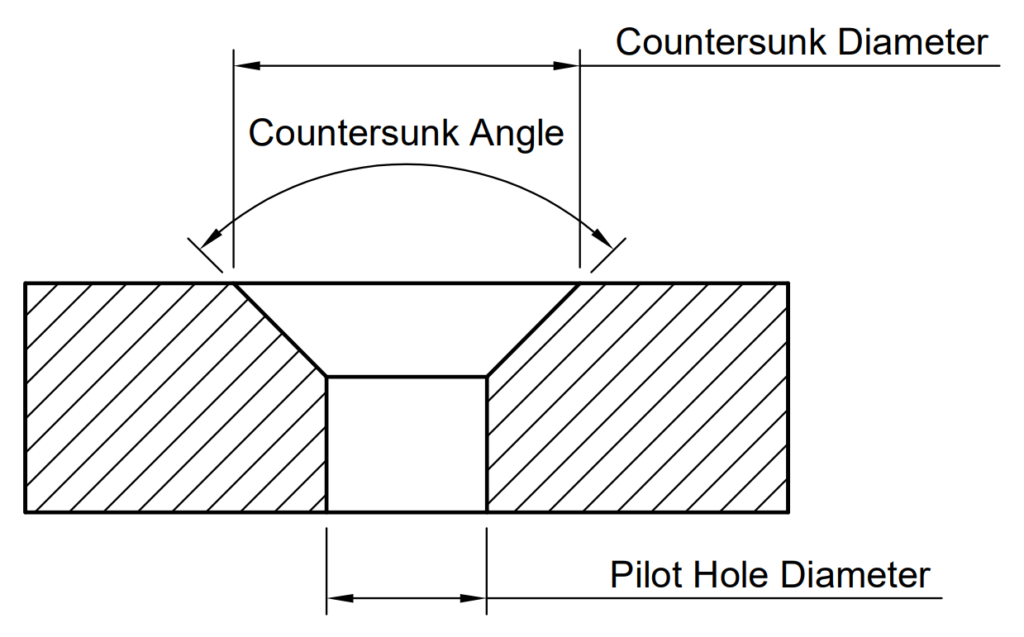

Countersink Guide . Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Understand the structure, types, and practical applications of countersinks in. Dive into the essentials of countersinks with ruko. Discover tips and tools needed to achieve a flush finish for your screws, enhancing both. Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used.

from engineersbible.com

Dive into the essentials of countersinks with ruko. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. Understand the structure, types, and practical applications of countersinks in. Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Discover tips and tools needed to achieve a flush finish for your screws, enhancing both. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection.

Countersunk Hole Size for Socket Flat Head (ANSI Inch)

Countersink Guide Dive into the essentials of countersinks with ruko. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Dive into the essentials of countersinks with ruko. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. Understand the structure, types, and practical applications of countersinks in. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Below are visuals of countersinking and counterboring in cutting and forming applications. Discover tips and tools needed to achieve a flush finish for your screws, enhancing both.

From www.ebay.com.au

7PC M3M12 HSS M2 Flat Countersink Guide Milling Cutter Deburring Countersink Guide Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with,. Countersink Guide.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersink Guide The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. It allows the fastener’s head to sit flush with the surface of the material or even. Countersink Guide.

From www.machinistguides.com

Spotfaces All About Machinist Guides Countersink Guide Below are visuals of countersinking and counterboring in cutting and forming applications. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. They serve the purpose of allowing the. Countersink Guide.

From mavink.com

Countersink Chart Countersink Guide A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Understand the structure, types, and practical applications of countersinks in. Dive. Countersink Guide.

From www.dawsonmetal.com

Countersink Guide Countersink Guide Below are visuals of countersinking and counterboring in cutting and forming applications. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Dive into the essentials of countersinks with ruko. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined. Countersink Guide.

From www.orient-river.com

MultiAngle Countersink Drill Guide Pat. OR317 Countersink Guide Understand the structure, types, and practical applications of countersinks in. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersinking is a machining. Countersink Guide.

From sbtools.en.taiwantrade.com

Multi Angle Countersink Drill Guide Countersink Guide Dive into the essentials of countersinks with ruko. Understand the structure, types, and practical applications of countersinks in. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load. Countersink Guide.

From www.orient-river.com

MultiAngle Countersink Drill Guide Pat. OR317 Countersink Guide Understand the structure, types, and practical applications of countersinks in. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Dive. Countersink Guide.

From rosewoodissues.com

What is a Countersink Bit Wood Issues, Wood tools and Guide Countersink Guide It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersinking is a machining process that creates a conical hole matching. Countersink Guide.

From www.toolsid.com

IRWIN® 12412 5/8" HSS Metal Countersink Countersink Guide Understand the structure, types, and practical applications of countersinks in. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to. Countersink Guide.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Guide Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Understand the structure, types, and practical applications of countersinks in. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. They serve the purpose of allowing the fasteners to sit flush. Countersink Guide.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersink Guide They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom.. Countersink Guide.

