Spiral Bevel Gear Assembly . The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. This design is highly complex, allowing each wheel to turn at a different rate. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. The most common form of spiral bevel gearbox is a differential, like that found in a car. Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. Slight errors in pinion or gear positioning can turn a well designed, quality. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. Spiral bevel gears are one. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Bevel gear systems are particularly sensitive to improper assembly. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more.

from www.mdpi.com

Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. Slight errors in pinion or gear positioning can turn a well designed, quality. A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Bevel gear systems are particularly sensitive to improper assembly. Spiral bevel gears are one. This design is highly complex, allowing each wheel to turn at a different rate. The most common form of spiral bevel gearbox is a differential, like that found in a car. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles.

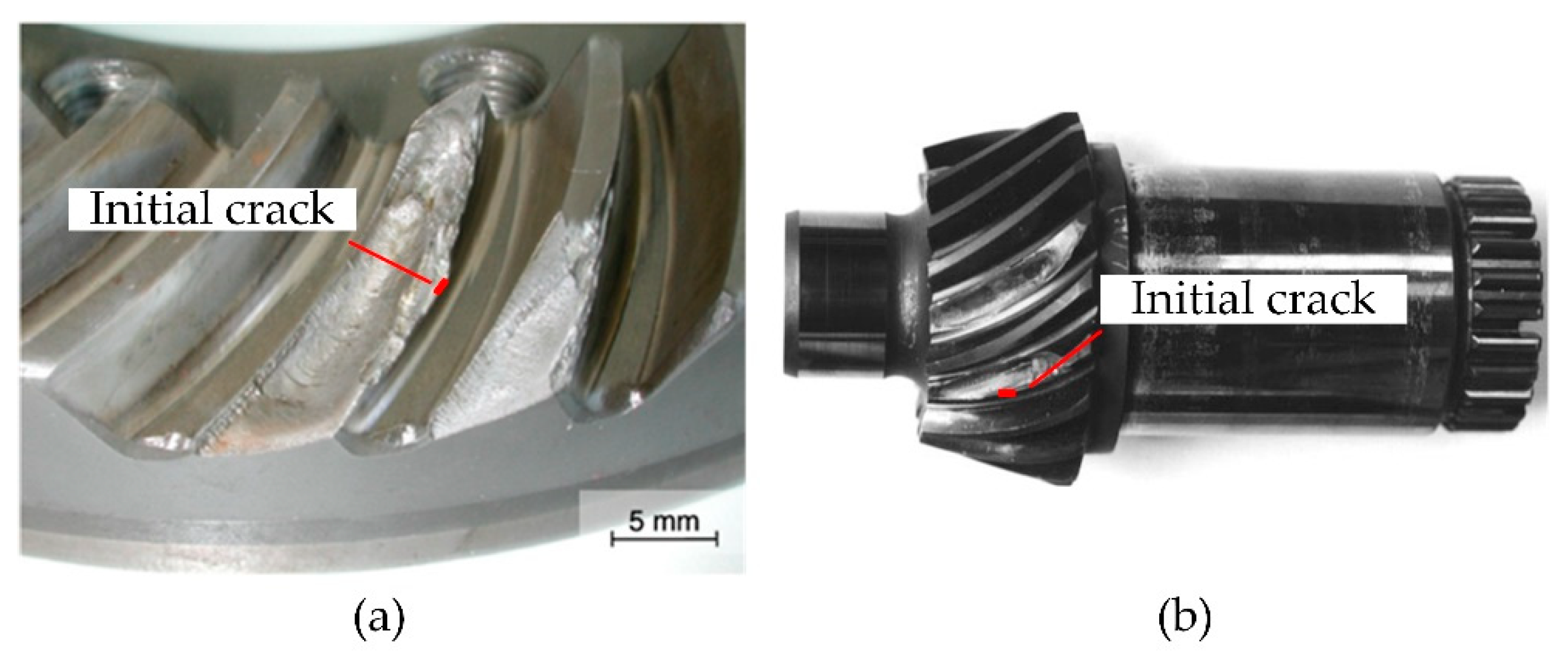

Machines Free FullText Dynamic Simulation of Cracked Spiral Bevel

Spiral Bevel Gear Assembly It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Bevel gear systems are particularly sensitive to improper assembly. Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. The most common form of spiral bevel gearbox is a differential, like that found in a car. This design is highly complex, allowing each wheel to turn at a different rate. Slight errors in pinion or gear positioning can turn a well designed, quality. The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Spiral bevel gears are one.

