Fish Plate Welding Procedure . A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Fully weld the butt joints and then. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. It is often used to. So i decided to cut the frame of my project truck to make it a short wheelbase. It is commonly employed in the construction and repair of. The way it is usualy done is weld top & bottom leaving the ends.

from www.scribd.com

Fully weld the butt joints and then. So i decided to cut the frame of my project truck to make it a short wheelbase. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. It is often used to. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. The way it is usualy done is weld top & bottom leaving the ends. It is commonly employed in the construction and repair of. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables.

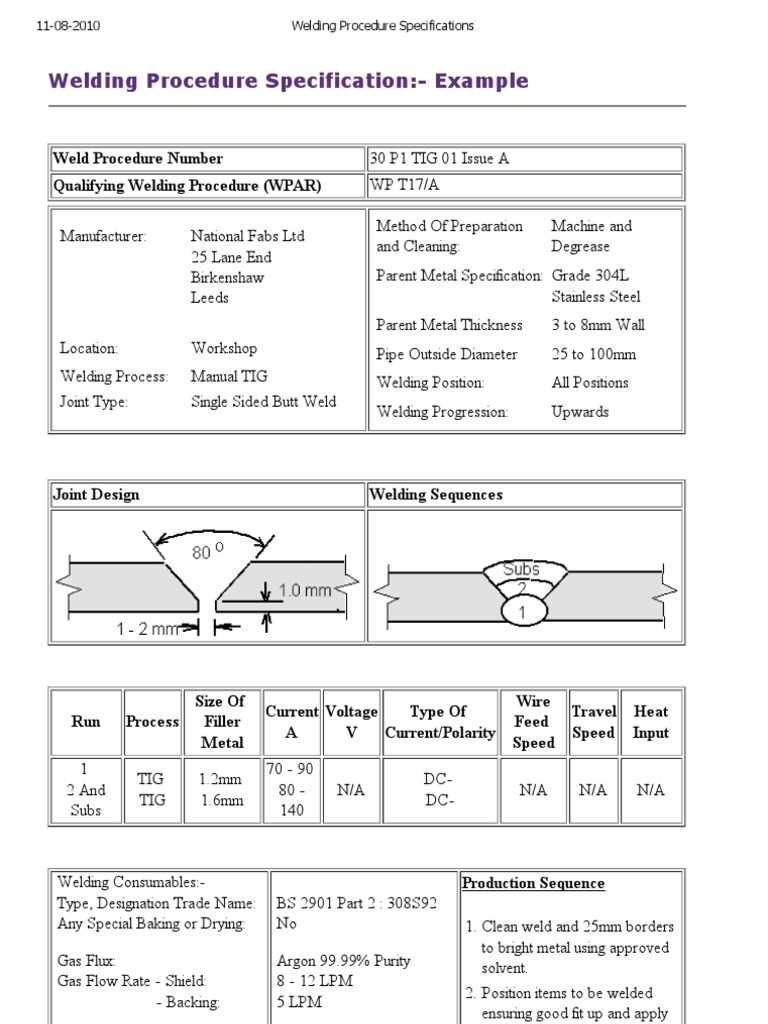

Welding Procedure Specifications

Fish Plate Welding Procedure Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. Fully weld the butt joints and then. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. The way it is usualy done is weld top & bottom leaving the ends. It is commonly employed in the construction and repair of. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. It is often used to. So i decided to cut the frame of my project truck to make it a short wheelbase.

From www.youtube.com

How to brace your welds with a fish plate! Reinforce your truck frame for strength YouTube Fish Plate Welding Procedure It is often used to. Fully weld the butt joints and then. So i decided to cut the frame of my project truck to make it a short wheelbase. It is commonly employed in the construction and repair of. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated. Fish Plate Welding Procedure.

From www.researchgate.net

(a) Schematics of laser welding process and (b) fish bone (Ishikawa)... Download Scientific Fish Plate Welding Procedure Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. So i decided to cut the frame of my project truck to make it a short wheelbase. The way it is usualy done is weld top & bottom leaving the ends. It is commonly employed in the construction and repair of. Fully. Fish Plate Welding Procedure.

From www.yesterdaystractors.com

Another welding question Yesterday's Tractors Fish Plate Welding Procedure It is often used to. It is commonly employed in the construction and repair of. So i decided to cut the frame of my project truck to make it a short wheelbase. The way it is usualy done is weld top & bottom leaving the ends. Fully weld the butt joints and then. Fish plate welding is a process by. Fish Plate Welding Procedure.

