Internal Gear Teeth Manufacturing . By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. For that, you’ll need a. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. This means that size and shape of a tooth gap must be completely matched to the tool. How to apply gear manufacturing. They also enable a velocity change without a. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: The gear tool profile typically needs to be tailored to the specific gear wheel.

from www.zhygear.com

This means that size and shape of a tooth gap must be completely matched to the tool. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: They also enable a velocity change without a. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. How to apply gear manufacturing. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear.

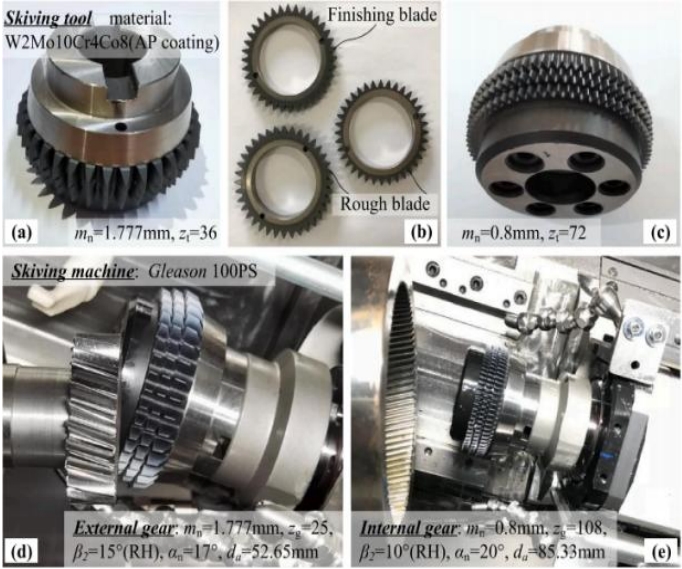

Research on Tooth Profile Design and Manufacturing of Tooth Cutting

Internal Gear Teeth Manufacturing This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. The gear tool profile typically needs to be tailored to the specific gear wheel. How to apply gear manufacturing. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. For that, you’ll need a. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. This means that size and shape of a tooth gap must be completely matched to the tool. They also enable a velocity change without a.

From klavpfghu.blob.core.windows.net

Gears Internal Tooth at Terri Brown blog Internal Gear Teeth Manufacturing By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. They also enable a velocity change without a. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The gear tool profile typically needs to be tailored to. Internal Gear Teeth Manufacturing.

From www.youtube.com

Gears Manufacturing Internal teeth cutting [Spur] on Shaper Machine Internal Gear Teeth Manufacturing This means that size and shape of a tooth gap must be completely matched to the tool. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. For that, you’ll need a. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. Understanding the. Internal Gear Teeth Manufacturing.

From www.indiamart.com

4.5 Meter Internal Teeth Cutting Gear at best price in Pune ID Internal Gear Teeth Manufacturing Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. This means that size and shape of a tooth gap must be completely matched to the tool.. Internal Gear Teeth Manufacturing.

From www.dreamstime.com

Manufacturing and Cutting of a Gear Shaft Tooth on an Oilcooled Gear Internal Gear Teeth Manufacturing Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The gear tool profile typically needs to be tailored to the specific gear wheel. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. This gear manufacturing process is typical for internal gears. Internal Gear Teeth Manufacturing.

From www.practicalmachinist.com

Machining internal gear teeth with a right angle head Internal Gear Teeth Manufacturing For that, you’ll need a. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. This means that size and shape of a tooth gap must be completely matched to the tool. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. Internal gears. Internal Gear Teeth Manufacturing.

From khkgears.net

Gear Manufacturing KHK Gears Internal Gear Teeth Manufacturing For that, you’ll need a. The gear tool profile typically needs to be tailored to the specific gear wheel. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for. Internal Gear Teeth Manufacturing.

From www.tradebearings.com

VSI200644N Internal Gear Teeth Slewing Bearing, VSI 20 0644N bearing Internal Gear Teeth Manufacturing This means that size and shape of a tooth gap must be completely matched to the tool. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. How to apply gear manufacturing. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the. Internal Gear Teeth Manufacturing.

