Faulty Equipment Procedure . An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. By taking necessary precautions, businesses can minimise the. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms.

from www.slideserve.com

Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. By taking necessary precautions, businesses can minimise the. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability.

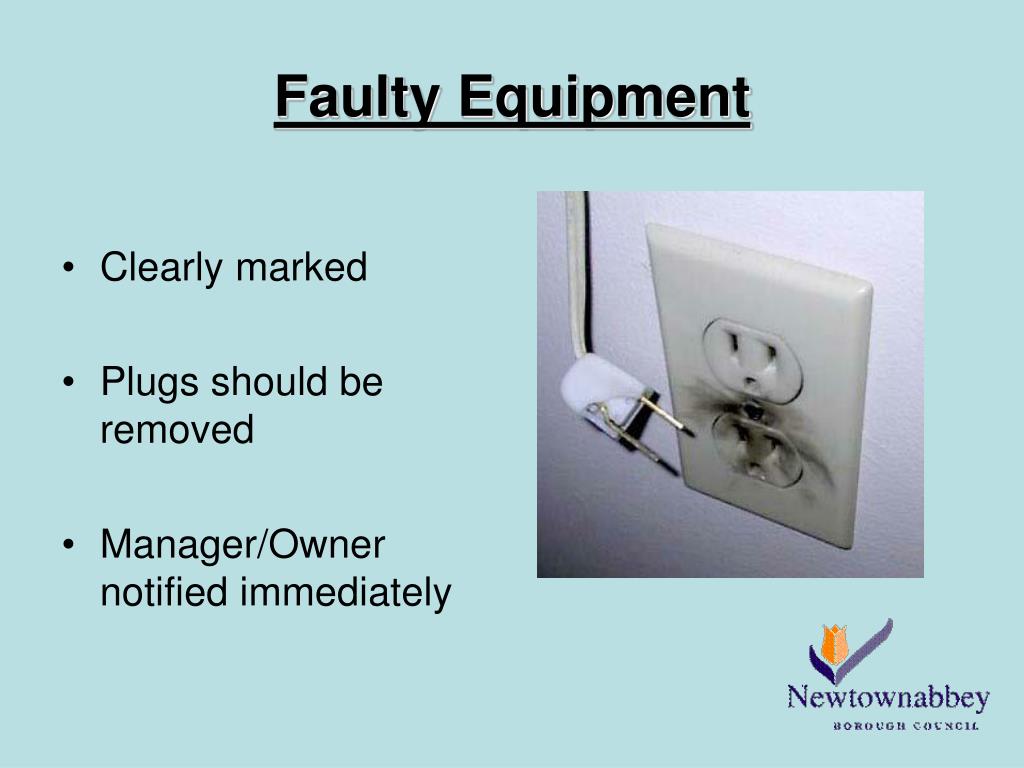

PPT HEALTH AND SAFETY IN HAIRDRESSING. PowerPoint Presentation, free

Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. By taking necessary precautions, businesses can minimise the. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and.

From www.leavittmartinlaw.com

Defective Equipment, What is It? Faulty Equipment Procedure In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. Where upkeep and. Faulty Equipment Procedure.

From www.slideserve.com

PPT OPERATE BASIC SECURITY EQUIPMENT PowerPoint Presentation, free Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. By taking necessary. Faulty Equipment Procedure.

From stock.adobe.com

Zdjęcie Stock Safe workplace yellow out of service tag placing on RCD Faulty Equipment Procedure Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective. Faulty Equipment Procedure.

From slideplayer.com

Advanced Power Protection Lecture No.1 ppt download Faulty Equipment Procedure Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective. Faulty Equipment Procedure.

From www.slideserve.com

PPT Top Four Hazards in the Construction Industry PowerPoint Faulty Equipment Procedure By taking necessary precautions, businesses can minimise the. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Implementing a defense against failure and. Faulty Equipment Procedure.

From www.slideserve.com

PPT HEALTH AND SAFETY IN HAIRDRESSING. PowerPoint Presentation, free Faulty Equipment Procedure In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. By taking necessary precautions, businesses can minimise the. An overview of fault detection and. Faulty Equipment Procedure.

From www.slideserve.com

PPT HOME SAFETY AND SCHOOL SAFETY PowerPoint Presentation, free Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. Where upkeep and. Faulty Equipment Procedure.

From wordwall.net

Action on finding Faulty Equipment Orden correcto Faulty Equipment Procedure In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. An overview of fault detection and diagnostics (fdd) and its use to improve the. Faulty Equipment Procedure.

From www.inpaspages.com

Damaged equipment process Faulty Equipment Procedure By taking necessary precautions, businesses can minimise the. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. In this blog,. Faulty Equipment Procedure.

From www.researchgate.net

fault location procedure (a) faulty feeder Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. By taking necessary precautions, businesses can minimise the. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance. Faulty Equipment Procedure.