From www.railroadpart.com

How to change fish plates on a plain joint Fish Plate Welding Procedure Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. It is commonly employed in the construction and repair of. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. A welding procedure specification (wps) sets broad guidelines for. Fish Plate Welding Procedure.

From www.pro-touring.com

Adding "fish plates" to a welded joint? Fish Plate Welding Procedure It is often used to. Fully weld the butt joints and then. So i decided to cut the frame of my project truck to make it a short wheelbase. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. A welding procedure specification (wps) sets broad guidelines. Fish Plate Welding Procedure.

From www.scribd.com

Welding Procedure Specifications Fish Plate Welding Procedure Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. Fully weld the butt joints and then. It is often used to. So i decided to cut the frame. Fish Plate Welding Procedure.

From weldingtorchapes.com

Welding technique and method of fish scale welding APES Fish Plate Welding Procedure It is often used to. It is commonly employed in the construction and repair of. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. So i. Fish Plate Welding Procedure.

From beavereng.com.au

Fish Plates Beaver Engineering Fish Plate Welding Procedure So i decided to cut the frame of my project truck to make it a short wheelbase. It is often used to. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. The way it is usualy done is weld top & bottom leaving the ends. Fully. Fish Plate Welding Procedure.

From www.jwwelding.ca

Welding Projects & Epoxy Glue JW Portable Welding & Repairs Fish Plate Welding Procedure It is often used to. So i decided to cut the frame of my project truck to make it a short wheelbase. Fully weld the butt joints and then. It is commonly employed in the construction and repair of. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated. Fish Plate Welding Procedure.

From www.youtube.com

WELDING POSITIONS FLAT POSITION HORIZONTAL POSITION VERTICAL POSITION OVERHEAD POSITION Fish Plate Welding Procedure So i decided to cut the frame of my project truck to make it a short wheelbase. It is often used to. It is commonly employed in the construction and repair of. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. Fully weld the butt joints. Fish Plate Welding Procedure.

From www.bgstructuralengineering.com

Welding Intro Fish Plate Welding Procedure Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. The way it is usualy done is weld top & bottom leaving the ends. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Fish plate welding. Fish Plate Welding Procedure.

From www.vimalsonic.com

sequence of hot plate welding Fish Plate Welding Procedure Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. The way it is usualy done is weld top & bottom leaving the ends. It is often used to. It is commonly employed in the construction and repair of. Recommend you lay cat tails or runoffs at. Fish Plate Welding Procedure.

From www.pinterest.com

Pin by American Welder on Welding Pocket knife, Knife, Welding Fish Plate Welding Procedure So i decided to cut the frame of my project truck to make it a short wheelbase. It is commonly employed in the construction and repair of. It is often used to. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. Fully weld the butt joints and then. A welding procedure. Fish Plate Welding Procedure.

From weldingblos.netlify.app

Welding Design Guidelines Pdf Fish Plate Welding Procedure Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. Fully weld the butt joints and then. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. It is commonly employed in the construction and repair of. It is. Fish Plate Welding Procedure.

From www.qfweld.com.au

Home Quality Fabrications and Welding Fish Plate Welding Procedure The way it is usualy done is weld top & bottom leaving the ends. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. It is commonly employed in the construction and repair of. A welding procedure specification (wps) sets broad guidelines for the shop and field. Fish Plate Welding Procedure.

From www.reddit.com

Customer had ripped the cylinder mount off and cracked the top of the boom in the process. Fish Fish Plate Welding Procedure A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. It is often used to. So i decided to cut the frame of my project truck to make it a short wheelbase. The way it is usualy done is weld top & bottom leaving the. Fish Plate Welding Procedure.

From uhobbie.com

+22 Truck Frame Fish Plate Welding References Fish Plate Welding Procedure It is often used to. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. The way it is usualy done is weld top & bottom leaving the ends. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate.. Fish Plate Welding Procedure.

From www.youtube.com

Welding a fish plate and why YouTube Fish Plate Welding Procedure Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. It is often used to. Fully weld the butt joints and then. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. The way it is usualy. Fish Plate Welding Procedure.

From www.youtube.com

Fish Plate Welding Repair YouTube Fish Plate Welding Procedure Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. It is commonly employed in the construction and repair of. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. A welding procedure specification (wps) sets broad guidelines for. Fish Plate Welding Procedure.

From uhobbie.com

+22 Truck Frame Fish Plate Welding References Fish Plate Welding Procedure It is commonly employed in the construction and repair of. The way it is usualy done is weld top & bottom leaving the ends. Fully weld the butt joints and then. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. Recommend you lay cat tails or. Fish Plate Welding Procedure.

