Copper Pipe Sizes Refrigeration . Pipe plugs for testing, blocking, bypassing, line stopping, and more. Standard specifications for seamless copper tube used. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. Check out our copper tubing sizes & dimensions chart online at petersen. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Working pressure (psi) ratings based on service temperature max. The expansion of piping must be. Obtain proper oil return while complying with refrigerant velocity guidelines. The higher purity level of refrigerant copper tube makes. Accurate line sizing is important to achieve several important requirements: Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%.

from www.china-refrigerantgas.com

Obtain proper oil return while complying with refrigerant velocity guidelines. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Accurate line sizing is important to achieve several important requirements: Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. The expansion of piping must be. Check out our copper tubing sizes & dimensions chart online at petersen. Working pressure (psi) ratings based on service temperature max. Standard specifications for seamless copper tube used. The higher purity level of refrigerant copper tube makes. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%.

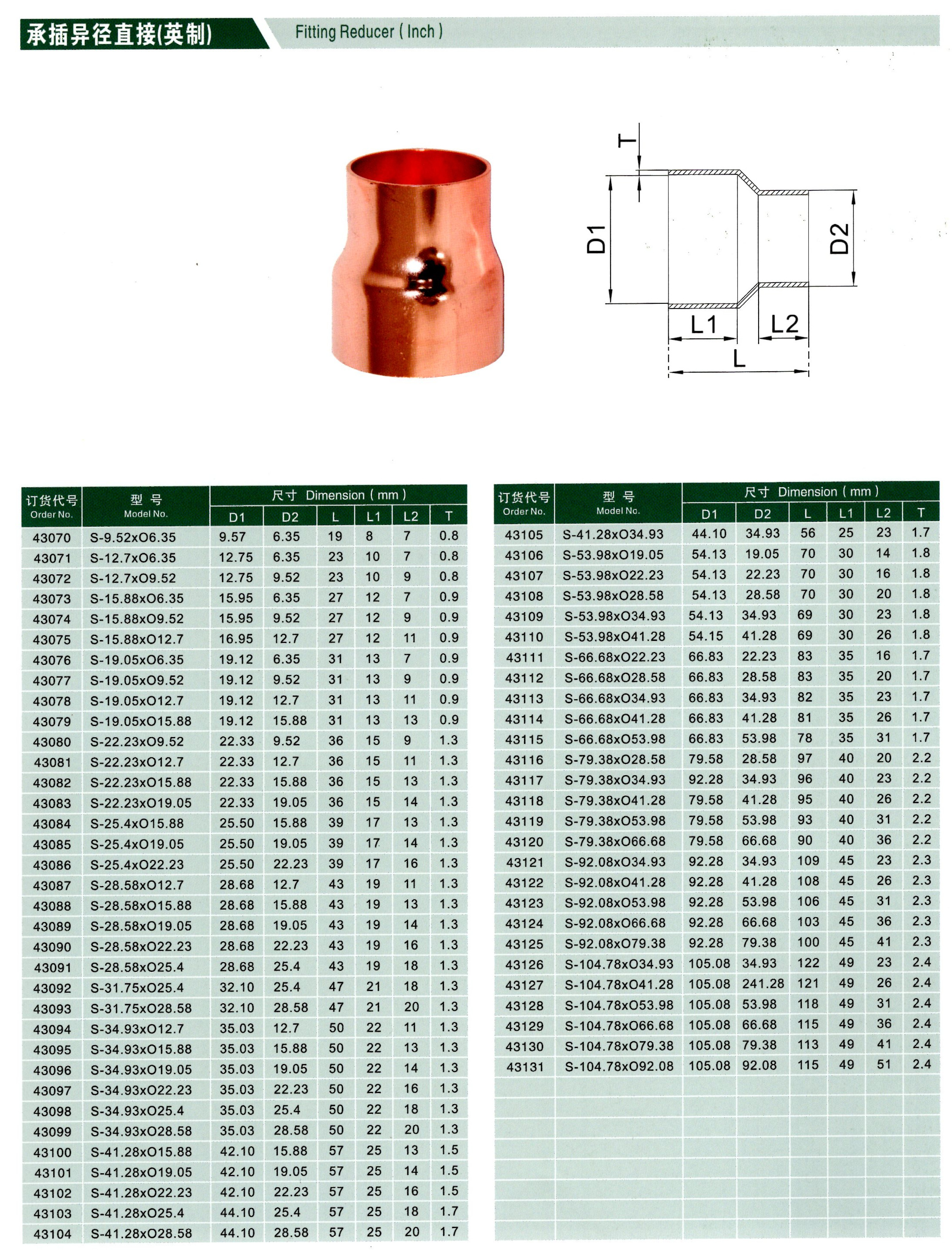

Refrigeration and AC copper fitting

Copper Pipe Sizes Refrigeration Standard specifications for seamless copper tube used. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Obtain proper oil return while complying with refrigerant velocity guidelines. Check out our copper tubing sizes & dimensions chart online at petersen. Working pressure (psi) ratings based on service temperature max. Pipe plugs for testing, blocking, bypassing, line stopping, and more. Standard specifications for seamless copper tube used. The expansion of piping must be. Accurate line sizing is important to achieve several important requirements: The higher purity level of refrigerant copper tube makes.

From mavink.com

R410a Pipe Sizing Chart Copper Pipe Sizes Refrigeration The higher purity level of refrigerant copper tube makes. Accurate line sizing is important to achieve several important requirements: The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Obtain proper oil return while complying with refrigerant velocity guidelines. The expansion of piping must be. Standard specifications for seamless copper tube used. Good refrigeration piping design. Copper Pipe Sizes Refrigeration.

