Copper Elongation Formula . Elongation (%) = 100 x ∆l/lo. Find the original and final lengths of the material specimen. A f = cross ectional area. At that stress, the onset of necking will occur and will continue until the specimen fractures. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Subtract original length from final length to obtain change in length. Tensile strength is the maximum stress a material will sustain with uniform elongation. Use the following formula to calculate elongation:

from www.youtube.com

There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Use the following formula to calculate elongation: Elongation (%) = 100 x ∆l/lo. Tensile strength is the maximum stress a material will sustain with uniform elongation. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. Subtract original length from final length to obtain change in length. At that stress, the onset of necking will occur and will continue until the specimen fractures. Find the original and final lengths of the material specimen. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. A f = cross ectional area.

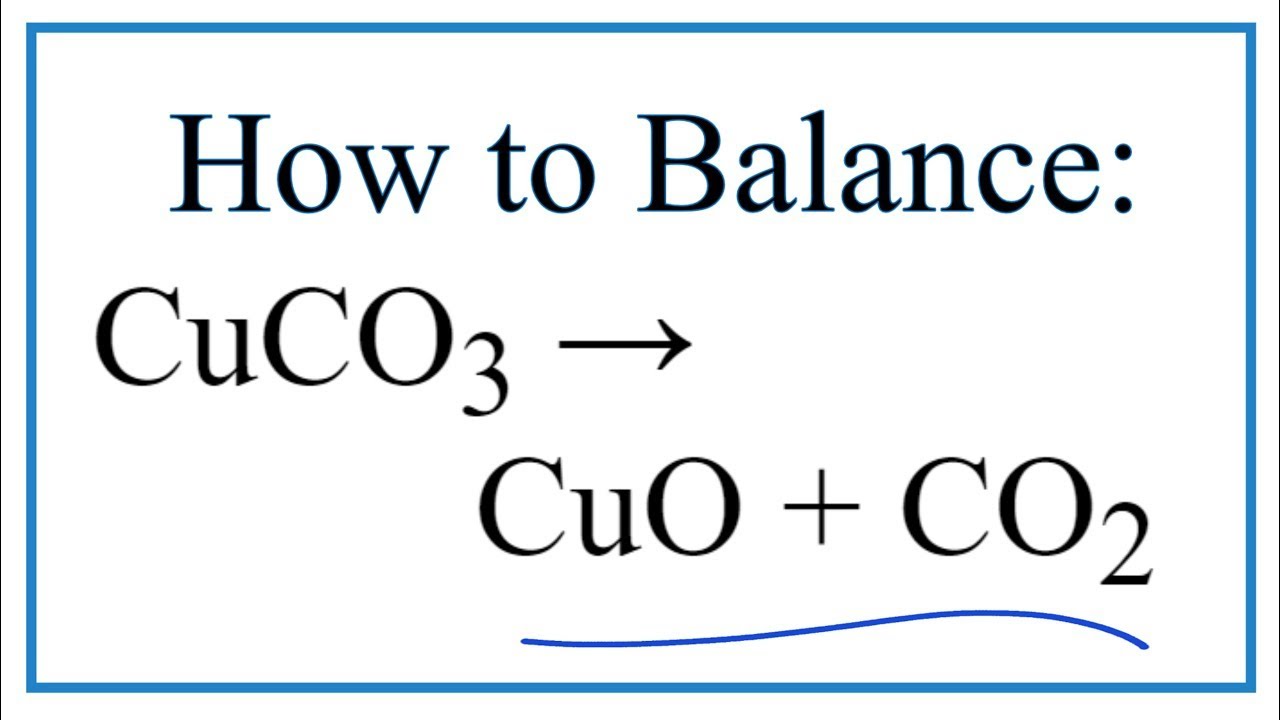

Equation for of CuCO3 Copper (II) Carbonate YouTube

Copper Elongation Formula The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. Find the original and final lengths of the material specimen. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. Elongation (%) = 100 x ∆l/lo. Subtract original length from final length to obtain change in length. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. A f = cross ectional area. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. At that stress, the onset of necking will occur and will continue until the specimen fractures. Use the following formula to calculate elongation: Tensile strength is the maximum stress a material will sustain with uniform elongation.

From www.scribd.com

Load Vs Elongation MM552 Copper PDF Copper Elongation Formula By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. Find the original and final lengths of the material specimen. A f = cross ectional area. There is a specific formula you. Copper Elongation Formula.

From ar.inspiredpencil.com

Civil Engineering Construction Formulas Copper Elongation Formula Find the original and final lengths of the material specimen. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. Use the following formula to calculate elongation: Subtract original length from final length to obtain change in length. Elongation (%) = 100 x ∆l/lo. For most alloys the tensile strength, yield strength,. Copper Elongation Formula.

