Gauge Alignment . While the dials may seem confusing at first, they’re easy to read once you understand what they mean. Dial indicators are measuring devices designed expressly to measure relative position. Measure the a, b, & c dimensions. Learn about the machine you are aligning. Below we will cover reverse dial indication method. Dial gauge indicator method for alignment 5. The primary parts of a dial indicator. Familiarize with terms, techniques and procedure. To perform the rim & face method, you must: The plunger moves a needle clockwise when. Mount the dial indicators fixtures. Alignment procedure step by step 6. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. There are several steps which need to be taken for a successful alignment job. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy.

from www.mechanical-knowledge.com

While the dials may seem confusing at first, they’re easy to read once you understand what they mean. Below we will cover reverse dial indication method. The primary parts of a dial indicator. The plunger moves a needle clockwise when. Dial indicators are measuring devices designed expressly to measure relative position. Measure the a, b, & c dimensions. Learn about the machine you are aligning. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Familiarize with terms, techniques and procedure. There are several steps which need to be taken for a successful alignment job.

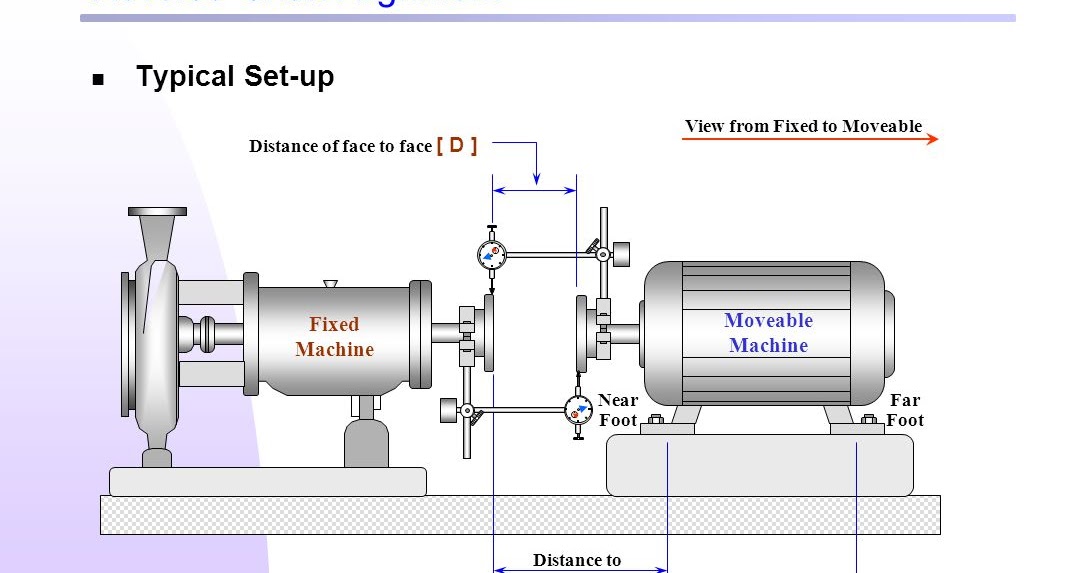

SHAFT ALIGNMENT REVERSE DIAL INDICATOR ALIGNMENT

Gauge Alignment Measure the a, b, & c dimensions. To perform the rim & face method, you must: Familiarize with terms, techniques and procedure. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. Below we will cover reverse dial indication method. Measure the a, b, & c dimensions. The plunger moves a needle clockwise when. Dial gauge indicator method for alignment 5. There are several steps which need to be taken for a successful alignment job. Dial indicators are measuring devices designed expressly to measure relative position. While the dials may seem confusing at first, they’re easy to read once you understand what they mean. The primary parts of a dial indicator. Learn about the machine you are aligning. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Mount the dial indicators fixtures. Alignment procedure step by step 6.

From www.engineeringtribe.com

Dial Gauge (PDF) Parts, Working Principle, Types, Uses, etc Gauge Alignment Alignment procedure step by step 6. Familiarize with terms, techniques and procedure. The plunger moves a needle clockwise when. Dial gauge indicator method for alignment 5. To perform the rim & face method, you must: Dial indicators are measuring devices designed expressly to measure relative position. The primary parts of a dial indicator. Measure the a, b, & c dimensions.. Gauge Alignment.

