Lathe Turning Tool Geometry . This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. The diagram shows the working area for each geometry based. Choosing the right insert shape for your turning tool is essential. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. The shape of the insert can affect the vibration during operation, the ability. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. There are several key measurements.

from www.youtube.com

Choosing the right insert shape for your turning tool is essential. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. The diagram shows the working area for each geometry based. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. The shape of the insert can affect the vibration during operation, the ability. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to.

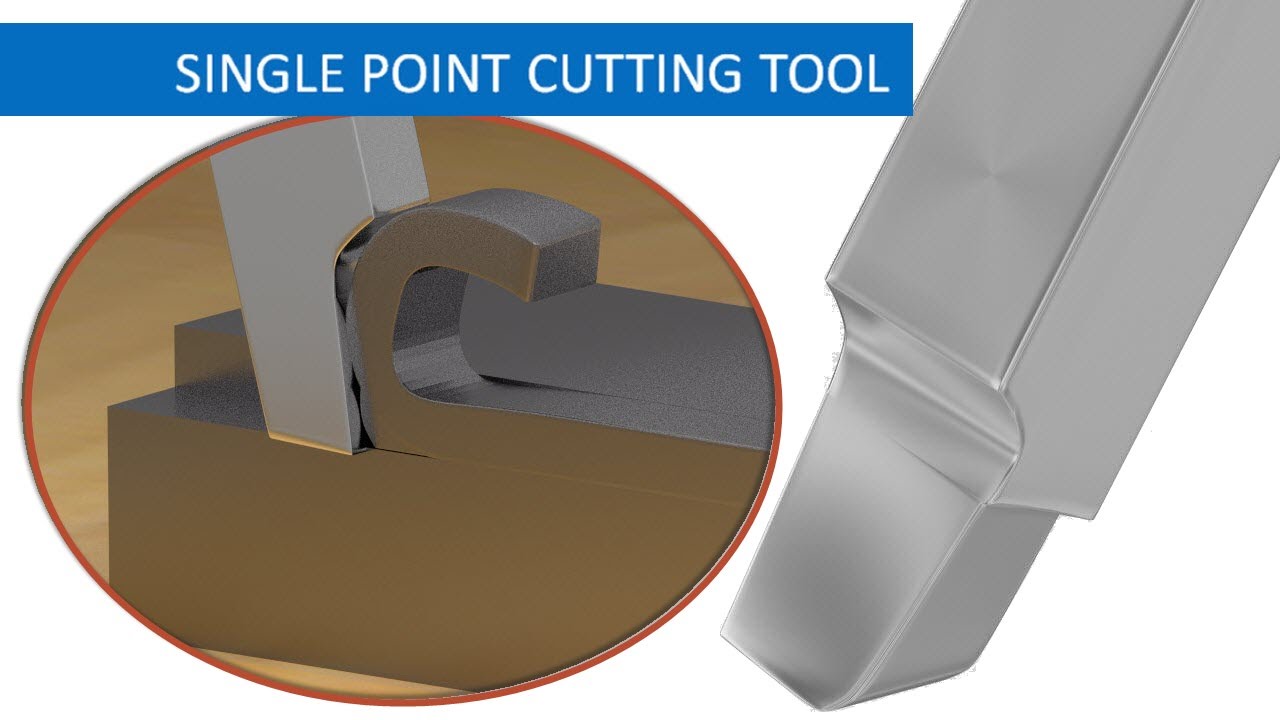

Understanding Cutting Tool Geometry YouTube

Lathe Turning Tool Geometry The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. There are several key measurements. The shape of the insert can affect the vibration during operation, the ability. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. The diagram shows the working area for each geometry based. Choosing the right insert shape for your turning tool is essential. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to.

From www.engineeringchoice.com

What is A Lathe? Definition, Types, and Operations Engineering Choice Lathe Turning Tool Geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The diagram shows the working area for each geometry based. The shape of the insert can affect the vibration during operation, the ability. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed. Lathe Turning Tool Geometry.

