Grinding Wheels Uses . The abrasive grains act as. The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Soft grade wheels are used for rapid. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels are abrasive cutting tools. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process.

from www.walmart.com

Soft grade wheels are used for rapid. The abrasive grains act as. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels are abrasive cutting tools. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Grinding wheels, regardless of their manufacturer, are made up of three main components: The abrasive grains distributed on the surface of the wheel form thousands of. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Aluminum oxide, silicon carbide, zirconia,.

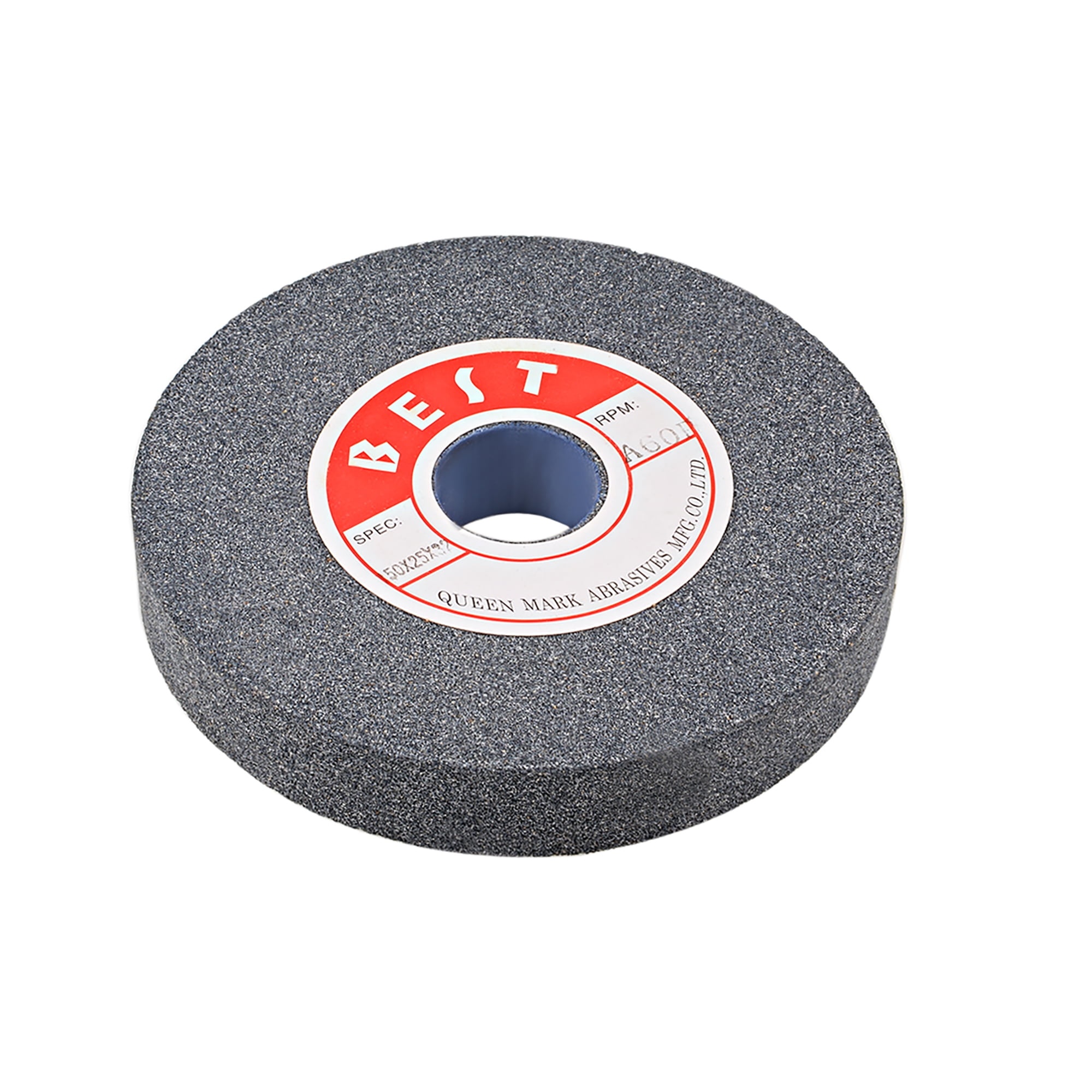

6Inch Bench Grinding Wheel Aluminum Oxide A 60 Grit for Surface

Grinding Wheels Uses Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Grinding wheels are abrasive cutting tools. Grinding wheels, regardless of their manufacturer, are made up of three main components: Aluminum oxide, silicon carbide, zirconia,. The abrasive grains act as. Soft grade wheels are used for rapid. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process.

From www.residencestyle.com

How to Choose From the Different Types of Grinding Wheels? » Residence Grinding Wheels Uses The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Grinding wheels are widely used across various industries for material removal, surface. Grinding Wheels Uses.

