How To Finish Foam Board Edge . After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Have you ever wondered how to make the edge of foam seats firm? Finishing and sealing the cut edges. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. Follow the steps and tips to get clean, professional. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. To cut foam board, use a pair of heavy duty. Once cut i always use a fine sandpaper. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Well, here’s a tip on. How to make them last longer and stop the foam creeping away from the front edge?

from www.familyhandyman.com

After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Finishing and sealing the cut edges. Follow the steps and tips to get clean, professional. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. Have you ever wondered how to make the edge of foam seats firm? Once cut i always use a fine sandpaper. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Well, here’s a tip on. How to make them last longer and stop the foam creeping away from the front edge?

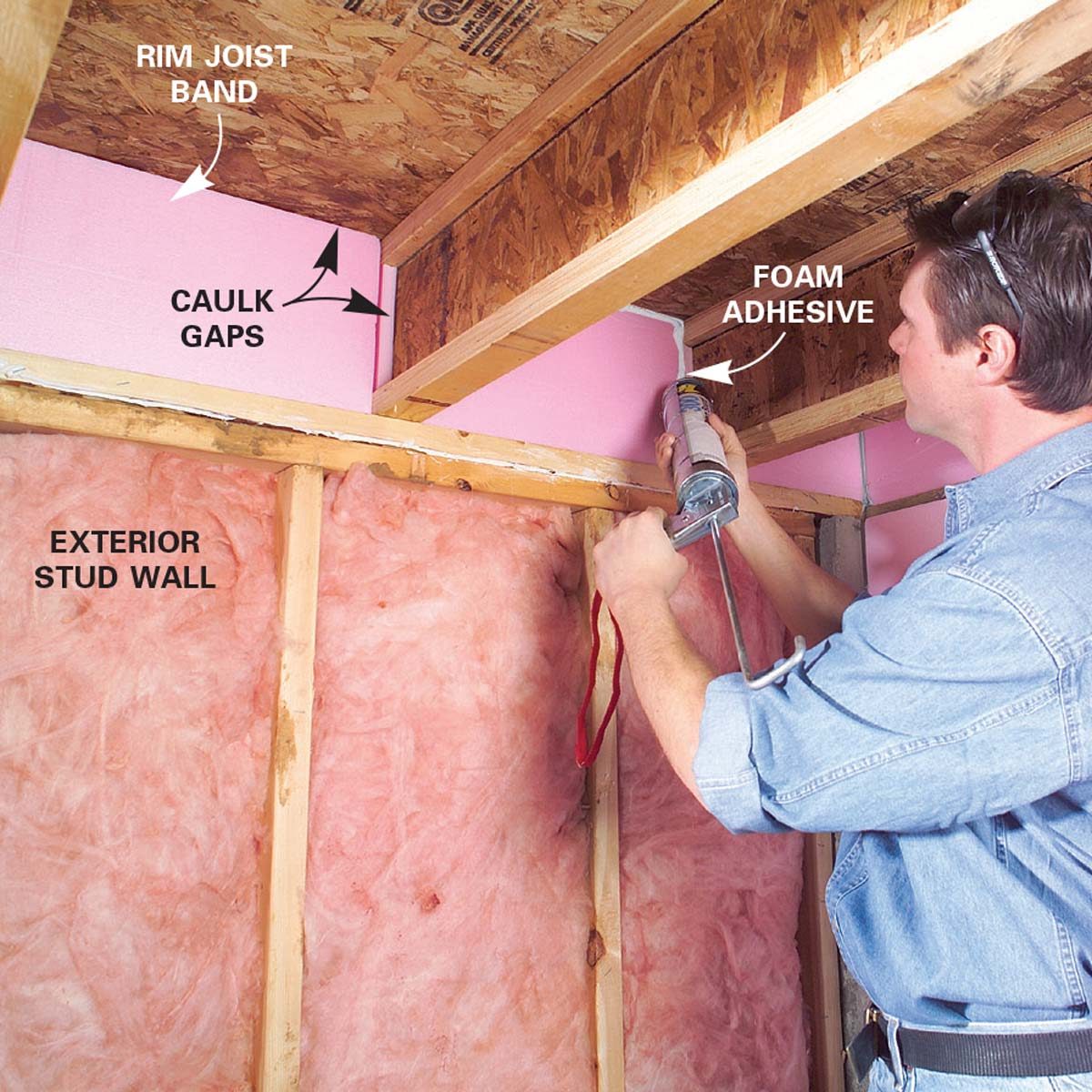

How to Finish a Basement Framing and Insulating The Family Handyman

How To Finish Foam Board Edge Finishing and sealing the cut edges. Once cut i always use a fine sandpaper. Well, here’s a tip on. Have you ever wondered how to make the edge of foam seats firm? Follow the steps and tips to get clean, professional. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Finishing and sealing the cut edges. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. How to make them last longer and stop the foam creeping away from the front edge? To cut foam board, use a pair of heavy duty. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish.

From theplywood.com

How to Install Foam Board Insulation in Attic ⋆ 🌲 How To Finish Foam Board Edge To cut foam board, use a pair of heavy duty. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Finishing. How To Finish Foam Board Edge.

From www.popco-usa.com

foamboard edge protector sign channels Popco How To Finish Foam Board Edge After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Well, here’s a tip on. Have you ever wondered how to make the edge of foam seats firm? As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. How to make. How To Finish Foam Board Edge.

From exomakvso.blob.core.windows.net

Foam Board Edge Trim at Todd Johnson blog How To Finish Foam Board Edge Finishing and sealing the cut edges. Have you ever wondered how to make the edge of foam seats firm? Once cut i always use a fine sandpaper. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Well, here’s a tip on. Applying. How To Finish Foam Board Edge.