From www.numerade.com

SOLVED A piece of copper with a Young's Modulus of 110 GPa originally Copper Elongation Formula A f = cross ectional area. Use the following formula to calculate elongation: Subtract original length from final length to obtain change in length. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. At that stress, the onset of necking will occur and will continue until the specimen fractures.. Copper Elongation Formula.

From www.keytometals.com

Engineering Stressstrain Curve KEY to METALS Articles Copper Elongation Formula At that stress, the onset of necking will occur and will continue until the specimen fractures. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a. Copper Elongation Formula.

From mainlinemetals.com

Metal Measurement Elongation Mainline Metals Copper Elongation Formula A f = cross ectional area. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Elongation (%) = 100 x ∆l/lo. Tensile strength is the maximum stress a material will sustain with uniform elongation. Subtract original length from final length to obtain. Copper Elongation Formula.

From www.xometry.com

Elongation at Break Definition, Calculation, Benefits, Limitations Copper Elongation Formula There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Subtract original length from final length to obtain change in length. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. By using. Copper Elongation Formula.

From copper.org

Standards & Properties Mechanical Properties of Copper and Copper Copper Elongation Formula At that stress, the onset of necking will occur and will continue until the specimen fractures. Elongation (%) = 100 x ∆l/lo. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. Tensile strength is the maximum stress a material will sustain with uniform elongation. Find the original and final lengths of. Copper Elongation Formula.

From www.researchgate.net

Tensile strength and elongation of some befree highstrength copper Copper Elongation Formula Subtract original length from final length to obtain change in length. Use the following formula to calculate elongation: At that stress, the onset of necking will occur and will continue until the specimen fractures. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. Find the original and final. Copper Elongation Formula.

From www.researchgate.net

Graph of voltage vs percentage elongation for 0.66 mm Ø CuETP and Copper Elongation Formula There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Use the following formula to calculate elongation: A f = cross ectional area. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material.. Copper Elongation Formula.

From www.slideshare.net

Simpale stress and simple strain Copper Elongation Formula At that stress, the onset of necking will occur and will continue until the specimen fractures. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed. Copper Elongation Formula.

From www.youtube.com

Example Calculating Elongation from Strain YouTube Copper Elongation Formula There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Elongation (%) = 100 x ∆l/lo. Tensile strength is the maximum stress a material will sustain with uniform elongation. The reduction of area is reported as additional information (to the percent elongation) on. Copper Elongation Formula.

From copper.org

Standards & Properties Mechanical Properties of Copper and Copper Copper Elongation Formula A f = cross ectional area. Tensile strength is the maximum stress a material will sustain with uniform elongation. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. Subtract original length from final length to obtain change in length. At that stress, the onset of necking will occur and. Copper Elongation Formula.

From www.youtube.com

Equation for of CuCO3 Copper (II) Carbonate YouTube Copper Elongation Formula By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. Find the original and final lengths of the material specimen. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. Elongation (%) = 100 x ∆l/lo. A f = cross ectional. Copper Elongation Formula.

From www.numerade.com

SOLVED Consider the copper tubes joined below using a "sweated" joint Copper Elongation Formula Tensile strength is the maximum stress a material will sustain with uniform elongation. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. At that stress, the onset of necking will occur and will continue until the specimen fractures. By using this formula, we can determine the elongation percentage,. Copper Elongation Formula.

From ahssinsights.org

Uniform Elongation AHSS Guidelines Copper Elongation Formula Elongation (%) = 100 x ∆l/lo. A f = cross ectional area. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Use the following. Copper Elongation Formula.

From www.youtube.com

Tensile's Stress, UTS Ultimate Tensile Strength, Yield, Percentage Copper Elongation Formula Elongation (%) = 100 x ∆l/lo. Find the original and final lengths of the material specimen. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. A f = cross ectional area. Use the following formula to calculate elongation: At that stress, the onset of necking will occur and will continue until. Copper Elongation Formula.

From www.coursehero.com

[Solved] A copper wire of length 3m and 1mm diameter is subjected to a Copper Elongation Formula Subtract original length from final length to obtain change in length. At that stress, the onset of necking will occur and will continue until the specimen fractures. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. There is a specific formula you can follow to find the elongation. Copper Elongation Formula.

From www.researchgate.net

Normalized resistance plotted against the elongation rate for (a Copper Elongation Formula Subtract original length from final length to obtain change in length. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. The reduction of area. Copper Elongation Formula.

From www.chegg.com

Solved We wish to produce a 3 mm diameter wire of copper Copper Elongation Formula At that stress, the onset of necking will occur and will continue until the specimen fractures. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. A f = cross ectional area. For most alloys the tensile strength, yield strength, elongation and notch. Copper Elongation Formula.

