Define Shear Lag . Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The attached image shows the gusset plate connection of typical bracing members. The most important thing to notice is the way in. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Most of literature dealing with bending of stiffened plates took the. What is meant by “shear lag effect”?

from jonochshorn.com

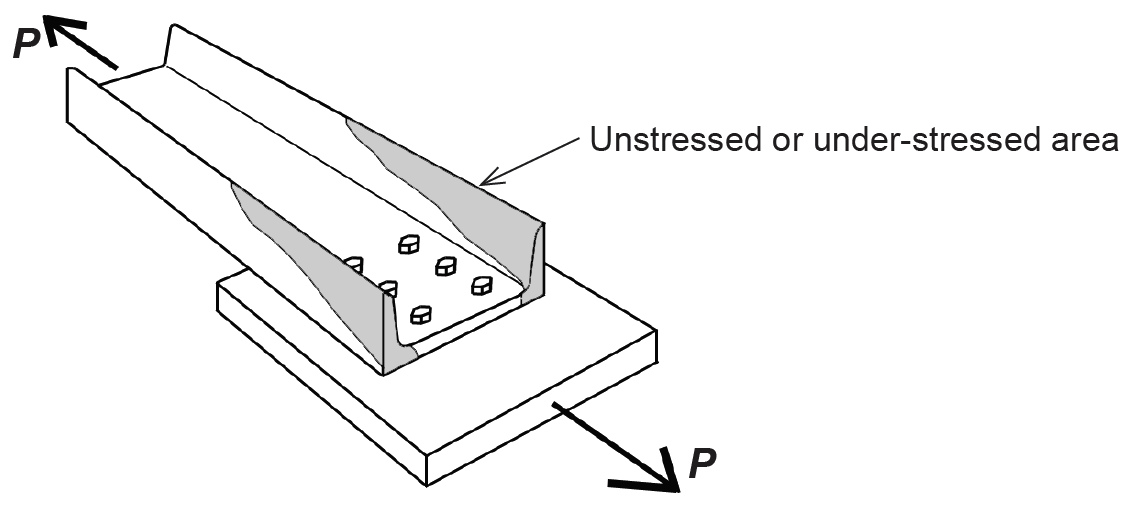

Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Most of literature dealing with bending of stiffened plates took the. The attached image shows the gusset plate connection of typical bracing members. The most important thing to notice is the way in. What is meant by “shear lag effect”? Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the.

Steel Jonathan Ochshorn's Structural Elements text, Third Edition

Define Shear Lag Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The most important thing to notice is the way in. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. Most of literature dealing with bending of stiffened plates took the. What is meant by “shear lag effect”? The attached image shows the gusset plate connection of typical bracing members.

From www.youtube.com

Tension Member Shear Lag Effect YouTube Define Shear Lag The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. Because a finite thickness adhesive layer. Define Shear Lag.

From www.mdpi.com

Buildings Free FullText Study on ShearLag Effect of SteelUHPC Define Shear Lag What is meant by “shear lag effect”? The most important thing to notice is the way in. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. The attached image shows the gusset plate connection of typical bracing members. The shear lag. Define Shear Lag.

From www.semanticscholar.org

Shear Lag Factor for Longitudinally Welded Tension Members using Finite Define Shear Lag The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. What is meant by “shear lag effect”? The attached image shows the gusset plate connection of typical bracing members. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate. Define Shear Lag.

From www.mdpi.com

Buildings Free FullText Shear Lag Analysis of Simply Supported Box Define Shear Lag Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Shear lag is a concept used to account for uneven stress distribution. Define Shear Lag.

From www.scribd.com

Shear Lag PDF Strength Of Materials Beam (Structure) Define Shear Lag Most of literature dealing with bending of stiffened plates took the. The most important thing to notice is the way in. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. The attached image shows the gusset plate connection of typical bracing. Define Shear Lag.

From www.scribd.com

Shear Lag Factor PDF Define Shear Lag Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. Most of literature dealing with bending of stiffened plates took the. The attached image shows the gusset plate connection of typical bracing members. The shear lag models are based on the concept that after cracking the transverse ply. Define Shear Lag.

From www.researchgate.net

influence of shear lag on tube behavior [8] Download Scientific Diagram Define Shear Lag The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Most of literature dealing with bending of stiffened plates took the. What is meant by “shear lag effect”? The attached image shows the gusset plate connection of typical bracing members. Shear lag is a. Define Shear Lag.

From www.researchgate.net

Shearlag and interface slip effects in the composite girder bridge Define Shear Lag The attached image shows the gusset plate connection of typical bracing members. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. What is meant by “shear lag effect”? Most of literature dealing with bending of stiffened plates took the. Shear lag is a concept used to account. Define Shear Lag.

From www.eigenplus.com

Shear lag effect in the angle sections eigenplus Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The shear lag models are based on the concept that. Define Shear Lag.

From www.chegg.com

Solved why we choose the shear lag factor 1 in this problem Define Shear Lag The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. The most important thing to notice is the way in. Most of literature dealing with bending of stiffened plates took the. The attached image shows the gusset plate connection of typical bracing members. Shear. Define Shear Lag.

From structures-explained.com

Shear Forces and Shear Stresses in Structures Structures Explained Define Shear Lag The attached image shows the gusset plate connection of typical bracing members. What is meant by “shear lag effect”? Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. Most of literature dealing with bending of stiffened plates took the. The most important thing to notice is the. Define Shear Lag.

From pt.slideshare.net

Shear Stress; Id no. 10.01.03.033 Define Shear Lag The most important thing to notice is the way in. The attached image shows the gusset plate connection of typical bracing members. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Shear lag is a concept used to account for uneven stress distribution. Define Shear Lag.