From www.huttie.com

Laser Wheel Alignment Gauge Huttie Gauge Alignment Learn about the machine you are aligning. Measure the a, b, & c dimensions. Below we will cover reverse dial indication method. There are several steps which need to be taken for a successful alignment job. The primary parts of a dial indicator. Alignment procedure step by step 6. In principle, reverse dial indication (rdi) and laser alignment are identical. Gauge Alignment.

From www.youtube.com

Wheel alignment gauges in use. YouTube Gauge Alignment Measure the a, b, & c dimensions. Below we will cover reverse dial indication method. There are several steps which need to be taken for a successful alignment job. To perform the rim & face method, you must: Dial indicators are measuring devices designed expressly to measure relative position. While the dials may seem confusing at first, they’re easy to. Gauge Alignment.

From unimaterna.com.br

Industrial & Scientific Test Ulnar Welder Inspection Gauge Stainless Gauge Alignment To perform the rim & face method, you must: Measure the a, b, & c dimensions. Familiarize with terms, techniques and procedure. Dial gauge indicator method for alignment 5. Mount the dial indicators fixtures. The primary parts of a dial indicator. Learn about the machine you are aligning. There are several steps which need to be taken for a successful. Gauge Alignment.

From www.youtube.com

Alignment Procedure(Step by step) While Using Dial Gauge Indicator Gauge Alignment Below we will cover reverse dial indication method. Familiarize with terms, techniques and procedure. Alignment procedure step by step 6. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Learn about the machine you are aligning. The plunger moves a needle clockwise when. Mount the dial indicators fixtures. While. Gauge Alignment.

From www.rockler.com

Betterley UNAGAUGE Universal Alignment and Adjustment Gauge Rockler Gauge Alignment Below we will cover reverse dial indication method. Learn about the machine you are aligning. Alignment procedure step by step 6. While the dials may seem confusing at first, they’re easy to read once you understand what they mean. Familiarize with terms, techniques and procedure. Mount the dial indicators fixtures. Measure the a, b, & c dimensions. To perform the. Gauge Alignment.

From www.mechanical-knowledge.com

SHAFT ALIGNMENT REVERSE DIAL INDICATOR ALIGNMENT Gauge Alignment There are several steps which need to be taken for a successful alignment job. Dial indicators are measuring devices designed expressly to measure relative position. The plunger moves a needle clockwise when. Below we will cover reverse dial indication method. To perform the rim & face method, you must: Dial gauge indicator method for alignment 5. Familiarize with terms, techniques. Gauge Alignment.

From www.uniquetoolssolution.in

ATC Alignment Gauge Unique Tools Solution Gauge Alignment The plunger moves a needle clockwise when. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. The primary parts of a dial indicator. Alignment procedure step by step 6. Learn about the machine you are aligning. Dial indicators are measuring devices designed expressly to measure relative position. Familiarize with terms, techniques. Gauge Alignment.

From styleprds.xsrv.jp

Trackace Wheel Alignment/Tracking Trackrite Camber/Castor Pressure Gauge Alignment The plunger moves a needle clockwise when. Learn about the machine you are aligning. The primary parts of a dial indicator. Familiarize with terms, techniques and procedure. Dial indicators are measuring devices designed expressly to measure relative position. Measure the a, b, & c dimensions. Below we will cover reverse dial indication method. Alignment procedure step by step 6. In. Gauge Alignment.

From racecarsdirect.com

Dunlop optical wheel alignment gauge Gauge Alignment Dial indicators are measuring devices designed expressly to measure relative position. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. There are several steps which need to be taken for a successful alignment job. Below we will cover reverse dial indication method. Mount the dial indicators fixtures. Alignment procedure step by. Gauge Alignment.

From www.gemco.co.uk

Dunlop Optical Alignment Gauges for wheel alignment Gauge Alignment The plunger moves a needle clockwise when. Alignment procedure step by step 6. Dial indicators are measuring devices designed expressly to measure relative position. Familiarize with terms, techniques and procedure. Measure the a, b, & c dimensions. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. Below we will cover reverse. Gauge Alignment.

From speed.academy

DIY Wheel Alignment It’s Easier Than You Think! Speed Academy Gauge Alignment To perform the rim & face method, you must: Measure the a, b, & c dimensions. While the dials may seem confusing at first, they’re easy to read once you understand what they mean. The primary parts of a dial indicator. Dial gauge indicator method for alignment 5. The plunger moves a needle clockwise when. Familiarize with terms, techniques and. Gauge Alignment.

