Belt Drive Maintenance Procedure . In addition to proper selection. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. What is a good belt maintenance program? Removing old belts, inspecting all components for wear and damage, checking. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. A comprehensive, effective program of preventive maintenance consists of.

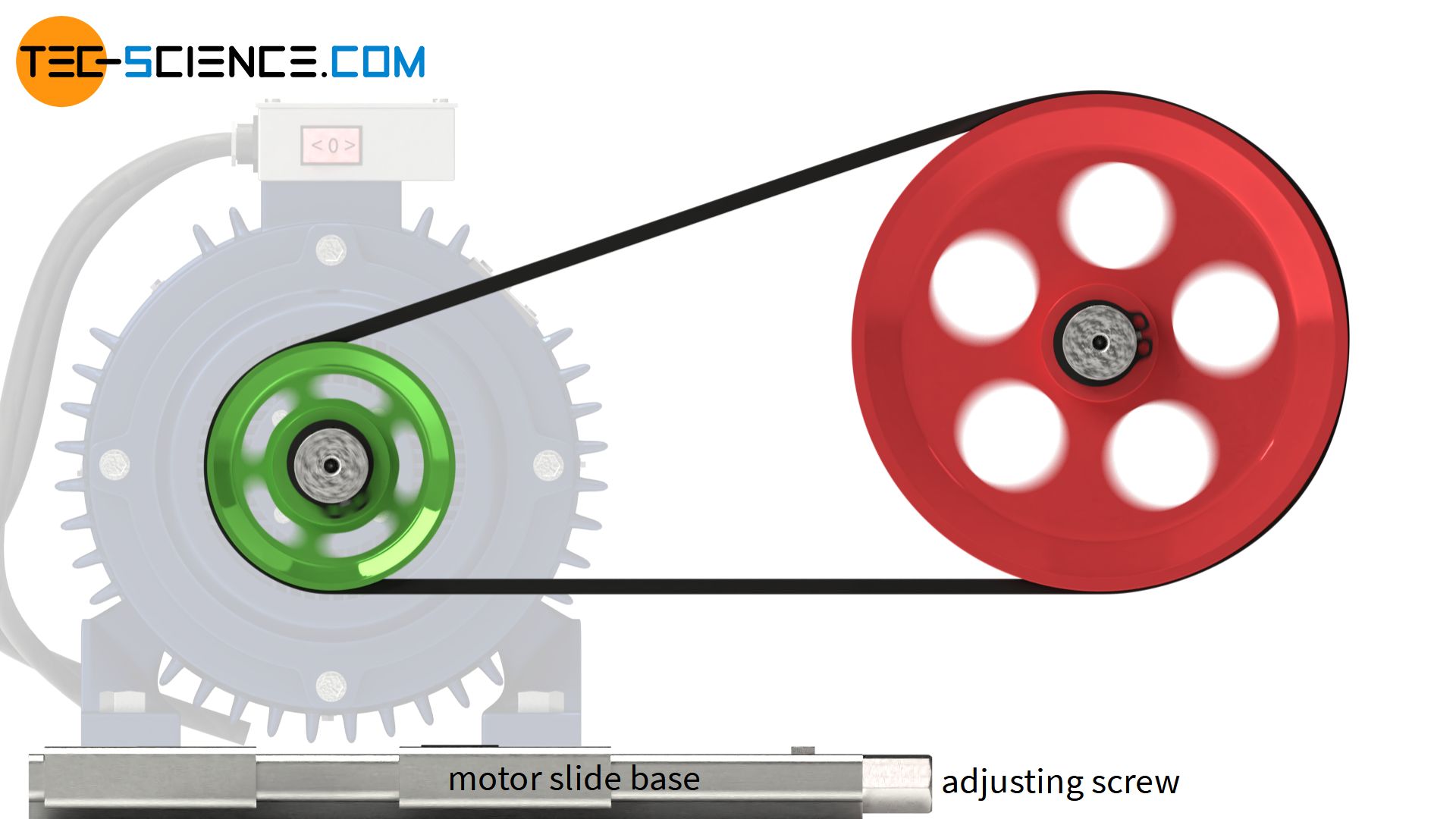

from www.tec-science.com

Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. A comprehensive, effective program of preventive maintenance consists of. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. In addition to proper selection. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. What is a good belt maintenance program? Removing old belts, inspecting all components for wear and damage, checking.

Belt tensioner systems for belt drives tecscience

Belt Drive Maintenance Procedure Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. A comprehensive, effective program of preventive maintenance consists of. What is a good belt maintenance program? Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. In addition to proper selection. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Removing old belts, inspecting all components for wear and damage, checking. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance.

