Flat Bottom Drill Vs End Mill . End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. In summary, the key differences between flat bottom drills and end mills are: Unlike their rounded counterparts, the flat. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and.

from www.slideserve.com

The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. In summary, the key differences between flat bottom drills and end mills are: An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. Unlike their rounded counterparts, the flat. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites.

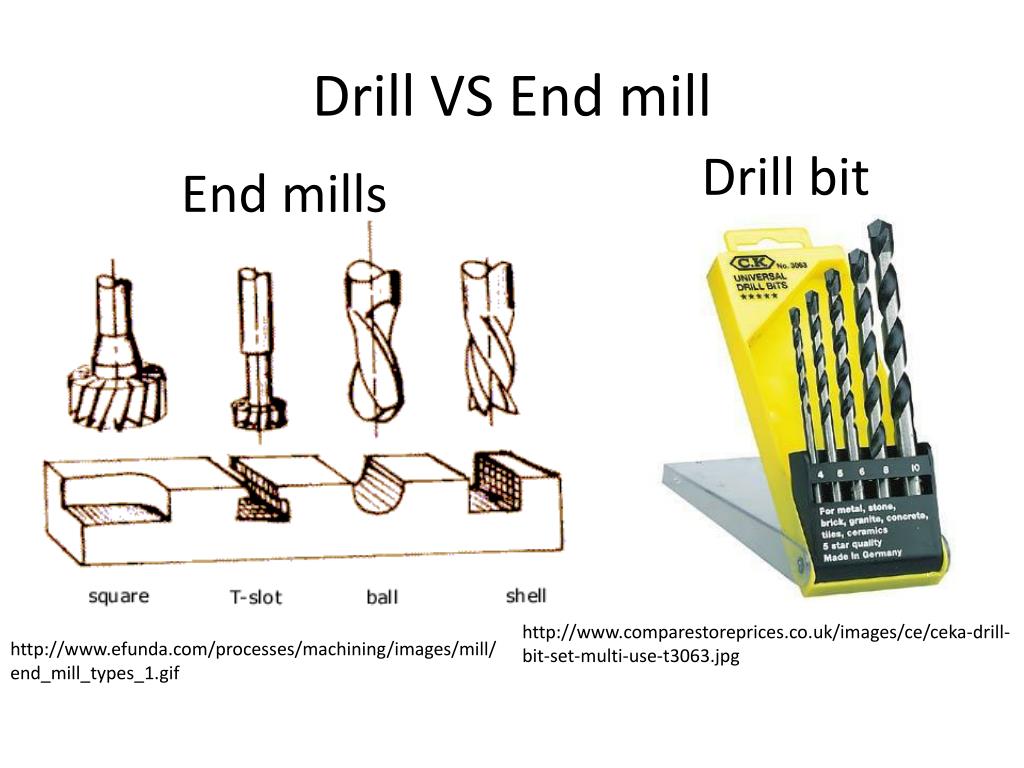

PPT Design Graphics Mech 289 PowerPoint Presentation, free download

Flat Bottom Drill Vs End Mill An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. In summary, the key differences between flat bottom drills and end mills are: End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. Unlike their rounded counterparts, the flat. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape.

From sh22barsa.blogspot.com

bull nose end mill vs flat end mill Moses Flat Bottom Drill Vs End Mill Unlike their rounded counterparts, the flat. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while. Flat Bottom Drill Vs End Mill.

From www.shop-apt.co.uk

18.5mm Diameter Flat Bottom Carbide Drill 16mm Shank 84mm Max Depth for Flat Bottom Drill Vs End Mill The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. In summary, the key differences between flat bottom drills and end mills are: The milling machine moves the workpiece against the rotating end mill,. Flat Bottom Drill Vs End Mill.

From www.tools-zone.com

End Mill vs Drill Bit What Is The Difference? Tools Zone Flat Bottom Drill Vs End Mill Unlike their rounded counterparts, the flat. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. In summary, the key differences between flat bottom drills and. Flat Bottom Drill Vs End Mill.

From www.ingersoll-imc.com

QF 3xD Indexable Flat Bottom Drill Flat Bottom Drill Vs End Mill An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. When end mills and drill bits are compared, there are several key differences that can be noticed in terms. Flat Bottom Drill Vs End Mill.

