Frp Grating Banding . High tension and compression capacities enable heavy industrial loads. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. Certain applications benefit significantly from banding which. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Banding may be specified on any grating product. 2.3.2 grating panels installed over multiple spans will further. Frp eliminates rust and paint maintenance even in the.

from www.tfcomposite.com

The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Certain applications benefit significantly from banding which. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. 2.3.2 grating panels installed over multiple spans will further. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. High tension and compression capacities enable heavy industrial loads. Banding may be specified on any grating product. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm.

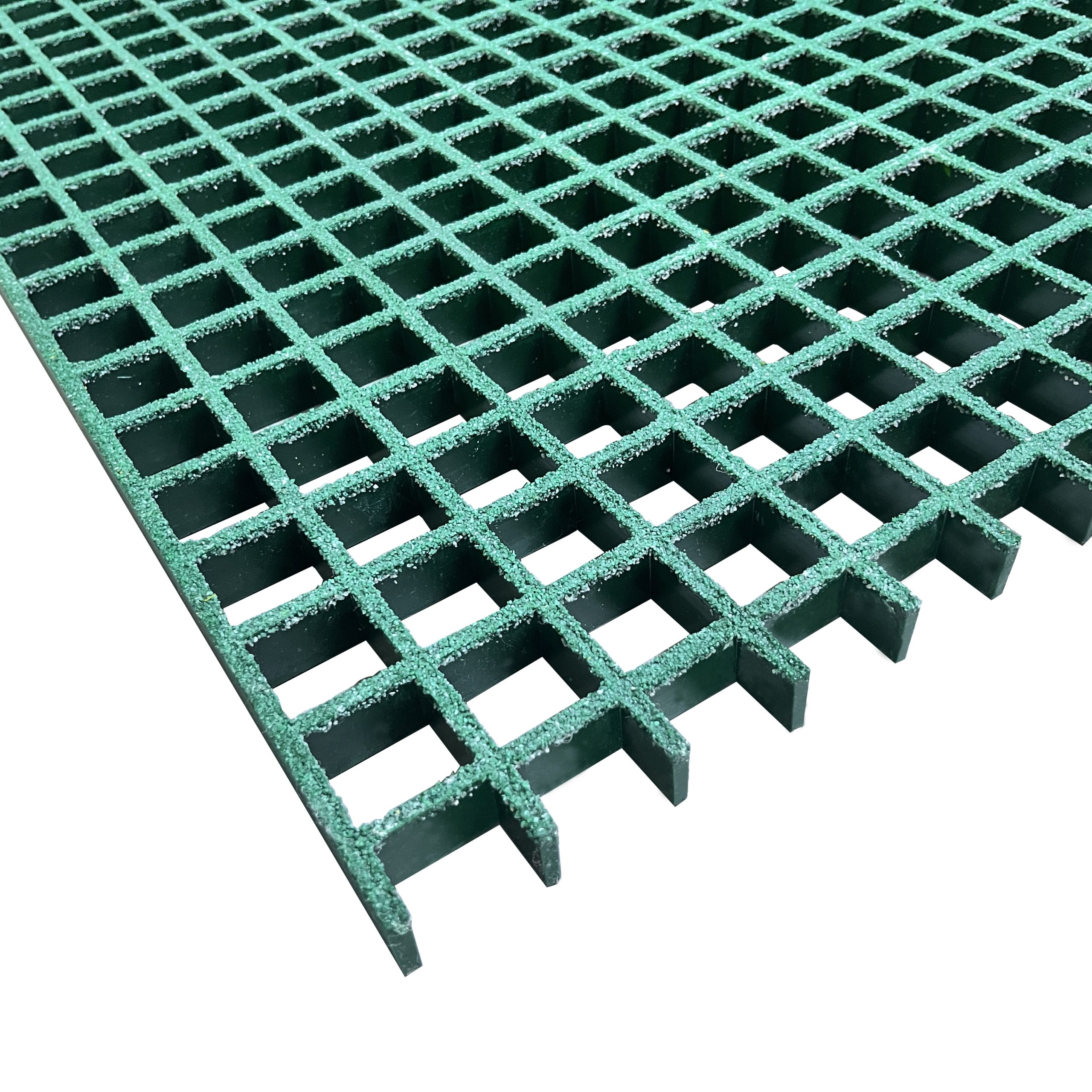

FRP Molded Grating With Gritted Surface

Frp Grating Banding 2.3.2 grating panels installed over multiple spans will further. During the banding process, a metal flat bar is welded to the open ends of the grating panel. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Certain applications benefit significantly from banding which. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Banding may be specified on any grating product. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. 2.3.2 grating panels installed over multiple spans will further. Frp eliminates rust and paint maintenance even in the. High tension and compression capacities enable heavy industrial loads. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function.

From gratingpacific.com

Banding Grating Pacific Frp Grating Banding Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. Banding may be specified on. Frp Grating Banding.

From oritec.co.id

FRP Grating is Widely Used in Various Sectors and Industries Around The Frp Grating Banding Certain applications benefit significantly from banding which. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. The polymer resin. Frp Grating Banding.

From www.indiamart.com

FRP Gratings, Size 1 Mtr X 2 Mtr X 30mm Or 40mm, Rs 6500 /per sq meter Frp Grating Banding Frp eliminates rust and paint maintenance even in the. Certain applications benefit significantly from banding which. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. Banding may be specified on any grating product. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural. Frp Grating Banding.

From www.muifatt.com.my

Fiberglass FRP Grating Frp Grating Banding 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. During the banding process, a metal flat bar is welded to the open ends of the grating panel. 2.3.2 grating panels installed over multiple spans will further. Certain applications benefit significantly. Frp Grating Banding.