From www.china-refrigerantgas.com

Refrigeration and AC copper fitting Copper Pipe Sizes Refrigeration Standard specifications for seamless copper tube used. The expansion of piping must be. Working pressure (psi) ratings based on service temperature max. Accurate line sizing is important to achieve several important requirements: Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. Refrigeration copper typically. Copper Pipe Sizes Refrigeration.

From ethanthompson.z19.web.core.windows.net

Copper Tube Sizes Chart Copper Pipe Sizes Refrigeration The higher purity level of refrigerant copper tube makes. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Check out our copper tubing sizes & dimensions chart online at petersen. Working pressure (psi) ratings based on service temperature max. Obtain proper oil return while complying with refrigerant velocity guidelines. Accurate line sizing is important to. Copper Pipe Sizes Refrigeration.

From mavink.com

Refrigeration Pipe Sizes Copper Pipe Sizes Refrigeration Obtain proper oil return while complying with refrigerant velocity guidelines. The expansion of piping must be. Working pressure (psi) ratings based on service temperature max. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. Refrigeration copper typically has a purity level of 99.9%, while. Copper Pipe Sizes Refrigeration.

From www.climatedoctors.com

3/8 OD x 50 ft Refrigeration Soft Copper Tubing Climatedoctors Copper Pipe Sizes Refrigeration Working pressure (psi) ratings based on service temperature max. The expansion of piping must be. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. Accurate line sizing is important to achieve several important requirements: Standard specifications for seamless copper tube used. The temperature variations. Copper Pipe Sizes Refrigeration.

From goldstonehvacr.com

ACR Copper Tube Gold Stone HVAC/R Copper Pipe Sizes Refrigeration Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Check out our copper tubing sizes & dimensions chart online at petersen. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of. Copper Pipe Sizes Refrigeration.

From www.refrigerationpipefittings.com

LWC Copper Refrigeration Tubing Hard Drawn Copper Pipe for Copper Pipe Sizes Refrigeration The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. The expansion of piping must be. Standard specifications for seamless copper tube used. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Check out our copper tubing sizes & dimensions chart online at petersen. Good refrigeration. Copper Pipe Sizes Refrigeration.