From www.moldmakingtechnology.com

End Mills, Drills, Inserts and More for Mold Building Needs Flat Bottom Drill Vs End Mill Unlike their rounded counterparts, the flat. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. In summary, the key differences between flat bottom drills and end mills are: End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites.. Flat Bottom Drill Vs End Mill.

From atelier-yuwa.ciao.jp

End Mill Vs Drill Bit atelieryuwa.ciao.jp Flat Bottom Drill Vs End Mill The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. In summary, the key differences between flat bottom drills and end. Flat Bottom Drill Vs End Mill.

From www.youtube.com

Differences between Drilling and End Milling (Drill Vs End Mill) YouTube Flat Bottom Drill Vs End Mill An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. In summary, the key differences between flat bottom drills and end mills are: Unlike their rounded counterparts, the flat. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material. Flat Bottom Drill Vs End Mill.

From www.tools-zone.com

End Mill vs Drill Bit What Is The Difference? Tools Zone Flat Bottom Drill Vs End Mill In summary, the key differences between flat bottom drills and end mills are: Unlike their rounded counterparts, the flat. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting. Flat Bottom Drill Vs End Mill.

From www.youtube.com

Dream Drill Flat Bottom YG1 Tools México YouTube Flat Bottom Drill Vs End Mill End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. The. Flat Bottom Drill Vs End Mill.

From www.aliexpress.com

M2Al Hss Aluminum End Mill 4 Flute 16mm Shank Drill 95mm Length Flat Flat Bottom Drill Vs End Mill End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. Unlike their rounded counterparts, the flat. In summary, the key differences between flat bottom drills and. Flat Bottom Drill Vs End Mill.

From www.banggood.com

10mm diameter 4 flute tungsten carbide end mill 75mm length flat bottom Flat Bottom Drill Vs End Mill When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. End mills are versatile tools that can be used to cut a variety of materials, including. Flat Bottom Drill Vs End Mill.

From www.cnccookbook.com

Everything You Need to Know About Flat Bottom Drill Bit CNCCookbook Flat Bottom Drill Vs End Mill When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. In summary, the key differences between flat bottom drills and end mills are: The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a. Flat Bottom Drill Vs End Mill.

From www.harveyperformance.com

10 Reasons to Use Flat Bottom Tools In The Loupe Flat Bottom Drill Vs End Mill When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and. Flat Bottom Drill Vs End Mill.

From www.alibaba.com

Bfl Endmill Solid Carbide Flat Bottom End Mill Rough Cutting End Mills Flat Bottom Drill Vs End Mill The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to. Flat Bottom Drill Vs End Mill.

From www.shop-apt.co.uk

3.5mm Diameter Flat Bottom Carbide Drill 4mm Shank 17mm Max Depth for Flat Bottom Drill Vs End Mill An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect. Flat Bottom Drill Vs End Mill.

From www.machinery.co.uk

Sumitomo offers SEC flatbottom drills and mills Flat Bottom Drill Vs End Mill An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. In summary, the key differences between flat bottom drills and end mills are: When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. End mills are versatile tools that can be used. Flat Bottom Drill Vs End Mill.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools Flat Bottom Drill Vs End Mill Unlike their rounded counterparts, the flat. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. In summary, the key differences between flat bottom drills and end mills are: The geometry. Flat Bottom Drill Vs End Mill.

From www.datron.com

Drill vs. End Mill? Some Basic Guidelines DATRON Dynamics Flat Bottom Drill Vs End Mill In summary, the key differences between flat bottom drills and end mills are: When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a. Flat Bottom Drill Vs End Mill.

From engineeringlearn.com

Types of Milling Cutter Tools and Their Uses [with Pictures Flat Bottom Drill Vs End Mill The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. In summary, the key differences between flat bottom drills and end mills are: When end mills. Flat Bottom Drill Vs End Mill.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI Flat Bottom Drill Vs End Mill When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and. Flat Bottom Drill Vs End Mill.

From atelier-yuwa.ciao.jp

End Mill Vs Drill Bit atelieryuwa.ciao.jp Flat Bottom Drill Vs End Mill When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. When used correctly, the following flat bottom tools can make the. Flat Bottom Drill Vs End Mill.