From www.youtube.com

3 Different Shapes and Types of Grinding Wheels Built up Wheel Grinding Wheels Uses Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels are abrasive cutting tools. Grinding wheels, regardless of their manufacturer,. Grinding Wheels Uses.

From www.starabrasives.com

How To Choose The Vitrified Grinding Wheels Star Abrasives Grinding Wheels Uses The abrasive grains act as. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Soft grade wheels are used for rapid. Grinding wheels contain abrasive grains and layers of fiberglass. Grinding Wheels Uses.

From humanfocus.co.uk

Grinding Wheels Types, Purposes and Uses Human Focus Grinding Wheels Uses Soft grade wheels are used for rapid. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. The abrasive grains act as. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Grinding wheels are abrasive cutting tools. Therefore, it is an important operation that is performed. Grinding Wheels Uses.

From www.pinterest.ca

Grinding Wheel Uses, Applications and Its Types Grind, Wheel, Type Grinding Wheels Uses The abrasive grains act as. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Soft grade wheels are used for rapid. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Aluminum oxide,. Grinding Wheels Uses.

From www.alamy.com

Grinding wheels used for welding applications Stock Photo Alamy Grinding Wheels Uses Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Grinding wheels, regardless of. Grinding Wheels Uses.

From www.museoinclusivo.com

Aluminum Grinding Wheels Uses, Benefits, Differences & Safety Tips Grinding Wheels Uses Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Soft grade wheels are used for rapid. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels. Grinding Wheels Uses.

From www.walmart.com

TSV 41/2Inch Double Row Diamond Cup Grinding Wheel, Grinding Wheel Grinding Wheels Uses Soft grade wheels are used for rapid. The abrasive grains distributed on the surface of the wheel form thousands of. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels contain abrasive grains and. Grinding Wheels Uses.

From ronixtools.com

A Beginner’s Guide to Angle Grinder Wheels Ronix Mag Grinding Wheels Uses Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Soft grade wheels are used for rapid. The abrasive grains distributed on the surface of the wheel form thousands of. The abrasive grains act as. Aluminum oxide, silicon carbide, zirconia,. Therefore,. Grinding Wheels Uses.

From learnmechanical.com

Grinding WheelDefinition, Material, Grit, Grades, Structure, Types Grinding Wheels Uses Grinding wheels are abrasive cutting tools. Grinding wheels, regardless of their manufacturer, are made up of three main components: The abrasive grains act as. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. The abrasive grains distributed on the surface of the wheel form thousands of. Common usage of grinding wheels is. Grinding Wheels Uses.

From finemetalworking.com

Surface Grinding Wheels Types and Specification Grinding Wheels Uses Grinding wheels are abrasive cutting tools. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. The abrasive grains act as. Soft grade wheels are used for rapid. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Aluminum oxide, silicon. Grinding Wheels Uses.

From www.wanlongmachines.com

What are the uses and types of grinding wheels? Grinding Wheels Uses Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Aluminum oxide, silicon carbide, zirconia,. Therefore, it is an important operation that is performed. Grinding Wheels Uses.

From www.alamy.com

Grinding wheels used for welding applications Stock Photo Alamy Grinding Wheels Uses Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. The abrasive grains distributed on the surface of the wheel form thousands of. Soft grade wheels are used for rapid. Grinding. Grinding Wheels Uses.

From www.shutterstock.com

Grinding And Burnishing Wheels Uses For Grinding And Cleaning Metals. A Grinding Wheels Uses Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. The abrasive grains distributed on the surface of the wheel form thousands of. Soft grade wheels are used for rapid. Grinding wheels contain. Grinding Wheels Uses.

From www.dreamstime.com

Grinding and Burnishing Wheels Uses for Grinding and Cleaning Me Stock Grinding Wheels Uses Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels are abrasive cutting tools. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Soft grade wheels are used for rapid. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining. Grinding Wheels Uses.

From www.museoinclusivo.com

Aluminum Grinding Wheels Uses, Benefits, Differences & Safety Tips Grinding Wheels Uses The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Soft grade wheels are used for rapid. Grinding wheels, regardless of their manufacturer, are made up of three main components: Common usage of grinding wheels is to grind the workpiece and. Grinding Wheels Uses.

From www.easygetproduct.com

Top 10 Best Grinding Wheels in 2021 Cut Off Wheel Grinding Wheels Uses The abrasive grains distributed on the surface of the wheel form thousands of. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Soft grade wheels are used for rapid. Grinding wheels are abrasive cutting tools.. Grinding Wheels Uses.

From www.youtube.com

Surface Grinder Basics How to Install a Grinding Wheel YouTube Grinding Wheels Uses Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels are abrasive cutting tools. The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels, regardless. Grinding Wheels Uses.

From www.alamy.com

Grinding wheels used for welding applications Stock Photo Alamy Grinding Wheels Uses Grinding wheels are abrasive cutting tools. The abrasive grains distributed on the surface of the wheel form thousands of. The abrasive grains act as. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Soft grade wheels are used for rapid. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels contain abrasive grains and layers of. Grinding Wheels Uses.

