Sandvik Coromant Material Codes . Regardless of component size, material or design, the insert grade you use can make all the difference in your. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. In this application guide, we show you how to achieve threading success with sandvik coromant tools. The cutter selected has a 45. Operation and the coromant material classification (cmc) code is needed. Our aim is to help you to choose the right. Sandvik coromant grade and geometry selection guide. Use the filter to easily find. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online.

from www.grainger.com

Sandvik coromant grade and geometry selection guide. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Operation and the coromant material classification (cmc) code is needed. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. In this application guide, we show you how to achieve threading success with sandvik coromant tools. The cutter selected has a 45. Our aim is to help you to choose the right. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,.

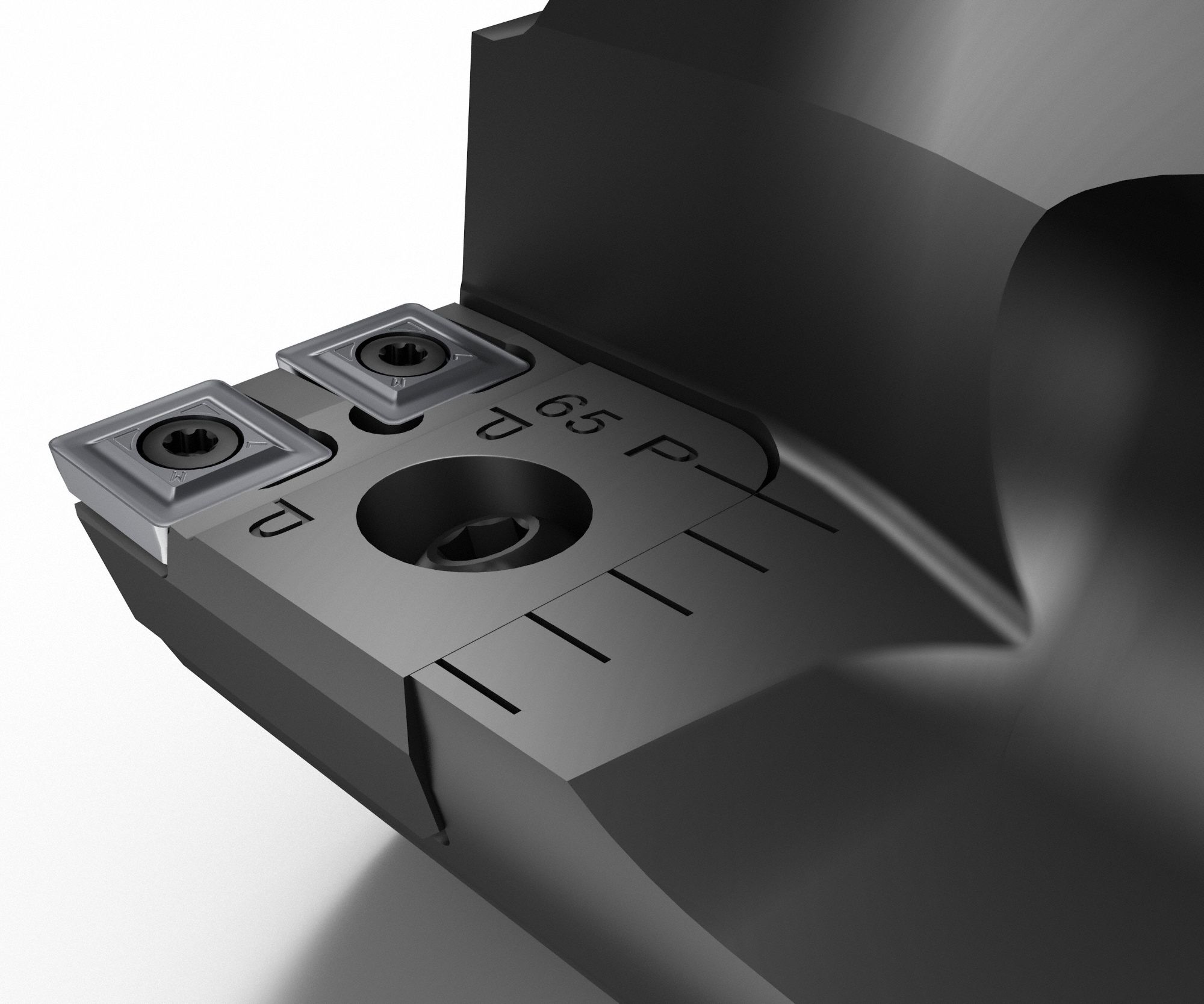

SANDVIK COROMANT Drilling Tool, CoroDrill, 880D3900L4003 4PVR3880

Sandvik Coromant Material Codes When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Use the filter to easily find. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Sandvik coromant grade and geometry selection guide. Our aim is to help you to choose the right. The cutter selected has a 45. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. In this application guide, we show you how to achieve threading success with sandvik coromant tools. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Operation and the coromant material classification (cmc) code is needed. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Regardless of component size, material or design, the insert grade you use can make all the difference in your.

