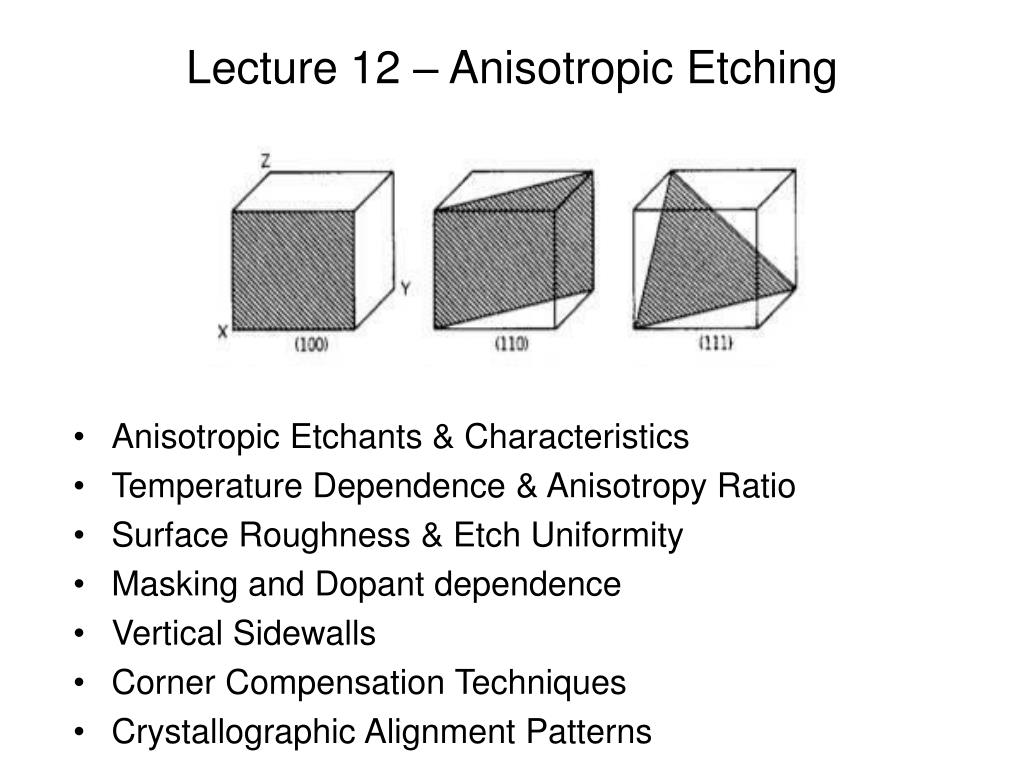

What Is Meant By Anisotropic Etch . Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. * some wet and plasma chemistries can have high anisotropy by using. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. Anisotropy can depend on mean free path, or on dc plasma bias. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific.

from www.slideserve.com

Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. Anisotropy can depend on mean free path, or on dc plasma bias. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. * some wet and plasma chemistries can have high anisotropy by using.

PPT Lecture 12 Anisotropic Etching PowerPoint Presentation, free download ID1490740

What Is Meant By Anisotropic Etch In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. * some wet and plasma chemistries can have high anisotropy by using. Anisotropy can depend on mean free path, or on dc plasma bias. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific.

From www.slideserve.com

PPT Section 3 Etching PowerPoint Presentation, free download ID2938121 What Is Meant By Anisotropic Etch In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Wet anisotropic. What Is Meant By Anisotropic Etch.

From www.iue.tuwien.ac.at

6.3 Anisotropic Wet Etching What Is Meant By Anisotropic Etch In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Wet anisotropic. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Introduction to etching. Wet chemical etching isotropic. Anisotropic etching of What Is Meant By Anisotropic Etch In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropy can depend on mean free path, or on dc plasma bias. * some wet and plasma chemistries can have high anisotropy by using. Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. Wet. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Lecture 12 Anisotropic Etching PowerPoint Presentation, free download ID1490740 What Is Meant By Anisotropic Etch In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. Wet anisotropic etching is extensively employed in silicon. What Is Meant By Anisotropic Etch.

From www.youtube.com

Anisotropic etch charact of Silicon Nitride & Polysilicon in the Trion ICP RIE Anisotropic Etch What Is Meant By Anisotropic Etch Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Chapter 10 Etching PowerPoint Presentation, free download ID652137 What Is Meant By Anisotropic Etch Anisotropy can depend on mean free path, or on dc plasma bias. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. * some wet and plasma chemistries can have high anisotropy by using. In this study, microwave plasma with a temperature below 100 °c is employed to investigate. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Anisotropic wet etching process (A) A [110]SOI substrate is covered... Download Scientific What Is Meant By Anisotropic Etch Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. Anisotropic etching is. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Microfabrication PowerPoint Presentation, free download ID6569701 What Is Meant By Anisotropic Etch Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Result of anisotropic etch on a typical (100) wafer using a mask... Download Scientific Diagram What Is Meant By Anisotropic Etch Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions. What Is Meant By Anisotropic Etch.

From www.researchgate.net

8 (a) SEM image of a highly anisotropic etching with a fast etchrate... Download Scientific What Is Meant By Anisotropic Etch Anisotropy can depend on mean free path, or on dc plasma bias. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. * some wet and plasma chemistries can have high anisotropy by using. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging.. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Introduction to etching. Wet chemical etching isotropic. Anisotropic etching of What Is Meant By Anisotropic Etch Anisotropy can depend on mean free path, or on dc plasma bias. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Wet anisotropic etching is extensively employed in silicon bulk. What Is Meant By Anisotropic Etch.

