Exhaust Manifold Shrinkage . Changing the turbo location will change your intake and exhaust piping. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). A crack at the y junction has a rather odd origin. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. In most cases, there is a sudden loss of power, especially when accelerating. Heat cycling of the manifold causes it to change shape slightly over time. The thick wall (0.25 vs. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. To this aim, through a finite element analysis, a. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher.

from kedopartsaustralia.com

The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. Heat cycling of the manifold causes it to change shape slightly over time. 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. Changing the turbo location will change your intake and exhaust piping. In most cases, there is a sudden loss of power, especially when accelerating. A crack at the y junction has a rather odd origin. To this aim, through a finite element analysis, a. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. The thick wall (0.25 vs.

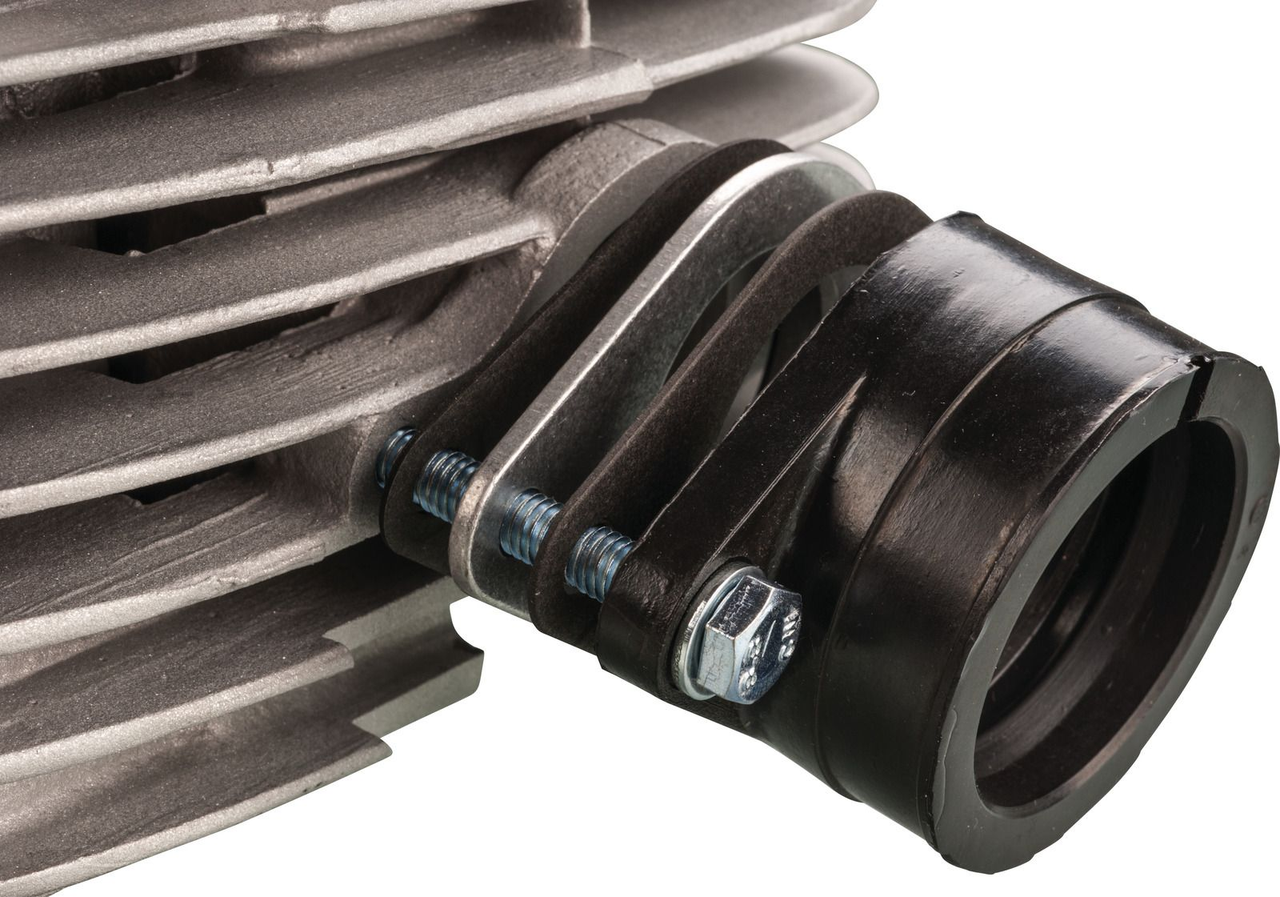

Intake Manifold Spacer 3mm for Cylinder Head, compensates shrinkage of

Exhaust Manifold Shrinkage If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. In most cases, there is a sudden loss of power, especially when accelerating. Heat cycling of the manifold causes it to change shape slightly over time. 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. To this aim, through a finite element analysis, a. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. The thick wall (0.25 vs. Changing the turbo location will change your intake and exhaust piping. A crack at the y junction has a rather odd origin.

From www.mgaguru.com

EXHAUST MANIFOLD Shrinkage And Cracks Exhaust Manifold Shrinkage A crack at the y junction has a rather odd origin. The thick wall (0.25 vs. In most cases, there is a sudden loss of power, especially when accelerating. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was. Exhaust Manifold Shrinkage.

From www.cumminsforum.com

Exhaust manifold shrinkage and other newb questions Cummins Diesel Forum Exhaust Manifold Shrinkage The thick wall (0.25 vs. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). Heat cycling of the manifold causes it to change shape slightly over time. A crack at the y junction has a rather odd origin. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the. Exhaust Manifold Shrinkage.

From www.speedhunters.com

Project Thirty Four How To Build A Single Turbo Manifold Speedhunters Exhaust Manifold Shrinkage To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. In most cases, there is a sudden loss of power, especially when accelerating. Heat cycling of the manifold causes it to change shape slightly over time. Changing the turbo location will change your intake and exhaust piping. A crack at the y. Exhaust Manifold Shrinkage.

