Flexible Hose Length Calculation . Always install the metal hose assembly so that flexing occurs in one plane only and this is. Measure the extended length, then scale up if necessary to determine the. • up to 400 mm length: The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. These calculators will help you to determine the. To find the minimum live hose length requirement for your assembly, consult the calculator below. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. Length the overall length of hoses shall be specified by the client. A hose must be of the correct length in order to serve its purpose. Flexing a metal hose in two separate planes of movement will torque the hose assembly. Run the flexible tubing between them with full radii round bends.

from hosemart.in

Always install the metal hose assembly so that flexing occurs in one plane only and this is. Measure the extended length, then scale up if necessary to determine the. Flexing a metal hose in two separate planes of movement will torque the hose assembly. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Length the overall length of hoses shall be specified by the client. • up to 400 mm length: These calculators will help you to determine the. Run the flexible tubing between them with full radii round bends. A hose must be of the correct length in order to serve its purpose.

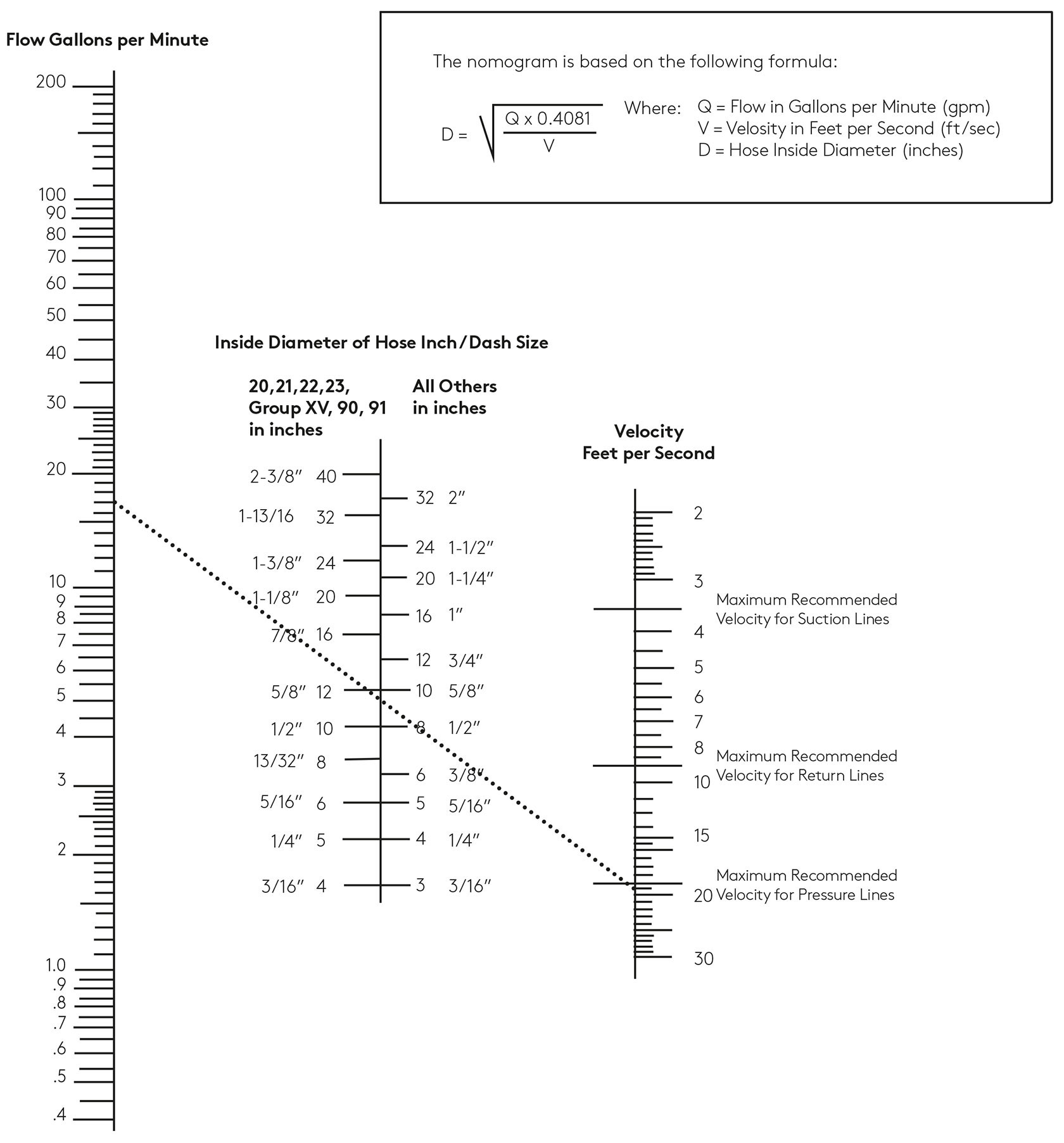

Determine Hydraulic Hose Size (Using Nomogram) HoseMart

Flexible Hose Length Calculation Always install the metal hose assembly so that flexing occurs in one plane only and this is. Flexing a metal hose in two separate planes of movement will torque the hose assembly. • up to 400 mm length: These calculators will help you to determine the. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Always install the metal hose assembly so that flexing occurs in one plane only and this is. Run the flexible tubing between them with full radii round bends. A hose must be of the correct length in order to serve its purpose. Measure the extended length, then scale up if necessary to determine the. To find the minimum live hose length requirement for your assembly, consult the calculator below. Length the overall length of hoses shall be specified by the client. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less.

From www.youtube.com

How to correctly measure flexible hose from shipping box to complete Flexible Hose Length Calculation To find the minimum live hose length requirement for your assembly, consult the calculator below. These calculators will help you to determine the. A hose must be of the correct length in order to serve its purpose. Flexing a metal hose in two separate planes of movement will torque the hose assembly. The hose is flexed at the end fitting,. Flexible Hose Length Calculation.

From www.adinaporter.com

Flex Duct Sizing Chart AdinaPorter Flexible Hose Length Calculation Always install the metal hose assembly so that flexing occurs in one plane only and this is. To find the minimum live hose length requirement for your assembly, consult the calculator below. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. These calculators will. Flexible Hose Length Calculation.

From eflex.vn