From paintingleader.com

How to Paint Foam Board Without It Warping Expert Tips How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. How to make them last longer and stop the foam creeping away from the front edge? Applying edge banding to the sides of the pvc foam board can create a polished, professional look while. How To Finish Foam Board Edge.

From www.youtube.com

Insulating concrete floor. How to prepare to lay down foam board YouTube How To Finish Foam Board Edge How to make them last longer and stop the foam creeping away from the front edge? Follow the steps and tips to get clean, professional. Well, here’s a tip on. Have you ever wondered how to make the edge of foam seats firm? Once cut i always use a fine sandpaper. After cutting the foam board, it’s essential to finish. How To Finish Foam Board Edge.

From www.aiophotoz.com

How To Cut Foam Board Straight All You Need Infos Images and Photos How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. How to make them last longer and stop the foam creeping away from the front edge? Finishing and sealing the cut edges. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. As others say, first cut to score the. How To Finish Foam Board Edge.

From exomakvso.blob.core.windows.net

Foam Board Edge Trim at Todd Johnson blog How To Finish Foam Board Edge I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Once cut i always use a fine sandpaper. Well, here’s a tip on. How to make them last longer and stop the foam creeping away from the front edge? As others say, first. How To Finish Foam Board Edge.

From www.dwellingsbydevore.com

Dwellings By DeVore DIY Foamboard Valance How To Finish Foam Board Edge Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. Well, here’s a tip on. Finishing and sealing the cut edges. Have you ever wondered how to. How To Finish Foam Board Edge.

From www.youtube.com

Prop Shop Smoothing Foam Edges YouTube How To Finish Foam Board Edge How to make them last longer and stop the foam creeping away from the front edge? Once cut i always use a fine sandpaper. Have you ever wondered how to make the edge of foam seats firm? After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Finishing and sealing the cut edges.. How To Finish Foam Board Edge.

From www.fictiv.com

Guide to Foamcore Joining Techniques How To Finish Foam Board Edge To cut foam board, use a pair of heavy duty. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Have you ever wondered how to make the edge of foam seats firm? Follow the steps and tips to get clean, professional. Once cut i always use a fine sandpaper. I recently made. How To Finish Foam Board Edge.

