Thermal Pad Compression Ratio . Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. Providing a thermal path between a hot component and a. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Gap fillers are a very specific type of thermal interface material (tim). The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. Without minimal compression, efficiency is not guaranteed. Compression ratio of the material. They are designed to deform various gaps when dealing with.

from www.azom.com

The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Compression ratio of the material. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. Without minimal compression, efficiency is not guaranteed. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Providing a thermal path between a hot component and a. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. They are designed to deform various gaps when dealing with. Gap fillers are a very specific type of thermal interface material (tim).

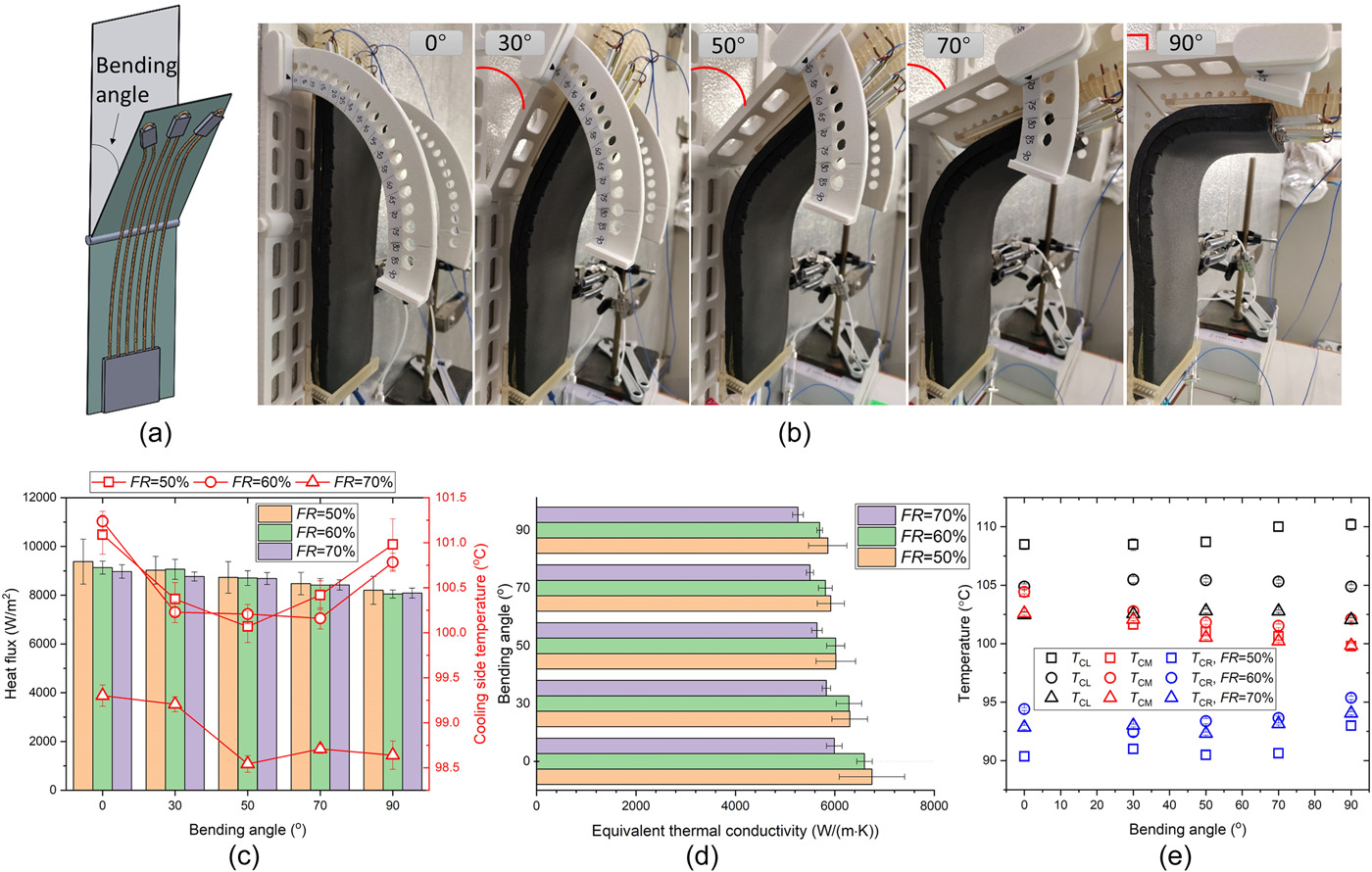

Soft Heat Pipes Inspired by Squids

Thermal Pad Compression Ratio The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. They are designed to deform various gaps when dealing with. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Compression ratio of the material. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. Providing a thermal path between a hot component and a. Without minimal compression, efficiency is not guaranteed. Gap fillers are a very specific type of thermal interface material (tim).

