Steel Pipe Bending Force . Drawn bends can be further. Learn the tips and tricks to boost your pipe bending skills and achieve. The conversion of quantities between systems. Drawn bends, press bends, and welded bends. The material, machine, tooling, and lubrication. There are different bending methods that can be used to form a cold pipe bend as mentioned below: Pipe bending can be categorized into three types: Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Pipe bending methods, tolerances, process and material requirement. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Discover the top 10 methods for bending pipes like a pro!

from eziil.com

Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. Drawn bends, press bends, and welded bends. The conversion of quantities between systems. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. There are different bending methods that can be used to form a cold pipe bend as mentioned below: In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Pipe bending methods, tolerances, process and material requirement. Pipe bending can be categorized into three types: Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Learn the tips and tricks to boost your pipe bending skills and achieve.

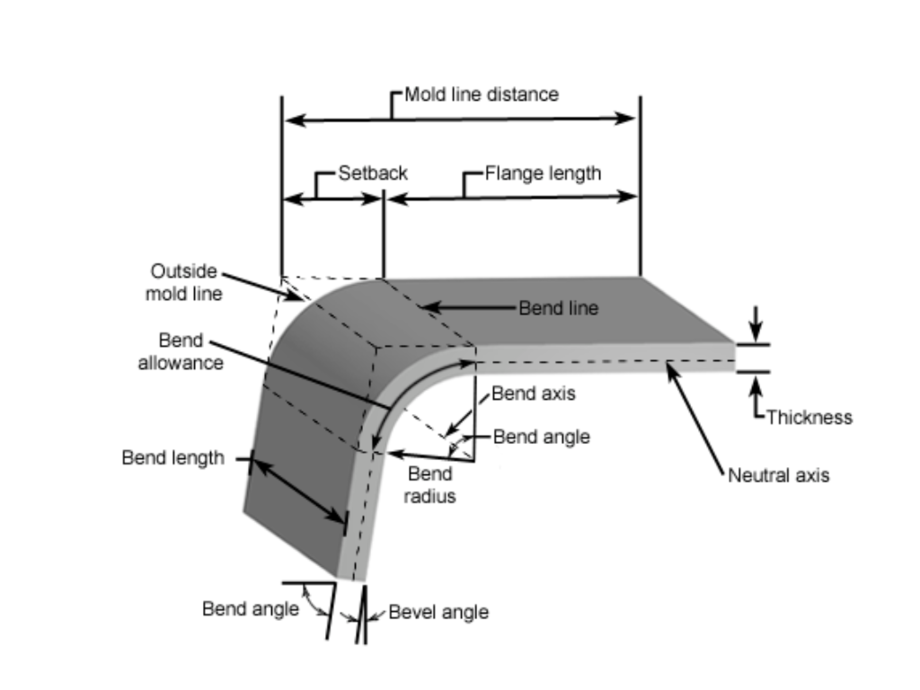

Sheet Metal Bend Radius Full Guide Chart

Steel Pipe Bending Force Learn the tips and tricks to boost your pipe bending skills and achieve. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. Discover the top 10 methods for bending pipes like a pro! Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. There are different bending methods that can be used to form a cold pipe bend as mentioned below: The conversion of quantities between systems. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. The material, machine, tooling, and lubrication. Drawn bends can be further. Drawn bends, press bends, and welded bends. Pipe bending can be categorized into three types: Learn the tips and tricks to boost your pipe bending skills and achieve. Pipe bending methods, tolerances, process and material requirement.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending Steel Pipe Bending Force Drawn bends, press bends, and welded bends. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: There are different bending methods that can be used to form a cold pipe bend as mentioned below: The conversion of quantities between systems. Pipe bending methods, tolerances,. Steel Pipe Bending Force.

From www.thefabricator.com

Tube bending basics How to bend tubing and metal pipe Steel Pipe Bending Force Drawn bends, press bends, and welded bends. Discover the top 10 methods for bending pipes like a pro! Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is. Steel Pipe Bending Force.

From www.iqsdirectory.com

Tube Bending What Is It? How Does It Work? Types Of Steel Pipe Bending Force In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Drawn bends can be further. The conversion of quantities between systems. Cold bends or field bends are produced by applying very high force to help bring the. Steel Pipe Bending Force.

From www.alamy.com

Detail of stainless steel pipe bending machine Stock Photo Alamy Steel Pipe Bending Force Drawn bends can be further. Drawn bends, press bends, and welded bends. There are different bending methods that can be used to form a cold pipe bend as mentioned below: Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: The material, machine, tooling, and. Steel Pipe Bending Force.

From www.youtube.com

Pipe Stress Fundamentals Forces & Moments on Piping YouTube Steel Pipe Bending Force Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. Drawn bends, press bends, and welded bends. Pipe bending methods, tolerances, process and material requirement. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. Pipe bending can be. Steel Pipe Bending Force.

