Inspection Gauge Design . Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. For the feature to pass. The gage is represented in green,. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Below is an example of a functional gage. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear.

from www.semanticscholar.org

Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. The gage is represented in green,. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. For the feature to pass. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Below is an example of a functional gage.

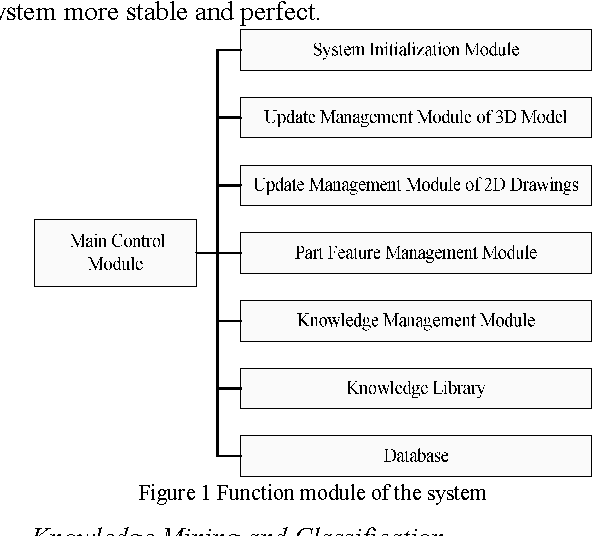

Figure 1 from Research on KnowledgeReuseBased Windshield Inspection

Inspection Gauge Design Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Below is an example of a functional gage. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. The gage is represented in green,. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. For the feature to pass. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear.

From lasardfixtures.com

CMM Inspection Lasard Fixture and Gauge Ltd. Inspection Gauge Design Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. The gage is represented in green,. For the feature to pass. Gauges •. Inspection Gauge Design.

From phoenixsystempune.com

Inspection Gauges Inspection Gauge Design Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Below is an example of a functional gage. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. The gage is represented in. Inspection Gauge Design.

From copeprecision.co.uk

Inspection Gauges & Fixtures Cope Precision Inspection Gauge Design Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. The gage is represented in green,. A functional gage can inspect parts quickly and. Inspection Gauge Design.

From www.johnsongage.com

Internal Thread Inspection Systems Johnson Gage Inspection Gauge Design Below is an example of a functional gage. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified.. Inspection Gauge Design.

From www.walmart.com

ESTINK CAM Gauge,Welder Inspection Gauge,Welding Gauge Stainless Steel Inspection Gauge Design Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. Below is an example of a functional gage. Gauges • gauges are inspection tool of. Inspection Gauge Design.

From www.broad-world.com

Inspection Gauge Produced By Steel Processing Company BroadWorld Inspection Gauge Design The gage is represented in green,. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. For the feature to pass. Below is. Inspection Gauge Design.

From www.ultratoolmfg.com

Customized gauges establish design and quality standards for metal Inspection Gauge Design Below is an example of a functional gage. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. For the feature to pass. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Limit gauges do not determine the actual value. Inspection Gauge Design.

From www.researchgate.net

Pipeline inspection gauge capsule with different types of sensor Inspection Gauge Design Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Below is an example of a functional gage. The gage is represented in green,. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Limit gauges do not determine. Inspection Gauge Design.

From www.indiamart.com

Inspection Gauges Fixture at Rs 10000/piece Inspection Gauges in Pune Inspection Gauge Design A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. For the feature to pass. Visual inspection gauges, also known as appearance standard gauges and. Inspection Gauge Design.

From spectooling.com

Diameter Inspection Gauge Specialist Tooling Technologies LTD Inspection Gauge Design Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the. Inspection Gauge Design.

From www.kintek.it

Inspection Gauges Kintek Inspection Gauge Design The gage is represented in green,. Below is an example of a functional gage. For the feature to pass. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects. Inspection Gauge Design.

From www.researchgate.net

(PDF) MultiDiameter Pipeline Inspection Gauge for Lang Distance Inspection Gauge Design The gage is represented in green,. Below is an example of a functional gage. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of. Inspection Gauge Design.

From www.phdata.io

How to Use the Gauge Chart Template phData Inspection Gauge Design Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Below is an example of a functional gage. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear.. Inspection Gauge Design.

From www.indiamart.com

Inspection Gauges at Rs 7000/unit पेंट इंस्पेक्शन गेज in Gurgaon ID Inspection Gauge Design Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. The gage is represented in green,. Below is an example of a functional gage.. Inspection Gauge Design.

From www.greensladeandcompany.com

Custom Gages Specialty Gages Fastener Inspection Equipment Design Inspection Gauge Design The gage is represented in green,. Below is an example of a functional gage. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Visual inspection gauges, also known as appearance standard. Inspection Gauge Design.