From www.autozone.com

Repair Guides Routine Maintenance Belts Belt Drive Maintenance Procedure The gates belt drive preventive maintenance and safety guide lays it out, step by step. A comprehensive, effective program of preventive maintenance consists of. In addition to proper selection. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime. Belt Drive Maintenance Procedure.

From dokumen.tips

(PDF) Installation & Maintenance of VBelt Drives DOKUMEN.TIPS Belt Drive Maintenance Procedure Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. A comprehensive, effective program of preventive maintenance consists of. Removing old belts, inspecting all components for wear and. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Belt Drive Maintenance Procedure What is a good belt maintenance program? Removing old belts, inspecting all components for wear and damage, checking. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety.. Belt Drive Maintenance Procedure.

From www.sparksbelting.com

5 Questions to Ask Before a Conveyor Belt Repair Sparks Belting Belt Drive Maintenance Procedure In addition to proper selection. What is a good belt maintenance program? Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Removing old belts, inspecting all components for wear and damage, checking. Too much or too. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance And Tuneup Belts Belt Drive Maintenance Procedure Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Removing old belts, inspecting all components for wear and damage, checking. What is a good belt maintenance program? Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. The gates. Belt Drive Maintenance Procedure.

From www.tec-science.com

Belt tensioner systems for belt drives tecscience Belt Drive Maintenance Procedure Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. In addition to proper selection. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators. Belt Drive Maintenance Procedure.

From www.cbac.com

Car Basics All the Drive Belts Explained Christian Brothers Belt Drive Maintenance Procedure In addition to proper selection. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. A comprehensive, effective program of preventive maintenance consists of. Good drive maintenance involves a number of steps, roughly half. Belt Drive Maintenance Procedure.

From www.justanswer.com

Cub Cadet Drive Belt Replacement Instructions Expert Q&A Belt Drive Maintenance Procedure In addition to proper selection. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. A comprehensive, effective program of preventive maintenance consists of. What is a good belt maintenance. Belt Drive Maintenance Procedure.

From www.howacarworks.com

Checking, adjusting and refitting drive belts How a Car Works Belt Drive Maintenance Procedure What is a good belt maintenance program? The gates belt drive preventive maintenance and safety guide lays it out, step by step. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take. Belt Drive Maintenance Procedure.

From studylib.net

VBelt Installation & Maintenance Belt Drive Maintenance Procedure Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Removing old belts, inspecting all components for wear and damage, checking. The gates belt drive preventive maintenance and safety guide. Belt Drive Maintenance Procedure.

From industrialbeltdrives.com

Preventative Maintenance Industrial Belt Drives Belt Drive Maintenance Procedure Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Removing old belts, inspecting all components for wear and damage, checking. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. The gates belt drive preventive maintenance and safety guide lays it out, step by step.. Belt Drive Maintenance Procedure.

From vfauto.com

Drive Belt Maintenance Signs of Wear and Tear V&F Auto Inc Belt Drive Maintenance Procedure Removing old belts, inspecting all components for wear and damage, checking. What is a good belt maintenance program? Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance.. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance And Tuneup Belts Belt Drive Maintenance Procedure A comprehensive, effective program of preventive maintenance consists of. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. What is a good belt maintenance program? Good drive maintenance involves a number of steps, roughly half of. Belt Drive Maintenance Procedure.

From mowerslab.com

Gravely Drive Belt Diagram Guide for Easy Maintenance Belt Drive Maintenance Procedure What is a good belt maintenance program? Removing old belts, inspecting all components for wear and damage, checking. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Fortunately, when it comes to belt drives, downtime can. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Belt Drive Maintenance Procedure Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Removing old belts, inspecting all components for wear and damage, checking. The gates belt drive preventive maintenance and safety guide lays it out, step by step. In addition to proper selection. What is a good belt maintenance program? Good drive maintenance involves. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance Accessory Drive Belts Belt Drive Maintenance Procedure What is a good belt maintenance program? Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Removing old belts, inspecting all components for wear and damage, checking. Too much or too little belt tension, worn pulleys. Belt Drive Maintenance Procedure.

From www.fleetmaintenance.com

Belt Drive System best practices Fleet Maintenance Belt Drive Maintenance Procedure Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. A comprehensive, effective program of preventive maintenance consists of. Removing old belts, inspecting all components for wear and. Belt Drive Maintenance Procedure.

From thegardengadgets.com

Craftsman LT2000 drive belt diagram explanation How it works Belt Drive Maintenance Procedure In addition to proper selection. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Removing old belts, inspecting all components for wear and damage, checking. Too much. Belt Drive Maintenance Procedure.

From www.youtube.com

Toro Lawn Mower Repair How to replace the Drive Belt YouTube Belt Drive Maintenance Procedure A comprehensive, effective program of preventive maintenance consists of. In addition to proper selection. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Good drive maintenance involves a number of steps, roughly half. Belt Drive Maintenance Procedure.