From medium.com

FRP Moulded Grating A Versatile and Durable Flooring Solution by Frp Grating Banding 2.3.2 grating panels installed over multiple spans will further. High tension and compression capacities enable heavy industrial loads. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Unlike steel and aluminum. Frp Grating Banding.

From www.tfcomposite.com

FRP Molded Grating With Gritted Surface Frp Grating Banding The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. Banding may be specified on any grating product. 51mm deep molded. Frp Grating Banding.

From www.shopspecnet.com.au

FRP grating Frp Grating Banding The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Frp eliminates rust and paint maintenance even in the. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. Certain applications benefit. Frp Grating Banding.

From www.ecplaza.net

FRP Grating/GRP Grating/Fiberglass Pultruded Grating Hebei Zhengshun Frp Grating Banding The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. 2.3.2 grating panels installed over multiple spans will further. Frp eliminates rust and paint maintenance even in the. During the banding process, a metal flat bar is. Frp Grating Banding.

From gratingpacific.com

Banding Products & Features Frp Grating Banding Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. Certain applications benefit significantly from banding which. During the banding process, a metal flat bar is welded to the open ends of the grating panel. 2.3.2 grating panels installed over multiple spans will further. Permastruct® frp grating is far superior in performance and. Frp Grating Banding.

From duracomposites.com.au

GRP Grating Products Dura Composites Frp Grating Banding Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. Certain applications benefit significantly from banding which. 2.3.2 grating panels installed over multiple spans will further. High tension and compression capacities enable heavy industrial loads. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. The polymer. Frp Grating Banding.

From www.grpaustralia.com.au

FRP Moulded Grating 38x38 Mesh FRP Grating and Treads Frp Grating Banding Certain applications benefit significantly from banding which. High tension and compression capacities enable heavy industrial loads. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. Banding, commonly. Frp Grating Banding.

From www.compositeengineering.com.au

MaxiGRATE FRP Grating Design & Manufacture Frp Grating Banding During the banding process, a metal flat bar is welded to the open ends of the grating panel. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. Frp eliminates rust and paint maintenance even in the. Unlike steel and aluminum gratings it is not necessary to edge band molded. Frp Grating Banding.