From www.homenish.com

14 Different Types of Lathe Tools Explained Homenish Lathe Turning Tool Geometry The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The. Lathe Turning Tool Geometry.

From 4mechtech.blogspot.com

Mechanical Technology Lathe Machine Cutting Tool Angles Lathe Turning Tool Geometry The diagram shows the working area for each geometry based. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The shape of the insert can affect the. Lathe Turning Tool Geometry.

From www.pinterest.es

Tools and Equipment Metal lathe tools, Lathe, Cnc machine tools Lathe Turning Tool Geometry The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select. Lathe Turning Tool Geometry.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Lathe Turning Tool Geometry The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. There are several key measurements. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The diagram shows the working area for each geometry based. To maximize the advantages of these tools,. Lathe Turning Tool Geometry.

From www.pinterest.com

Lathe Turning tool, Grind angles lathe tools Pinterest Turning Lathe Turning Tool Geometry There are several key measurements. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. Choosing the right insert shape for your turning tool is essential. The diagram shows the working area for each geometry based. This article provides a guide to the diverse range of lathe tools utilized in cnc turning. Lathe Turning Tool Geometry.

From www.familyhandyman.com

7 Basic Woodturning Tools To Start With Lathe Turning Tool Geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. The diagram shows the working area for each geometry based. Choosing the right insert shape for your turning tool. Lathe Turning Tool Geometry.

From www.robertsonprecision.com

Shear Geometry® Cutting Tools Lathe Turning Tool Geometry There are several key measurements. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators. Lathe Turning Tool Geometry.

From www.reddit.com

other than a bit missing from the tip, is their anything i need to Lathe Turning Tool Geometry To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. The shape of the insert can affect the vibration during operation, the ability.. Lathe Turning Tool Geometry.

From www.youtube.com

Cutting Tool Geometries Lathe and Mill SME YouTube Lathe Turning Tool Geometry The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. Choosing the right insert shape for your turning tool is. Lathe Turning Tool Geometry.

From www.smartlathe.com

Components Of A Lathe Cutting Tool Lathe Turning Tool Geometry The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. Insert geometry should also be selected based on the type. Lathe Turning Tool Geometry.

From www.researchgate.net

Tool Geometry of Single Point Download Scientific Diagram Lathe Turning Tool Geometry The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. Choosing the right insert shape for your turning tool is essential. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. Turning geometries can be divided into three basic styles that are. Lathe Turning Tool Geometry.

From ibls.org

Lathe Tool Setup IBLS Lathe Turning Tool Geometry To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. The diagram shows the working area for each geometry based. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. Turning geometries can be divided into. Lathe Turning Tool Geometry.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Lathe Turning Tool Geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. This. Lathe Turning Tool Geometry.

From machiningtool.blogspot.com

Machining Turning Tools and Geometry Lathe Turning Tool Geometry The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. Turning geometries can be divided into three basic styles that are optimized. Lathe Turning Tool Geometry.

From www.youtube.com

Lathe Machine Tool Angle Types of Tool Technical Achievement Lathe Turning Tool Geometry There are several key measurements. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. Choosing the. Lathe Turning Tool Geometry.

From mavink.com

Lathe Tooling Chart Lathe Turning Tool Geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The shape of the insert can affect the vibration during operation, the ability. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied. Lathe Turning Tool Geometry.

From www.youtube.com

LATHE CUTTING EDGE POSITIONING, HOW TO SET UP LATHE TOOLS FOR TURNING Lathe Turning Tool Geometry The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. There are several key measurements. The diagram shows the working. Lathe Turning Tool Geometry.

From www.cutwel.co.uk

Learn The Turning Tool ISO Code System Cutwel Ltd Lathe Turning Tool Geometry The shape of the insert can affect the vibration during operation, the ability. The diagram shows the working area for each geometry based. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed. Lathe Turning Tool Geometry.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Lathe Turning Tool Geometry The shape of the insert can affect the vibration during operation, the ability. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one.. Lathe Turning Tool Geometry.