From mavink.com

Copper Pipe Sizes Chart Metric Copper Pipe Sizes Refrigeration Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Pipe plugs for testing, blocking, bypassing, line stopping, and more. Obtain proper oil return while complying with refrigerant velocity guidelines. The. Copper Pipe Sizes Refrigeration.

From bceweb.org

Copper Pipe Size Chart Of Astm B280 Standards By Winland Trading Co A Copper Pipe Sizes Refrigeration Check out our copper tubing sizes & dimensions chart online at petersen. Standard specifications for seamless copper tube used. Obtain proper oil return while complying with refrigerant velocity guidelines. Pipe plugs for testing, blocking, bypassing, line stopping, and more. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per. Copper Pipe Sizes Refrigeration.

From blog.thepipingmart.com

Differences between Refrigeration Copper and Plumbing Copper Copper Pipe Sizes Refrigeration The expansion of piping must be. Working pressure (psi) ratings based on service temperature max. The higher purity level of refrigerant copper tube makes. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Standard specifications for seamless copper tube used. Check out our copper tubing sizes & dimensions chart online at petersen. Good refrigeration piping. Copper Pipe Sizes Refrigeration.

From ponasa.condesan-ecoandes.org

Refrigerant Copper Pipe Size Chart Ponasa Copper Pipe Sizes Refrigeration Pipe plugs for testing, blocking, bypassing, line stopping, and more. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Obtain proper oil return while complying with refrigerant velocity guidelines. Check out our copper tubing sizes & dimensions chart online at petersen. Accurate line sizing is important to achieve several important. Copper Pipe Sizes Refrigeration.

From www.refrigerationpipefittings.com

LWC Copper Refrigeration Tubing Hard Drawn Copper Pipe for Copper Pipe Sizes Refrigeration Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. The higher purity level of refrigerant copper tube makes. The expansion of piping must be. Working pressure (psi) ratings based on service temperature max. Refrigeration copper typically has a purity level of 99.9%, while plumbing. Copper Pipe Sizes Refrigeration.

From www.indiamart.com

16mm Refrigeration Copper Pipe, For Refrigerator, Thickness 0.50mm Copper Pipe Sizes Refrigeration The higher purity level of refrigerant copper tube makes. Check out our copper tubing sizes & dimensions chart online at petersen. The expansion of piping must be. Pipe plugs for testing, blocking, bypassing, line stopping, and more. Obtain proper oil return while complying with refrigerant velocity guidelines. Accurate line sizing is important to achieve several important requirements: Good refrigeration piping. Copper Pipe Sizes Refrigeration.

From laurenbanks.z13.web.core.windows.net

Copper Tube Sizes Chart Copper Pipe Sizes Refrigeration The higher purity level of refrigerant copper tube makes. Standard specifications for seamless copper tube used. Pipe plugs for testing, blocking, bypassing, line stopping, and more. Obtain proper oil return while complying with refrigerant velocity guidelines. Working pressure (psi) ratings based on service temperature max. Accurate line sizing is important to achieve several important requirements: The expansion of piping must. Copper Pipe Sizes Refrigeration.

From www.refrigerationpipefittings.com

Custom Size Copper Refrigeration Tubing Copper Plumbing Pipe Air Copper Pipe Sizes Refrigeration Pipe plugs for testing, blocking, bypassing, line stopping, and more. Accurate line sizing is important to achieve several important requirements: The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. The higher purity level of refrigerant copper tube makes. Standard specifications for seamless copper tube used. Working pressure (psi) ratings based on service temperature max. Good. Copper Pipe Sizes Refrigeration.

From resour.en.made-in-china.com

China Straight Copper Pipe, Air Conditioning Copper Tubes Copper Pipe Sizes Refrigeration Pipe plugs for testing, blocking, bypassing, line stopping, and more. Check out our copper tubing sizes & dimensions chart online at petersen. Accurate line sizing is important to achieve several important requirements: Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. The temperature variations. Copper Pipe Sizes Refrigeration.

