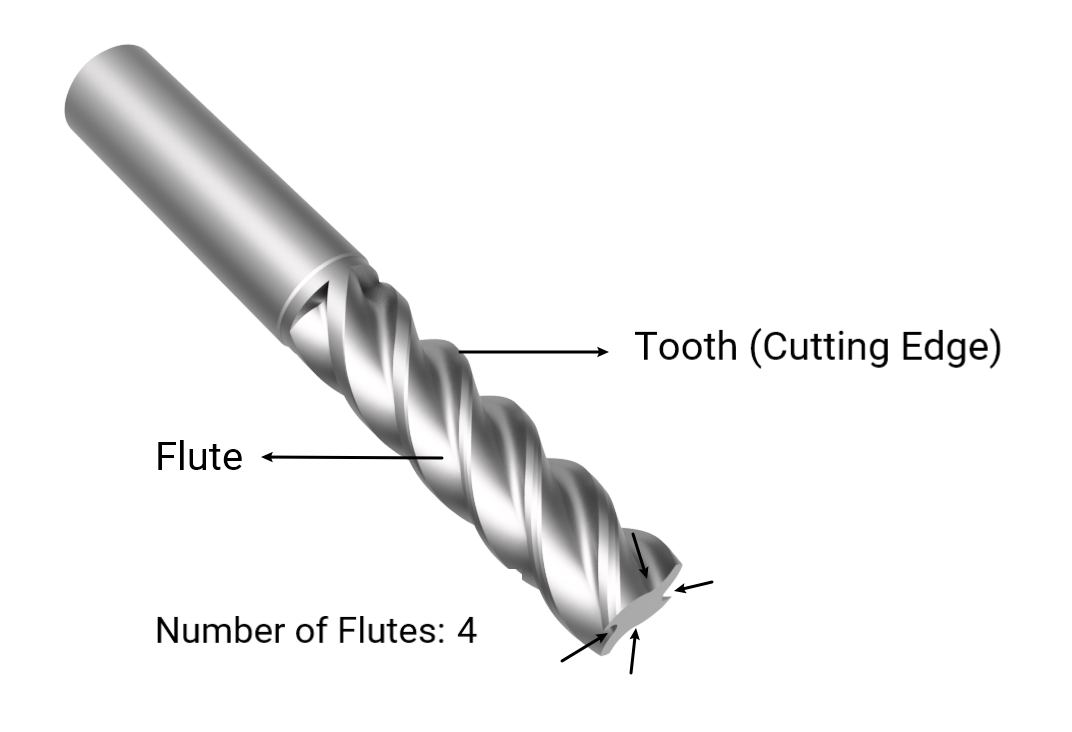

Flutes Machining . These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. There is a vast array of small yet important decisions that must be made when working in cnc machining. Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. Flutes are the easiest part of the end mill to recognize. For example, it is vital to choose the right number of flutes on end mills to enable. By distributing cutting forces evenly, these cutters. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. Understanding flute count is essential for selecting the right end mill. Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges.

from support.snapmaker.com

These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Understanding flute count is essential for selecting the right end mill. 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. There is a vast array of small yet important decisions that must be made when working in cnc machining. By distributing cutting forces evenly, these cutters. Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges.

CNC Snapmaker

Flutes Machining Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. By distributing cutting forces evenly, these cutters. Flutes are the easiest part of the end mill to recognize. Understanding flute count is essential for selecting the right end mill. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. There is a vast array of small yet important decisions that must be made when working in cnc machining. Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. For example, it is vital to choose the right number of flutes on end mills to enable. 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge.

From www.bantamtools.com

Bantam Tools Blog — When to Use SingleFlute Tooling Flutes Machining Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. For example, it is vital to choose the right number of flutes on end mills to enable. Understanding flute count is essential for selecting the right end mill. These are the deep spiraled grooves in the tool that allow for chip. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining Flutes are the easiest part of the end mill to recognize. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. There is a vast array of small yet important decisions that. Flutes Machining.

