Air Seal Bearing . It is resilient, efficient, and requires little maintenance. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. See product specifications, design features, industry applications, and support resources. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications.

from www.kemel.com

Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. See product specifications, design features, industry applications, and support resources.

KEMEL EAGLE INDUSTRY CO.,LTD.

Air Seal Bearing Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. See product specifications, design features, industry applications, and support resources. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. It is resilient, efficient, and requires little maintenance. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case.

From www.newwayairbearings.com

Non Contact Shaft Seals & Air Seals New Way Air Bearings Air Seal Bearing Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and. Air Seal Bearing.

From simplybearings.co.uk

Double Row Deep Groove Ball Bearings Replacement Deep Groove Bearings Air Seal Bearing Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. It is resilient, efficient, and requires little maintenance. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. See product specifications, design features, industry applications, and support resources. Air seals. Air Seal Bearing.

From bearingfinder.ntnamericas.com

Item AC6000LLB, AC Bearings Double Sealed (NonContact Rubber Seal Air Seal Bearing It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Sepco sas is a pneumatic sealing system that seals the. Air Seal Bearing.

From www.youtube.com

A Closer Look Main bearing Pt. 7 Carbon seals YouTube Air Seal Bearing Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Explore the history, advantages, and design features of air bearings, and how to choose the best type for. Air Seal Bearing.

From www.firstcomponents.com

Sealed Bearing Headset Maintenance, Installation, Removal Air Seal Bearing See product specifications, design features, industry applications, and support resources. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. It is resilient, efficient, and requires little. Air Seal Bearing.

From www.tdbearing.com

How to Protect Bearings from the Elements Air Seal Bearing Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. See product specifications, design features, industry applications, and support resources. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. It is resilient, efficient, and requires. Air Seal Bearing.

From www.ibspe.com

Vacuum preloaded air bearings for precision motion control engineering Air Seal Bearing See product specifications, design features, industry applications, and support resources. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Air seals use engineered clearances and directional flow. Air Seal Bearing.

From www.airbearings.co.uk

What is an Air Bearing? · Air Bearings Limited Air Seal Bearing It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. See product specifications, design features, industry applications, and support resources.. Air Seal Bearing.

From www.newwayairbearings.com

Air Bearings Mythbusters Guide New Way Air Bearings Air Seal Bearing Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Explore the history, advantages, and design features of air bearings,. Air Seal Bearing.

From www.pumpsandsystems.com

Bearing Isolators Are Key for Overall System Reliability Pumps & Systems Air Seal Bearing Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Air seals are advanced sealing devices that utilize a thin layer of air. Air Seal Bearing.

From www.kemel.com

KEMEL EAGLE INDUSTRY CO.,LTD. Air Seal Bearing It is resilient, efficient, and requires little maintenance. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Sepco sas is a pneumatic sealing system that seals the shafts of. Air Seal Bearing.

From www.bearingtips.com

What are labyrinth seals for bearings? Bearing Tips Air Seal Bearing Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles. Air Seal Bearing.

From www.mdpi.com

Aerospace Free FullText Numerical Investigation on Windback Seals Air Seal Bearing Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic. Air Seal Bearing.

From empoweringpumps.com

Sealing HighSpeed Shafts in Turbomachinery [Fluid Sealing Association Air Seal Bearing Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing devices that utilize a thin layer of. Air Seal Bearing.

From www.researchgate.net

Bearing seal by labyrinth and sealing air [3] I) sealing air housing Air Seal Bearing It is resilient, efficient, and requires little maintenance. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Explore the history, advantages, and design features of air bearings,. Air Seal Bearing.

From www.tribonet.org

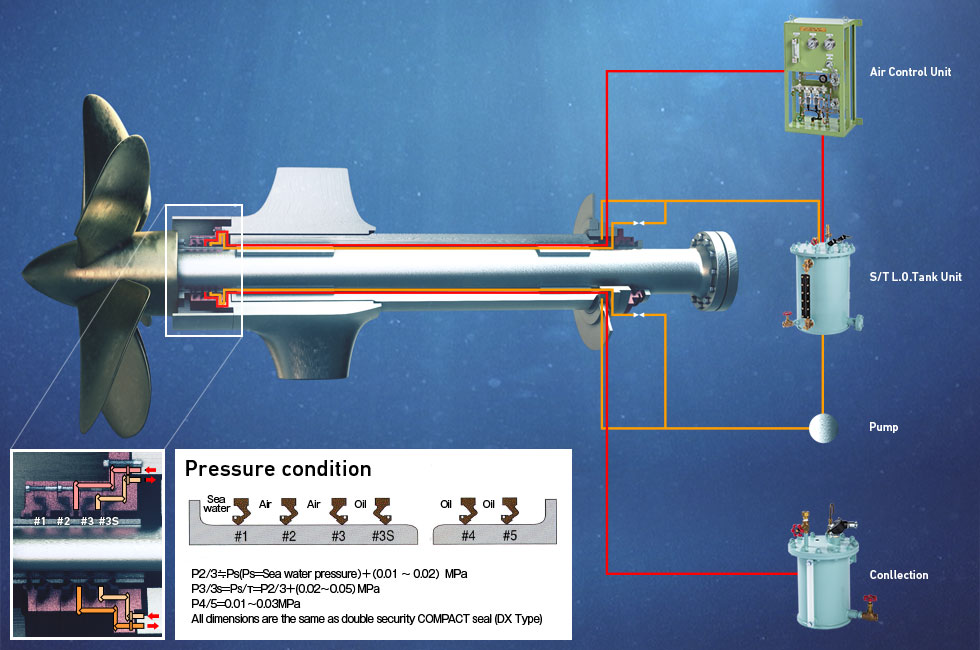

Stern Tube Sealing System About Tribology Air Seal Bearing It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. See product specifications, design features, industry applications, and support resources. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Learn how. Air Seal Bearing.