From www.walmart.com

6Inch Bench Grinding Wheel Aluminum Oxide A 60 Grit for Surface Grinding Wheels Uses Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. The abrasive grains act as. Common usage of grinding wheels is to. Grinding Wheels Uses.

From shirazee.co.in

What is the Diamond Grinding Wheel? Types and Uses Grinding Wheels Uses Aluminum oxide, silicon carbide, zirconia,. The abrasive grains act as. The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels are abrasive cutting tools. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional. Grinding Wheels Uses.

From www.practicalmachinist.com

Cutting metal grinding machine, spark. Practical Machinist Grinding Wheels Uses The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Soft grade wheels are used for rapid. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Aluminum oxide, silicon carbide, zirconia,.. Grinding Wheels Uses.

From www.dreamstime.com

Old used grinding wheels stock photo. Image of wheel 105260088 Grinding Wheels Uses Soft grade wheels are used for rapid. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. The abrasive grains distributed on the surface of the wheel form thousands of. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made up of three main components: Common usage of grinding wheels. Grinding Wheels Uses.

From www.extremeabrasives.com

Cutting and Grinding Wheels Application Guide Archives Extreme Grinding Wheels Uses The abrasive grains distributed on the surface of the wheel form thousands of. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels are widely used across various industries for material removal, surface. Grinding Wheels Uses.

From lifeeconomic.com

Best die grinder grinding wheels 4U Life Grinding Wheels Uses Aluminum oxide, silicon carbide, zirconia,. The abrasive grains act as. Soft grade wheels are used for rapid. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels are abrasive cutting tools. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface. Grinding Wheels Uses.

From www.forturetools.com

How to read a grinding wheel's specification Forture Tools Grinding Wheels Uses Grinding wheels, regardless of their manufacturer, are made up of three main components: Aluminum oxide, silicon carbide, zirconia,. Soft grade wheels are used for rapid. Grinding wheels are abrasive cutting tools. The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another. Grinding Wheels Uses.

From www.museoinclusivo.com

Aluminum Grinding Wheels Uses, Benefits, Differences & Safety Tips Grinding Wheels Uses Soft grade wheels are used for rapid. Grinding wheels, regardless of their manufacturer, are made up of three main components: The abrasive grains act as. Grinding wheels are abrasive cutting tools. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Common usage of grinding wheels is to grind the workpiece and. Grinding Wheels Uses.

From www.youtube.com

GRINDING WHEELS 101, DIFFERENT TYPES OF GRINDING WHEELS, HOW THEY ARE Grinding Wheels Uses Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Grinding wheels are abrasive cutting tools. Soft grade wheels are used for rapid. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels, regardless of their manufacturer, are made. Grinding Wheels Uses.

From learnmechanical.com

Grinding Wheel Definition, Types, Grain, Grade, Structure, Bond Grinding Wheels Uses Grinding wheels, regardless of their manufacturer, are made up of three main components: Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. The abrasive grains distributed on the surface of the wheel form thousands of. Soft grade wheels are used for rapid. Therefore, it is an important operation that is performed on. Grinding Wheels Uses.

From lntsufin.com

What are Grinding Wheels Uses & Applications L&TSuFin Grinding Wheels Uses Aluminum oxide, silicon carbide, zirconia,. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Grinding wheels are abrasive cutting tools. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the. Grinding Wheels Uses.

From www.pinterest.co.uk

Grinding Wheel Uses, Applications and Its Types Grind, Wheel, Remove Grinding Wheels Uses Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels, regardless of their manufacturer, are made up of three main components: The abrasive grains act as. Soft grade wheels are used for rapid. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve. Grinding Wheels Uses.

From www.youtube.com

grinding wheel specifications explained (English) YouTube Grinding Wheels Uses Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. The abrasive grains act as. Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process.. Grinding Wheels Uses.

From www.slideserve.com

PPT Uses of Grinding Wheels PowerPoint Presentation, free download Grinding Wheels Uses The abrasive grains distributed on the surface of the wheel form thousands of. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Soft grade wheels are used for rapid. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Grinding wheels are. Grinding Wheels Uses.

From www.slideserve.com

PPT Different Uses of Grinding Wheels PowerPoint Presentation, free Grinding Wheels Uses Therefore, it is an important operation that is performed on almost every workpiece before finalizing the machining process. Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Grinding wheels are widely used across various industries for material removal, surface finishing, and shaping operations. Soft grade wheels are used. Grinding Wheels Uses.

From www.museoinclusivo.com

Aluminum Grinding Wheels Uses, Benefits, Differences & Safety Tips Grinding Wheels Uses Common usage of grinding wheels is to grind the workpiece and achieve the desired dimensional accuracy or improve its surface finish. Soft grade wheels are used for rapid. Aluminum oxide, silicon carbide, zirconia,. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels, regardless of their manufacturer, are made up of. Grinding Wheels Uses.