Slotting Machining . Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. This process is used to produce components with precise slots, keyways, or channels. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. It is a highly versatile and precise machining method. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Kennametal's slotting mills for efficient metalworking. Side and face cutters offer the most efficient. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Our indexable milling tools offer precision and durability for all your slotting needs.

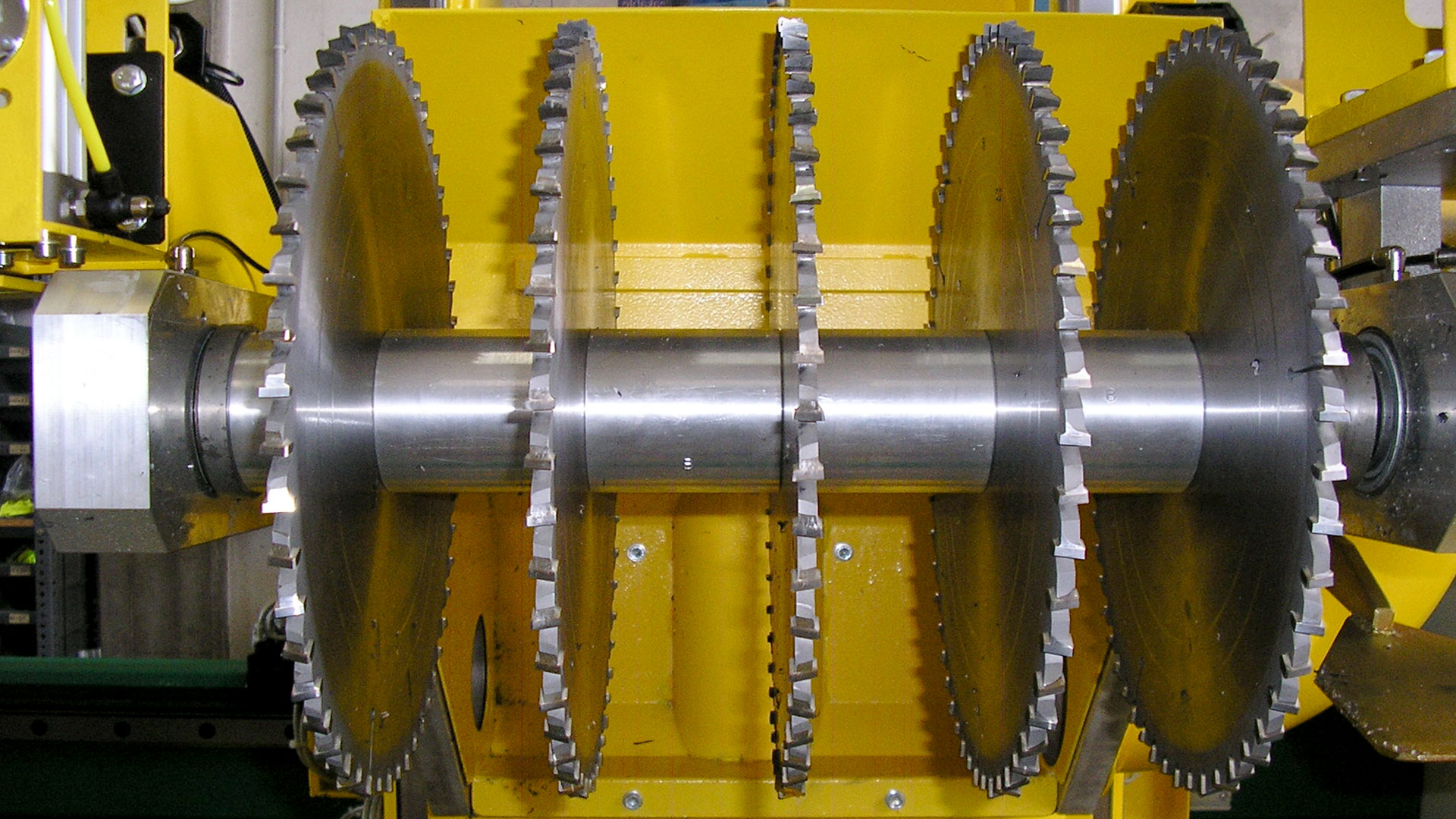

from www.baruffaldi.eu

It is a highly versatile and precise machining method. Kennametal's slotting mills for efficient metalworking. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Our indexable milling tools offer precision and durability for all your slotting needs. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Side and face cutters offer the most efficient. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. This process is used to produce components with precise slots, keyways, or channels.

