Cured Ply Thickness Equation . The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. The calculation is based on the. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. Enter material set number for ply number 1: Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. 0 enter material set number for ply number 2: This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and.

from www.chegg.com

Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. The calculation is based on the. This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. 0 enter material set number for ply number 2: Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. Enter material set number for ply number 1:

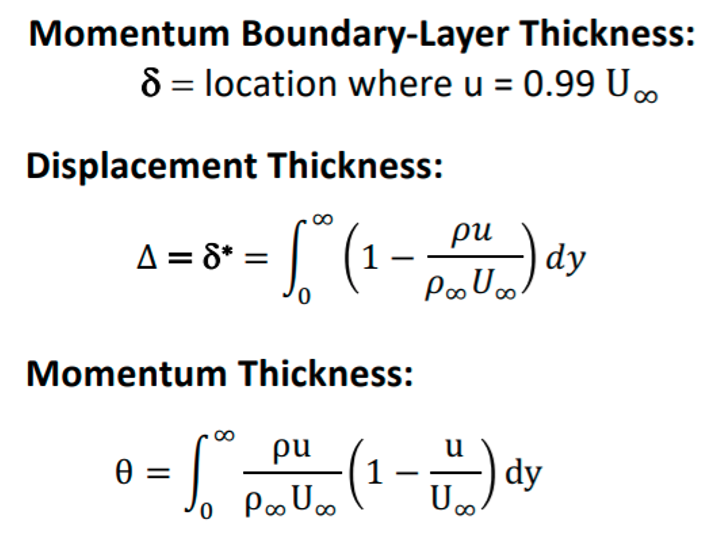

Solved Use the following boundary layer thickness equations

Cured Ply Thickness Equation Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. 0 enter material set number for ply number 2: (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. The calculation is based on the. Enter material set number for ply number 1: Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting.

From www.chegg.com

A composite material supplier is selling a Cured Ply Thickness Equation The calculation is based on the. Enter material set number for ply number 1: Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. Each layer. Cured Ply Thickness Equation.

From mechcontent.com

Thermal boundary layer Definition, Thickness equation [with Pdf] Cured Ply Thickness Equation Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. 0 enter material set number for ply number 2: This tool calculates the thickness of individual plies, cured. Cured Ply Thickness Equation.

From www.researchgate.net

Nonaxisymmetric strain change during cure (32ply pipe and plate). Download Scientific Diagram Cured Ply Thickness Equation Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. Its cured ply thickness and fibre volume fraction are known. Cured Ply Thickness Equation.

From www.researchgate.net

The influence of the cracking ply thickness on the normalized extension... Download Scientific Cured Ply Thickness Equation Enter material set number for ply number 1: Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. 0 enter material set number for ply number 2: This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate. Cured Ply Thickness Equation.

From slideplayer.com

Elements of Fabrication II Material Properties Developed and Testing ppt download Cured Ply Thickness Equation Enter material set number for ply number 1: 0 enter material set number for ply number 2: The calculation is based on the. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. This tool calculates the thickness of individual plies, cured (for thermoset. Cured Ply Thickness Equation.

From slideplayer.com

Elements of Fabrication II Material Properties Developed and Testing ppt download Cured Ply Thickness Equation The calculation is based on the. Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. 0 enter material set number for ply number 2: This tool calculates the thickness of individual plies,. Cured Ply Thickness Equation.

From mil-spec.tpub.com

Cured Ply Thickness Cured Ply Thickness Equation 0 enter material set number for ply number 2: This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. The cured ply thickness is. Cured Ply Thickness Equation.

From www.slideserve.com

PPT The Thickness equation (Hypsometric equation) PowerPoint Presentation ID6911030 Cured Ply Thickness Equation This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy. Cured Ply Thickness Equation.

From www.semanticscholar.org

Figure 1 from Mechanical Behavior of AnglePlied CFRP Laminates with Different Ply Cured Ply Thickness Equation The calculation is based on the. This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. (1) the material to be examined is made up of one or. Cured Ply Thickness Equation.

From slideplayer.com

Elements of Fabrication II Material Properties Developed and Testing ppt download Cured Ply Thickness Equation Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. 0 enter material set number for ply number 2: The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. The calculation is based on the. Enter material. Cured Ply Thickness Equation.

From slideplayer.com

Elements of Fabrication II Material Properties Developed and Testing ppt download Cured Ply Thickness Equation This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. 0 enter material set number for ply number 2: Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. Each ply is typically a thin (approximately 0.2 mm). Cured Ply Thickness Equation.

From rangechange.ca

cosa non pagato punch composite laminate thickness calculation Marrone Matematico Costituire Cured Ply Thickness Equation 0 enter material set number for ply number 2: (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. The calculation is based on the. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is. Cured Ply Thickness Equation.

From www.researchgate.net

Cured ply properties of UD laminates. MR60/Epoxy[9] M55/Epoxy [15]... Download Scientific Diagram Cured Ply Thickness Equation (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. The calculation is based on the. Enter material set number for ply number 1: Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a. Cured Ply Thickness Equation.

From www.slideserve.com

PPT The Thickness equation (Hypsometric equation) PowerPoint Presentation ID6911030 Cured Ply Thickness Equation 0 enter material set number for ply number 2: Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. The calculation is based on the. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. This tool calculates the thickness. Cured Ply Thickness Equation.