From shopee.ph

3251mm Exhaust Shrinkage For Motorcycles Shopee Philippines Exhaust Manifold Shrinkage Changing the turbo location will change your intake and exhaust piping. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. To this aim, through a finite element analysis, a. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as. Exhaust Manifold Shrinkage.

From mgaguru.com

EXHAUST MANIFOLD Shrinkage And Cracks Exhaust Manifold Shrinkage Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). Heat cycling of the manifold causes it to change shape slightly over time. A crack at the y junction has a rather odd origin. In most cases, there is a sudden loss of power, especially when accelerating. The thick wall (0.25 vs. The failed exhaust manifolds in this study. Exhaust Manifold Shrinkage.

From ipgparts.com

Gates PowerGrip SB Hose Shrink Clamp for Radiator Hoses IPGparts Exhaust Manifold Shrinkage Heat cycling of the manifold causes it to change shape slightly over time. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). The thick wall (0.25 vs. To this aim, through a finite element analysis, a. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. Changing the turbo location. Exhaust Manifold Shrinkage.

From forums.tdiclub.com

High Failure Rates, Shrinkage and Distortion Tubular Exhaust Manifolds Exhaust Manifold Shrinkage To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. A crack at the y junction has a rather odd origin. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). If you go cheap and reuse it, you can start by centering it on the engine, and grind out the. Exhaust Manifold Shrinkage.

From mgaguru.com

EXHAUST MANIFOLD Shrinkage And Cracks Exhaust Manifold Shrinkage Heat cycling of the manifold causes it to change shape slightly over time. In most cases, there is a sudden loss of power, especially when accelerating. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. The failed exhaust manifolds in this study were designed for natural gas. Exhaust Manifold Shrinkage.

From www.semanticscholar.org

Figure 2 from Simulation of Shrinkage Defect Formation in Exhaust Exhaust Manifold Shrinkage To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. To this aim, through a finite element analysis, a. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). The thick wall (0.25 vs. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was. Exhaust Manifold Shrinkage.

From forums.tdiclub.com

High Failure Rates, Shrinkage and Distortion Tubular Exhaust Manifolds Exhaust Manifold Shrinkage The thick wall (0.25 vs. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. Changing the turbo location will change your intake and exhaust piping. To analyze the failure causes of exhaust manifold. Exhaust Manifold Shrinkage.