From khkgears.net

Gear Manufacturing KHK Gears Internal Gear Teeth Manufacturing They also enable a velocity change without a. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. This means that size and shape of a tooth gap must be completely matched to the. Internal Gear Teeth Manufacturing.

From www.freepik.com

Premium AI Image Closeup of gear teeth in a manufacturing unit Internal Gear Teeth Manufacturing They also enable a velocity change without a. This means that size and shape of a tooth gap must be completely matched to the tool. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Internal gear is a gear with its teeth cut in the internal surface. Internal Gear Teeth Manufacturing.

From electrovo.com

Gear Design, number of Teeth 105 and Internal gear teeth 14 Electrovo Internal Gear Teeth Manufacturing They also enable a velocity change without a. This means that size and shape of a tooth gap must be completely matched to the tool. The gear tool profile typically needs to be tailored to the specific gear wheel. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world:. Internal Gear Teeth Manufacturing.

From khkgears.net

Gear Manufacturing KHK Gears Internal Gear Teeth Manufacturing The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. They also enable a velocity change without a. This gear manufacturing process is typical for internal gears but. Internal Gear Teeth Manufacturing.

From www.dreamstime.com

Helical Tooth Gear Shaft Manufacturing. Grinding Machine Stock Photo Internal Gear Teeth Manufacturing In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The gear tool profile typically needs to be tailored to the specific gear wheel. Internal gears provide designers with the ability to achieve higher. Internal Gear Teeth Manufacturing.

From www.geartec.com

Gear Hobbing, Milling, Gashing & Gear Teeth Grinding GearTec Internal Gear Teeth Manufacturing This means that size and shape of a tooth gap must be completely matched to the tool. This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Understanding the manufacturing methods for internal ring gears. Internal Gear Teeth Manufacturing.

From www.zhygear.com

Research on Tooth Profile Design and Manufacturing of Tooth Cutting Internal Gear Teeth Manufacturing For that, you’ll need a. This means that size and shape of a tooth gap must be completely matched to the tool. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality,. Internal Gear Teeth Manufacturing.

From electrovo.com

Gear Design, number of Teeth 105 and Internal gear teeth 14 Electrovo Internal Gear Teeth Manufacturing For that, you’ll need a. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear. Internal Gear Teeth Manufacturing.

From www.dreamstime.com

Gear Ring with Internal Teeth, Gear Cutting Production on CNC Machines Internal Gear Teeth Manufacturing Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. They also enable a velocity change without a. The gear tool profile typically needs to be tailored to the specific gear wheel. For that, you’ll need a. This gear manufacturing process is typical for internal gears but you can. Internal Gear Teeth Manufacturing.

From www.dreamstime.com

Helical Tooth Gear Manufacturing. Grinding Machine Stock Image Image Internal Gear Teeth Manufacturing The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: This means that size and shape of a tooth gap must be completely matched to the tool. For that, you’ll need a. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and. Internal Gear Teeth Manufacturing.

From www.liebherr.com

Evotion 2023 Everything from a single source Liebherr tools used by Internal Gear Teeth Manufacturing Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. How to apply gear manufacturing. For that, you’ll need a. This means that size and shape of a tooth gap must be completely matched to the tool. They also enable a velocity change without a. Understanding the manufacturing methods. Internal Gear Teeth Manufacturing.

From corrugatedreplacements.com

CR26381 Martin Internal Tooth Gear Corrugated Replacements, Inc. Internal Gear Teeth Manufacturing Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and. Internal Gear Teeth Manufacturing.

From www.benoygear.com

Highprecision internal gears work by the meshing of teeth and teeth Internal Gear Teeth Manufacturing In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: The gear. Internal Gear Teeth Manufacturing.

From www.researchgate.net

Design of teeth, gears and the internal epicycloidal gear systems (a Internal Gear Teeth Manufacturing The gear tool profile typically needs to be tailored to the specific gear wheel. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. This means that size and shape of a tooth gap. Internal Gear Teeth Manufacturing.