From homedude.co

How To Install Rigid Foam Insulation On Exterior Concrete Walls homedude How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. Finishing and sealing the cut edges. Have you ever wondered how to make the edge of foam seats firm? Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. As others say, first cut to score the paper, second cut. How To Finish Foam Board Edge.

From www.youtube.com

Foam Board Edging YouTube How To Finish Foam Board Edge To cut foam board, use a pair of heavy duty. Once cut i always use a fine sandpaper. How to make them last longer and stop the foam creeping away from the front edge? After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Follow the steps and tips to get clean, professional.. How To Finish Foam Board Edge.

From www.youtube.com

PVC Foam Board Plastic What are the Uses ? Foam Board Tutorial How To Finish Foam Board Edge How to make them last longer and stop the foam creeping away from the front edge? Have you ever wondered how to make the edge of foam seats firm? Finishing and sealing the cut edges. To cut foam board, use a pair of heavy duty. After cutting the foam board, it’s essential to finish and seal the cut edges for. How To Finish Foam Board Edge.

From blogszerotwo.blogspot.com

How To Cut Foam Board Perfectly All You Need Infos How To Finish Foam Board Edge Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. Have you ever wondered how to make the edge of foam seats firm? How to make them last longer and stop the foam creeping away from the front edge? Follow the steps and tips to get clean, professional. I. How To Finish Foam Board Edge.

From www.familyhandyman.com

How to Finish a Basement Framing and Insulating The Family Handyman How To Finish Foam Board Edge To cut foam board, use a pair of heavy duty. Once cut i always use a fine sandpaper. Finishing and sealing the cut edges. How to make them last longer and stop the foam creeping away from the front edge? Well, here’s a tip on. Applying edge banding to the sides of the pvc foam board can create a polished,. How To Finish Foam Board Edge.

From jtechphotonics.com

Cutting 1/8" and 3/16" Foam Board with the 1.7W laser upgrade kit J How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. Have you ever wondered how to make the edge of foam seats firm? After cutting the foam board, it’s essential to finish and seal the cut edges for a professional.. How To Finish Foam Board Edge.

From www.youtube.com

Tips and Techniques for working with FloraCraft Smooth Finish How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Finishing and sealing the cut edges. Well, here’s a tip on. How. How To Finish Foam Board Edge.

From yardandgardenguru.com

How To Paint Foam Board Without It Warping How To Finish Foam Board Edge I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. Once cut i always use a fine sandpaper. To cut foam. How To Finish Foam Board Edge.

From www.popco-usa.com

Popco foam board edgeprotector Popco How To Finish Foam Board Edge As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. To cut foam board, use a pair of heavy duty. Follow the steps and tips to get clean, professional. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a. How To Finish Foam Board Edge.

From www.youtube.com

How to Cut Foam Board YouTube How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Well, here’s. How To Finish Foam Board Edge.

From blogszerotwo.blogspot.com

How To Cut Foam Board Straight All You Need Infos How To Finish Foam Board Edge Well, here’s a tip on. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Finishing and sealing the cut edges. Once cut i always use a fine sandpaper. Follow the steps and tips to get clean, professional. To cut foam board, use a pair of heavy duty. As others say, first cut. How To Finish Foam Board Edge.

From www.wikihow.com

How to Cut a Foam Board 3 Best Methods for a Clean Finish How To Finish Foam Board Edge Finishing and sealing the cut edges. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. To cut foam board, use a pair of heavy duty. How to make them last longer and stop the foam creeping away from the front edge? I recently made a foam model for. How To Finish Foam Board Edge.

From www.youtube.com

Foam Cutting Types For Industries; How to Cut Foam YouTube How To Finish Foam Board Edge How to make them last longer and stop the foam creeping away from the front edge? To cut foam board, use a pair of heavy duty. Well, here’s a tip on. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Once cut i always use a fine sandpaper. Finishing and sealing the. How To Finish Foam Board Edge.