From en.wikipedia.org

Spiral bevel gear Wikipedia Spiral Bevel Gear Assembly It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Spiral bevel gears are one. A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. Slight errors. Spiral Bevel Gear Assembly.

From www.ligongmachinery.com

34C2981 Liugong/ZF spiral bevel gear assembly Guangxi Ligong Spiral Bevel Gear Assembly Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Slight errors in pinion or gear positioning can turn a well designed, quality. Spiral gears, primarily used in bevel gear systems, are designed to transmit power. Spiral Bevel Gear Assembly.

From www.dreamstime.com

3D Rendering FEA Spiral Bevel Gear Assembly Stock Illustration Spiral Bevel Gear Assembly A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Spiral bevel gears are one. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Bevel gear systems are particularly sensitive to improper assembly. Unlike the straight teeth of bevel. Spiral Bevel Gear Assembly.

From www.lampin.com

The Top 4 Advantages of Spiral Bevel Gears for Engineers Lampin Spiral Bevel Gear Assembly Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Spiral bevel gears are one. Slight errors in pinion or gear positioning can turn a well designed, quality. It also relies on a pinion and ring gear. Spiral Bevel Gear Assembly.

From parts.kenotractors.com

Spiral Bevel Gear Assembly Spiral Bevel Gear Assembly Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. The most common form of spiral bevel gearbox is a differential, like that found in a car. Bevel gears are cone shaped gears which transmit motion between. Spiral Bevel Gear Assembly.

From hkaa2011.en.made-in-china.com

Custom CNC Steel Straight Bevel Gear, Spiral Bevel Gear Assembly Spiral Bevel Gear Assembly The most common form of spiral bevel gearbox is a differential, like that found in a car. This design is highly complex, allowing each wheel to turn at a different rate. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts,. Spiral Bevel Gear Assembly.

From www.ligongmachinery.com

34C2981 Liugong/ZF spiral bevel gear assembly Guangxi Ligong Spiral Bevel Gear Assembly Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. The most common form of spiral bevel gearbox is a differential, like that found in a car. Spiral gears, primarily used in bevel gear systems, are. Spiral Bevel Gear Assembly.

From www.ien.eu

Helical Bevel Gear Units Spiral Bevel Gear Assembly Slight errors in pinion or gear positioning can turn a well designed, quality. The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right. Spiral Bevel Gear Assembly.

From www.belongear.com

China Premium Vehicle Bevel Gear Set factory and manufacturers Belon Spiral Bevel Gear Assembly Slight errors in pinion or gear positioning can turn a well designed, quality. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. This design is highly complex, allowing each wheel to turn at a different rate. A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Spiral. Spiral Bevel Gear Assembly.

From www.dreamstime.com

3D Rendering Mechanical Study Stress Analysis of a Spiral Bevel Gear Spiral Bevel Gear Assembly Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Spiral bevel gears are a specialized. Spiral Bevel Gear Assembly.

From in.misumi-ec.com

Ground Spiral Bevel Gear MBSG KOHARA GEAR INDUSTRY MISUMI India Spiral Bevel Gear Assembly Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Slight errors in pinion or gear positioning can turn a well designed, quality. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Unlike the straight teeth of bevel. Spiral Bevel Gear Assembly.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Spiral Bevel Gear Assembly Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. Bevel gear systems are particularly sensitive to improper assembly. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. The most common form of spiral bevel gearbox is a differential, like that found in a car.. Spiral Bevel Gear Assembly.