From www.youtube.com

What are Thermal Relief Pads? PCB Knowledge YouTube Thermal Pad Compression Ratio The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. They are designed to deform various gaps when dealing with. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. This paper focuses on the characteristics of gap fillers. Thermal Pad Compression Ratio.

From www.caplinq.com

Thermal Gap Pads Thermal Interface Materials CAPLINQ Corporation Thermal Pad Compression Ratio This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Providing a thermal path between a hot component and a. The compression ratio refers to. Thermal Pad Compression Ratio.

From www.reddit.com

ASUS TUF 3080 Thermal Pads Gelid Extreme (8 degree improvement for me Thermal Pad Compression Ratio The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. Compression ratio of the material. Gap fillers are a very specific type of thermal interface material (tim). They are designed to deform various gaps when dealing with. This paper focuses on the characteristics of gap fillers and how they impact a. Thermal Pad Compression Ratio.

From www.youtube.com

Guide How I measure the exact size of Thermal pads krisfixgermany Thermal Pad Compression Ratio Gap fillers are a very specific type of thermal interface material (tim). They are designed to deform various gaps when dealing with. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to. Thermal Pad Compression Ratio.

From www.aok-technologies.com

Thermal Interface Material Comparison Thermal Pads vs Thermal Grease AOK Thermal Pad Compression Ratio This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. Compression ratio of the material. Without minimal compression, efficiency is not guaranteed. Gap fillers are. Thermal Pad Compression Ratio.

From www.exsun-china.com

Thermal silicone sheet (thermal pad) Thermal pads Product Center Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. Gap fillers are a very specific type of thermal interface material (tim). This is done with the ratio of the gap filler pad, meters to millimeters squared —. Thermal Pad Compression Ratio.

From www.aliexpress.com

Thermal Conductive 8.5W Pad Honeywell PTM7950 Phase Change Silicone Pad Thermal Pad Compression Ratio Providing a thermal path between a hot component and a. Compression ratio of the material. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Gap fillers are a very specific type of thermal interface material (tim). The extensive gap pad family provides an effective thermal interface. Thermal Pad Compression Ratio.

From www.reddit.com

PSA Thermal pads need compression to get their "rated" thermal Thermal Pad Compression Ratio Gap fillers are a very specific type of thermal interface material (tim). Providing a thermal path between a hot component and a. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Once the thermal pad is set up, it must be compressed in order to drive the. Thermal Pad Compression Ratio.

From resources.altium.com

Thermal Pads vs Thermal Paste Best Solution for Mounting Heatsinks on Thermal Pad Compression Ratio Providing a thermal path between a hot component and a. They are designed to deform various gaps when dealing with. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. This paper focuses. Thermal Pad Compression Ratio.

From www.thermalmgt.com

Thermal Pad Thermal Management Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Compression ratio of the material. Gap fillers are a very specific type of thermal interface material (tim). The extensive gap pad family provides an effective thermal interface between. Thermal Pad Compression Ratio.

From www.hkdivedi.com

DIESEL CYCLE VOLUMETRIC COMPRESSION RATIO, EXPANSION RATIO, CUTOFF Thermal Pad Compression Ratio The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. Without minimal compression, efficiency is not guaranteed. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. This paper focuses on the characteristics of gap fillers and how they impact. Thermal Pad Compression Ratio.

From www.researchgate.net

Compression stressstrain curve for rubbers with different hardness Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Without minimal compression, efficiency is not guaranteed. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and. Thermal Pad Compression Ratio.

From www.researchgate.net

Compressive static load and thermal impedance for various compression Thermal Pad Compression Ratio Without minimal compression, efficiency is not guaranteed. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. Compression ratio of the material. This paper focuses. Thermal Pad Compression Ratio.

From www.dazmode.com

Fujipoly Sarcon® Extremeperformance Thermal Pad 0.5mm 13mk/W DazMode Thermal Pad Compression Ratio Providing a thermal path between a hot component and a. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. Without minimal compression, efficiency is not guaranteed. Once the. Thermal Pad Compression Ratio.

From www.doghouserepair.com

Calculate Compression Ratio Doghouse Repair Thermal Pad Compression Ratio Gap fillers are a very specific type of thermal interface material (tim). The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. This is done with the ratio of the. Thermal Pad Compression Ratio.

From www.youtube.com

Understanding Thermal Gap Filler Pads, PCB Deflection, and Stress YouTube Thermal Pad Compression Ratio Without minimal compression, efficiency is not guaranteed. Gap fillers are a very specific type of thermal interface material (tim). Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. They. Thermal Pad Compression Ratio.

From www.azom.com

Soft Heat Pipes Inspired by Squids Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. Providing a thermal path between a hot component and a. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface. Thermal Pad Compression Ratio.

From www.semanticscholar.org

Alternative fine pitch solution of low cost and high throughput thermal Thermal Pad Compression Ratio This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Without minimal compression, efficiency is not guaranteed. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. This is done with the ratio of the gap filler pad, meters to. Thermal Pad Compression Ratio.