From toolcentre.co.za

Sandvik Coromant 2S3422000100PB 1730 CoroMill™ Plura solid carbide Sandvik Coromant Material Codes Our aim is to help you to choose the right. Operation and the coromant material classification (cmc) code is needed. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. The cutter selected has a 45. Regardless of component size, material or design, the insert grade you use can make all the difference in your. When machining materials,. Sandvik Coromant Material Codes.

From www.autodesk.com

Fusion 360 and Sandvik Coromant Fusion 360 Sandvik Coromant Material Codes Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Our aim is to help you to choose the right. Operation and the coromant material classification (cmc) code is needed. The cutter selected has a 45. Use the filter to easily find. Regardless of component size, material or design, the insert grade you use can make all the difference. Sandvik Coromant Material Codes.

From www.stellarindustrial.com

Stellar Industrial Sandvik Coromant 6612767 TMax® P Turning Insert Sandvik Coromant Material Codes Use the filter to easily find. In this application guide, we show you how to achieve threading success with sandvik coromant tools. Operation and the coromant material classification (cmc) code is needed. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Choose workpiece material (iso p/steel, iso m/stainless steel, iso. Sandvik Coromant Material Codes.

From www.amazon.com

Sandvik Coromant Carbide Grv Insert, N151.3A097254G1125 Sandvik Coromant Material Codes Use the filter to easily find. Sandvik coromant grade and geometry selection guide. Operation and the coromant material classification (cmc) code is needed. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Download sandvik coromant’s catalogues and handbooks as. Sandvik Coromant Material Codes.

From www.ftfarfan.com

Sandvik Coromant FT Farfan Limited Sandvik Coromant Material Codes Regardless of component size, material or design, the insert grade you use can make all the difference in your. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Our. Sandvik Coromant Material Codes.

From dokumen.tips

(PDF) 36951259 Sandvik Material Cross Ref List DOKUMEN.TIPS Sandvik Coromant Material Codes When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Use the filter to easily find. The cutter selected has a 45. Sandvik coromant grade and geometry selection guide. Sandvik coromant has used the cmc code system (coromant material classification) to identify and. Sandvik Coromant Material Codes.

From www.sandvik.coromant.com

Sandvik Coromant introduces new brand identity Sandvik Coromant Material Codes Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. The cutter selected has a 45. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. Sandvik coromant grade and geometry selection guide. Operation and the coromant material classification (cmc) code is needed. Use. Sandvik Coromant Material Codes.

From www.sandvik.coromant.com

Prepared for the future Sandvik Coromant Capto and coolant applied in Sandvik Coromant Material Codes Sandvik coromant grade and geometry selection guide. Operation and the coromant material classification (cmc) code is needed. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Regardless of component size, material or design, the insert grade you use can make all the difference in your.. Sandvik Coromant Material Codes.

From www.mscdirect.com

Sandvik Coromant Milling Insert RCKT 13 04 00PM 4340 4340, Solid Sandvik Coromant Material Codes Our aim is to help you to choose the right. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Sandvik coromant grade and geometry selection guide. Sandvik. Sandvik Coromant Material Codes.

From www.mscdirect.com

Sandvik Coromant Grooving Insert N151.3304G 1125, Solid Carbide Sandvik Coromant Material Codes When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. Our aim is to help you to choose the right. Sandvik coromant grade and geometry selection guide. The cutter selected has. Sandvik Coromant Material Codes.

From webshop.industriacenter.fi

Sandvik Coromant MACR 3 250T 1025 CoroCut® XS katkaisuterä Sandvik Coromant Material Codes Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Operation and the coromant material classification (cmc) code is needed. The cutter selected has a 45. Sandvik coromant grade and geometry selection guide. Use the filter to easily find. Our aim is to help you to choose the right. Regardless of component size, material or design, the insert grade. Sandvik Coromant Material Codes.