From www.itmfl.com

Universal Flute Grinders ITM International Tool Machines Flutes Machining Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. Flutes are the easiest part of the end mill to recognize. Understanding flute count is essential for selecting the right end mill. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool. Flutes Machining.

From www.walmart.com

21mm Cutting Diameter Straight Shank 4 Flutes End Mill Milling Cutter Flutes Machining Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. Understanding flute count is essential for selecting the right end mill. Flutes are the easiest part of the end mill to recognize. By distributing cutting forces evenly, these cutters. Unequal flute spacing in osg’s variable geometry end mill line is designed. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its. Flutes Machining.

From www.youtube.com

Sharpening the Flutes on a Milling Cutter YouTube Flutes Machining By distributing cutting forces evenly, these cutters. There is a vast array of small yet important decisions that must be made when working in cnc machining. 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. Flutes are the easiest part of the end mill to recognize. Understanding flute count is essential for selecting. Flutes Machining.

From forums.autodesk.com

Solved 4th axis flute machining Autodesk Community Flutes Machining By distributing cutting forces evenly, these cutters. For example, it is vital to choose the right number of flutes on end mills to enable. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Understanding flute count is essential for selecting the right end mill.. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. By distributing cutting forces evenly, these cutters. For example, it is vital to choose the right number of flutes on end. Flutes Machining.

From www.aliexpress.com

BB 200mm Carbide Spiral Flutes Machine Reamer Long Length Coated H7 Flutes Machining 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. Flutes are the easiest part of the end mill to recognize. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Instead, these machines work best with lower flute. Flutes Machining.

From sheffieldtooling.co.uk

M2.5 x 0.45 Spiral Flute Machine Tap HSSE Purple Ring Sheffield Flutes Machining Flutes are the easiest part of the end mill to recognize. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. There is a vast array of small yet important decisions that must be made when working in cnc machining. 2 flute and 4 flute. Flutes Machining.

From www.alvordpolk.com

Specifications Special Reamers and Core Drills Flute Specifications Flutes Machining Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Flutes are the easiest part of the end mill to recognize. There is a vast array of small yet. Flutes Machining.

From www.youtube.com

How to make Flute Flute Making at Home Easy Flute Making Process Flutes Machining 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. Understanding flute count is essential for. Flutes Machining.

From heygotools.com

Hss Spiral Flute Machine Taps For Tapping Internal Threads Flutes Machining Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. Understanding flute count is essential for selecting the right end mill. Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. These are the deep spiraled grooves in the tool that allow. Flutes Machining.

From www.aliexpress.com

4 flute Roughing Endmill Flutes 4 Center Cutting Rough End Mill Cnc Flutes Machining 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. Understanding flute count is essential for selecting the right end mill. For example, it is vital to choose the right number of flutes on end mills to enable. Flutes are the easiest part of the end mill to recognize. Unequal flute spacing in osg’s. Flutes Machining.

From www.youtube.com

4 Flutes Machining Shop Tour YouTube Flutes Machining There is a vast array of small yet important decisions that must be made when working in cnc machining. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. With fewer flutes, these end mills work best for. Flutes Machining.

From 4flutesmachining.com

4 Flutes Machining Flutes Machining Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. For example, it is vital to choose the right number of flutes on end mills to enable. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Flutes are the easiest. Flutes Machining.

From weima.com.my

YAMAWA SP Spiral Flute Machine Tap, YAMAWA, Kuala Lumpur, Malaysia Flutes Machining Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. There is a vast array of small yet important decisions that must be made when working in cnc machining. Flutes are the easiest part of the end mill to recognize. Milling cutters with variable helix flutes feature. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining Understanding flute count is essential for selecting the right end mill. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. There is a vast array of small yet important decisions that must be made when working in cnc machining. Simply put, flutes are the. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining Understanding flute count is essential for selecting the right end mill. Flutes are the easiest part of the end mill to recognize. By distributing cutting forces evenly, these cutters. 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. For example, it is vital to choose the right number of flutes on end mills. Flutes Machining.

