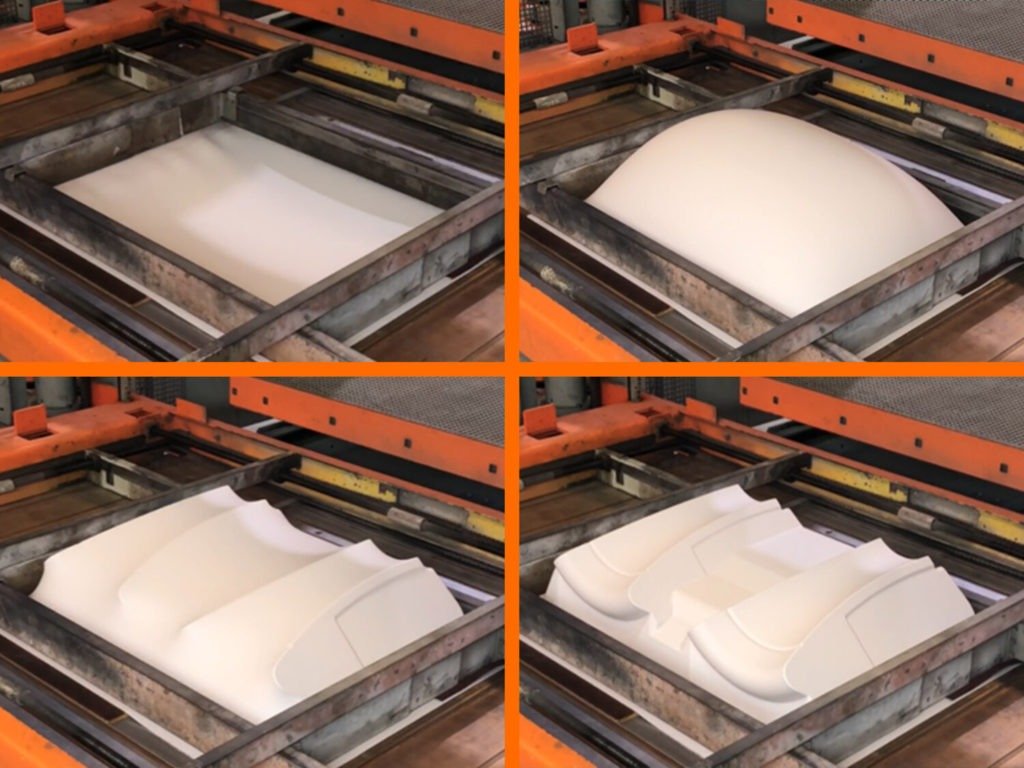

How Does Vacuum Molding Work . Vacuum forming is a straightforward manufacturing process that involves five major. How does vacuum casting work? Contents covered in this article. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Advantages and disadvantages of vacuum casting. How does vacuum forming work? Characteristics & applications of vacuum casting. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single.

from www.plas-tech.co.uk

The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Contents covered in this article. How does vacuum forming work? How does vacuum casting work? Characteristics & applications of vacuum casting. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Advantages and disadvantages of vacuum casting. Vacuum forming is a straightforward manufacturing process that involves five major.

Vac Forming The Advantages of Vacuum Forming

How Does Vacuum Molding Work Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. How does vacuum casting work? How does vacuum forming work? Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Contents covered in this article. Advantages and disadvantages of vacuum casting. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Characteristics & applications of vacuum casting. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic.

From www.open.edu

"V" Process (Vacuum sealed moulding process) OpenLearn Open University How Does Vacuum Molding Work Advantages and disadvantages of vacuum casting. How does vacuum forming work? Contents covered in this article. Characteristics & applications of vacuum casting. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing. How Does Vacuum Molding Work.

From www.researchgate.net

4 Mold design for vacuumassisted micro injection molding with venting How Does Vacuum Molding Work The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Advantages and disadvantages of vacuum casting. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Vacuum forming is a. How Does Vacuum Molding Work.