From fenghuagroup.en.made-in-china.com

Copper Pipe Coppercopper Copper Pipes Refrigeration Part Copper Pipe Copper Pipe Sizes Refrigeration The expansion of piping must be. Obtain proper oil return while complying with refrigerant velocity guidelines. The higher purity level of refrigerant copper tube makes. Check out our copper tubing sizes & dimensions chart online at petersen. Accurate line sizing is important to achieve several important requirements: The temperature variations of refrigeration and defrost cycles cause piping to expand and. Copper Pipe Sizes Refrigeration.

From www.youtube.com

copper tube standard sizes ,refrigeration copper pipe sizes YouTube Copper Pipe Sizes Refrigeration Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. The expansion of piping must be. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Check out our copper tubing sizes & dimensions chart online at petersen. Obtain proper oil return while complying with refrigerant velocity. Copper Pipe Sizes Refrigeration.

From dat.perueduca.edu.pe

Refrigeration Pipe Sizing Chart Printable Templates Free Copper Pipe Sizes Refrigeration Working pressure (psi) ratings based on service temperature max. Accurate line sizing is important to achieve several important requirements: Pipe plugs for testing, blocking, bypassing, line stopping, and more. Obtain proper oil return while complying with refrigerant velocity guidelines. Check out our copper tubing sizes & dimensions chart online at petersen. Good refrigeration piping design requires that the refrigeration lines. Copper Pipe Sizes Refrigeration.

From refrigerationnew.blogspot.com

Refrigeration Refrigeration Copper Fitting Dimensions Copper Pipe Sizes Refrigeration Obtain proper oil return while complying with refrigerant velocity guidelines. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Working pressure (psi) ratings based on service temperature max. The expansion of piping must be. Check out our copper tubing sizes & dimensions chart online at petersen. The higher purity level of refrigerant copper tube makes.. Copper Pipe Sizes Refrigeration.

From wegadgets.net

8 R410A Refrigerant Pipe Sizing Charts 2k23 Copper Pipe Sizes Refrigeration The higher purity level of refrigerant copper tube makes. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. Accurate line sizing is important to achieve several important requirements: Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity. Copper Pipe Sizes Refrigeration.

From www.rona.ca

WOLVERINE RefrigerationType Copper Pipe 1/4"x50' 4413 RONA Copper Pipe Sizes Refrigeration The expansion of piping must be. Obtain proper oil return while complying with refrigerant velocity guidelines. Working pressure (psi) ratings based on service temperature max. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per. Copper Pipe Sizes Refrigeration.

From www.unilab.eu

Il dimensionamento delle tubazioni di un circuito frigorifero Parte I Copper Pipe Sizes Refrigeration The expansion of piping must be. The higher purity level of refrigerant copper tube makes. Check out our copper tubing sizes & dimensions chart online at petersen. Working pressure (psi) ratings based on service temperature max. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Accurate line sizing is important. Copper Pipe Sizes Refrigeration.

From classhoffmann.z19.web.core.windows.net

Copper Pipe Sizing Chart Copper Pipe Sizes Refrigeration The higher purity level of refrigerant copper tube makes. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Pipe plugs for testing, blocking, bypassing, line stopping, and more. Accurate line sizing is important to achieve several important requirements: The temperature variations of refrigeration and defrost cycles cause piping to expand. Copper Pipe Sizes Refrigeration.

From www.sexiezpicz.com

Refrigeration Copper Pipe Size Chart SexiezPicz Porn Copper Pipe Sizes Refrigeration Check out our copper tubing sizes & dimensions chart online at petersen. The higher purity level of refrigerant copper tube makes. Pipe plugs for testing, blocking, bypassing, line stopping, and more. The expansion of piping must be. Standard specifications for seamless copper tube used. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity. Copper Pipe Sizes Refrigeration.

From www.pipelagging.com

Air Conditioning Copper Tube Refrigeration Grade Pipe 12.7mm 1/2 6m Copper Pipe Sizes Refrigeration Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Working pressure (psi) ratings based on service temperature max. The higher purity level of refrigerant copper tube makes. Check out our copper tubing sizes & dimensions chart online at petersen. Standard specifications for seamless copper tube used. The expansion of piping. Copper Pipe Sizes Refrigeration.