Flexible Metal Hose with Braiding EFR Flexible Hose Length Calculation To find the minimum live hose length requirement for your assembly, consult the calculator below. These calculators will help you to determine the. Always install the metal hose assembly so that flexing occurs in one plane only and this is. Flexing a metal hose in two separate planes of movement will torque the hose assembly. Run the flexible tubing between. Flexible Hose Length Calculation.

From www.orientflexhose.com

Flexible Metal Hose Orientflex Flexible Hose Length Calculation • up to 400 mm length: The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Run the flexible tubing between them with full radii round bends. Measure the extended length, then scale up if necessary to determine the. To find the minimum live hose. Flexible Hose Length Calculation.

From hydraflex.co.uk

STAINLESS STEEL BESPOKE BRAIDED FLEXIBLE HOSE ASSEMBLIES Hydraflex Flexible Hose Length Calculation A hose must be of the correct length in order to serve its purpose. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. These calculators will help you to determine the. To find the minimum live hose length requirement for your assembly, consult the. Flexible Hose Length Calculation.

From fixedtoday.com.au

What Is A Flexible Plumbing Hose? [Learn Plumbing] ‐ Fixed Today Plumbing Flexible Hose Length Calculation Length the overall length of hoses shall be specified by the client. These calculators will help you to determine the. • up to 400 mm length: The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Flexing a metal hose in two separate planes of. Flexible Hose Length Calculation.

From www.hotzxgirl.com

Flexible Hose Sizes Hot Sex Picture Flexible Hose Length Calculation A hose must be of the correct length in order to serve its purpose. • up to 400 mm length: The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Length the overall length of hoses shall be specified by the client. Whether static or. Flexible Hose Length Calculation.

From www.hosemaster.com

Tools for Calculating Proper Hose Length Hose Master Flexible Hose Length Calculation Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. Run the flexible tubing between them with full radii round bends. Measure the extended length, then scale up if necessary to determine the. A hose must be of the correct length in order to serve. Flexible Hose Length Calculation.

From www.pneumatictips.com

How do you select compressed air hose sizes? Flexible Hose Length Calculation A hose must be of the correct length in order to serve its purpose. To find the minimum live hose length requirement for your assembly, consult the calculator below. Always install the metal hose assembly so that flexing occurs in one plane only and this is. Length the overall length of hoses shall be specified by the client. • up. Flexible Hose Length Calculation.

From www.hosemaster.com

Tools for Calculating Proper Hose Length Hose Master Flexible Hose Length Calculation To find the minimum live hose length requirement for your assembly, consult the calculator below. A hose must be of the correct length in order to serve its purpose. • up to 400 mm length: These calculators will help you to determine the. Always install the metal hose assembly so that flexing occurs in one plane only and this is.. Flexible Hose Length Calculation.