From thegodalmingpost.blogspot.com

end mill types and uses Best Bit EZine Fonction Flat Bottom Drill Vs End Mill In summary, the key differences between flat bottom drills and end mills are: Unlike their rounded counterparts, the flat. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting. Flat Bottom Drill Vs End Mill.

From atelier-yuwa.ciao.jp

End Mill Vs Drill Bit atelieryuwa.ciao.jp Flat Bottom Drill Vs End Mill In summary, the key differences between flat bottom drills and end mills are: When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a. Flat Bottom Drill Vs End Mill.

From www.datron.com

Drill vs. End Mill? Some Basic Guidelines DATRON Dynamics Flat Bottom Drill Vs End Mill Unlike their rounded counterparts, the flat. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. When end mills and drill bits are compared, there are several key differences that can be. Flat Bottom Drill Vs End Mill.

From www.kennametal.com

HighPerformance Solid Carbide Drills 180° FlatBottom Drills • Through Flat Bottom Drill Vs End Mill The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. Unlike their rounded counterparts, the flat. In summary, the key differences between flat bottom drills and end mills are: The milling machine moves the. Flat Bottom Drill Vs End Mill.

From www.slideserve.com

PPT Design Graphics Mech 289 PowerPoint Presentation, free download Flat Bottom Drill Vs End Mill Unlike their rounded counterparts, the flat. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. When used correctly, the following flat bottom tools can make. Flat Bottom Drill Vs End Mill.

From atelier-yuwa.ciao.jp

End Mill Vs Drill Bit atelieryuwa.ciao.jp Flat Bottom Drill Vs End Mill The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. The geometry of flat bottom end mills is fundamentally designed to achieve precision. Flat Bottom Drill Vs End Mill.

From indotech-group.co.id

End Mill Ketahui Jenis Jenis End Mill Indotech Trimitra Abadi Flat Bottom Drill Vs End Mill End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. The geometry of flat bottom end mills is fundamentally designed to achieve precision. Flat Bottom Drill Vs End Mill.

From www.aliexpress.com

M2Al End Mill 4 Flute 16mm Shank Drill 95mm Length Flat Bottom Endmill Flat Bottom Drill Vs End Mill The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. In summary, the key differences between flat bottom drills and end. Flat Bottom Drill Vs End Mill.

From www.speedtigertools.com

End Mill Cutting & End Milling Technical Guide Flat Bottom Drill Vs End Mill End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. Unlike their rounded counterparts, the flat. When end mills and drill bits are compared, there are several key differences. Flat Bottom Drill Vs End Mill.

From www.datron.com

Drill vs. End Mill? Some Basic Guidelines DATRON Dynamics Flat Bottom Drill Vs End Mill An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. When end mills and drill bits are compared, there are several key differences that can be noticed in terms. Flat Bottom Drill Vs End Mill.

From fab.academany.org

ComputerControlled Machining Flat Bottom Drill Vs End Mill In summary, the key differences between flat bottom drills and end mills are: The milling machine moves the workpiece against the rotating end mill, which cuts into the material and removes chips of material to create a desired shape. The geometry of flat bottom end mills is fundamentally designed to achieve precision and efficiency in milling operations. Unlike their rounded. Flat Bottom Drill Vs End Mill.

From www.tools-zone.com

End Mill vs Drill Bit What Is The Difference? Tools Zone Flat Bottom Drill Vs End Mill In summary, the key differences between flat bottom drills and end mills are: Unlike their rounded counterparts, the flat. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly.. Flat Bottom Drill Vs End Mill.

From www.aerospacemanufacturinganddesign.com

5 Things You Need to Know about Flat Bottom Drilling Aerospace Flat Bottom Drill Vs End Mill When used correctly, the following flat bottom tools can make the difference between botched jobs and perfect parts. An end mill’s thicker web and slower spiral hinder chip evacuation during holemaking operations while also raising cutting forces significantly. In summary, the key differences between flat bottom drills and end mills are: Unlike their rounded counterparts, the flat. The geometry of. Flat Bottom Drill Vs End Mill.

From www.austgen.com.au

Best Drilling End Mills 2018 Guide Melbourne Metal Fabrication Flat Bottom Drill Vs End Mill When end mills and drill bits are compared, there are several key differences that can be noticed in terms of their functions and. End mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. Unlike their rounded counterparts, the flat. When used correctly, the following flat bottom tools can make. Flat Bottom Drill Vs End Mill.