From h-o-m-e.org

Elongation Formula A Comprehensive Guide Copper Elongation Formula Tensile strength is the maximum stress a material will sustain with uniform elongation. At that stress, the onset of necking will occur and will continue until the specimen fractures. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. There is a specific formula you can follow to find the elongation at. Copper Elongation Formula.

From www.researchgate.net

The variations of the elongation and the lowest major limit of FLD for Copper Elongation Formula Use the following formula to calculate elongation: There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. At that stress, the onset of necking will occur and will continue until the specimen fractures. Tensile strength is the maximum stress a material will sustain. Copper Elongation Formula.

From h-o-m-e.org

Elongation Formula A Comprehensive Guide Copper Elongation Formula For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. Subtract original length from final length to obtain change in length. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. At that stress, the onset of necking will. Copper Elongation Formula.

From www.youtube.com

Calculate Cable Elongation Stress & Strain Example YouTube Copper Elongation Formula Tensile strength is the maximum stress a material will sustain with uniform elongation. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a. Copper Elongation Formula.

From www.researchgate.net

Calculated elongation of the securing elements in either direction (m Copper Elongation Formula A f = cross ectional area. Subtract original length from final length to obtain change in length. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. Elongation (%) = 100 x ∆l/lo. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature. Copper Elongation Formula.

From h-o-m-e.org

Elongation Formula A Comprehensive Guide Copper Elongation Formula For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. Elongation (%) = 100 x ∆l/lo. By using this formula, we can determine the elongation percentage, which indicates how. Copper Elongation Formula.

From www.copper.org

Standards & Properties Mechanical Properties of Copper and Copper Copper Elongation Formula Tensile strength is the maximum stress a material will sustain with uniform elongation. At that stress, the onset of necking will occur and will continue until the specimen fractures. Elongation (%) = 100 x ∆l/lo. Find the original and final lengths of the material specimen. Use the following formula to calculate elongation: By using this formula, we can determine the. Copper Elongation Formula.

From www.researchgate.net

Dependence of the relative elongation on the load for pure copper Copper Elongation Formula The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. Subtract original length from final length to obtain change in length. Use the following formula to calculate elongation: There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s. Copper Elongation Formula.

From www.youtube.com

What will the resultant elongation be? if E=110 GPa, Stress is 276 Mpa Copper Elongation Formula Subtract original length from final length to obtain change in length. A f = cross ectional area. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. Elongation (%) = 100 x ∆l/lo. By using this formula, we can determine the elongation percentage,. Copper Elongation Formula.

From www.nagwa.com

Question Video Writing the Equation for the Reaction at the Anode Copper Elongation Formula For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. Subtract original length from final length to obtain change in length. Find the original and final lengths of the material specimen. At that stress, the onset of necking will occur and will continue until the specimen fractures. There is. Copper Elongation Formula.

From www.youtube.com

Problem on Calculation of Total Elongation of a Bar Stress and Strain Copper Elongation Formula Subtract original length from final length to obtain change in length. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage. A f = cross ectional area. Tensile strength is the maximum stress a material will sustain with uniform elongation. For most alloys. Copper Elongation Formula.

From www.numerade.com

SOLVED Copper is put into AgNO3 solution. Write all of the half Copper Elongation Formula Tensile strength is the maximum stress a material will sustain with uniform elongation. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. There is a specific formula you can follow to find the elongation at break for a wide range of materials, and it’s normally expressed as a percentage.. Copper Elongation Formula.

From www.researchgate.net

A) Yield stress and elongation, b) yield stress and hardness of anneal Copper Elongation Formula Elongation (%) = 100 x ∆l/lo. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. Find the original and final lengths of the material specimen. Tensile strength is the maximum stress a material will sustain with uniform elongation. Subtract original length from final length to obtain change in length. For most. Copper Elongation Formula.

From www.slideserve.com

PPT Lecture 7 Mechanical Properties Of Metals PowerPoint Presentation Copper Elongation Formula A f = cross ectional area. Find the original and final lengths of the material specimen. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. For most alloys the tensile strength,. Copper Elongation Formula.

From www.researchgate.net

The stress elongation of the initial copper and aluminum alloy and the Copper Elongation Formula Find the original and final lengths of the material specimen. Elongation (%) = 100 x ∆l/lo. The reduction of area is reported as additional information (to the percent elongation) on the deformational characteristics of the material. For most alloys the tensile strength, yield strength, elongation and notch tensile strength increased in the temperature range from 295 to. At that stress,. Copper Elongation Formula.

From www.toppr.com

The total elongation of the bar, if the bar is subjected to axial Copper Elongation Formula Subtract original length from final length to obtain change in length. At that stress, the onset of necking will occur and will continue until the specimen fractures. By using this formula, we can determine the elongation percentage, which indicates how much the wire stretched before. Use the following formula to calculate elongation: Tensile strength is the maximum stress a material. Copper Elongation Formula.