From fabacademy.org

Week_8 Flutes Machining With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Flutes are the easiest part of the end mill to recognize. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Instead, these machines work best with lower flute. Flutes Machining.

From www.youtube.com

5 Flute Solid Carbide End Mill Machining 4140 steel YouTube Flutes Machining By distributing cutting forces evenly, these cutters. Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. There is a vast array of small yet important decisions that must be made when working in cnc machining. With fewer flutes, these end mills work best for applications such as full slotting, which. Flutes Machining.

From wxaunoland.en.made-in-china.com

FM1450g Automatic Multifunction HighSpeed Flute Laminating Machine Flutes Machining Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. There is a vast array of small yet important decisions that must be made when working in cnc machining.. Flutes Machining.

From www.ebay.com

LOT OF 8 VTG HAND STRAIGHT FLUTE MACHINING REAMERS AS PICTURED AND Flutes Machining Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Understanding flute count is essential for. Flutes Machining.

From www.4flutesmachining.com

4 Flutes Machining Flutes Machining With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip evacuation spaces between cutting edges. Understanding flute count is essential for selecting the right end mill. By. Flutes Machining.

From support.snapmaker.com

CNC Snapmaker Flutes Machining Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. For example, it is vital to choose the right number of flutes on end mills to enable. Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. Understanding flute count is essential. Flutes Machining.

From youbond-packaging.en.made-in-china.com

Labeling Flute Laminator Machine Flute Laminating Machine Automatic Flutes Machining With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Flutes are the easiest part of the end mill to recognize. For example, it is vital to choose the right number of flutes on end mills to enable. These are the deep spiraled grooves in. Flutes Machining.

From www.metricmcc.com

212A High Speed Steel Straight Flute Machine Reamer Flutes Machining For example, it is vital to choose the right number of flutes on end mills to enable. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Flutes are the easiest part of the end mill to recognize. Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during. Flutes Machining.

From www.mightools.com

Spiral Flute Machine Tap Flutes Machining Unequal flute spacing in osg’s variable geometry end mill line is designed to reduce vibration during machining by altering. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. There is a vast array of small yet important decisions that must be made when working. Flutes Machining.

From www.facebook.com

4 Flutes Machining Home Facebook Flutes Machining There is a vast array of small yet important decisions that must be made when working in cnc machining. By distributing cutting forces evenly, these cutters. Simply put, flutes are the part of the anatomy that allows the end mill to cut on its edge. Flutes are the easiest part of the end mill to recognize. Unequal flute spacing in. Flutes Machining.

From rifleshooter.com

How to flute a rifle barrel Flutes Machining For example, it is vital to choose the right number of flutes on end mills to enable. By distributing cutting forces evenly, these cutters. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Flutes are the easiest part of the end mill to recognize.. Flutes Machining.

From www.youtube.com

Multi Flute Milling video YouTube Flutes Machining For example, it is vital to choose the right number of flutes on end mills to enable. Understanding flute count is essential for selecting the right end mill. These are the deep spiraled grooves in the tool that allow for chip formation and evacuation. Simply put, flutes are the part of the anatomy that allows the end mill to cut. Flutes Machining.

From www.toolgal.com

Flute Grinding Toolgal Innovative Diamond Tools Flutes Machining For example, it is vital to choose the right number of flutes on end mills to enable. With fewer flutes, these end mills work best for applications such as full slotting, which engages the full tool diameter and takes large radial stepovers. Instead, these machines work best with lower flute counts that incorporate larger chip gullets or flute cavities—the chip. Flutes Machining.

From www.facebook.com

4 Flutes Machining Vicksburg MI Flutes Machining 2 flute and 4 flute end mills offer different performance benefits, depending on material type and. Milling cutters with variable helix flutes feature varying geometries along the cutting edge, reducing sound and vibration during machining. There is a vast array of small yet important decisions that must be made when working in cnc machining. Simply put, flutes are the part. Flutes Machining.