From kedopartsaustralia.com

Intake Manifold Spacer 3mm for Cylinder Head, compensates shrinkage of Exhaust Manifold Shrinkage Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). A crack at the y junction has a rather odd origin. The thick wall (0.25 vs. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. In most cases, there is a sudden loss of power, especially. Exhaust Manifold Shrinkage.

From www.linkedin.com

4cylinder Exhaust Manifold with Catia V5 Sarath Madavakkara Sathish Exhaust Manifold Shrinkage In most cases, there is a sudden loss of power, especially when accelerating. 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. The thick wall (0.25 vs. The failed exhaust manifolds in this study were designed for natural. Exhaust Manifold Shrinkage.

From www.semanticscholar.org

Figure 4 from Simulation of Shrinkage Defect Formation in Exhaust Exhaust Manifold Shrinkage The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. The thick wall (0.25 vs. Changing the turbo location will change your intake and exhaust piping. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. In most cases, there is. Exhaust Manifold Shrinkage.

From www.cumminsforum.com

Exhaust manifold shrinkage and other newb questions Cummins Diesel Forum Exhaust Manifold Shrinkage A crack at the y junction has a rather odd origin. In most cases, there is a sudden loss of power, especially when accelerating. Heat cycling of the manifold causes it to change shape slightly over time. 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. In the present research, crack failure analysis on a d5s. Exhaust Manifold Shrinkage.

From forums.tdiclub.com

High Failure Rates, Shrinkage and Distortion Tubular Exhaust Manifolds Exhaust Manifold Shrinkage In most cases, there is a sudden loss of power, especially when accelerating. To this aim, through a finite element analysis, a. The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. Changing the turbo location will change your intake and exhaust piping. 0.15) flange design increases strength, eliminating. Exhaust Manifold Shrinkage.

From mgaguru.com

EXHAUST MANIFOLD Shrinkage And Cracks Exhaust Manifold Shrinkage In most cases, there is a sudden loss of power, especially when accelerating. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis. Exhaust Manifold Shrinkage.

From forums.tdiclub.com

High Failure Rates, Shrinkage and Distortion Tubular Exhaust Manifolds Exhaust Manifold Shrinkage 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. The thick wall (0.25 vs. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). Heat cycling of the manifold causes it to change shape. Exhaust Manifold Shrinkage.

From forums.tdiclub.com

High Failure Rates, Shrinkage and Distortion Tubular Exhaust Manifolds Exhaust Manifold Shrinkage In most cases, there is a sudden loss of power, especially when accelerating. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. The thick wall (0.25 vs. A crack at the y junction has a rather odd origin. Heat cycling of the manifold causes it to change. Exhaust Manifold Shrinkage.

From www.semanticscholar.org

[PDF] Simulation of Shrinkage Defect Formation in Exhaust Manifold Exhaust Manifold Shrinkage To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. A crack at the y junction has a rather odd origin. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. Heat cycling of the manifold causes it to. Exhaust Manifold Shrinkage.

From kedopartsaustralia.com

Intake Manifold Spacer 3mm for Cylinder Head, compensates shrinkage of Exhaust Manifold Shrinkage The thick wall (0.25 vs. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. To this aim, through a finite element analysis, a. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was. Exhaust Manifold Shrinkage.

From www.jalopyjournal.com

Technical Exhaust manifold spreader The H.A.M.B. Exhaust Manifold Shrinkage Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). A crack at the y junction has a rather odd origin. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. The thick wall (0.25 vs. To this aim, through a finite element analysis, a. In most. Exhaust Manifold Shrinkage.

From dxoxgtybn.blob.core.windows.net

How To Shrink Exhaust Pipe at Vicente Slaughter blog Exhaust Manifold Shrinkage To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. The thick wall (0.25 vs. In most cases, there. Exhaust Manifold Shrinkage.

From forums.tdiclub.com

High Failure Rates, Shrinkage and Distortion Tubular Exhaust Manifolds Exhaust Manifold Shrinkage 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. To this aim, through a finite element analysis, a. The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. The thick wall (0.25 vs. In most cases, there is a sudden loss of power, especially when. Exhaust Manifold Shrinkage.