From www.researchgate.net

The design parameters of the flexible hose Length L h 400m Download Table Flexible Hose Length Calculation Flexing a metal hose in two separate planes of movement will torque the hose assembly. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Measure the extended length, then scale up if necessary to determine the. Whether static or dynamic, the first rule concerning. Flexible Hose Length Calculation.

From www.aeroflexindia.com

Complete Guide To Install The Stainless Steel Flexible Hose Flexible Hose Length Calculation Always install the metal hose assembly so that flexing occurs in one plane only and this is. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Run the flexible tubing between them with full radii round bends. Length the overall length of hoses shall. Flexible Hose Length Calculation.

From blog.flexaust.com

Hose Bend Radius Essentials Flexaust Inc. Flexible Hose Length Calculation A hose must be of the correct length in order to serve its purpose. Run the flexible tubing between them with full radii round bends. Length the overall length of hoses shall be specified by the client. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the. Flexible Hose Length Calculation.

From www.polyhose.com

SS Flexible Hose Manufacturer Polyhose India pvt ltd Flexible Hose Length Calculation Flexing a metal hose in two separate planes of movement will torque the hose assembly. Run the flexible tubing between them with full radii round bends. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Whether static or dynamic, the first rule concerning the. Flexible Hose Length Calculation.

From kingdaflex.com

What Is The Minimum Hydraulic Hose Bend Radius? [How To Calculate Bend Flexible Hose Length Calculation A hose must be of the correct length in order to serve its purpose. Measure the extended length, then scale up if necessary to determine the. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. • up to 400 mm length: Always install the. Flexible Hose Length Calculation.

From hosemart.in

Determine Hydraulic Hose Size (Using Nomogram) HoseMart Flexible Hose Length Calculation A hose must be of the correct length in order to serve its purpose. Measure the extended length, then scale up if necessary to determine the. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. • up to 400 mm length: Whether static or. Flexible Hose Length Calculation.

From dokumen.tips

(PDF) Hose Assembly Live Length Calculation Guide DOKUMEN.TIPS Flexible Hose Length Calculation Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. A hose must be of the correct length in order to serve its purpose. Length the overall length of hoses shall be specified by the client. Flexing a metal hose in two separate planes of. Flexible Hose Length Calculation.

From flexonics.com

Series 700 High Pressure Stainless Steel Hose Flexible Hose Length Calculation To find the minimum live hose length requirement for your assembly, consult the calculator below. Run the flexible tubing between them with full radii round bends. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. These calculators will help you to determine the. A. Flexible Hose Length Calculation.

From www.metraflex.com

Why Use Steel Braided Hose? Metraflex Flexible Hose Length Calculation Always install the metal hose assembly so that flexing occurs in one plane only and this is. Length the overall length of hoses shall be specified by the client. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. Flexing a metal hose in two. Flexible Hose Length Calculation.

From hydraflex.co.uk

STAINLESS STEEL BESPOKE BRAIDED FLEXIBLE HOSE ASSEMBLIES Hydraflex Flexible Hose Length Calculation Run the flexible tubing between them with full radii round bends. Measure the extended length, then scale up if necessary to determine the. These calculators will help you to determine the. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. To find the minimum. Flexible Hose Length Calculation.

From www.aeroflexindia.com

The Ultimate End Fittings Guide For Stainless Steel Flexible Hoses Flexible Hose Length Calculation Always install the metal hose assembly so that flexing occurs in one plane only and this is. Length the overall length of hoses shall be specified by the client. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. Run the flexible tubing between them. Flexible Hose Length Calculation.

From www.hoseandfittings.com

Measuring Hose Length Hose and Fittings Source Flexible Hose Length Calculation Measure the extended length, then scale up if necessary to determine the. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. Run the flexible tubing between them with full radii round bends. The hose is flexed at the end fitting, with stress being applied. Flexible Hose Length Calculation.

From www.pinterest.ca

Home Air Ventilation Stunning Hvac Duct Sizes Duct Sizing Chart Flexible Hose Length Calculation These calculators will help you to determine the. Flexing a metal hose in two separate planes of movement will torque the hose assembly. A hose must be of the correct length in order to serve its purpose. • up to 400 mm length: Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend. Flexible Hose Length Calculation.