From www.ligongmachinery.com

34C2981 Liugong/ZF spiral bevel gear assembly Guangxi Ligong Spiral Bevel Gear Assembly Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. Spiral bevel gears are one. Bevel gear systems are particularly sensitive to improper assembly. This design is highly complex, allowing each wheel to turn at a different rate. The nominal spiral angl.e of the spiral bevel gear or pinion is the. Spiral Bevel Gear Assembly.

From www.oilmanchina.com

Spiral Bevel Gear Set Alloy Steel 90 Degree Shaft Angle Spiral Bevel Gear Assembly The most common form of spiral bevel gearbox is a differential, like that found in a car. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. The nominal spiral angl.e of the spiral bevel gear or pinion. Spiral Bevel Gear Assembly.

From www.eltrex-motion.com

Spiral Bevel Gear Eltrex Motion Spiral Bevel Gear Assembly Spiral bevel gears are one. This design is highly complex, allowing each wheel to turn at a different rate. The most common form of spiral bevel gearbox is a differential, like that found in a car. Slight errors in pinion or gear positioning can turn a well designed, quality. It also relies on a pinion and ring gear assembly, where. Spiral Bevel Gear Assembly.

From stock.adobe.com

Collection of the ring gear and pinion forming a spiral bevel gear Spiral Bevel Gear Assembly Spiral bevel gears are one. A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible. Spiral Bevel Gear Assembly.

From www.ebay.co.uk

Spiral Bevel Gear Assembly for Makita 9555 NB 9554 NB 9557 NB 9558 NB Spiral Bevel Gear Assembly It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Spiral bevel gears are one. Slight errors in pinion or gear positioning can turn a well designed, quality. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. The nominal spiral angl.e of the spiral bevel. Spiral Bevel Gear Assembly.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Spiral Bevel Gear Assembly This design is highly complex, allowing each wheel to turn at a different rate. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Bevel gear systems are particularly. Spiral Bevel Gear Assembly.

From www.pinterest.es

spiral bevel gears mitre 11 or ratio crown and pinion Gears, Spiral Spiral Bevel Gear Assembly The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. Spiral bevel gears are one. Slight errors in pinion or gear positioning can turn a well designed, quality. This design is highly complex, allowing each wheel to turn at a different rate.. Spiral Bevel Gear Assembly.

From www.ligongmachinery.com

34C2981 Liugong/ZF spiral bevel gear assembly Guangxi Ligong Spiral Bevel Gear Assembly Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. This design is highly complex, allowing each wheel to turn at a different rate. Bevel gear systems are particularly sensitive to improper assembly. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. It also relies on a. Spiral Bevel Gear Assembly.

From www.zhygear.com

Tooth surface reconstruction of spiral bevel gear based on NURBS method Spiral Bevel Gear Assembly A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Slight errors in pinion or gear positioning can turn a well designed, quality. This design is highly complex, allowing each wheel to turn at a different rate. Spiral bevel gears are a specialized type of bevel gears with unique design characteristics. Spiral Bevel Gear Assembly.

From www.dreamstime.com

3D Rendering Spiral Bevel Gear Assembly Stock Illustration Spiral Bevel Gear Assembly Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. Spiral bevel gears are one. Slight errors in pinion or gear positioning can turn a well designed, quality. Bevel gear systems are particularly sensitive to improper assembly. The. Spiral Bevel Gear Assembly.

From grabcad.com

spiral bevel gear assembly correct mates 3D CAD Model Library GrabCAD Spiral Bevel Gear Assembly Slight errors in pinion or gear positioning can turn a well designed, quality. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more.. Spiral Bevel Gear Assembly.

From ar.inspiredpencil.com

Spiral Bevel Gear Drawing Spiral Bevel Gear Assembly Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. Spiral bevel gears are one. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Spiral. Spiral Bevel Gear Assembly.

