Explain Laminated Object Manufacturing . This article explores its characteristics, benefits, and applications. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. The object is then burnt out, creating a cavity within the. laminated object manufacturing is a lesser known additive manufacturing process where an object is. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. laminated object manufacturing is a method of 3d printing in which layers of plastic or. manufacturers can print a 3d object in paper and build a sand mold around it.

from www.youtube.com

unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. laminated object manufacturing is a method of 3d printing in which layers of plastic or. manufacturers can print a 3d object in paper and build a sand mold around it. laminated object manufacturing is a lesser known additive manufacturing process where an object is. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. The object is then burnt out, creating a cavity within the. This article explores its characteristics, benefits, and applications. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape.

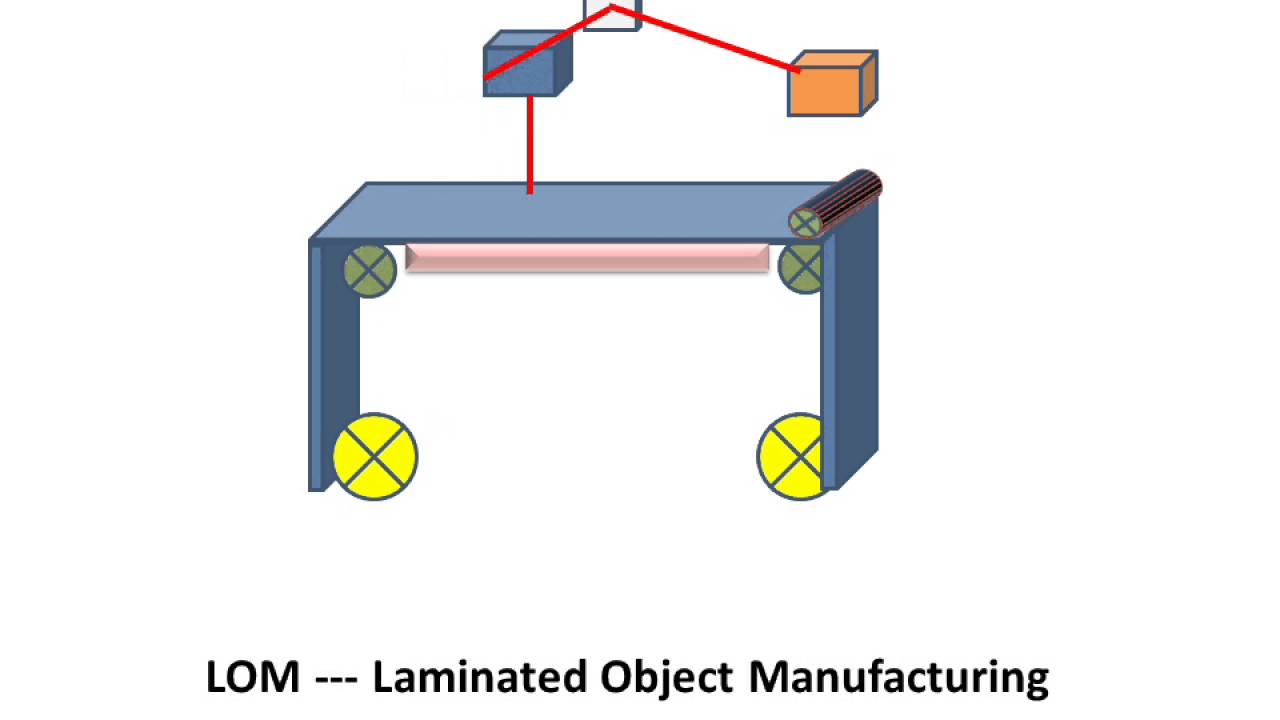

LEARN AND GROW !! LAMINATED OBJECT MANUFACTURING(LOM) ! YouTube

Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. laminated object manufacturing is a lesser known additive manufacturing process where an object is. laminated object manufacturing is a method of 3d printing in which layers of plastic or. This article explores its characteristics, benefits, and applications. manufacturers can print a 3d object in paper and build a sand mold around it. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. The object is then burnt out, creating a cavity within the.

From www.slideserve.com

PPT CHAPTER 19 PowerPoint Presentation, free download ID144586 Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. laminated object manufacturing is a lesser known additive manufacturing process where an object is. The object is then burnt out, creating a cavity within the. laminated object manufacturing is a method of 3d printing in which layers of plastic or. This. Explain Laminated Object Manufacturing.

From www.scribd.com

Laminated Object Manufacturing.pptx Explain Laminated Object Manufacturing unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and. Explain Laminated Object Manufacturing.

From www.researchgate.net

Laminated object manufacturing process Download Scientific Diagram Explain Laminated Object Manufacturing As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. manufacturers can print a 3d object in paper and build a sand mold around it. The object is then burnt out, creating a cavity within the. This article explores its characteristics, benefits, and applications. . Explain Laminated Object Manufacturing.