From www.mathscinotes.com

Electrical Conduit Math Math Encounters Blog Steel Pipe Bending Force Learn the tips and tricks to boost your pipe bending skills and achieve. The conversion of quantities between systems. Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. Drawn bends, press bends, and welded bends. Pipe bending methods, tolerances, process and material requirement. The material, machine, tooling, and lubrication.. Steel Pipe Bending Force.

From www.rapiddirect.com

Bending Stainless Steel Tubing Effective Processes and Considerations Steel Pipe Bending Force Drawn bends, press bends, and welded bends. Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. The material, machine, tooling, and lubrication. There are different bending methods that can be used to form a cold pipe bend as mentioned below: Pipe bending methods, tolerances, process and material requirement. The. Steel Pipe Bending Force.

From www.slideserve.com

PPT ME 350 Lecture 18 Chapter 20 PowerPoint Presentation, free Steel Pipe Bending Force The material, machine, tooling, and lubrication. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Pipe bending can be categorized into three types: Drawn bends can be further. Learn the tips and tricks to boost your pipe bending skills and achieve. Discover the top. Steel Pipe Bending Force.

From www.comsol.com

The Intriguing Stresses in Pipe Bends COMSOL Blog Steel Pipe Bending Force The conversion of quantities between systems. Drawn bends can be further. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. There are different bending methods that can be used to form a cold pipe bend as. Steel Pipe Bending Force.

From support.goldsim.com

Hydrodynamic Force on a Pipe Bend GoldSim Help Center Steel Pipe Bending Force Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: The conversion of quantities between systems. Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. In order to properly calculate the size thrust blocks. Steel Pipe Bending Force.

From www.tecnocurve.com

Tube bending the Kfactor for tube bending feasibility Tecnocurve Steel Pipe Bending Force Pipe bending methods, tolerances, process and material requirement. Drawn bends, press bends, and welded bends. There are different bending methods that can be used to form a cold pipe bend as mentioned below: The conversion of quantities between systems. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation. Steel Pipe Bending Force.

From www.scribd.com

Forces On Pipe Bends Pipes Fluid Mechanics Engineering Reference Steel Pipe Bending Force Drawn bends can be further. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Pipe bending can be categorized into three types: There are different bending methods that can be used to form a cold pipe. Steel Pipe Bending Force.

From www.sunnysteel.com

5D bend pipe, 5D Pipe Bending, 5D bending, 5D bend, Buttwelded pipe Steel Pipe Bending Force Learn the tips and tricks to boost your pipe bending skills and achieve. Discover the top 10 methods for bending pipes like a pro! In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. The conversion of. Steel Pipe Bending Force.

From blog.thepipingmart.com

Bending Stainless Steel Tubing An Overview Steel Pipe Bending Force In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Drawn bends can be further. Discover the top 10 methods for bending pipes like a pro! There are different bending methods that can be used to form. Steel Pipe Bending Force.

From apexpiping.com

Pipe Bending Services & Pipe Forming Services Apex Steel Pipe Bending Force In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Pipe bending can be categorized into three types: Discover the top 10 methods for bending pipes like a pro! Drawn bends, press bends, and welded bends. Pipe. Steel Pipe Bending Force.

From in.pinterest.com

Bending force calculation Metal bending tools, Metal bending, Sheet metal Steel Pipe Bending Force Pipe bending can be categorized into three types: Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. Pipe bending methods, tolerances, process and material requirement. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just. Steel Pipe Bending Force.

From www.nan-steel.com

Causes of bending deformation of steel pipe Steel Pipe Bending Force The conversion of quantities between systems. Drawn bends, press bends, and welded bends. Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary. Steel Pipe Bending Force.

From www.youtube.com

Pipe Bending Machine / Bending 3 1/2" carbon steel pipe ( how to bend Steel Pipe Bending Force Pipe bending methods, tolerances, process and material requirement. Drawn bends, press bends, and welded bends. Discover the top 10 methods for bending pipes like a pro! In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Pipe. Steel Pipe Bending Force.

From www.metalsupplies.com

Tube Bending Services from Metal Supplies Steel Pipe Bending Force Pipe bending can be categorized into three types: The material, machine, tooling, and lubrication. Pipe bending methods, tolerances, process and material requirement. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. The conversion of quantities between systems. Learn the tips and tricks to boost your pipe bending skills. Steel Pipe Bending Force.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Steel Pipe Bending Force Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Learn the. Steel Pipe Bending Force.

From www.unifiedalloys.com

Pipe Bends A Quick Primer Unified Alloys Steel Pipe Bending Force Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Pipe bending can be categorized into three types: Pipe bending methods, tolerances, process and material requirement. Drawn bends can be further. Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced. Steel Pipe Bending Force.