From innovationdiscoveries.space

Belt Drive and its Types Belt Drive Maintenance Procedure Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. The gates belt drive preventive maintenance and safety guide lays it out, step by step. In addition to proper selection. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Fortunately, when it comes to belt. Belt Drive Maintenance Procedure.

From www.scribd.com

Belt Drive Maintenance Gates PDF Belt (Mechanical) Mechanical Belt Drive Maintenance Procedure What is a good belt maintenance program? Removing old belts, inspecting all components for wear and damage, checking. In addition to proper selection. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. A. Belt Drive Maintenance Procedure.

From www.youtube.com

Indian Scout final drive belt alignment procedure YouTube Belt Drive Maintenance Procedure Removing old belts, inspecting all components for wear and damage, checking. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. The gates belt drive preventive maintenance and safety guide lays it out, step by step. In addition to proper selection. What is a good belt maintenance program? Fortunately, when it comes to belt. Belt Drive Maintenance Procedure.

From www.heiyi-belt.com

Proper Belt Drive Maintenance HEIYI HE BEI HEI YI RUBBER CO.,LTD Belt Drive Maintenance Procedure Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Removing old belts, inspecting all components for wear and damage, checking.. Belt Drive Maintenance Procedure.

From www.engineerlive.com

Belt drive optimisation and energy saving, Gates Power Transmission Belt Drive Maintenance Procedure Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. The gates belt drive preventive maintenance and safety guide lays it out, step by step. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. Good drive maintenance involves a number of steps, roughly. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance Accessory Drive Belts Belt Drive Maintenance Procedure Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. Removing old belts, inspecting all components for wear and damage, checking. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Inspecting and replacing belts and faulty drive. Belt Drive Maintenance Procedure.

From www.tec-science.com

How does a belt drive work? tecscience Belt Drive Maintenance Procedure A comprehensive, effective program of preventive maintenance consists of. Removing old belts, inspecting all components for wear and damage, checking. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Fortunately, when it comes to belt. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance And Tuneup Belts Belt Drive Maintenance Procedure What is a good belt maintenance program? Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Removing. Belt Drive Maintenance Procedure.

From armychemicaloperations.tpub.com

Maintenance of the Drive Belts. Belt Drive Maintenance Procedure A comprehensive, effective program of preventive maintenance consists of. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. The gates belt drive preventive maintenance and safety guide lays it out, step by step. What is a good belt maintenance program? In addition to proper selection. Good drive maintenance involves a number. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance And Tuneup Belts Belt Drive Maintenance Procedure Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. In addition to proper selection. A comprehensive, effective program of preventive maintenance consists of. What is a good belt maintenance program? Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators. Belt Drive Maintenance Procedure.

From www.je-bearing.com

Belt Drive Maintenance JE Bearing Belt Drive Maintenance Procedure What is a good belt maintenance program? In addition to proper selection. Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. A comprehensive, effective program of preventive maintenance consists of. Removing old belts, inspecting all. Belt Drive Maintenance Procedure.

From cambelt.com

A Guide To Conveyor Belt Maintenance Cambelt International Belt Drive Maintenance Procedure Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance.. Belt Drive Maintenance Procedure.

From limblecmms.com

The Basics of Conveyor Maintenance Belt Drive Maintenance Procedure Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. What is a good belt maintenance program? Removing old belts, inspecting all components for wear and damage, checking. Too much or too little belt tension, worn pulleys and pulley misalignment are key indicators of poor maintenance. The gates belt drive preventive maintenance and safety. Belt Drive Maintenance Procedure.

From www.motorcyclistonline.com

Motorcycle Belt Drive Maintenance Motorcyclist Belt Drive Maintenance Procedure Removing old belts, inspecting all components for wear and damage, checking. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. What is a good belt maintenance program? Inspecting and replacing belts and faulty drive components before they fail will reduce costly downtime and production delays.. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance Belts Belt Drive Maintenance Procedure Removing old belts, inspecting all components for wear and damage, checking. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Fortunately, when it comes to belt drives, downtime can often be prevented, and there are straightforward steps you can take to improve workplace safety. The gates belt drive preventive maintenance and safety guide. Belt Drive Maintenance Procedure.

From www.autozone.com

Repair Guides Routine Maintenance And Tuneup Belts Belt Drive Maintenance Procedure The gates belt drive preventive maintenance and safety guide lays it out, step by step. Removing old belts, inspecting all components for wear and damage, checking. In addition to proper selection. Good drive maintenance involves a number of steps, roughly half of which involve aligning the drive. Fortunately, when it comes to belt drives, downtime can often be prevented, and. Belt Drive Maintenance Procedure.