From www.indiamart.com

FRP Heavy Duty Grating, For Industrial at Rs 3200/square meter in Frp Grating Banding Banding may be specified on any grating product. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Frp eliminates rust and paint maintenance even in the. Certain applications benefit significantly from banding which. Banding, commonly required on steel grating panels,. Frp Grating Banding.

From gratingpacific.com

Banding Grating Pacific Frp Grating Banding Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. Frp eliminates rust and paint maintenance even in the. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. Certain applications benefit significantly from banding which. High tension and compression capacities enable heavy industrial. Frp Grating Banding.

From frp.co.nz

Steel Grating Glossary FRP Products Frp Grating Banding Certain applications benefit significantly from banding which. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. During the banding process, a metal flat bar is welded to the open ends of the grating panel. High tension and compression capacities enable heavy industrial loads. Banding may be specified on any grating product. Banding, commonly required on steel grating. Frp Grating Banding.

From qinghuiplastic.en.made-in-china.com

Customize FRP Grating Manufacturer Fiber Glass Grating FRP Fibreglass Frp Grating Banding 2.3.2 grating panels installed over multiple spans will further. Frp eliminates rust and paint maintenance even in the. Banding may be specified on any grating product. Certain applications benefit significantly from banding which. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. During the banding process, a metal flat bar is welded to the open ends. Frp Grating Banding.

From www.chemstoregroup.com.au

FRP Grating Frp Grating Banding During the banding process, a metal flat bar is welded to the open ends of the grating panel. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Frp eliminates rust and paint maintenance even in the. 2.3.2 grating panels installed over multiple spans will further. 51mm deep molded gratings are acceptable for spans from 1219mm to. Frp Grating Banding.

From www.compositeengineering.com.au

FRP Grating, a versatile solution Composite Engineering Frp Grating Banding Frp eliminates rust and paint maintenance even in the. Banding may be specified on any grating product. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. 2.3.2 grating panels installed over multiple spans will further. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. Banding,. Frp Grating Banding.

From www.indiamart.com

CUSTOMIZED FRP GRATING at Rs 200/square meter FRP Gratings in Frp Grating Banding Banding may be specified on any grating product. Frp eliminates rust and paint maintenance even in the. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for. Frp Grating Banding.

From grmcp.com

GRM FRP Grating FRP Grating (936) 4415910 Call Us! Frp Grating Banding Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. High tension and compression capacities enable heavy industrial loads. 2.3.2 grating panels installed over multiple spans will further. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. Frp eliminates rust and paint maintenance. Frp Grating Banding.

From www.compositeengineering.com.au

FRP Grating Design & Manufacture MaxiGRATE FRP Grating Frp Grating Banding Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. High tension and compression capacities enable heavy industrial loads. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Certain applications benefit significantly from banding which. Unlike steel and. Frp Grating Banding.

From nationalgrating.com

HLC FRP Grating National Grating Frp Grating Banding High tension and compression capacities enable heavy industrial loads. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Certain applications benefit significantly from banding which. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. 2.3.2 grating panels. Frp Grating Banding.

From frpengineering.net

Floor Grating FRP Engineering Perth, Western Australia Frp Grating Banding Certain applications benefit significantly from banding which. 2.3.2 grating panels installed over multiple spans will further. High tension and compression capacities enable heavy industrial loads. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. During the banding process, a metal flat. Frp Grating Banding.

From www.grpaustralia.com.au

FRP Moulded Grating 38x38 Mesh FRP Grating and Treads Frp Grating Banding The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Certain applications benefit significantly from banding which. 2.3.2 grating panels installed over multiple spans will further. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. Unlike steel and aluminum gratings it is not necessary to edge. Frp Grating Banding.