Slotting Machines Baruffaldi

Slotting Machining Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. It is a highly versatile and precise machining method. Our indexable milling tools offer precision and durability for all your slotting needs. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Kennametal's slotting mills for efficient metalworking. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. This process is used to produce components with precise slots, keyways, or channels. Side and face cutters offer the most efficient.

From allangreenengineering.co.uk

Slotting and Broaching Allan Green & Son Slotting Machining The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. Groove or slot milling is an operation in which side and face milling is often preferred to end. Slotting Machining.

From www.market-prospects.com

What Is A Slotting Machine and Its Structure and Works? Market Prospects Slotting Machining Our indexable milling tools offer precision and durability for all your slotting needs. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. It is a highly versatile and precise machining method. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. The slotting machine is a. Slotting Machining.

From www.gskequipment.com

BK5010 CNC Slotting Machine Supplier China Slotting Machining Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Our indexable milling tools offer precision and durability for all your slotting needs. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Slot machining, a specialized area within machining, employs techniques like end. Slotting Machining.

From www.youtube.com

slotting machine construction and working of slotter machine Metal Slotting Machining This process is used to produce components with precise slots, keyways, or channels. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined,. Slotting Machining.

From ravimachines.com

Slotting Machine 10 Inch Stroke Toolroom Slotting Machine Price Slotting Machining Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. It is a highly versatile and precise machining method. Slot milling is a machining operation that uses a rotating tool that. Slotting Machining.

From www.tapping-slottingmachines.com

Manufacturer of slotting machines, slotting machine Slotting Machining Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Delve into the intricacies of slot milling, an indispensable. Slotting Machining.

From www.youtube.com

04 Slotting machine Keyways YouTube Slotting Machining Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. This process is used to produce components with precise slots, keyways, or channels. Side and face cutters offer the most efficient.. Slotting Machining.

From www.keyway-spline-broaching.com

C.A.M.S. Slotting Machine 200 Broaching Technologies Slotting Machining Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Groove or slot milling is an operation in which side and face milling is often preferred to end milling.. Slotting Machining.

From www.directindustry.com

Automatic slotting machine 320 Cormak Slotting Machining Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. The slotting machine is a reciprocating machine tool in which, the vertical slide. Slotting Machining.

From www.ctemag.com

Going deep into slotting Cutting Tool Engineering Slotting Machining Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Side and face cutters offer the most efficient. Our indexable milling tools offer precision and durability for all your slotting needs. Slot milling is a machining operation that uses a rotating tool that has multiple. Slotting Machining.

From www.cabe.it

Slotting Machine ST5 CNC Cabe Stozzatrici Machine Tools Slotting Machining Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. Groove or. Slotting Machining.

From www.opsudyog.com

Slotting Machine Heavy Duty Slotting Machine Manufacturer from Batala Slotting Machining It is a highly versatile and precise machining method. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Our indexable milling tools offer precision and durability for all. Slotting Machining.

From gisstec.com

Slotting Tool Archives Gisstec Broaching Tools Angle Heads Slotting Machining Side and face cutters offer the most efficient. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. It is a highly versatile and precise machining method. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Our indexable milling tools offer precision and durability for all. Slotting Machining.

From ravimachines.com

Slotting Machine 12 Inch Stroke Slotting Price High Strock Machine Slotting Machining Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice. Slotting Machining.

From ravimachines.com

Slotting Machine 10 Inch Stroke Toolroom Slotting Machine Price Slotting Machining Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Slotting machines or slotters are cutting machines designed. Slotting Machining.

From www.directindustry.com

NC slotting machine 500A (850) 3AC CAMS srl 3axis / rotating table Slotting Machining Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Side and face cutters offer the most efficient. It is a highly versatile and precise machining method. Explore various techniques, from end. Slotting Machining.

From www.nakamura-tome.com

Machining internal keyway with slotting tool Slotting Machining Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Side and face cutters offer the most efficient. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Groove or slot milling is an operation in which side and. Slotting Machining.

From allangreenengineering.co.uk

Slotting and Broaching Allan Green & Son Slotting Machining Our indexable milling tools offer precision and durability for all your slotting needs. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be. Slotting Machining.