From refrigerationtoday.blogspot.com

Refrigeration Refrigeration Piping Size Chart Copper Pipe Sizes Refrigeration Check out our copper tubing sizes & dimensions chart online at petersen. The higher purity level of refrigerant copper tube makes. Standard specifications for seamless copper tube used. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet or 1. Obtain proper oil return while complying with. Copper Pipe Sizes Refrigeration.

From www.youtube.com

refrigeration copper pipe sizes ,copper pipe insulation YouTube Copper Pipe Sizes Refrigeration Pipe plugs for testing, blocking, bypassing, line stopping, and more. The higher purity level of refrigerant copper tube makes. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Check out our copper tubing sizes & dimensions. Copper Pipe Sizes Refrigeration.

From mungfali.com

Refrigeration Copper Pipe Size Chart Copper Pipe Sizes Refrigeration Working pressure (psi) ratings based on service temperature max. Standard specifications for seamless copper tube used. Obtain proper oil return while complying with refrigerant velocity guidelines. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Pipe plugs for testing, blocking, bypassing, line stopping, and more. The expansion of piping must be. Good refrigeration piping design. Copper Pipe Sizes Refrigeration.

From www.youtube.com

copper refrigeration tubing sizes ,standard copper pipe sizes YouTube Copper Pipe Sizes Refrigeration Working pressure (psi) ratings based on service temperature max. Check out our copper tubing sizes & dimensions chart online at petersen. The higher purity level of refrigerant copper tube makes. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Standard specifications for seamless copper tube used. Good refrigeration piping design. Copper Pipe Sizes Refrigeration.

From www.alibaba.com

Factory Wholesale Price All Size Ac Copper Tube/pipe Per Kg For Hvac Copper Pipe Sizes Refrigeration The expansion of piping must be. Accurate line sizing is important to achieve several important requirements: Obtain proper oil return while complying with refrigerant velocity guidelines. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. The. Copper Pipe Sizes Refrigeration.

From www.alibaba.com

Refrigeration Hvac System Copper Pipe Fittings Buy Copper Fitting Copper Pipe Sizes Refrigeration The higher purity level of refrigerant copper tube makes. Standard specifications for seamless copper tube used. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Working pressure (psi) ratings based on service temperature max. Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow. Copper Pipe Sizes Refrigeration.

From greenbushfarmcom.blogspot.com

Hvac Copper Pipe Size Chart Copper Pipe Sizes Refrigeration Standard specifications for seamless copper tube used. Check out our copper tubing sizes & dimensions chart online at petersen. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Working pressure (psi) ratings based on service temperature max. Pipe plugs for testing, blocking, bypassing, line stopping, and more. Obtain proper oil. Copper Pipe Sizes Refrigeration.

From www.alibaba.com

Factory Wholesale Price All Size Ac Copper Tube/pipe Per Kg For Hvac Copper Pipe Sizes Refrigeration The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Refrigeration copper typically has a purity level of 99.9%, while plumbing copper usually has a purity level of 95%. Obtain proper oil return while complying with refrigerant velocity guidelines. Check out our copper tubing sizes & dimensions chart online at petersen. Good refrigeration piping design requires. Copper Pipe Sizes Refrigeration.

From lcmeide.en.made-in-china.com

Industrial Refrigeration C5102 C51000 Cuag0.10 Cw013 Flat Copper Coil Copper Pipe Sizes Refrigeration Standard specifications for seamless copper tube used. The expansion of piping must be. The temperature variations of refrigeration and defrost cycles cause piping to expand and contract. Accurate line sizing is important to achieve several important requirements: Good refrigeration piping design requires that the refrigeration lines be pitched in the direction of flow at approximately 1/2 inch per 10 feet. Copper Pipe Sizes Refrigeration.