From www.mdpi.com

Buildings Free FullText A Beam Finite Element Model Considering Define Shear Lag The most important thing to notice is the way in. Most of literature dealing with bending of stiffened plates took the. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Shear lag is a concept used to account for uneven stress distribution in. Define Shear Lag.

From www.youtube.com

Shear Strain of Block With Shear Force Applied to It (Strength of Define Shear Lag The most important thing to notice is the way in. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are.. Define Shear Lag.

From www.youtube.com

Part9 Shear Lag Factor Equal Angle YouTube Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. What is meant by “shear lag effect”? The most important thing to notice is the way in. The shear lag models are based on the concept that after cracking the transverse ply. Define Shear Lag.

From www.eigenplus.com

Shear lag effect in the angle sections eigenplus Define Shear Lag The attached image shows the gusset plate connection of typical bracing members. Most of literature dealing with bending of stiffened plates took the. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. Shear lag is a concept used to account for uneven stress distribution in connected members. Define Shear Lag.

From www.semanticscholar.org

Figure 4 from Shear Lag in Tube Structures Semantic Scholar Define Shear Lag The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Most of literature dealing with bending of stiffened plates took the. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. Shear. Define Shear Lag.

From www.researchgate.net

Shearlag effect in framed tubes. Used with permission of Taylor Define Shear Lag Most of literature dealing with bending of stiffened plates took the. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.). Define Shear Lag.

From www.mdpi.com

Applied Sciences Free FullText Parametric Analysis of the Shear Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. The attached image shows the gusset plate connection of typical bracing members. The most important thing to notice is the way in. The shear lag models are based on the concept that. Define Shear Lag.

From structures-explained.com

Shear Forces and Shear Stresses in Structures Structures Explained Define Shear Lag Most of literature dealing with bending of stiffened plates took the. The most important thing to notice is the way in. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The shear lag models are based on the concept that after cracking the transverse ply does not. Define Shear Lag.

From www.slideserve.com

PPT SHEAR LAG PowerPoint Presentation, free download ID6835241 Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. The attached image shows the gusset plate connection of typical bracing members. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient. Define Shear Lag.

From es.scribd.com

Shear Lag Factors For Connections To Tension Members PDF Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. What is meant by “shear lag effect”? The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane,. Define Shear Lag.

From www.researchgate.net

The schematic of the shearlag model considering the interface Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. What is meant by “shear lag effect”? The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane,. Define Shear Lag.

From yydase.weebly.com

Sap2000 v17 shear diagram convention yydase Define Shear Lag The most important thing to notice is the way in. What is meant by “shear lag effect”? The attached image shows the gusset plate connection of typical bracing members. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Shear lag is a concept. Define Shear Lag.

From www.mdpi.com

Buildings Free FullText Study on ShearLag Effect of SteelUHPC Define Shear Lag What is meant by “shear lag effect”? Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The attached image shows the gusset plate connection of typical bracing members. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not. Define Shear Lag.

From www.slideserve.com

PPT SHEAR LAG PowerPoint Presentation, free download ID6835241 Define Shear Lag What is meant by “shear lag effect”? The most important thing to notice is the way in. Most of literature dealing with bending of stiffened plates took the. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The attached image shows the gusset plate connection of typical. Define Shear Lag.

From www.youtube.com

What is Shear Strain (Example) YouTube Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. The most important thing to notice is the way in. What is meant by “shear lag effect”? The shear lag models are based on the concept that after cracking the transverse ply. Define Shear Lag.

From jonochshorn.com

Steel Jonathan Ochshorn's Structural Elements text, Third Edition Define Shear Lag The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Most of literature dealing with bending of stiffened plates took the. What is meant by “shear lag effect”? The most important thing to notice is the way in. The attached image shows the gusset. Define Shear Lag.

From www.eigenplus.com

Shear stress Definition, limitation and application eigenplus Define Shear Lag Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The most important thing to notice is the way in. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Shear lag. Define Shear Lag.

From www.semanticscholar.org

Figure 2 from The Dependence of Shear Lag on Loading in Composite Beams Define Shear Lag What is meant by “shear lag effect”? The most important thing to notice is the way in. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. Most of literature dealing with bending of stiffened plates took the. The shear lag models. Define Shear Lag.

From www.scribd.com

Shear Lag Factors PDF Define Shear Lag The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial load in the crack plane, while. Most of literature dealing with bending of stiffened plates took the. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements. Define Shear Lag.

From www.chegg.com

Solved 1) Calculate the shear lag factor for the WT 180×36 Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. The attached image shows the gusset plate connection of typical bracing members. The shear lag models are based on the concept that after cracking the transverse ply does not carry any axial. Define Shear Lag.

From www.slideserve.com

PPT SHEAR LAG PowerPoint Presentation, free download ID6835241 Define Shear Lag Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all of their elements (flange, web, leg, etc.) are. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. What is meant by “shear lag effect”? Most of literature. Define Shear Lag.

From www.youtube.com

Types of Shear failures in Beam? Civil Engineering YouTube Define Shear Lag Most of literature dealing with bending of stiffened plates took the. Because a finite thickness adhesive layer bonds between the bst microbar and the aluminum substrate the strain or strain gradient in the. The most important thing to notice is the way in. Shear lag is a concept used to account for uneven stress distribution in connected members where some. Define Shear Lag.

From www.researchgate.net

Figure A2. Geometric definition of shear strain. Download Scientific Define Shear Lag The attached image shows the gusset plate connection of typical bracing members. The most important thing to notice is the way in. What is meant by “shear lag effect”? Most of literature dealing with bending of stiffened plates took the. Shear lag is a concept used to account for uneven stress distribution in connected members where some but not all. Define Shear Lag.