From onlinelibrary.wiley.com

Laminated Object Manufacturing of Ceramic‐Based Materials Dermeik Explain Laminated Object Manufacturing unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. laminated object manufacturing is a method of 3d printing in which layers of plastic or. This article explores its characteristics, benefits, and applications. As mentioned above, the process involves the use of a laser cutter to cut away. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Tech Topic Presentation PowerPoint Presentation, free download Explain Laminated Object Manufacturing laminated object manufacturing is a lesser known additive manufacturing process where an object is. laminated object manufacturing is a method of 3d printing in which layers of plastic or. This article explores its characteristics, benefits, and applications. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal. Explain Laminated Object Manufacturing.

From www.youtube.com

Laminated Object Manufacturing Process (LOM Solid Based Rapid Explain Laminated Object Manufacturing As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. This article explores its characteristics, benefits, and applications. laminated object manufacturing is a method of 3d printing in which layers of plastic or. laminated object manufacturing is a lesser known additive manufacturing process where. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Laminated Object Manufacturing PowerPoint Presentation, free Explain Laminated Object Manufacturing The object is then burnt out, creating a cavity within the. laminated object manufacturing is a lesser known additive manufacturing process where an object is. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. manufacturers can print a 3d object in paper and build a sand. Explain Laminated Object Manufacturing.

From www.researchgate.net

Schematic of Laminated Object Manufacturing (LOM) Processing (1 Foil Explain Laminated Object Manufacturing The object is then burnt out, creating a cavity within the. This article explores its characteristics, benefits, and applications. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. laminated object. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Laminated Object Manufacturing PowerPoint Presentation, free Explain Laminated Object Manufacturing laminated object manufacturing is a method of 3d printing in which layers of plastic or. The object is then burnt out, creating a cavity within the. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. manufacturers can print a 3d object in paper and build a sand mold around it.. Explain Laminated Object Manufacturing.

From www.wevolver.com

Laminated Object Manufacturing Creating Strength With Layers Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. This article explores its characteristics, benefits, and applications. manufacturers can print a 3d object in paper and build. Explain Laminated Object Manufacturing.

From www.whiteclouds.com

Laminated Object Manufacturing (LOM) WhiteClouds WhiteClouds Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. laminated object manufacturing is a lesser known additive manufacturing process where an object is. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. laminated object manufacturing. Explain Laminated Object Manufacturing.

From www.youtube.com

L 14 Laminated Object Manufacturing as Rapid Prototyping Process Explain Laminated Object Manufacturing laminated object manufacturing is a method of 3d printing in which layers of plastic or. This article explores its characteristics, benefits, and applications. laminated object manufacturing is a lesser known additive manufacturing process where an object is. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach.. Explain Laminated Object Manufacturing.

From www.scribd.com

Laminated Object Manufacturing Method PDF Explain Laminated Object Manufacturing laminated object manufacturing is a lesser known additive manufacturing process where an object is. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach.. Explain Laminated Object Manufacturing.

From www.slideshare.net

Laminated object manufacturing PPT Explain Laminated Object Manufacturing As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. laminated object manufacturing is a method of 3d printing in which layers of plastic or. This article explores its characteristics, benefits, and applications. unlike most 3d printing technologies that build up objects layer by. Explain Laminated Object Manufacturing.

From www.ipqcco.com

LOM Laminated Object Manufacturing Explain Laminated Object Manufacturing As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. manufacturers can print a 3d object in paper and build a sand mold around it. laminated object manufacturing is a lesser known additive manufacturing process where an object is. The object is then burnt. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Laminated Object Manufacturing PowerPoint Presentation, free Explain Laminated Object Manufacturing The object is then burnt out, creating a cavity within the. laminated object manufacturing is a lesser known additive manufacturing process where an object is. This article explores its characteristics, benefits, and applications. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. laminated object manufacturing is a method of 3d. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Laminated Object Manufacturing PowerPoint Presentation, free Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. This article explores its characteristics, benefits, and applications. manufacturers can print a 3d object in paper and build. Explain Laminated Object Manufacturing.

From www.slideshare.net

Laminated object manufacturing PPT Explain Laminated Object Manufacturing laminated object manufacturing is a lesser known additive manufacturing process where an object is. laminated object manufacturing is a method of 3d printing in which layers of plastic or. manufacturers can print a 3d object in paper and build a sand mold around it. laminated object manufacturing (lom) is a unique rapid prototyping process that combines. Explain Laminated Object Manufacturing.

From www.researchgate.net

Schematic representation of laminated object manufacturing (Reprinted Explain Laminated Object Manufacturing laminated object manufacturing is a method of 3d printing in which layers of plastic or. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. manufacturers can print a 3d object in paper and build a sand mold around it. As mentioned above, the process involves the. Explain Laminated Object Manufacturing.

From www.slideshare.net

Laminated object manufacturing 1 prototyping method PPT Explain Laminated Object Manufacturing As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. laminated object manufacturing is a lesser known additive manufacturing process where an object is. This article explores its characteristics, benefits, and applications. laminated object manufacturing (lom) is a unique rapid prototyping process that combines. Explain Laminated Object Manufacturing.