From autosolotools.com

Alignment Gauges AutoSolo Gauge Alignment Familiarize with terms, techniques and procedure. To perform the rim & face method, you must: Dial gauge indicator method for alignment 5. Mount the dial indicators fixtures. Below we will cover reverse dial indication method. The primary parts of a dial indicator. Dial indicators are measuring devices designed expressly to measure relative position. Learn about the machine you are aligning.. Gauge Alignment.

From www.ebay.co.uk

Dunlop Optical Alignment Gauge To Measure Tracking Toe Angles AG040 Gauge Alignment Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Measure the a, b, & c dimensions. Below we will cover reverse dial indication method. Dial indicators are measuring devices designed expressly to measure relative position. To perform the rim & face method, you must: In principle, reverse dial indication. Gauge Alignment.

From www.mechanical-knowledge.com

Dial Indicator Shaft Alignment Pdf Gauge Alignment Below we will cover reverse dial indication method. Dial indicators are measuring devices designed expressly to measure relative position. The primary parts of a dial indicator. There are several steps which need to be taken for a successful alignment job. Mount the dial indicators fixtures. Learn about the machine you are aligning. The plunger moves a needle clockwise when. Familiarize. Gauge Alignment.

From www.analogueseduction.net

Clearaudio High Precision Cartridge Alignment Gauge Analogue Seduction Gauge Alignment There are several steps which need to be taken for a successful alignment job. The plunger moves a needle clockwise when. Dial gauge indicator method for alignment 5. Mount the dial indicators fixtures. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. In principle, reverse dial indication (rdi) and. Gauge Alignment.

From www.rokadegroup.com

Dial Gauge Shaft Alignment, Electronic / Mechanical Alignment System Gauge Alignment Dial indicators are measuring devices designed expressly to measure relative position. Mount the dial indicators fixtures. The primary parts of a dial indicator. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. While the dials may seem confusing at first, they’re easy to read once you understand what they. Gauge Alignment.

From www.ideaengineering.us

EZAlign Dial Saw Gauge Alignment System Ideaengineering.us Gauge Alignment The plunger moves a needle clockwise when. While the dials may seem confusing at first, they’re easy to read once you understand what they mean. Alignment procedure step by step 6. The primary parts of a dial indicator. Below we will cover reverse dial indication method. Mount the dial indicators fixtures. Measure the a, b, & c dimensions. There are. Gauge Alignment.

From www.walmart.com

Zackman Scientific Wheel Alignment Clamp Tool for Use with Gauge Alignment Below we will cover reverse dial indication method. Dial indicators are measuring devices designed expressly to measure relative position. Learn about the machine you are aligning. The primary parts of a dial indicator. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. There are several steps which need to be taken. Gauge Alignment.

From jiji.ng

Optical/ Vehicle Alignment Gauge in Ojo Vehicle Parts & Accessories Gauge Alignment Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Measure the a, b, & c dimensions. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. The primary parts of a dial indicator. Dial indicators are measuring devices designed expressly to. Gauge Alignment.

From www.racingjunk.com

Diagnosing and Fixing Minor Alignment Issues RacingJunk News Gauge Alignment Measure the a, b, & c dimensions. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. While the dials may seem confusing at first, they’re easy to read once you understand what they mean. Dial indicators are measuring devices designed expressly to measure relative position. Below we will cover reverse dial. Gauge Alignment.

From victorbutler33.wordpress.com

DIY FrontEnd Alignment victorbutler33 Gauge Alignment To perform the rim & face method, you must: While the dials may seem confusing at first, they’re easy to read once you understand what they mean. Alignment procedure step by step 6. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. Dial gauge indicator method for alignment 5. The primary. Gauge Alignment.

From verticalsolutionscompany.com

Counterweight Aligning Gauge Vertical Solutions Company Gauge Alignment The primary parts of a dial indicator. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. Dial indicators are measuring devices designed expressly to measure relative position. The plunger moves a needle clockwise when. There are several steps which need to be taken for a successful alignment job. Familiarize with terms,. Gauge Alignment.

From www.ebay.co.uk

Motamec Camber / Castor Gauge Suspension Wheel Angle Gauge Alignment Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Familiarize with terms, techniques and procedure. The primary parts of a dial indicator. Dial gauge indicator method for alignment 5. Measure the a, b, & c dimensions. Mount the dial indicators fixtures. Dial indicators are measuring devices designed expressly to. Gauge Alignment.