From www.aircraftsystemstech.com

Aircraft Flexible Hose Fluid Lines Flexible Hose Length Calculation Always install the metal hose assembly so that flexing occurs in one plane only and this is. Measure the extended length, then scale up if necessary to determine the. These calculators will help you to determine the. Flexing a metal hose in two separate planes of movement will torque the hose assembly. • up to 400 mm length: Whether static. Flexible Hose Length Calculation.

From www.powermovingforward.com

Measuring the Length of a Hydraulic Hose ProPulse®—a Schieffer Company Flexible Hose Length Calculation Length the overall length of hoses shall be specified by the client. Measure the extended length, then scale up if necessary to determine the. Run the flexible tubing between them with full radii round bends. These calculators will help you to determine the. Always install the metal hose assembly so that flexing occurs in one plane only and this is.. Flexible Hose Length Calculation.

From studydbsommer.z13.web.core.windows.net

Gates Flex Hose Size Chart Flexible Hose Length Calculation Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. Flexing a metal hose in two separate planes of movement will torque the hose assembly. • up to 400 mm length: Length the overall length of hoses shall be specified by the client. To find. Flexible Hose Length Calculation.

From www.thepressurewasherpro.com

How To Determine Hose Size With GPM And Pressure The Pressure Washer Pro! Flexible Hose Length Calculation These calculators will help you to determine the. Always install the metal hose assembly so that flexing occurs in one plane only and this is. To find the minimum live hose length requirement for your assembly, consult the calculator below. A hose must be of the correct length in order to serve its purpose. Measure the extended length, then scale. Flexible Hose Length Calculation.

From stsaero.com

How to Order Hose Assemblies STS Aerospace Flexible Hose Length Calculation Always install the metal hose assembly so that flexing occurs in one plane only and this is. These calculators will help you to determine the. Flexing a metal hose in two separate planes of movement will torque the hose assembly. Length the overall length of hoses shall be specified by the client. Whether static or dynamic, the first rule concerning. Flexible Hose Length Calculation.

From www.hoseandfittings.com

STAMPED Hydraulic Fitting Size Chart Flexible Hose Length Calculation Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. Always install the metal hose assembly so that flexing occurs in one plane only and this is. Length the overall length of hoses shall be specified by the client. These calculators will help you to. Flexible Hose Length Calculation.

From matthewlwade.blob.core.windows.net

Water Pipe Sizing Calculator at matthewlwade blog Flexible Hose Length Calculation These calculators will help you to determine the. Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. To find the minimum live hose length requirement for your assembly, consult the calculator below. Run the flexible tubing between them with full radii round bends. •. Flexible Hose Length Calculation.

From whatispiping.com

Introduction to Flexible Hoses (With PDF) What Is Piping All about Flexible Hose Length Calculation A hose must be of the correct length in order to serve its purpose. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. Always install the metal hose assembly so that flexing occurs in one plane only and this is. Length the overall length. Flexible Hose Length Calculation.

From mungfali.com

SS Flexible Hose Flexible Hose Length Calculation The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. A hose must be of the correct length in order to serve its purpose. These calculators will help you to determine the. Measure the extended length, then scale up if necessary to determine the. Run. Flexible Hose Length Calculation.

From www.youtube.com

Flexible Hose length calculations YouTube Flexible Hose Length Calculation To find the minimum live hose length requirement for your assembly, consult the calculator below. Length the overall length of hoses shall be specified by the client. Always install the metal hose assembly so that flexing occurs in one plane only and this is. A hose must be of the correct length in order to serve its purpose. The hose. Flexible Hose Length Calculation.

From www.scribd.com

Flexible & Rigid PVC Pipe Size Identification Pipe (Fluid Conveyance Flexible Hose Length Calculation • up to 400 mm length: Flexing a metal hose in two separate planes of movement will torque the hose assembly. The hose is flexed at the end fitting, with stress being applied to the hose at an angle to the axis of the end fitting. A hose must be of the correct length in order to serve its purpose.. Flexible Hose Length Calculation.

From www.hosemaster.com

Tools for Calculating Proper Hose Length Hose Master Flexible Hose Length Calculation Whether static or dynamic, the first rule concerning the configuration of the hose is that the bend radius of the hose must never be less. These calculators will help you to determine the. Length the overall length of hoses shall be specified by the client. Flexing a metal hose in two separate planes of movement will torque the hose assembly.. Flexible Hose Length Calculation.