From nanohub.org

Resources ECE 695Q Lecture 44 Etching Watch Presentation What Is Meant By Anisotropic Etch Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. Anisotropy can depend on mean free path, or on dc plasma bias. Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Introduction to etching. Wet chemical etching isotropic. Anisotropic etching of What Is Meant By Anisotropic Etch * some wet and plasma chemistries can have high anisotropy by using. Anisotropy can depend on mean free path, or on dc plasma bias. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Result of anisotropic etch on a typical (100) wafer using a mask... Download Scientific Diagram What Is Meant By Anisotropic Etch In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. Anisotropy can depend on. What Is Meant By Anisotropic Etch.

From www.researchgate.net

DRIElag calibration. Plot of anisotropic etch rate as a function of... Download Scientific What Is Meant By Anisotropic Etch Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropy can depend on mean. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT MEMS Fabrication Process Flows and Bulk Silicon Etching PowerPoint Presentation ID6154225 What Is Meant By Anisotropic Etch Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities.. What Is Meant By Anisotropic Etch.

From www.mec-co.com

Anisotropic etching MEC COMPANY LTD. What Is Meant By Anisotropic Etch In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. Anisotropy can depend on mean. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Chapter 10 Etching PowerPoint Presentation ID1945566 What Is Meant By Anisotropic Etch Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. * some wet and plasma chemistries can have high anisotropy by using. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such. What Is Meant By Anisotropic Etch.

From www.flickr.com

MultiStep Anisotropic Etching Process Diagram of a multi… Flickr What Is Meant By Anisotropic Etch Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. * some wet and plasma chemistries can have high anisotropy by using. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropic etching is a subtractive microfabrication technique that. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Schematic demonstration of the wet anisotropically etched profiles of... Download Scientific What Is Meant By Anisotropic Etch Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. * some wet and plasma chemistries can have high anisotropy by using. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such. What Is Meant By Anisotropic Etch.

From loadingindustries.mystrikingly.com

Anisotropic Crystalline Etch Simulation What Is Meant By Anisotropic Etch Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. * some wet and plasma chemistries can have high anisotropy by using. Anisotropic etching is a subtractive microfabrication technique that aims to. What Is Meant By Anisotropic Etch.

From slideplayer.com

Surface Preparation and Wet Processing ppt download What Is Meant By Anisotropic Etch Anisotropy can depend on mean free path, or on dc plasma bias. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Wet anisotropic etching is extensively employed in silicon bulk. What Is Meant By Anisotropic Etch.

From www.researchgate.net

The formation and evolution of surface morphology for anisotropic... Download Scientific Diagram What Is Meant By Anisotropic Etch Anisotropy can depend on mean free path, or on dc plasma bias. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropic etching of (100) orientation silicon is being. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Chapter Extra2 Microfabrication process PowerPoint Presentation ID3100028 What Is Meant By Anisotropic Etch * some wet and plasma chemistries can have high anisotropy by using. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropic etching is a subtractive microfabrication technique that aims. What Is Meant By Anisotropic Etch.

From pubs.sciepub.com

Figure 18. (a) Bow Anisotropic Etch profile of RIE showing crystallographic orientations (b) The What Is Meant By Anisotropic Etch Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. * some wet and plasma chemistries. What Is Meant By Anisotropic Etch.

From www.protoexpress.com

Wet PCB Etching Using Acidic & Alkaline Sierra Circuits What Is Meant By Anisotropic Etch Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT A PRESENTATION ON “THIN FILM TECHNOLOGY ” PowerPoint Presentation ID2194846 What Is Meant By Anisotropic Etch In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. * some wet and plasma chemistries can have high anisotropy by using. In contrast to isotropic etching, which produces a lower resolution concave shape. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Anisotropic InP etch using a metal hardmask. Smoothness is only limited... Download Scientific What Is Meant By Anisotropic Etch * some wet and plasma chemistries can have high anisotropy by using. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropic etching of (100) orientation silicon is being widely. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Chapter 10 Etching PowerPoint Presentation, free download ID1945566 What Is Meant By Anisotropic Etch Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. Anisotropic etching of (100) orientation silicon is being widely used today and (110) orientation technology is emerging. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropy can depend. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Lecture 12 Anisotropic Etching PowerPoint Presentation, free download ID1490740 What Is Meant By Anisotropic Etch Anisotropy can depend on mean free path, or on dc plasma bias. Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. In contrast to isotropic etching, which produces a. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Crosssectional diagram of a combination of anisotropic etching (DRIE)... Download Scientific What Is Meant By Anisotropic Etch In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. * some. What Is Meant By Anisotropic Etch.

From www.slideserve.com

PPT Microfabrication Process PowerPoint Presentation, free download ID3217639 What Is Meant By Anisotropic Etch Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical. In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities.. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Result of anisotropic etch on an offaxis cut (113) wafer using a mask... Download Scientific What Is Meant By Anisotropic Etch In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Wet anisotropic. What Is Meant By Anisotropic Etch.

From www.researchgate.net

Result of anisotropic etch on a typical (100) wafer using a mask... Download Scientific Diagram What Is Meant By Anisotropic Etch In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. In this study, microwave plasma with a temperature below 100 °c is employed to investigate the dependence of microstructure. Anisotropy can. What Is Meant By Anisotropic Etch.

From www.researchgate.net

IntelliSuite example of anisotropic etch simulation results Download Scientific Diagram What Is Meant By Anisotropic Etch In contrast to isotropic etching, which produces a lower resolution concave shape under the photoresist etching mask, anisotropic etching removes material in specific directions enabling the production of geometric characteristics such as sharp corners, flat surfaces, and deep cavities. Anisotropy can depend on mean free path, or on dc plasma bias. Anisotropic etching is a subtractive microfabrication technique that aims. What Is Meant By Anisotropic Etch.