From www.youtube.com

Wheel alignment gauge 1690/1 Product Overview Unior Bike Tools Gauge Alignment Alignment procedure step by step 6. To perform the rim & face method, you must: Measure the a, b, & c dimensions. The primary parts of a dial indicator. There are several steps which need to be taken for a successful alignment job. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar. Gauge Alignment.

From tacrockford.com

KM Tool Changer Alignment Gauges Gauge Alignment Alignment procedure step by step 6. Measure the a, b, & c dimensions. Dial indicators are measuring devices designed expressly to measure relative position. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Mount the dial indicators fixtures. Familiarize with terms, techniques and procedure. In principle, reverse dial indication. Gauge Alignment.

From www.youtube.com

alignment dial gauge Kaise Dekhenalignment mechanical machine Gauge Alignment Dial gauge indicator method for alignment 5. Mount the dial indicators fixtures. There are several steps which need to be taken for a successful alignment job. Familiarize with terms, techniques and procedure. Measure the a, b, & c dimensions. The primary parts of a dial indicator. Dial indicators are measuring devices designed expressly to measure relative position. Alignment procedure step. Gauge Alignment.

From www.chegg.com

Shaft Alignment Cross Dial Gauge Method The diagram Gauge Alignment Familiarize with terms, techniques and procedure. Dial gauge indicator method for alignment 5. The plunger moves a needle clockwise when. Alignment procedure step by step 6. Below we will cover reverse dial indication method. There are several steps which need to be taken for a successful alignment job. While the dials may seem confusing at first, they’re easy to read. Gauge Alignment.

From www.prweb.com

VibrAlign Introduces the New Fixturlaser Dial Indicator Kit for Gauge Alignment The primary parts of a dial indicator. Measure the a, b, & c dimensions. Dial indicators are measuring devices designed expressly to measure relative position. Below we will cover reverse dial indication method. Learn about the machine you are aligning. Dial gauge indicator method for alignment 5. Familiarize with terms, techniques and procedure. Alignment procedure step by step 6. While. Gauge Alignment.

From www.for-sale.co.uk

Wheel Alignment Gauge for sale in UK 54 used Wheel Alignment Gauges Gauge Alignment The primary parts of a dial indicator. The plunger moves a needle clockwise when. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. Below we will cover reverse dial indication method. To perform the rim & face method, you must: Learn about the machine you are aligning. Familiarize with terms, techniques. Gauge Alignment.

From tacrockford.com

Steep Taper 50 (CAT/ANSI) Tool Changer Alignment Gauge Tool Changer Gauge Alignment Learn about the machine you are aligning. The plunger moves a needle clockwise when. In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. Alignment procedure step by step 6. To perform the rim & face method, you must: While the dials may seem confusing at first, they’re easy to read once. Gauge Alignment.

From www.aliexpress.com

Digital Gap and Step Gauge Electronic Digital Car Door Panel & Gap Gauge Alignment To perform the rim & face method, you must: The primary parts of a dial indicator. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Dial gauge indicator method for alignment 5. Mount the dial indicators fixtures. Dial indicators are measuring devices designed expressly to measure relative position. Alignment. Gauge Alignment.

From www.shutterstock.com

Alignment Pump Method Plunger Dial Indicators Stock Photo 1880820493 Gauge Alignment The plunger moves a needle clockwise when. Learn about the machine you are aligning. Alignment procedure step by step 6. The primary parts of a dial indicator. Dial indicators can be used to check round parts like wheels for straightness and are commonly used in machine shops. Familiarize with terms, techniques and procedure. Dial indicators are measuring devices designed expressly. Gauge Alignment.

From peacecommission.kdsg.gov.ng

Dial Gauge Alignment Gauge Alignment While the dials may seem confusing at first, they’re easy to read once you understand what they mean. Dial indicators are measuring devices designed expressly to measure relative position. There are several steps which need to be taken for a successful alignment job. Dial gauge indicator method for alignment 5. Measure the a, b, & c dimensions. Below we will. Gauge Alignment.

From www.indiamart.com

Dial Indicator Shaft Alignment System at Rs 400000/unit Laser Shaft Gauge Alignment In principle, reverse dial indication (rdi) and laser alignment are identical alignment methods each capable of similar accuracy. Learn about the machine you are aligning. To perform the rim & face method, you must: The plunger moves a needle clockwise when. Alignment procedure step by step 6. While the dials may seem confusing at first, they’re easy to read once. Gauge Alignment.