From ravimachines.com

Slotter Machine 10″ inch (250 mm) Key Way Rotary Table Punch Slotting Machining Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Our indexable milling tools offer precision and durability for all your slotting needs. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Slotting machines or slotters are cutting. Slotting Machining.

From www.lzcncmachine.com

B5032 Vertical Slotting Machine CNC Hydraulic Shaper, Slotting Slotting Machining Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Groove or slot milling is an operation in which side and face milling. Slotting Machining.

From ravimachines.com

Slotting Machine 6 Inch Stroke Slotting Machine Price Slotting Slotting Machining Kennametal's slotting mills for efficient metalworking. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. It is a highly versatile and precise machining method. Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of. Slotting Machining.

From millart.en.made-in-china.com

Vertical Slotting Machine B5020 Metal Slotting Machine China Slotter Slotting Machining Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. This process. Slotting Machining.

From www.keyway-spline-broaching.com

C.A.M.S. Slotting Machine 350 Broaching Technologies Slotting Machining It is a highly versatile and precise machining method. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. Our indexable milling tools offer precision and durability for all your slotting needs. This process is used to produce components with. Slotting Machining.

From lzmachine.en.made-in-china.com

Vertical Keyway slotting machine B5040 Slotting machine for metal Slotting Machining Our indexable milling tools offer precision and durability for all your slotting needs. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. Slot machining, a specialized area. Slotting Machining.

From gmtrajkotlathe.com

SLOTTING MACHINE to Ganesh Machine Tools Slotting Machining Kennametal's slotting mills for efficient metalworking. Side and face cutters offer the most efficient. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Slot machining, a specialized area within machining, employs. Slotting Machining.

From ravimachines.com

Slotting Machine 10 Inch Stroke Toolroom Slotting Machine Price Slotting Machining Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined, is mounted directly or in a vice on the work table. Delve into. Slotting Machining.

From www.mechical.com

Parts of Slotting Machine & Their Types,Operation,Mechanism Slotting Machining Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. The slotting machine is a reciprocating machine. Slotting Machining.

From engineeringlearner.com

Slotting Machine Definition, Parts, Types, Operation, Application Slotting Machining Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Side and face cutters offer the most efficient. Groove or slot milling is an operation in which side and face milling. Slotting Machining.

From www.gskequipment.com

BK5018 CNC Slotting Machine Wholesaler Slotting Machining This process is used to produce components with precise slots, keyways, or channels. It is a highly versatile and precise machining method. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical,. Slotting Machining.

From www.machineryhouse.com.au

S707 SL100 Swivel Head Slotting Machine Hare & Forbes Machineryhouse Slotting Machining Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. It is a highly versatile and precise machining method. Kennametal's slotting mills for efficient metalworking. Explore various techniques, from end milling to trochoidal milling, uncovering the nuances and advantages of each method. The slotting machine is a reciprocating machine tool in which, the vertical slide holding. Slotting Machining.

From www.cabe.it

Slotting Machine ST5 CNC Cabe Stozzatrici Machine Tools Slotting Machining Our indexable milling tools offer precision and durability for all your slotting needs. Groove or slot milling is an operation in which side and face milling is often preferred to end milling. Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. This process is used to produce components with precise slots, keyways, or. Slotting Machining.

From www.baruffaldi.eu

Slotting Machines Baruffaldi Slotting Machining Side and face cutters offer the most efficient. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. Delve into the intricacies of slot milling, an indispensable process in engineering and manufacturing. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting. Slotting Machining.

From gdmachinery.co.uk

Butler 21" Slotting Machine GD Machinery Slotters GD Machinery Slotting Machining Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. Side and face cutters offer the most efficient. Slotting machines or slotters are cutting machines designed to machine slots. Slotting Machining.

From www.gskequipment.com

BK5018 CNC Slotting Machine Wholesaler Slotting Machining Slotting machines or slotters are cutting machines designed to machine slots and grooves into a workpiece. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank. Slotting Machining.

From www.cabe.it

Slotting Machine ST4 CNC Cabe Stozzatrici Machine Tools Slotting Machining Our indexable milling tools offer precision and durability for all your slotting needs. Slotting machines are reciprocating machines that are mainly used to manufacture horizontal, vertical, or flat surfaces. The slotting machine is a reciprocating machine tool in which, the vertical slide holding the cutting tool is reciprocated by a crank and connecting rod mechanism, the job, to be machined,. Slotting Machining.