From mans.io

Sandvik Coromant (SANF) 6198209 download instruction manual pdf Sandvik Coromant Material Codes Operation and the coromant material classification (cmc) code is needed. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. In this application guide, we show you how to achieve threading success with sandvik coromant tools. Our aim is to help you to choose the right. Sandvik coromant has used the cmc code system (coromant material classification) to. Sandvik Coromant Material Codes.

From www.stellarindustrial.com

Stellar Industrial Sandvik Coromant 5733219 TMax® 1Sided Turning Sandvik Coromant Material Codes The cutter selected has a 45. Operation and the coromant material classification (cmc) code is needed. Sandvik coromant grade and geometry selection guide. Use the filter to easily find. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Download sandvik coromant’s catalogues and handbooks as. Sandvik Coromant Material Codes.

From edu.svet.gob.gt

Sandvik Ddjnr 2525m 15 edu.svet.gob.gt Sandvik Coromant Material Codes Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. In this application guide, we show you how to achieve threading success with sandvik coromant tools. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Use the filter to easily find. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast. Sandvik Coromant Material Codes.

From 911tooling.com

SANDVIK Coromant SPGN 322 09 03 08 H20 K20 Lathe Mill Carbide Inserts Sandvik Coromant Material Codes Regardless of component size, material or design, the insert grade you use can make all the difference in your. Use the filter to easily find. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety. Sandvik Coromant Material Codes.

From mavink.com

Tabla Aceros Sandvik Sandvik Coromant Material Codes Operation and the coromant material classification (cmc) code is needed. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. In this application guide, we show you how to achieve threading success with sandvik coromant tools. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Sandvik coromant has used the cmc. Sandvik Coromant Material Codes.

From www.myxxgirl.com

Sandvik Material Classification Chart My XXX Hot Girl Sandvik Coromant Material Codes When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Use the filter to easily find. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety. Sandvik Coromant Material Codes.

From www.amazon.de

Sandvik Coromant 266RL22V381A0402E 1125 PVD beschichtetes Vollkarbid Sandvik Coromant Material Codes Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Use the filter to easily find. The cutter selected has a 45. Our aim is to help you to choose the right. Sandvik coromant has used the cmc code system. Sandvik Coromant Material Codes.

From www.ebay.com

SANDVIK COROMANT TURNING INSERT CNGN 12 04 08T01020 650 QTY 10 eBay Sandvik Coromant Material Codes Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. The cutter selected has a 45. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Operation and the coromant material classification (cmc) code is needed. When machining materials, the most suitable cutting tool material. Sandvik Coromant Material Codes.

From www.mscdirect.com

Sandvik Coromant Grooving Insert N151.3507P 1125, Solid Carbide Sandvik Coromant Material Codes Regardless of component size, material or design, the insert grade you use can make all the difference in your. Use the filter to easily find. In this application guide, we show you how to achieve threading success with sandvik coromant tools. Sandvik coromant grade and geometry selection guide. When machining materials, the most suitable cutting tool material (grade) and insert. Sandvik Coromant Material Codes.

From dansdiscounttools.com

Sandvik Coromant Carbide Milling Insert 690100510MPSL S40T Sandvik Coromant Material Codes Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. Our aim is to help you to choose the right. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. In this application guide, we show you how to achieve threading success with sandvik coromant tools. The cutter selected has a 45. Regardless of component size, material. Sandvik Coromant Material Codes.

From www.amazon.co.uk

Sandvik Coromant R210125Q4014M CoroMill 210 face milling cutter Sandvik Coromant Material Codes Use the filter to easily find. Our aim is to help you to choose the right. Regardless of component size, material or design, the insert grade you use can make all the difference in your. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. In this application guide, we show you how to. Sandvik Coromant Material Codes.

From www.machinetoolsolutions.com.au

SANDVIK COROMANT — MACHINE TOOL SOLUTIONS PTY. LTD. Sandvik Coromant Material Codes In this application guide, we show you how to achieve threading success with sandvik coromant tools. Operation and the coromant material classification (cmc) code is needed. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast. Sandvik Coromant Material Codes.

From www.fabricatingandmetalworking.com

Sandvik Coromant Introduces new Brand Identity Fabricating and Sandvik Coromant Material Codes In this application guide, we show you how to achieve threading success with sandvik coromant tools. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Sandvik coromant grade and geometry selection guide. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. The cutter selected has a 45. When. Sandvik Coromant Material Codes.