From engineeringlearn.com

14 Types of Lathe Cutting Tools and Their Uses Guide Lathe Turning Tool Geometry There are several key measurements. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. This article provides a guide to the diverse range of lathe tools utilized in. Lathe Turning Tool Geometry.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Lathe Turning Tool Geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The diagram shows the working area for each geometry based. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. Insert geometry should also be selected based on. Lathe Turning Tool Geometry.

From www.pinterest.com

Tom's Techniques Reference Metal working tools, Machine shop Lathe Turning Tool Geometry The diagram shows the working area for each geometry based. The shape of the insert can affect the vibration during operation, the ability. Choosing the right insert shape for your turning tool is essential. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. To maximize the advantages of these tools, it. Lathe Turning Tool Geometry.

From toolnotes.com

Lathe Operations ToolNotes Lathe Turning Tool Geometry To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. The insert size should be chosen carefully. Lathe Turning Tool Geometry.

From www.minaprem.com

What is Single Point Turning Tool (SPTT)? Lathe Turning Tool Geometry To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones. Lathe Turning Tool Geometry.

From answer2questn.blogspot.com

Questions Answers About the Lathe Introduction of Centre Lathe Lathe Turning Tool Geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform. Lathe Turning Tool Geometry.

From www.metalworkingworldmagazine.com

Mechanical loads and cutting geometries in turning operations Metal Lathe Turning Tool Geometry Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. Turning geometries can be divided into three basic styles. Lathe Turning Tool Geometry.

From learnmech.com

Basic Lathe Operations Lathe operation Explained Lathe Turning Tool Geometry The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to. Choosing the right insert shape for your turning tool is essential. The diagram shows the working area for each geometry based. The shape of the insert can affect the vibration. Lathe Turning Tool Geometry.

From www.youtube.com

Everything About Single Point Cutting Tool Explained Geometry Parts Lathe Turning Tool Geometry Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. Choosing the right insert shape for your turning tool is essential. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. This article provides a guide to the diverse range of lathe. Lathe Turning Tool Geometry.

From journeymans-workshop.uk

HSS Lathe Tool Grinding Lathe Turning Tool Geometry Choosing the right insert shape for your turning tool is essential. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. There are several key measurements. The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. To maximize the advantages of these tools, it. Lathe Turning Tool Geometry.

From www.youtube.com

Understanding Cutting Tool Geometry YouTube Lathe Turning Tool Geometry The proper calculation and understanding of lathe cutting tool geometry is essential for achieving accurate and efficient machining. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform. Lathe Turning Tool Geometry.

From www.youtube.com

Tool Nomenclature of Single Point Cutting Tool ENGINEERING STUDY Lathe Turning Tool Geometry Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing operations. The insert size should be chosen carefully to match the operation’s requirements and the available space for the cutting tool. To. Lathe Turning Tool Geometry.

From www.yg1.kr

YG1, The Art of Threading Lathe Turning Tool Geometry This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. The diagram shows the working area for each geometry based. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be familiar with different tool geometries and how. Lathe Turning Tool Geometry.

From industrysurfer.com

Herramientas de corte de un solo punto nomenclatura, ángulos, formas y Lathe Turning Tool Geometry The shape of the insert can affect the vibration during operation, the ability. This article provides a guide to the diverse range of lathe tools utilized in cnc turning and explains how to select the suitable one. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations.. Lathe Turning Tool Geometry.

From www.meetyoucarbide.com

How to choose the turning insert angle Meetyou Carbide Lathe Turning Tool Geometry The shape of the insert can affect the vibration during operation, the ability. The diagram shows the working area for each geometry based. Insert geometry should also be selected based on the type of operation—larger point angles for roughing and smaller ones for finishing. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine. Lathe Turning Tool Geometry.