From www.taiwantrade.com

45Degree Angle Drill Guide & Countersink Drill Taiwantrade Countersink Guide A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. The ‘conical’ element differentiates a countersink from a counterbore, which has. Countersink Guide.

From www.scribd.com

CounterSink Depths Countersink Guide A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersinking is a machining process that. Countersink Guide.

From www.lzqtech.com

Guide Countersink CounterBore LZQ TOOL CO., LTD. Countersink Guide Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Below are visuals of countersinking and counterboring in cutting and forming applications. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Understand the. Countersink Guide.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersink Guide Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Dive into the essentials of countersinks with ruko. Countersink holes are conical recesses created on the surface of a material to accommodate. Countersink Guide.

From engineersbible.com

Countersunk Hole Size for Socket Flat Head (ANSI Inch) Countersink Guide Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Discover tips and tools needed to achieve a flush finish for your screws, enhancing both. A countersink is an angled taper. Countersink Guide.

From www.toolsid.com

IRWIN® 12411 1/2" HSS Metal Countersink Countersink Guide Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Discover tips and tools needed to achieve a flush finish for your screws,. Countersink Guide.

From www.richconn-cnc.com

What is Counter Sink? Your Comprehensive Guide Shenzhen Richconn Countersink Guide A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. A countersink is an angled taper applied to a hole that allows a fastener. Countersink Guide.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command Countersink Guide Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A countersink is a conical. Countersink Guide.

From www.wwgoa.com

5Piece Countersink Set WoodWorkers Guild of America Countersink Guide A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. The ‘conical’ element differentiates a countersink from a counterbore, which has. Countersink Guide.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Guide Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersink holes are conical recesses created on the surface of a material to. Countersink Guide.

From www.northbaycuttingtools.com

2" 82 DEGREE HIGH SPEED STEEL 3 FLUTE COUNTERSINK 1/2" SHANK North Countersink Guide A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink holes are conical recesses created on the surface of a. Countersink Guide.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Guide Understand the structure, types, and practical applications of countersinks in. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt,. Countersink Guide.

From www.gdandtbasics.com

Countersink GD&T Basics Countersink Guide They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Countersinking is a machining process that creates a conical. Countersink Guide.

From www.drills-oren.com

Deck angle guide + countersink OREN Countersinks for wood drills Countersink Guide A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A. Countersink Guide.

From www.cstmanufacturingservices.com

Countersink Tools Cleveland Steel Tool Countersink Guide A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. It allows the fastener’s head to sit flush with the surface of the material. Countersink Guide.

From www.amazon.com

3 Piece 120 Degree Countersink Bit Set with Drill Guide, Size 21, 30 Countersink Guide Discover tips and tools needed to achieve a flush finish for your screws, enhancing both. Understand the structure, types, and practical applications of countersinks in. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. It allows the fastener’s head to sit flush with the surface of the material or even below. Countersink Guide.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersink Guide It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Understand the structure, types, and practical applications of countersinks in. Dive into the essentials of countersinks with ruko. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. A countersink consists of a. Countersink Guide.

From www.wikihow.com

How to Countersink 13 Steps (with Pictures) wikiHow Countersink Guide Below are visuals of countersinking and counterboring in cutting and forming applications. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Dive into the essentials of countersinks with ruko. Discover tips and tools needed to achieve a flush finish for your. Countersink Guide.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersink Guide A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. They serve the purpose of allowing the fasteners to sit flush or below the material surface, distributing the load evenly, and providing a secure and visually appealing connection. Countersink holes are conical recesses created on the surface of a material to accommodate. Countersink Guide.

From www.scribd.com

Counterbore and Countersink Dimensions Chart Countersink Guide Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. The ‘conical’ element differentiates a countersink from a counterbore, which has a flat bottom. Discover tips and tools needed to achieve a flush finish for your screws, enhancing both. A countersink is a conical hole (cut) or conical depression (form) created in. Countersink Guide.

From www.youtube.com

Your OneStop Guide to Surface Fixing Your Deck With a Countersink Tool Countersink Guide Discover tips and tools needed to achieve a flush finish for your screws, enhancing both. A countersink is a conical hole (cut) or conical depression (form) created in a material around a hole. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Understand the structure, types,. Countersink Guide.

From woodenuknow.com

What is a Countersink in Woodworking? A Quick Guide for Beginners Countersink Guide Countersink holes are conical recesses created on the surface of a material to accommodate the heads of fasteners. Discover tips and tools needed to achieve a flush finish for your screws, enhancing both. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. The ‘conical’ element differentiates. Countersink Guide.

From woodenuknow.com

What is a Countersink in Woodworking? A Quick Guide for Beginners Countersink Guide Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A countersink is an angled taper applied to a hole that allows a fastener (usually a. Countersink Guide.