From www.grainger.com.mx

SANDVIK COROMANT Inserto para Roscado,CXS06TH160UN Herramientas para Sandvik Coromant Material Codes Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Sandvik coromant grade and geometry selection guide. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. Use the filter to easily find. The cutter selected has a 45. In this application guide, we show. Sandvik Coromant Material Codes.

From www.grainger.com

SANDVIK COROMANT, DNMG Insert, Neutral, Turning Insert 6KZV7DNMG 431 Sandvik Coromant Material Codes Download sandvik coromant’s catalogues and handbooks as pdf or view publications online. Use the filter to easily find. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Sandvik coromant grade and geometry selection guide. The cutter selected has a 45. Our aim is to help. Sandvik Coromant Material Codes.

From www.mscdirect.com

Sandvik Coromant Turning Inserts; Insert Style VNMG ; Insert Size Sandvik Coromant Material Codes Our aim is to help you to choose the right. In this application guide, we show you how to achieve threading success with sandvik coromant tools. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. When machining materials, the most suitable cutting tool material (grade). Sandvik Coromant Material Codes.

From webshop.industriacenter.fi

Sandvik Coromant DCMW11T304S01020E CB20 CoroTurn® 107 sorvausterä Sandvik Coromant Material Codes Sandvik coromant grade and geometry selection guide. The cutter selected has a 45. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Our aim is to help you to choose the right. Regardless of component size, material or design, the insert grade you use can. Sandvik Coromant Material Codes.

From webshop.industriacenter.fi

Sandvik Coromant N151.2800605P 1125 TMax® QCut muotosorvausterä Sandvik Coromant Material Codes Sandvik coromant grade and geometry selection guide. Regardless of component size, material or design, the insert grade you use can make all the difference in your. Use the filter to easily find. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Operation and the coromant. Sandvik Coromant Material Codes.

From www.grainger.com

SANDVIK COROMANT Drilling Tool, CoroDrill, 880D3900L4003 4PVR3880 Sandvik Coromant Material Codes Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. In this application guide, we show you how to achieve threading success with sandvik coromant tools. Sandvik coromant grade and. Sandvik Coromant Material Codes.

From www.directools.com

SANC 01671 Sandvik Coromant 5731483 TMax P Turning Insert, ANSI Code Sandvik Coromant Material Codes The cutter selected has a 45. Sandvik coromant grade and geometry selection guide. Regardless of component size, material or design, the insert grade you use can make all the difference in your. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. In. Sandvik Coromant Material Codes.

From www.penntoolco.com

Sandvik Coromant VBMT332MR 2025 Carbide Turning Insert TiCN/AI2O3/TiN Sandvik Coromant Material Codes Choose workpiece material (iso p/steel, iso m/stainless steel, iso k/cast iron,. The cutter selected has a 45. Sandvik coromant grade and geometry selection guide. Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. Download sandvik coromant’s catalogues and handbooks as pdf or view publications online.. Sandvik Coromant Material Codes.

From toolcentre.co.za

Sandvik Coromant PTGNR 2020K 16 TMax™ P shank tool for turning Sandvik Coromant Material Codes Regardless of component size, material or design, the insert grade you use can make all the difference in your. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Operation and the coromant material classification (cmc) code is needed. The cutter selected has a 45. Choose workpiece material (iso p/steel, iso m/stainless steel, iso. Sandvik Coromant Material Codes.

From bceweb.org

Iso Material Grade Chart A Visual Reference of Charts Chart Master Sandvik Coromant Material Codes Sandvik coromant has used the cmc code system (coromant material classification) to identify and describe materials from a variety of suppliers, standards and markets. In this application guide, we show you how to achieve threading success with sandvik coromant tools. Our aim is to help you to choose the right. Operation and the coromant material classification (cmc) code is needed.. Sandvik Coromant Material Codes.

From webshop.industriacenter.fi

Sandvik Coromant 1K2332000050NB H10F Täyskovametallinen CoroMill Sandvik Coromant Material Codes Regardless of component size, material or design, the insert grade you use can make all the difference in your. Use the filter to easily find. When machining materials, the most suitable cutting tool material (grade) and insert geometry for each workpiece. Our aim is to help you to choose the right. Download sandvik coromant’s catalogues and handbooks as pdf or. Sandvik Coromant Material Codes.