From www.warlimedia.com

FRP Gratings Manufacturer Frp Grating Banding Certain applications benefit significantly from banding which. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. 2.3.2 grating panels installed over multiple spans will further. Banding may be specified on any grating product. During the banding process, a metal flat bar is welded to. Frp Grating Banding.

From www.ecosinergi.com

Pengertian dan Tips Membeli FRP Molded Grating Frp Grating Banding Certain applications benefit significantly from banding which. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. 2.3.2 grating panels installed over multiple spans will further. During the banding process, a metal flat bar is welded to the open ends of. Frp Grating Banding.

From www.innovatematerials.com

FRP Molded Grating Innovate Materials FRP gratings, FRP Molded Mesh Frp Grating Banding 2.3.2 grating panels installed over multiple spans will further. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform the same function. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Certain applications. Frp Grating Banding.

From www.muifatt.com.my

Fiberglass FRP Grating Frp Grating Banding The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Frp eliminates rust and paint maintenance even in the. Banding may be specified on any grating product. 2.3.2 grating panels installed over multiple spans will further. During the banding process, a metal flat bar is welded to the open ends of the grating panel. 51mm deep molded. Frp Grating Banding.

From www.classicfibreglassindustries.com

1. FRP Gratings Classic Fibreglass Industries, Vadodara Frp Grating Banding Certain applications benefit significantly from banding which. 2.3.2 grating panels installed over multiple spans will further. Banding may be specified on any grating product. Frp eliminates rust and paint maintenance even in the. High tension and compression capacities enable heavy industrial loads. Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. Unlike steel. Frp Grating Banding.

From www.liweidafrp.com

FRP Molded Grating Professional manufacturer of GRP grating Frp Grating Banding Certain applications benefit significantly from banding which. 2.3.2 grating panels installed over multiple spans will further. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. During the banding process, a metal flat bar is welded to the open ends of the grating panel. 51mm deep molded gratings are acceptable for spans from. Frp Grating Banding.

From frpengineering.net

New Floor Grating FRP Engineering Australia Frp Grating Banding The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. Frp eliminates rust and paint maintenance even in the. Banding may be specified on any grating product. During the banding process, a metal flat bar is welded to the open ends of the grating panel.. Frp Grating Banding.

From co.pinterest.com

FRP moulded grating "Edge Banding" Frp Grating Banding During the banding process, a metal flat bar is welded to the open ends of the grating panel. The polymer resin matrix surrounding the embedded glass fibers provides complete corrosion protection. Banding may be specified on any grating product. Certain applications benefit significantly from banding which. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings. Frp Grating Banding.

From www.gajafiberglass.com

FRP Grating, Apa Itu? Ini Penggunaan & Penjelasannya 2023 Frp Grating Banding During the banding process, a metal flat bar is welded to the open ends of the grating panel. Frp eliminates rust and paint maintenance even in the. Certain applications benefit significantly from banding which. High tension and compression capacities enable heavy industrial loads. Banding, commonly required on steel grating panels, is not required for fiberglass panels, as cross rods perform. Frp Grating Banding.

From www.indiamart.com

FRP Molded Floor Grating at Rs 1500/square meter FRP Gratings ID Frp Grating Banding Permastruct® frp grating is far superior in performance and life cycle cost compared to traditional materials. 51mm deep molded gratings are acceptable for spans from 1219mm to 1372mm. During the banding process, a metal flat bar is welded to the open ends of the grating panel. Certain applications benefit significantly from banding which. Unlike steel and aluminum gratings it is. Frp Grating Banding.

From interstategratings.com

Grating 101 Interstate Gratings Frp Grating Banding Banding may be specified on any grating product. Unlike steel and aluminum gratings it is not necessary to edge band molded gratings for structural reasons. During the banding process, a metal flat bar is welded to the open ends of the grating panel. High tension and compression capacities enable heavy industrial loads. Frp eliminates rust and paint maintenance even in. Frp Grating Banding.