From www.slideserve.com

PPT IT'S YOUR LAST PAIR OF EYES PowerPoint Presentation, free Faulty Equipment Procedure By taking necessary precautions, businesses can minimise the. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines. Faulty Equipment Procedure.

From www.slideserve.com

PPT Chapter 13 Legal Liability, Risk, and Insurance Management Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. By taking necessary precautions, businesses can minimise the. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense. Faulty Equipment Procedure.

From www.youtube.com

How to handle faulty equipment YouTube Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. By taking necessary precautions, businesses can minimise the. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented. Faulty Equipment Procedure.

From borderlifting.com.au

Report Faulty Equipment Sign Border Lifting & Safety Pty Ltd Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. By taking necessary precautions, businesses can minimise the. An overview of fault detection and. Faulty Equipment Procedure.

From www.accuformnmc.com

Defective Equipment OSHA Danger Safety Tag MDT272 Faulty Equipment Procedure In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. By taking necessary precautions, businesses can minimise the. Implementing a defense against failure and ensuing downtime requires a thorough understanding of. Faulty Equipment Procedure.

From www.slideserve.com

PPT Nursing Skills PowerPoint Presentation, free download ID3848408 Faulty Equipment Procedure Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. By taking necessary precautions, businesses can minimise the. Implementing a defense against failure and. Faulty Equipment Procedure.

From www.slideshare.net

Diagnose faulty circuits with simple procedures using a digital clamp meter Faulty Equipment Procedure In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay. Faulty Equipment Procedure.

From www.pinterest.com

Equipment Fault Report Template (4) PROFESSIONAL TEMPLATES Report Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. In this blog, we will explore 11 common causes of equipment failure and effective. Faulty Equipment Procedure.

From www.compliancesigns.com

Be Careful Sign Don't Use Faulty Equipment Sign OSHA Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. By taking necessary precautions, businesses can minimise the. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Implementing a defense against failure and ensuing downtime requires a thorough understanding of. Faulty Equipment Procedure.

From saladinolaw.com

Most Common Faulty Equipment on the Job Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. By taking necessary. Faulty Equipment Procedure.

From fast-pc-repair.ueniweb.com

Fixing Faulty Equipment IT Works Fast Pc Repair Computer Repair Faulty Equipment Procedure In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine. Faulty Equipment Procedure.

From www.dreamstime.com

Yellow Out of Service Tag Attached on Faulty Damage Defect of Welding Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. By taking necessary. Faulty Equipment Procedure.

From www.staylegal.net

Defective Equipment? Take It Out of Service! DDS International Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay. Faulty Equipment Procedure.

From www.mysafetysign.com

Don't Use Faulty Equipment Sign (With Graphic), SKU S8461 Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense against failure and ensuing downtime requires a thorough. Faulty Equipment Procedure.

From safetysuppliescanada.com

Caution Defective Equipment Pack of 25 TG3009 Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. By taking necessary precautions, businesses can minimise the. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. An overview of fault detection and. Faulty Equipment Procedure.

From ar.inspiredpencil.com

Defective Faulty Equipment Procedure By taking necessary precautions, businesses can minimise the. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented. Faulty Equipment Procedure.

From www.scribd.com

Faulty Equipment Register PDF Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay. Faulty Equipment Procedure.

From www.researchgate.net

Flowchart of the proposed comprehensive multicriteria faulty feeder Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay. Faulty Equipment Procedure.

From epgi.com.au

How to Spot Faulty Wiring Electrical Plumbing Group Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. By taking necessary. Faulty Equipment Procedure.

From www.grainger.com

How to Diagnose and Fix Faulty Power Tools Grainger KnowHow Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. By taking necessary precautions, businesses can minimise the. In this blog,. Faulty Equipment Procedure.

From www.slideserve.com

PPT Nursing Skills PowerPoint Presentation, free download ID3848408 Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. By taking necessary precautions, businesses can minimise the. Implementing a defense. Faulty Equipment Procedure.

From lvaccident.com

Defective Equipments Risks Law Offices of T. Bochanis Faulty Equipment Procedure In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine. Faulty Equipment Procedure.

From www.atlanticcityaquarium.com

Equipment Fault Report Template Faulty Equipment Procedure An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Where upkeep and. Faulty Equipment Procedure.

From www.slideserve.com

PPT Medical Equipment and the Safe Medical Device Act (SMDA Faulty Equipment Procedure By taking necessary precautions, businesses can minimise the. Where upkeep and repair are concerned, standard operating procedure (sop) is a documented set of guidelines put in place to lay out the steps of corrective maintenance and. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. Implementing a defense against failure and. Faulty Equipment Procedure.

From www.scribd.com

Faulty Hospital Equipment PDF Hospital Health Care Faulty Equipment Procedure Implementing a defense against failure and ensuing downtime requires a thorough understanding of machine failures and their mechanisms. In this blog, we will explore 11 common causes of equipment failure and effective strategies to prevent them. An overview of fault detection and diagnostics (fdd) and its use to improve the equipment maintenance process and boost asset reliability. By taking necessary. Faulty Equipment Procedure.