From sewingcraftingsarah.blogspot.com

Sewing and Crafting with Sarah How to Cut Styrofoam How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. Have you ever wondered how to make the edge of foam seats firm? To cut foam board, use a pair of heavy duty. After cutting the foam board, it’s essential. How To Finish Foam Board Edge.

From www.flitetest.com

How to Build Anything with Foam Board! Flite Test How To Finish Foam Board Edge After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Have you ever wondered how to make the edge of foam seats firm? Well, here’s a tip on. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. Once cut i always. How To Finish Foam Board Edge.

From www.youtube.com

Scenic Quick Tip Cutting a Bevel Edge on Foam by Glenn Davis YouTube How To Finish Foam Board Edge Have you ever wondered how to make the edge of foam seats firm? As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. Once cut i always use a fine sandpaper. To cut foam board, use a pair of heavy duty. Applying edge banding to the sides of. How To Finish Foam Board Edge.

From www.121signs.com

PVC Frame (Capping) for Foam Board 121signs How To Finish Foam Board Edge Once cut i always use a fine sandpaper. Finishing and sealing the cut edges. Follow the steps and tips to get clean, professional. Well, here’s a tip on. How to make them last longer and stop the foam creeping away from the front edge? I recently made a foam model for a film (rigid insulation foam laminated together) and cut. How To Finish Foam Board Edge.

From oinksterrain.blogspot.com.au

Working with Foamboard Joining Basics Part 1 oinks overambitious How To Finish Foam Board Edge Once cut i always use a fine sandpaper. Well, here’s a tip on. Follow the steps and tips to get clean, professional. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. How to make them last longer and stop the foam creeping away from the front edge? To cut foam board, use. How To Finish Foam Board Edge.

From www.pinterest.jp

Pin on Foam Board Cutting & Design Tools How To Finish Foam Board Edge As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. Finishing and sealing the cut edges. Well, here’s a tip on. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get.. How To Finish Foam Board Edge.

From gluetips.com

How To Glue Foam Board To Wood? Gluetips How To Finish Foam Board Edge As others say, first cut to score the paper, second cut to do 80% of the foam, then third pass to finish. How to make them last longer and stop the foam creeping away from the front edge? After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. Applying edge banding to the. How To Finish Foam Board Edge.

From www.sandpaper.com

Edge Sanding Techniques Using Foam Abrasives Uneeda How To Finish Foam Board Edge Well, here’s a tip on. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. To cut foam board, use a pair of heavy duty. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. How to make them last longer and. How To Finish Foam Board Edge.

From basc.pnnl.gov

Exterior Edge Insulation for Existing Foundation Slabs Building How To Finish Foam Board Edge Follow the steps and tips to get clean, professional. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. As others say,. How To Finish Foam Board Edge.

From exomakvso.blob.core.windows.net

Foam Board Edge Trim at Todd Johnson blog How To Finish Foam Board Edge How to make them last longer and stop the foam creeping away from the front edge? Well, here’s a tip on. To cut foam board, use a pair of heavy duty. Have you ever wondered how to make the edge of foam seats firm? Finishing and sealing the cut edges. I recently made a foam model for a film (rigid. How To Finish Foam Board Edge.

From www.familyhandyman.com

How to Finish a Basement Wall (DIY) Family Handyman How To Finish Foam Board Edge Finishing and sealing the cut edges. After cutting the foam board, it’s essential to finish and seal the cut edges for a professional. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used a rasp to get. Well, here’s a tip on. Once cut i always use. How To Finish Foam Board Edge.

From www.huaxiajie.com

PVC Foam Skirting Board , Plastic Vinyl Foam Board Edge Trim How To Finish Foam Board Edge How to make them last longer and stop the foam creeping away from the front edge? Applying edge banding to the sides of the pvc foam board can create a polished, professional look while protecting the edges. I recently made a foam model for a film (rigid insulation foam laminated together) and cut it to a rough shape then used. How To Finish Foam Board Edge.