From www.indiamart.com

Checking Gauges Designing Service Stamp Inspection Gauge Design Inspection Gauge Design The gage is represented in green,. Below is an example of a functional gage. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Limit gauges do not determine. Inspection Gauge Design.

From www.kintek.it

Inspection Gauges Kintek Inspection Gauge Design Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the. Inspection Gauge Design.

From www.slideserve.com

PPT Gauge Design PowerPoint Presentation, free download ID7014427 Inspection Gauge Design Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Below is an example of a functional gage. Gauges • gauges are inspection tool of rigid design,. Inspection Gauge Design.

From www.semanticscholar.org

Figure 1 from Research on KnowledgeReuseBased Windshield Inspection Inspection Gauge Design Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. The gage is represented in green,. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Limit gauges do not determine the actual value of. Inspection Gauge Design.

From toolsfoundary.com

1pc Silver Bridge Cam Gauge Gage Test Ulnar 2"/ 50mm Mayitr Stainless Inspection Gauge Design Below is an example of a functional gage. For the feature to pass. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing. Inspection Gauge Design.

From www.tradeindia.com

Inspection Gauge For Measuring at 5000.00 INR in Ahmedabad Raghav Inspection Gauge Design Below is an example of a functional gage. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. For the feature to pass. The gage is represented in green,. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Limit gauges. Inspection Gauge Design.

From www.walmart.ca

Seam Inspection Gauge,Multifunction Weld Gauge Welder Weld Inspection Inspection Gauge Design Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. Below is an example of a functional gage. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. A functional gage can inspect parts. Inspection Gauge Design.

From www.universalhardnesstester.com

Stainless Steel Easy to Read Digital Welding Inspection Gauges with Inspection Gauge Design A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. For the feature to pass. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used. Inspection Gauge Design.

From www.qualtechproductsindustry.co.uk

Professional Paint Inspection Gauge ASTM D4138, BS EN ISO 2409, ISO 2808 Inspection Gauge Design Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Below is an example of a functional gage. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. A functional gage can inspect. Inspection Gauge Design.

From united-tool.com

PD Inspection Gauges United Tool Supply Inspection Gauge Design A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. The gage is represented in green,. Below is an example of a functional gage. Limit. Inspection Gauge Design.

From www.pinterest.com

121/4 Standard & Top Paint Inspection Gauge Gauges Inspection Gauge Design The gage is represented in green,. Below is an example of a functional gage. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear.. Inspection Gauge Design.

From www.newmantools.com

How to read welding inspection gauges, WG series gages Inspection Gauge Design Below is an example of a functional gage. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Limit gauges do not determine the actual value of the inspected dimensions of a. Inspection Gauge Design.

From www.researchgate.net

Front view of inspection gauge with sliding pin Download Scientific Inspection Gauge Design For the feature to pass. Below is an example of a functional gage. The gage is represented in green,. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions. Inspection Gauge Design.

From www.newmantools.com

How to read welding inspection gauges, WG series gages Inspection Gauge Design Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. For the feature to pass. The gage is represented in green,. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. A functional gage can inspect parts quickly and. Inspection Gauge Design.

From gographicsoutput.com

Visual Inspection Gauges The Secret to Easy Quality Checks Graphics Inspection Gauge Design Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Limit gauges do not determine the actual value of the inspected dimensions of a part. Inspection Gauge Design.

From www.johnsongage.com

Internal Thread Inspection Systems Johnson Gage Inspection Gauge Design A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Below is an example of a functional gage. The gage is represented in green,. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. Visual inspection gauges, also known as appearance. Inspection Gauge Design.

From socal.swagelok.com

Gap Inspection Gauge Swagelok Inspection Gauge Design Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the. Inspection Gauge Design.

From www.johnsongage.com

Internal Thread Inspection Systems Johnson Gage Inspection Gauge Design A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. For the feature to pass. Limit gauges are inspection tools of rigid design, without a scale, which serve to check the dimensions of manufactured parts. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used. Inspection Gauge Design.

From www.indiamart.com

Inspection Gauge at best price in Chennai by Tan Tools And Gauges ID Inspection Gauge Design Below is an example of a functional gage. A functional gage can inspect parts quickly and will give a pass or fail on the inspected part. Visual inspection gauges, also known as appearance standard gauges and quality control gauges, are clear templates used to identify visual defects in glass, paint, clear. The gage is represented in green,. For the feature. Inspection Gauge Design.

From tronixproductdesign.com

Pipeline Inspection Gauge Tronix Product Design Inspection Gauge Design The gage is represented in green,. Gauges • gauges are inspection tool of rigid design, without a scale, which serves to check the dimensions of manufacturing parts. For the feature to pass. Limit gauges do not determine the actual value of the inspected dimensions of a part but indicate whether the part dimensions are manufactured within the limits specified. Limit. Inspection Gauge Design.