From www.westermans.com

How to Weld Square Tube Step by Step! Westermans Blog Fish Plate Welding Procedure Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. It is commonly employed in the construction and repair of. Fully weld the butt joints and then. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables.. Fish Plate Welding Procedure.

From www.fleetmaintenance.com

Welding Types and Positions poster Fleet Maintenance Fish Plate Welding Procedure It is often used to. The way it is usualy done is weld top & bottom leaving the ends. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. It is commonly employed in the construction and repair of. Fully weld the butt joints and. Fish Plate Welding Procedure.

From weldingtorchapes.com

Welding technique and method of fish scale welding APES Fish Plate Welding Procedure It is commonly employed in the construction and repair of. The way it is usualy done is weld top & bottom leaving the ends. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. It is often used to. Recommend you lay cat tails or. Fish Plate Welding Procedure.

From www.youtube.com

1G Plate Stick Welding SMAW YouTube Fish Plate Welding Procedure So i decided to cut the frame of my project truck to make it a short wheelbase. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. It is commonly employed in the construction and repair of. Recommend you lay cat tails or runoffs at the edge. Fish Plate Welding Procedure.

From forum.ih8mud.com

Frame cutting, mods and welding IH8MUD Forum Fish Plate Welding Procedure A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. Fish plate welding is a process by which we fuse or reinforce two pieces of material to. Fish Plate Welding Procedure.

From www.researchgate.net

Fish bone diagram for welding quality Download Scientific Diagram Fish Plate Welding Procedure It is often used to. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. The way it is usualy done is weld top & bottom leaving the ends. So i decided to cut the frame of my project truck to make it a short wheelbase. Fish plate welding is a process. Fish Plate Welding Procedure.

From qastack.jp

フレームに魚をメッキすることは何ですか? Fish Plate Welding Procedure Fully weld the butt joints and then. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. The way it is usualy done is weld top & bottom leaving the ends. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of. Fish Plate Welding Procedure.

From uhobbie.com

+22 Truck Frame Fish Plate Welding References Fish Plate Welding Procedure Fully weld the butt joints and then. The way it is usualy done is weld top & bottom leaving the ends. It is commonly employed in the construction and repair of. So i decided to cut the frame of my project truck to make it a short wheelbase. Recommend you lay cat tails or runoffs at the edge termini of. Fish Plate Welding Procedure.

From www.youtube.com

welding fish plates, gone right YouTube Fish Plate Welding Procedure It is often used to. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. Fully weld the butt joints and then. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables.. Fish Plate Welding Procedure.

From www.researchgate.net

Numbering of weldseams in the multipass welding procedure. Placements... Download Scientific Fish Plate Welding Procedure The way it is usualy done is weld top & bottom leaving the ends. It is often used to. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. So i decided to cut the frame of my project truck to make it a short wheelbase. It. Fish Plate Welding Procedure.

From weldinglogic.com

Fish Plate Welding Fish Plate Weld Types, Design & More Welding Logic Fish Plate Welding Procedure A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. It is commonly employed in the construction and repair of. It is. Fish Plate Welding Procedure.

From weldinglogic.com

Fish Plate Welding Fish Plate Weld Types, Design & More Welding Logic Fish Plate Welding Procedure A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. So i decided to cut the frame of my project truck to make it a short wheelbase.. Fish Plate Welding Procedure.

From upweld.org

What are the 4 Basic Welding Positions for Fillet Welds Plate? UpWeld Fish Plate Welding Procedure It is often used to. So i decided to cut the frame of my project truck to make it a short wheelbase. Fish plate welding is a process by which we fuse or reinforce two pieces of material to create a stronger, more durable connection. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice. Fish Plate Welding Procedure.

From www.reddit.com

Fishplates for my "Z'ed" frame Welding Fish Plate Welding Procedure So i decided to cut the frame of my project truck to make it a short wheelbase. Recommend you lay cat tails or runoffs at the edge termini of the thinner section of the plate. Fully weld the butt joints and then. It is often used to. It is commonly employed in the construction and repair of. A welding procedure. Fish Plate Welding Procedure.

From inf.news

The highlevel fish scale welding technology is truly beautiful iNEWS Fish Plate Welding Procedure So i decided to cut the frame of my project truck to make it a short wheelbase. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. It is often used to. It is commonly employed in the construction and repair of. Recommend you lay. Fish Plate Welding Procedure.