From makeitfrommetal.com

How to Properly Bend Metal Pipe and Tube At Home Make It From Metal Steel Pipe Bending Force Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. Pipe bending can be categorized into three types: The material, machine, tooling, and lubrication.. Steel Pipe Bending Force.

From blog.sunnysteel.com

Steel Pipe Bend, Large radio Pipe Bending, Large size pipe bend, Butt Steel Pipe Bending Force The conversion of quantities between systems. Learn the tips and tricks to boost your pipe bending skills and achieve. Drawn bends can be further. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Discover the top 10 methods for bending pipes like a pro!. Steel Pipe Bending Force.

From www.youtube.com

MS pipe bending Machine Steel pipe bending Tool Home made pipe Steel Pipe Bending Force Drawn bends can be further. Pipe bending methods, tolerances, process and material requirement. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. The conversion of quantities between systems. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils. Steel Pipe Bending Force.

From jinglaimachinery.com

Round and Square Pipe Bending Machine Digital Steel Pipe Bender Steel Pipe Bending Force There are different bending methods that can be used to form a cold pipe bend as mentioned below: Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Discover the top 10 methods for bending pipes like a pro! Accurate pipe bending force calculation ensures. Steel Pipe Bending Force.

From www.neelconsteel.com

Pipe Bend Manufacturer, ASME B16.9 Stainless/ Carbon Steel Piggable Bend Steel Pipe Bending Force Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. Drawn bends can be further. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. Drawn bends, press bends, and welded bends. Pipe bending can be categorized into three. Steel Pipe Bending Force.

From engineeronadisk.com

eNotes Manufacturing Processes Steel Pipe Bending Force Drawn bends, press bends, and welded bends. The material, machine, tooling, and lubrication. Pipe bending can be categorized into three types: There are different bending methods that can be used to form a cold pipe bend as mentioned below: Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down. Steel Pipe Bending Force.

From www.youtube.com

How To Bend Steel Pipe YouTube Steel Pipe Bending Force Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. Drawn bends, press bends, and welded bends. Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. Regardless of whether you’re working with tube or pipe, and regardless of. Steel Pipe Bending Force.

From www.formingpres.com

Hydraulic Stainless Steel Pipe Bending Machine Steel Pipe Bending Force Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Drawn bends, press bends, and welded bends. Pipe bending methods, tolerances, process and material requirement. Learn the tips and tricks to boost your pipe bending skills and achieve. The material, machine, tooling, and lubrication. In. Steel Pipe Bending Force.

From www.merchantsfabrication.com

Understanding Bend Tests & Radius Merchants Fabrication, Inc Steel Pipe Bending Force Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: Learn the tips and tricks to boost your pipe bending skills and achieve. The material, machine, tooling, and lubrication. Cold bends or field bends are produced by applying very high force to help bring the. Steel Pipe Bending Force.

From blog.thepipingmart.com

How to Bend Steel Pipe A Complete Guide Steel Pipe Bending Force The material, machine, tooling, and lubrication. Drawn bends, press bends, and welded bends. There are different bending methods that can be used to form a cold pipe bend as mentioned below: Pipe bending methods, tolerances, process and material requirement. In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation. Steel Pipe Bending Force.

From www.youtube.com

03_03_P5 Calculating Force Required for Sheet Metal Bending YouTube Steel Pipe Bending Force Pipe bending can be categorized into three types: Pipe bending methods, tolerances, process and material requirement. Regardless of whether you’re working with tube or pipe, and regardless of the bending process, making the perfect bend boils down to just four factors: In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the. Steel Pipe Bending Force.

From www.rapiddirect.com

Bending Stainless Steel Tubing Effective Processes and Considerations Steel Pipe Bending Force In order to properly calculate the size thrust blocks or other devices to hold a pipe in place, the momentum equation is used to compute the necessary resistive force to hold the pipe. Drawn bends, press bends, and welded bends. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final. Steel Pipe Bending Force.

From www.youtube.com

RIDGID How To Bend Stainless Steel Pipe YouTube Steel Pipe Bending Force Pipe bending can be categorized into three types: Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. The material, machine, tooling, and lubrication. There are different bending methods that can be used to form a cold pipe bend as mentioned below: Learn the tips and tricks to boost your. Steel Pipe Bending Force.

From blog.thepipingmart.com

How to Bend Mild Steel? An Overview Steel Pipe Bending Force There are different bending methods that can be used to form a cold pipe bend as mentioned below: Accurate pipe bending force calculation ensures that the pipe can withstand the stress induced during bending, preventing failures such as. Cold bends or field bends are produced by applying very high force to help bring the pipe to its final shape. Regardless. Steel Pipe Bending Force.