Download Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Wet chemical and electrochemical etching processes, fig. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. A marking head is used to release a weak current to the metal. Electrochemical Etching Acid.

From www.researchgate.net

(a) Scheme of electrochemical etching method. (b) Surface morphologies Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in. Electrochemical Etching Acid.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Electrochemical Etching Acid Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. A marking head. Electrochemical Etching Acid.

From www.researchgate.net

The experimental configuration of the selective electrochemical etching Electrochemical Etching Acid The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. Electrochemical marking and etching are done exclusively on conductive metal surfaces. The electrochemical. Electrochemical Etching Acid.

From www.researchgate.net

Illustration of the electrochemical etching of Si ptype in the acid Electrochemical Etching Acid Wet chemical and electrochemical etching processes, fig. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in. Electrochemical Etching Acid.

From www.researchgate.net

Working principle of the electrochemical etching with a micromachined Electrochemical Etching Acid A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions,. Electrochemical Etching Acid.

From tustech.com

Electro Chemical Etching T.U.S. Technologies Electrochemical Etching Acid The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. Wet chemical and electrochemical etching processes, fig. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon. Electrochemical Etching Acid.

From www.researchgate.net

Basic schematic of electrochemical etching method Download Scientific Electrochemical Etching Acid The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. Electrochemical marking and etching are done exclusively on conductive metal surfaces. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. A marking head is. Electrochemical Etching Acid.

From frgmnt.org

Electrochemical Etching « frgmnt org Electrochemical Etching Acid The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to. Electrochemical Etching Acid.

From www.researchgate.net

Proposed mechanism for electrochemical etching of Ti 2 AlC in HCl Electrochemical Etching Acid Electrochemical marking and etching are done exclusively on conductive metal surfaces. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Wet chemical and electrochemical etching processes, fig. A marking. Electrochemical Etching Acid.

From www.researchgate.net

Electrochemical etching process. (a) At a beginning step. (b) At an Electrochemical Etching Acid The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Wet chemical and electrochemical etching processes, fig. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. A marking head is used to release a weak current. Electrochemical Etching Acid.

From www.researchgate.net

The electrochemical etching (ECE) cell setup Download Scientific Diagram Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. Wet chemical and electrochemical etching processes, fig. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etch process can be described by three. Electrochemical Etching Acid.

From www.researchgate.net

Schematic diagrams illustrating the progressive alkaline etching Electrochemical Etching Acid Electrochemical marking and etching are done exclusively on conductive metal surfaces. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Wet chemical and electrochemical etching processes, fig. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid.. Electrochemical Etching Acid.

From www.researchgate.net

Schematics of the electrochemical etching cell. a The Au wire (anode Electrochemical Etching Acid A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to. Electrochemical Etching Acid.

From www.researchgate.net

Schematic view of the electrochemical etching cell (a) and a picture of Electrochemical Etching Acid The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the structure that is to be. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous. Electrochemical Etching Acid.

From www.researchgate.net

Schematic representing the Cu electrochemical atomic layer etching Electrochemical Etching Acid Electrochemical marking and etching are done exclusively on conductive metal surfaces. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. The wet etch process can be described by three. Electrochemical Etching Acid.

From frgmnt.org

Electrochemical Etching « frgmnt org Electrochemical Etching Acid Electrochemical marking and etching are done exclusively on conductive metal surfaces. Wet chemical and electrochemical etching processes, fig. A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etch process can be described by three basic steps (1) diffusion of the liquid etchant to the. Electrochemical Etching Acid.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Electrochemical Etching Acid A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. Wet chemical and electrochemical etching processes, fig. Electrochemical marking and etching are done exclusively on conductive metal surfaces. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The electrochemical etching is based. Electrochemical Etching Acid.

From www.researchgate.net

Electrochemical etching setup Download Scientific Diagram Electrochemical Etching Acid A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The electrochemical etching is based on the removal of silicon clusters from the bulk silicon substrate in a solution containing hydrochloric. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions,. Electrochemical Etching Acid.

From www.researchgate.net

(a) Schematic illustration of the electrochemical etching approach to Electrochemical Etching Acid A marking head is used to release a weak current to the metal surface through a marking stencil/mask soaked in the electrolyte fluid. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Superoleophobic surfaces on zinc substrates are fabricated via electrochemical etching and perfluorooctanoic acid modification. The wet etch process. Electrochemical Etching Acid.