From www.youtube.com

Vacuum Molding Services and Industry Information YouTube How Does Vacuum Molding Work Contents covered in this article. Advantages and disadvantages of vacuum casting. Vacuum forming is a straightforward manufacturing process that involves five major. How does vacuum forming work? Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by. How Does Vacuum Molding Work.

From www.3ds.com

Vacuum Molding, What is it and how does it work? Dassault Systèmes® How Does Vacuum Molding Work Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process. How Does Vacuum Molding Work.

From www.mdeplastics.com

Vacuum Forming vs Injection Molding China MDE plastics Company How Does Vacuum Molding Work Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Advantages and disadvantages of vacuum casting. How does vacuum casting work?. How Does Vacuum Molding Work.

From www.youtube.com

vacuum molding of plastic YouTube How Does Vacuum Molding Work The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum forming, the simplest thermoforming method, uses. How Does Vacuum Molding Work.

From warringah-plastics.com.au

Industry Leaders in Vacuum Forming in Sydney Warringah Plastics How Does Vacuum Molding Work How does vacuum forming work? How does vacuum casting work? The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single.. How Does Vacuum Molding Work.

From hlhrapid.com

Vacuum Casting Process Overview, Benefits & Limitations How Does Vacuum Molding Work Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. How does vacuum forming work? Vacuum forming is a straightforward manufacturing process that involves five major. Advantages and disadvantages of vacuum casting.. How Does Vacuum Molding Work.

From www.youtube.com

Vacuum Molding Expandable Mold Casting Processes. YouTube How Does Vacuum Molding Work Advantages and disadvantages of vacuum casting. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming involves molding plastic by heating it until soft and then. How Does Vacuum Molding Work.

From www.plas-tech.co.uk

Vac Forming The Advantages of Vacuum Forming How Does Vacuum Molding Work How does vacuum forming work? Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Vacuum forming, the simplest thermoforming method, uses vacuum pressure. How Does Vacuum Molding Work.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited How Does Vacuum Molding Work Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Vacuum forming involves molding plastic by heating it until soft and then shaping it. How Does Vacuum Molding Work.

From www.youtube.com

Plastic Moulding Working Animation (Extrusion, Blow, Vacuum Forming How Does Vacuum Molding Work Vacuum forming is a straightforward manufacturing process that involves five major. Contents covered in this article. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. The vacuum forming process works by. How Does Vacuum Molding Work.

From www.youtube.com

compilation of the vacuum forming molding process YouTube How Does Vacuum Molding Work Characteristics & applications of vacuum casting. Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Contents covered in this article. How does vacuum casting work? Advantages and disadvantages of vacuum casting. How does vacuum forming work? Vacuum molding, sometimes. How Does Vacuum Molding Work.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY How Does Vacuum Molding Work Advantages and disadvantages of vacuum casting. Contents covered in this article. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Characteristics & applications of vacuum casting. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. How. How Does Vacuum Molding Work.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess How Does Vacuum Molding Work Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming is a straightforward manufacturing process that involves five. How Does Vacuum Molding Work.

From thetotalentrepreneurs.com

How Vacuum Molding Can Help Your Industrial Business How Does Vacuum Molding Work Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Vacuum forming is a straightforward manufacturing process that involves five major. How does vacuum forming work? The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming. How Does Vacuum Molding Work.

From www.youtube.com

Vacuum Jet Mold Venting YouTube How Does Vacuum Molding Work Advantages and disadvantages of vacuum casting. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. How does vacuum forming work? Contents covered in this article. Vacuum forming. How Does Vacuum Molding Work.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess How Does Vacuum Molding Work Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Characteristics & applications of vacuum casting. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a. How Does Vacuum Molding Work.

From mayku.me

How to Design for Vacuum Forming and Mold Making with Agustín… Mayku How Does Vacuum Molding Work Characteristics & applications of vacuum casting. How does vacuum forming work? The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a. How Does Vacuum Molding Work.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited How Does Vacuum Molding Work Contents covered in this article. How does vacuum casting work? Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Vacuum forming is a. How Does Vacuum Molding Work.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt How Does Vacuum Molding Work The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Advantages and disadvantages of vacuum casting. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that. How Does Vacuum Molding Work.