From medias-at.schaeffler.com

Sealing of the bearing positions Schaeffler medias Air Seal Bearing Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. It is resilient, efficient, and requires little maintenance. Sepco sas is a pneumatic. Air Seal Bearing.

From ibtinc.com

Sealmaster Bearings Save Bakery 50,000/year Air Seal Bearing Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. See product specifications, design features, industry applications, and support resources. Air seals use engineered clearances and directional flow. Air Seal Bearing.

From aeromodelbasic.blogspot.com

model aircraft Ring seals Air Seal Bearing It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. See product specifications, design features, industry applications, and support resources. Learn how. Air Seal Bearing.

From calgaryvacuums.ca

Motor 2 Stage Bypass 5.7″, Tangential Discharge 120 Volt Epoxy Painted Air Seal Bearing Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. It is resilient, efficient, and requires little maintenance. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Sepco sas is a pneumatic. Air Seal Bearing.

From www.wwgtp.com

Bearings & Seals World Wide Gas Turbine Products, Inc. (WWGTP) Air Seal Bearing Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Air. Air Seal Bearing.

From www.newwayairbearings.com

Porous Media Technology for Gas Seals New Way Air Bearings Air Seal Bearing Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. See product specifications, design features, industry applications, and support resources. Learn how air bearings use. Air Seal Bearing.

From boruiseal.en.made-in-china.com

Dry Running Air Shaft Seal Pneumatic Shaft Seal Bearing Protector Oil Air Seal Bearing Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). It is resilient, efficient, and requires little maintenance. Air seals are advanced sealing. Air Seal Bearing.

From santent.in

Fundamentals of Air Bearings SantEnt Air Seal Bearing It is resilient, efficient, and requires little maintenance. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Air seals are advanced sealing devices that utilize a. Air Seal Bearing.

From www.windpowermonthly.com

SKF launches rotor shaft bearing seal Windpower Monthly Air Seal Bearing It is resilient, efficient, and requires little maintenance. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. See product specifications, design features, industry applications, and support resources. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Air seals. Air Seal Bearing.

From smbbearings.blogspot.com

SMB Bearings Ltd Blog Bearing closures types, uses & selection... Air Seal Bearing Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. See product specifications, design features, industry applications, and support resources. Explore the history, advantages, and design features. Air Seal Bearing.

From bigamart.com

XIKE 4 Pcs 6000ZZ Double Metal Seal Bearings,Prelubricated and Stable Air Seal Bearing Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). See product specifications, design features, industry applications, and support resources. It is resilient, efficient, and requires little maintenance. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too. Air Seal Bearing.

From www.bearingcentre.net

Bearings Lubrication Systems in South Africa Bearing Centre Air Seal Bearing Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for precision positioning and high speed applications. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too. Air Seal Bearing.

From advanced-emc.com

Polymer Labyrinth Seals Advanced EMC Technologies Air Seal Bearing See product specifications, design features, industry applications, and support resources. It is resilient, efficient, and requires little maintenance. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Learn how. Air Seal Bearing.

From www.kracht.nl

Bearings Air Bearings Frictionless bearings for industrial Air Seal Bearing Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Air. Air Seal Bearing.

From www.lily-bearing.com

Shielded Vs Sealed Bearings LILY Bearing Air Seal Bearing Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact between surfaces. See product specifications, design features, industry applications, and support resources. Sepco sas is a pneumatic sealing system that seals the. Air Seal Bearing.

From boruiseal.en.made-in-china.com

Bearing Isolator Mixer Shaft Seal Shaft Runout Seal Air Shaft Seal Air Seal Bearing See product specifications, design features, industry applications, and support resources. Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Learn how air bearings use a thin. Air Seal Bearing.

From www.newwayairbearings.com

The System Integrator’s Guide to Bonded Bearings New Way Air Bearings Air Seal Bearing Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Explore the history, advantages, and design features of air bearings, and how to choose the best type for your use case. See product specifications, design features, industry applications, and support resources. Learn how air bearings use a thin film of pressurized. Air Seal Bearing.

From www.indiamart.com

OAV Air Bearings at Rs 2000/piece Air Bearings in Kolkata ID Air Seal Bearing Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Air seals are advanced sealing devices that utilize a thin layer of air to prevent direct contact. Air Seal Bearing.

From agdproducts.com

DURASHIELD E SERIES SEALS Air Seal Bearing Sepco sas is a pneumatic sealing system that seals the shafts of equipment where contact seals are too costly. Air seals use engineered clearances and directional flow paths to create uniform pressure and velocity profiles that generate a pneumatic seal (see figure 2). Learn how air bearings use a thin film of pressurized air to provide frictionless, loadbearing interfaces for. Air Seal Bearing.