From www.dreamstime.com

Gear Ring with Internal Teeth, Gear Cutting Production on CNC Machines Internal Gear Teeth Manufacturing They also enable a velocity change without a. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet. Internal Gear Teeth Manufacturing.

From www.indiamart.com

Mild Steel Internal Gear Teeth, For Automobile Industry at Rs 250/piece Internal Gear Teeth Manufacturing This means that size and shape of a tooth gap must be completely matched to the tool. How to apply gear manufacturing. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the. Internal Gear Teeth Manufacturing.

From www.researchgate.net

(PDF) Experimental and Numerical Study of Internal Gear Manufacturing Internal Gear Teeth Manufacturing How to apply gear manufacturing. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. For that, you’ll need a. They also enable a velocity change without a. Understanding the manufacturing methods for. Internal Gear Teeth Manufacturing.

From www.dreamstime.com

Gear Ring with Internal Teeth, Gear Cutting Production on CNC Machines Internal Gear Teeth Manufacturing The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting. Internal Gear Teeth Manufacturing.

From www.youtube.com

CNC INTERNAL GEAR TEETH GENERATOR TO MAKE GEAR HONE YouTube Internal Gear Teeth Manufacturing The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: This means that size and shape of a tooth gap must be completely matched to the tool. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances.. Internal Gear Teeth Manufacturing.

From www.youtube.com

DIY Internal Gear Teeth Cutting Process in Slotting machine Machining Internal Gear Teeth Manufacturing This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. For that, you’ll need a. They also enable a velocity change without a. Understanding the manufacturing methods for internal. Internal Gear Teeth Manufacturing.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Internal Gear Teeth Manufacturing This means that size and shape of a tooth gap must be completely matched to the tool. They also enable a velocity change without a. This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. Internal gear is a gear with its teeth cut in the internal surface of a. Internal Gear Teeth Manufacturing.

From www.geartechnology.com

The Basics of Gear Theory Gear Technology Magazine Internal Gear Teeth Manufacturing Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. The gear tool profile typically needs to be tailored to the specific gear wheel. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: They also enable a. Internal Gear Teeth Manufacturing.

From www.rapiddirect.com

Gear Manufacturing 101 A Comolete Guide on Gear Production Processes Internal Gear Teeth Manufacturing For that, you’ll need a. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. How to apply gear manufacturing. They also enable a velocity change without a.. Internal Gear Teeth Manufacturing.

From www.youtube.com

DIY Internal Gear Teeth Cutting Process in Slotting machine Machining Internal Gear Teeth Manufacturing The gear tool profile typically needs to be tailored to the specific gear wheel. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. They also enable a velocity change without a. The three commonly used methods of cutting internal gear teeth each have benefits and a place in. Internal Gear Teeth Manufacturing.

From www.columbiapointequipment.com

SHAFTINTERNAL GEAR TEETH Columbia Point Equipment Company, INC. Internal Gear Teeth Manufacturing Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. This means that. Internal Gear Teeth Manufacturing.

From www.youtube.com

Remanufacturing a gear tooth using additive manufacturing and CNC Internal Gear Teeth Manufacturing They also enable a velocity change without a. By selecting the appropriate manufacturing method, engineers and manufacturers can produce internal ring gears that meet the desired specifications for various. The three commonly used methods of cutting internal gear teeth each have benefits and a place in the gear manufacturing world: In its manufacturing, because of its shape, the usual hobbing. Internal Gear Teeth Manufacturing.

From nnceaonline.com

Tooling Solutions for Gear Skiving NN Combined Engineering Agencies Internal Gear Teeth Manufacturing Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. This gear manufacturing process is typical for internal gears but you can use it to make external teeth as well. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes. Internal Gear Teeth Manufacturing.

From www.tec-science.com

External and internal toothing of gears tecscience Internal Gear Teeth Manufacturing Understanding the manufacturing methods for internal ring gears is essential for optimizing gear production, ensuring quality, and meeting specific design requirements. This means that size and shape of a tooth gap must be completely matched to the tool. They also enable a velocity change without a. This gear manufacturing process is typical for internal gears but you can use it. Internal Gear Teeth Manufacturing.