From www.mdpi.com

Machines Free FullText Dynamic Simulation of Cracked Spiral Bevel Spiral Bevel Gear Assembly Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. This design is highly complex, allowing each wheel to turn at a different rate. A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Spiral bevel gears are one. Bevel gear systems. Spiral Bevel Gear Assembly.

From www.jactonindustry.com

Spiral Bevel Gears Application,angular spiral bevel gears 90 degree Spiral Bevel Gear Assembly Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. The most common form of spiral bevel gearbox is a differential, like that found in a car. This design is highly complex, allowing each wheel to turn at a different rate. Spiral bevel gears are one. Slight errors in pinion or gear positioning can turn a well. Spiral Bevel Gear Assembly.

From stock.adobe.com

Collection of the ring gear and pinion forming a spiral bevel gear Spiral Bevel Gear Assembly Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Spiral bevel gears are one. The most common form of spiral bevel gearbox is a differential, like that found in a car. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. Slight errors in pinion or. Spiral Bevel Gear Assembly.

From www.dreamstime.com

3D Rendering Closeup of a Spiral Bevel Gear Assembly Stock Spiral Bevel Gear Assembly Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Slight errors in pinion or gear positioning can turn a well designed, quality. Bevel gear systems are particularly sensitive to improper assembly. The nominal spiral angl.e of the. Spiral Bevel Gear Assembly.

From www.docsity.com

Helical Bevel Gear Design Docsity Spiral Bevel Gear Assembly It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size. This design is highly complex, allowing each wheel to turn at a different rate. Slight errors in pinion or gear positioning can turn a well designed, quality. Bevel gear systems are particularly sensitive to improper assembly. Bevel gears are. Spiral Bevel Gear Assembly.

From stock.adobe.com

Collection of the ring gear and pinion forming a spiral bevel gear Spiral Bevel Gear Assembly Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Slight errors in pinion or gear positioning can turn a well designed, quality. Spiral bevel gears are one. Bevel gears are. Spiral Bevel Gear Assembly.

From www.zhygear.com

Virtual assembly and interference inspection of spiral bevel gears Spiral Bevel Gear Assembly A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Spiral gears, primarily used in bevel gear systems, are designed to transmit power between intersecting shafts, typically at right angles. Spiral bevel gears are a specialized type of bevel gears with unique design characteristics that allow them to transmit. The nominal. Spiral Bevel Gear Assembly.

From www.engineeringclicks.com

Types of Gears a guide to 11 important types you must know Spiral Bevel Gear Assembly The most common form of spiral bevel gearbox is a differential, like that found in a car. Bevel gear systems are particularly sensitive to improper assembly. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. It also relies on a pinion and ring gear assembly, where the driving and driven gears are very different in size.. Spiral Bevel Gear Assembly.

From www.youtube.com

FUSION 360 SPIRAL BEVEL GEAR PINION HELICAL GEAR MODELLING Spiral Bevel Gear Assembly A spiral bevel gear is a more complex type of bevel gear, distinguished by its curved and oblique teeth. Spiral bevel gears are one. The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. Slight errors in pinion or gear positioning can. Spiral Bevel Gear Assembly.

From www.grainger.com

Spiral, Gear Ratio 3, Ground Spiral Bevel Gear 793DF6SBSG2.54515R Spiral Bevel Gear Assembly Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Spiral bevel gears are one. The nominal spiral angl.e of the spiral bevel gear or pinion is the angle measured from the center of the tooth, itis possible to use a bevel generating. Spiral. Spiral Bevel Gear Assembly.

From www.oilmanchina.com

Spiral Bevel Gear Set Alloy Steel 90 Degree Shaft Angle Spiral Bevel Gear Assembly Slight errors in pinion or gear positioning can turn a well designed, quality. Bevel gears are cone shaped gears which transmit motion between two intersecting shafts. Bevel gear systems are particularly sensitive to improper assembly. Unlike the straight teeth of bevel gears, the spiral tooth orientation provides more. Spiral bevel gears are one. The nominal spiral angl.e of the spiral. Spiral Bevel Gear Assembly.