From journals.sagepub.com

Tensile, compression, and flexural characteristics of acrylonitrile Thermal Pad Compression Ratio Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Gap fillers are a very specific type of thermal interface material (tim). The extensive gap pad. Thermal Pad Compression Ratio.

From smcinternational.in

Buy The Best PreBuilt & Custom Built Gaming PCs in India SMC Thermal Pad Compression Ratio Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. Gap fillers are a very specific type of thermal interface material (tim). The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. This paper focuses on the characteristics of gap. Thermal Pad Compression Ratio.

From ezonelb.com

CoolerMaster Thermal Pad 1.0mm Purple 13.3W/MK 95X95 ExpertZone Thermal Pad Compression Ratio Compression ratio of the material. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Without minimal compression, efficiency is not guaranteed. Gap fillers are a very specific. Thermal Pad Compression Ratio.

From www.linkedin.com

Enhancing Structural Integrity and Safety in EV Battery Packs The Role Thermal Pad Compression Ratio Without minimal compression, efficiency is not guaranteed. Compression ratio of the material. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. Providing a thermal path between a hot. Thermal Pad Compression Ratio.

From www.aliexpress.com

Thermal Conductive 8.5w Pad honeywell Ptm7950 Phase Change Silicone Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. Compression ratio of the material. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Providing a thermal path between a hot component and a. Once the thermal pad is set up, it must be compressed in order. Thermal Pad Compression Ratio.

From unitedseal.com

High Thermal Conductivity Gap Filler Pads Thermal Interface Materials Thermal Pad Compression Ratio Gap fillers are a very specific type of thermal interface material (tim). The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. Compression ratio of the material. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Once the thermal. Thermal Pad Compression Ratio.

From www.desertcart.nz

Buy ARCTIC Thermal Pad 145 x 145 x 1.5 mm (Pack of 1) Thermal Thermal Pad Compression Ratio Compression ratio of the material. Gap fillers are a very specific type of thermal interface material (tim). They are designed to deform various gaps when dealing with. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. This paper focuses on the characteristics of gap fillers and how they impact a. Thermal Pad Compression Ratio.

From www.tapesolutions.saint-gobain.com

Improve EV Battery Protection w/ Compression Pads SaintGobain Thermal Pad Compression Ratio This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Compression ratio of the material. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. The extensive gap pad family provides an effective thermal interface between heat sinks and. Thermal Pad Compression Ratio.

From www.thermazig.com

Compressible Silicone Thermal Pad TIF840HP High Conductivity Micro Heat Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Without minimal compression, efficiency is. Thermal Pad Compression Ratio.

From dsportmag.com

Performance Tech Compression Ratio 101 Part2 DSPORT Magazine Thermal Pad Compression Ratio Compression ratio of the material. The compression ratio refers to the material’s thickness change under different pressures, providing a convenient parameter for thermal. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. The extensive gap pad family provides an effective thermal interface between heat sinks and. Thermal Pad Compression Ratio.

From www.reddit.com

PSA Thermal pads need compression to get their "rated" thermal Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. Without minimal compression, efficiency is. Thermal Pad Compression Ratio.

From theaxo.com

Thermal Paste VS Thermal Pads Which Is The Ultimate Thermal Interface Thermal Pad Compression Ratio Without minimal compression, efficiency is not guaranteed. Gap fillers are a very specific type of thermal interface material (tim). Providing a thermal path between a hot component and a. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including compression characteristics of. The compression ratio refers to the material’s thickness change. Thermal Pad Compression Ratio.

From www.researchgate.net

Thermal conductivity ratio at different volume concentrations and Thermal Pad Compression Ratio Gap fillers are a very specific type of thermal interface material (tim). This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. Once the thermal pad is set up, it must be compressed in order to drive the air out, and thus be efficient. The compression ratio. Thermal Pad Compression Ratio.

From www.ctwinc.com

Standard Compression Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. Compression ratio of the material. Gap fillers are a very specific type of thermal interface material (tim). Providing a thermal path between a hot component and a. This paper focuses on. Thermal Pad Compression Ratio.

From insights.globalspec.com

Innovative compression pads for maximum EV battery cell performance Thermal Pad Compression Ratio Without minimal compression, efficiency is not guaranteed. The extensive gap pad family provides an effective thermal interface between heat sinks and electronic devices where uneven surface. They are designed to deform various gaps when dealing with. Compression ratio of the material. This paper focuses on the characteristics of gap fillers and how they impact a printed circuit board (pcb) including. Thermal Pad Compression Ratio.

From www.fqbms.com

China Fuzhou Fuqiang Precision Co., Ltd. latest company cases about Thermal Pad Compression Ratio They are designed to deform various gaps when dealing with. Without minimal compression, efficiency is not guaranteed. Gap fillers are a very specific type of thermal interface material (tim). This is done with the ratio of the gap filler pad, meters to millimeters squared — the ratio to thickness and surface area. The extensive gap pad family provides an effective. Thermal Pad Compression Ratio.