From blog.adafruit.com

How to Make a Vacuum Forming Machine « Adafruit Industries Makers How Does Vacuum Molding Work Contents covered in this article. How does vacuum casting work? The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Characteristics & applications of vacuum casting. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum forming. How Does Vacuum Molding Work.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess How Does Vacuum Molding Work Contents covered in this article. Characteristics & applications of vacuum casting. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. How does vacuum forming work? Advantages and disadvantages of vacuum casting. Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming involves molding plastic by heating it. How Does Vacuum Molding Work.

From prototechasia.com

How Does the Vacuum Molding Process Work? • Prototech Asia How Does Vacuum Molding Work How does vacuum casting work? Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Advantages and disadvantages of vacuum casting. Characteristics & applications of vacuum casting. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a. How Does Vacuum Molding Work.

From www.petervaldivia.com

Fabrication of Plastics Tecnología ESO en Ingles How Does Vacuum Molding Work The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Characteristics & applications of vacuum casting. How does vacuum forming work? Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Vacuum molding, sometimes called vacuum forming, is. How Does Vacuum Molding Work.

From stock.adobe.com

thermal vacuum molding process. Obtaining volumetric parts from plastic How Does Vacuum Molding Work Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Characteristics & applications of vacuum casting. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Vacuum forming is a straightforward manufacturing process that. How Does Vacuum Molding Work.

From www.youtube.com

How to Use a Vacuum Mold! YouTube How Does Vacuum Molding Work Contents covered in this article. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. How does vacuum casting work? Characteristics & applications of vacuum casting. Vacuum forming. How Does Vacuum Molding Work.

From formlabs.com

Introduction to Vacuum Forming How Does Vacuum Molding Work Contents covered in this article. How does vacuum forming work? Vacuum forming is a straightforward manufacturing process that involves five major. Characteristics & applications of vacuum casting. Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. How does vacuum casting work? Vacuum forming, the simplest thermoforming method, uses vacuum pressure. How Does Vacuum Molding Work.

From plasticmouldingsnorthern.co.uk

How To Vacuum Form Plastic Mouldings Northern How Does Vacuum Molding Work How does vacuum casting work? Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Contents covered in this article.. How Does Vacuum Molding Work.

From www.hotrod.com

How to build a vacuum forming mold to make your own plastic parts How Does Vacuum Molding Work Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. Characteristics & applications of vacuum casting. Vacuum molding, sometimes called vacuum. How Does Vacuum Molding Work.

From www.youtube.com

Pressure Vacuum Form Mold Borke Mold Specialists inc YouTube How Does Vacuum Molding Work Characteristics & applications of vacuum casting. Vacuum forming, the simplest thermoforming method, uses vacuum pressure to shape heated plastic by drawing it onto a mold. How does vacuum casting work? Contents covered in this article. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto. How Does Vacuum Molding Work.

From www.manufacturingguide.com

Vacuum forming Find suppliers, processes & material How Does Vacuum Molding Work Vacuum forming involves molding plastic by heating it until soft and then shaping it over a mold using suction. Characteristics & applications of vacuum casting. Contents covered in this article. How does vacuum casting work? How does vacuum forming work? Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of. How Does Vacuum Molding Work.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality How Does Vacuum Molding Work The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Advantages and disadvantages of vacuum casting. How does vacuum casting work? Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum forming involves molding plastic by heating it until soft and then shaping it over. How Does Vacuum Molding Work.

From www.researchgate.net

Vacuum bagging technique performed on the molding of the composite How Does Vacuum Molding Work The vacuum forming process works by heating a plastic sheet, forming it into a shaped vacuum forming tool using vacuum, cooling the plastic. Vacuum forming is a straightforward manufacturing process that involves five major. Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a. How Does Vacuum Molding Work.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess How Does Vacuum Molding Work Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single. Contents covered in this article. Advantages and disadvantages of vacuum casting. Characteristics & applications of vacuum casting. How does vacuum forming work? Vacuum forming is a straightforward manufacturing process that involves five major.. How Does Vacuum Molding Work.