From www.researchgate.net

Panel cured ply thickness results. Error bars represent ±1 of 815... Download Scientific Diagram Cured Ply Thickness Equation Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. Enter material set number for ply number 1: The calculation is based on the. Its cured ply. Cured Ply Thickness Equation.

From www.researchgate.net

Oven cure of variable thickness panel, and cocured 4 and 24 ply panels Download Scientific Cured Ply Thickness Equation Enter material set number for ply number 1: This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. The calculation is based on the. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. Each layer. Cured Ply Thickness Equation.

From www.researchgate.net

Obtained DCI by applying a variation to the mean of ply thickness. Download Scientific Diagram Cured Ply Thickness Equation Enter material set number for ply number 1: The calculation is based on the. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other. Cured Ply Thickness Equation.

From www.youtube.com

Derivation of energy thickness equation II YouTube Cured Ply Thickness Equation Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. 0 enter material set number for ply number 2: The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. The calculation is based on the. This tool calculates the thickness of individual plies,. Cured Ply Thickness Equation.

From www.mdpi.com

J. Compos. Sci. Free FullText Static and Fatigue Tensile Properties of CrossPly Carbon Cured Ply Thickness Equation Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in. Cured Ply Thickness Equation.

From www.coursehero.com

[Solved] Prove the above thickness equation..... Solve correctly. +c Course Hero Cured Ply Thickness Equation Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. 0 enter material set number for ply number 2: (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. The. Cured Ply Thickness Equation.

From arvengtraining.com

Understanding Piping Wall thickness calculation Arveng Training & Engineering Cured Ply Thickness Equation The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are. Cured Ply Thickness Equation.

From www.researchgate.net

Cured ply thickness, hp , fibre volume fraction, Vf , glass tranistion... Download Scientific Cured Ply Thickness Equation 0 enter material set number for ply number 2: Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. The calculation is based on the. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that. Cured Ply Thickness Equation.

From id.scribd.com

Cured Ply Thickness (CPT) Method For Fiber Reinforce Polymer Composite PDF Cured Ply Thickness Equation Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. This. Cured Ply Thickness Equation.

From www.chegg.com

Solved Analyze a laminated composite beam in a Cured Ply Thickness Equation The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. The calculation is based on the. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. Enter material set number for ply number 1: This tool calculates the thickness. Cured Ply Thickness Equation.

From www.researchgate.net

Cure progression of samples of different thickness at fixed T = (19.8 ±... Download Scientific Cured Ply Thickness Equation Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. Enter material set number for ply number 1: The calculation is based on the. The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. Each ply is typically a thin (approximately 0.2 mm). Cured Ply Thickness Equation.

From khkgears.net

Tooth Thickness KHK Cured Ply Thickness Equation Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers. Cured Ply Thickness Equation.

From www.chegg.com

A composite laminate, [0/90/plusminus 35]5 has a Cured Ply Thickness Equation Enter material set number for ply number 1: The calculation is based on the. Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. 0 enter. Cured Ply Thickness Equation.

From www.researchgate.net

Crosssection of 48ply specimen after curing. Download Scientific Diagram Cured Ply Thickness Equation This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. The calculation is based on the. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. Each layer has a fiber direction and ‘thickness’. Cured Ply Thickness Equation.

From www.chegg.com

Solved Use the following boundary layer thickness equations Cured Ply Thickness Equation This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y. Cured Ply Thickness Equation.

From mellowpine.com

Plywood Thickness Chart and Sizes [All Types] MellowPine Cured Ply Thickness Equation Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. Enter material set number for ply number 1: Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. 0 enter material set number for ply number 2: The cured ply. Cured Ply Thickness Equation.

From www.numerade.com

SOLVED Consider a T300 carbon fiber epoxy crossply laminate with the layup [0/90]s Cured Ply Thickness Equation 0 enter material set number for ply number 2: The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. This tool calculates the thickness of individual plies, cured (for thermoset systems) or consolidated (for thermoplastic systems) in laminate form. Its cured ply thickness and fibre volume fraction are known to be. Cured Ply Thickness Equation.

From www.slideserve.com

PPT The Thickness equation (Hypsometric equation) PowerPoint Presentation ID6911030 Cured Ply Thickness Equation The cured ply thickness is the final thickness of a single layer in a composite after curing and compacting. The calculation is based on the. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers. Cured Ply Thickness Equation.

From www.chegg.com

Composite Materials problem You are provided with two Cured Ply Thickness Equation Its cured ply thickness and fibre volume fraction are known to be 0.13 mm and 57.7%, respectively [5]. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all uniformly parallel and. The calculation is based on the. This tool calculates the thickness of individual plies, cured (for. Cured Ply Thickness Equation.

From www.slideserve.com

PPT The Thickness equation (Hypsometric equation) PowerPoint Presentation ID6911030 Cured Ply Thickness Equation 0 enter material set number for ply number 2: Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. The calculation is based on the. (1) the material to be examined is made up of one or more plies (layers), each ply consisting of fibers that are all. Cured Ply Thickness Equation.

From slideplayer.com

CHAPTER 4 MACROMECHANICAL ANALYSIS OF LAMINATES ppt video online download Cured Ply Thickness Equation Each ply is typically a thin (approximately 0.2 mm) sheet of collimated fibers impregnated with an uncured epoxy or other thermosetting polymer matrix material. Each layer has a fiber direction and ‘thickness’ specified by the design requirements (x,y are body coordinates) ‘thickness’ is a function of. Its cured ply thickness and fibre volume fraction are known to be 0.13 mm. Cured Ply Thickness Equation.