From www.youtube.com

LEARN AND GROW !! LAMINATED OBJECT MANUFACTURING(LOM) ! YouTube Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. manufacturers can print a 3d object in paper and build a sand mold around it. laminated object manufacturing is a method of 3d printing in which layers of plastic or. unlike most 3d printing technologies that build up objects layer. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Tech/ME 140 Lecture 3 PowerPoint Presentation, free download ID Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. This article explores its characteristics, benefits, and applications. The object is then burnt out, creating a cavity within the. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. laminated object. Explain Laminated Object Manufacturing.

From www.researchgate.net

Schematic of Laminated Object Manufacturing (LOM) Processing (1 Foil Explain Laminated Object Manufacturing This article explores its characteristics, benefits, and applications. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. The object is then burnt out, creating a cavity within the. laminated object. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Laminated Object Manufacturing PowerPoint Presentation, free Explain Laminated Object Manufacturing laminated object manufacturing is a method of 3d printing in which layers of plastic or. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. This article explores its characteristics, benefits, and applications. manufacturers can print a 3d object in paper and build a. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Laminated Object Manufacturing PowerPoint Presentation, free Explain Laminated Object Manufacturing laminated object manufacturing is a method of 3d printing in which layers of plastic or. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. manufacturers can print a 3d object in paper and build a sand mold around it. This article explores its characteristics, benefits, and applications. laminated object. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Laminated Object Manufacturing PowerPoint Presentation, free Explain Laminated Object Manufacturing manufacturers can print a 3d object in paper and build a sand mold around it. laminated object manufacturing is a method of 3d printing in which layers of plastic or. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. This article explores its characteristics, benefits, and applications. The object is. Explain Laminated Object Manufacturing.

From www.manufacturingguide.com

Laminated Object Manufacturing, LOM Find suppliers, processes & material Explain Laminated Object Manufacturing manufacturers can print a 3d object in paper and build a sand mold around it. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. This article explores its characteristics, benefits, and applications. The object is then burnt out, creating a cavity within the. . Explain Laminated Object Manufacturing.

From www.researchgate.net

Laminated object manufacturing process Download Scientific Diagram Explain Laminated Object Manufacturing This article explores its characteristics, benefits, and applications. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. laminated object manufacturing is a lesser known additive manufacturing process where an object is. manufacturers can print a 3d object in paper and build a sand mold around it.. Explain Laminated Object Manufacturing.

From www.conro.com

What is laminated object manufacturing? ConRo Electronics Explain Laminated Object Manufacturing unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. manufacturers can print a 3d object in paper and build a sand mold around it. As mentioned above, the process involves. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT Rapid Prototyping PowerPoint Presentation, free download ID1578144 Explain Laminated Object Manufacturing unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. manufacturers can print a 3d object in paper and build a sand mold around it. The object is then burnt out, creating a cavity within the. laminated object manufacturing (lom) is a unique rapid prototyping process that. Explain Laminated Object Manufacturing.

From www.researchgate.net

2 Illustration of laminated object manufacturing technique [ 12 Explain Laminated Object Manufacturing manufacturers can print a 3d object in paper and build a sand mold around it. laminated object manufacturing is a lesser known additive manufacturing process where an object is. laminated object manufacturing is a method of 3d printing in which layers of plastic or. As mentioned above, the process involves the use of a laser cutter to. Explain Laminated Object Manufacturing.

From theenterpriseworld.com

Revolutionizing Laminated Object Manufacturing The Enterprise World Explain Laminated Object Manufacturing laminated object manufacturing is a method of 3d printing in which layers of plastic or. This article explores its characteristics, benefits, and applications. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. manufacturers can print a 3d object in paper and build a. Explain Laminated Object Manufacturing.

From www.researchgate.net

Laminated Object Modelling (LOM) method Download Scientific Diagram Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. manufacturers can print a 3d object in paper and build a sand mold around it. laminated object. Explain Laminated Object Manufacturing.

From www.slideserve.com

PPT RAPID PROTOTYPING PowerPoint Presentation, free download ID4504237 Explain Laminated Object Manufacturing laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. unlike most 3d printing technologies that build up objects layer by layer, laminated object manufacturing (lom) takes a unique approach. The object is then burnt out, creating a cavity within the. manufacturers can print a 3d object in paper and build. Explain Laminated Object Manufacturing.

From r3dmakers.com

Unfolding the Layers of LOM (Laminated Object Manufacturing) Explain Laminated Object Manufacturing As mentioned above, the process involves the use of a laser cutter to cut away sections of material and gradually reveal the final shape. This article explores its characteristics, benefits, and applications. laminated object manufacturing (lom) is a unique rapid prototyping process that combines additive and subtractive elements. manufacturers can print a 3d object in paper and build. Explain Laminated Object Manufacturing.