From diselars.ru

Каталог запасных частей к технике Valmet 612 DSIL. TURBOCHARGERINLET Exhaust Manifold Shrinkage Heat cycling of the manifold causes it to change shape slightly over time. A crack at the y junction has a rather odd origin. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. In most cases, there is a sudden loss of power, especially when accelerating.. Exhaust Manifold Shrinkage.

From www.semanticscholar.org

Figure 3 from Simulation of Shrinkage Defect Formation in Exhaust Exhaust Manifold Shrinkage In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. 0.15) flange design increases strength, eliminating warping and cracking prevalent in the factory. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. A crack. Exhaust Manifold Shrinkage.

From kedopartsaustralia.com

Intake Manifold Spacer 3mm for Cylinder Head, compensates shrinkage of Exhaust Manifold Shrinkage The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. A crack at the y junction has a rather odd origin. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. Changing the turbo location will change. Exhaust Manifold Shrinkage.

From forums.tdiclub.com

High Failure Rates, Shrinkage and Distortion Tubular Exhaust Manifolds Exhaust Manifold Shrinkage Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. The thick wall (0.25 vs. Heat cycling of the manifold causes it to change shape slightly over time. The failed exhaust manifolds in this study were designed. Exhaust Manifold Shrinkage.

From www.linkedin.com

PERKINS3778C111 Manifold Exhaust Exhaust Manifold Shrinkage Heat cycling of the manifold causes it to change shape slightly over time. In most cases, there is a sudden loss of power, especially when accelerating. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. To this aim, through a finite element analysis, a. Embrittlement rates. Exhaust Manifold Shrinkage.

From www.bid-on-equipment.com

PDC Steam Tunnel, Steam Exhaust Manifold, and Vent Blower Assembly Exhaust Manifold Shrinkage In most cases, there is a sudden loss of power, especially when accelerating. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). A crack at the y junction has a rather odd origin. If you go cheap and reuse it,. Exhaust Manifold Shrinkage.

From kedopartsaustralia.com

Intake Manifold Spacer 3mm for Cylinder Head, compensates shrinkage of Exhaust Manifold Shrinkage If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you. To this aim, through a finite element analysis, a. Heat cycling of the manifold causes it to change shape slightly over time. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged. Exhaust Manifold Shrinkage.

From dxohahasp.blob.core.windows.net

How Well Does Exhaust Wrap Work at Jennifer Cordero blog Exhaust Manifold Shrinkage To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. Changing the turbo location will change your intake and exhaust piping. The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. In the present research, crack failure analysis on a d5s. Exhaust Manifold Shrinkage.

From ar.inspiredpencil.com

Broken Exhaust Flange Exhaust Manifold Shrinkage Embrittlement rates become negligible below 600°f (315°c) or above 1000°f (540°c). The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. Changing the turbo location will change your intake and exhaust piping. A crack at the y junction has a rather odd origin. To analyze the failure causes of. Exhaust Manifold Shrinkage.

From omnidexcastings.com

Aluminum Manifolds Defect Free Casting Solutions Omnidex Exhaust Manifold Shrinkage The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. Changing the turbo location will change your intake and exhaust piping. The thick wall (0.25 vs. If you go cheap and reuse it, you can start by centering it on the engine, and grind out the holes as you.. Exhaust Manifold Shrinkage.

From www.914world.com

The largest online 914 community! Exhaust Manifold Shrinkage The failed exhaust manifolds in this study were designed for natural gas engines, of which the exhaust gas temperature was higher. To analyze the failure causes of exhaust manifold cracks in a diesel engine, experimental analysis and finite element. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first. Exhaust Manifold Shrinkage.

From www.mgaguru.com

EXHAUST MANIFOLD Shrinkage And Cracks Exhaust Manifold Shrinkage Heat cycling of the manifold causes it to change shape slightly over time. In the present research, crack failure analysis on a d5s exhaust manifold of a turbocharged engine was done in the first mode. Changing the turbo location will change your intake and exhaust piping. If you go cheap and reuse it, you can start by centering it on. Exhaust Manifold Shrinkage.