Thread Rolling Process Step By Step . The dies, imprinted with the thread profile, penetrate the. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Let’s delve into each step of the process in detail: In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Preparation before thread rolling can begin Thread rolling is not a metal cutting process. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Thread rolling makes use of hardened steel cylindrical dies to shape materials;

from www.slideserve.com

Thread rolling is not a metal cutting process. Preparation before thread rolling can begin Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The dies, imprinted with the thread profile, penetrate the. Rolling changes physical properties, hardening and. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Let’s delve into each step of the process in detail: Thread rolling makes use of hardened steel cylindrical dies to shape materials; The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces.

PPT Chapter 42 Thread and Gear Manufacturing PowerPoint Presentation

Thread Rolling Process Step By Step Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Let’s delve into each step of the process in detail: Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Preparation before thread rolling can begin The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. The dies, imprinted with the thread profile, penetrate the. Thread rolling makes use of hardened steel cylindrical dies to shape materials; In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process.

From www.researchgate.net

Forming stages during thread rolling process Download Scientific Diagram Thread Rolling Process Step By Step The dies, imprinted with the thread profile, penetrate the. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is not a metal. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Rolling changes physical properties, hardening and. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Thread rolling is not a metal cutting process. Thread rolling makes use of hardened steel cylindrical dies to shape materials; The dies, imprinted with the thread profile, penetrate the. Thread. Thread Rolling Process Step By Step.

From www.mech4study.com

Rolling Process Types, Working, Terminology and Application mech4study Thread Rolling Process Step By Step Rolling changes physical properties, hardening and. Thread rolling makes use of hardened steel cylindrical dies to shape materials; The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Thread rolling is not a metal cutting process. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the. Thread Rolling Process Step By Step.

From www.semanticscholar.org

Automation of a Thread Rolling Machine for use in a Flexible Workcell Thread Rolling Process Step By Step Thread rolling is not a metal cutting process. The dies, imprinted with the thread profile, penetrate the. Preparation before thread rolling can begin Rolling changes physical properties, hardening and. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The thread rolling process the thread rolling process. Thread Rolling Process Step By Step.

From www.slideserve.com

PPT BULK DEFORMATION PROCESSES IN METALWORKING PowerPoint Thread Rolling Process Step By Step Let’s delve into each step of the process in detail: Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Preparation before thread rolling can begin In this “how it works” note, we explain the thread rolling process, its advantages, and how we help. Thread Rolling Process Step By Step.

From www.slideserve.com

PPT Bulk Deformation Processes in Metal Forming Chapter 19 Part 1 Thread Rolling Process Step By Step Rolling changes physical properties, hardening and. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Preparation before thread rolling can begin Thread. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Preparation before thread rolling can begin Rolling changes physical properties, hardening and. Thread rolling makes use of hardened steel cylindrical dies to shape materials; In this “how it works” note, we explain the thread rolling process, its advantages, and how we. Thread Rolling Process Step By Step.

From www.researchgate.net

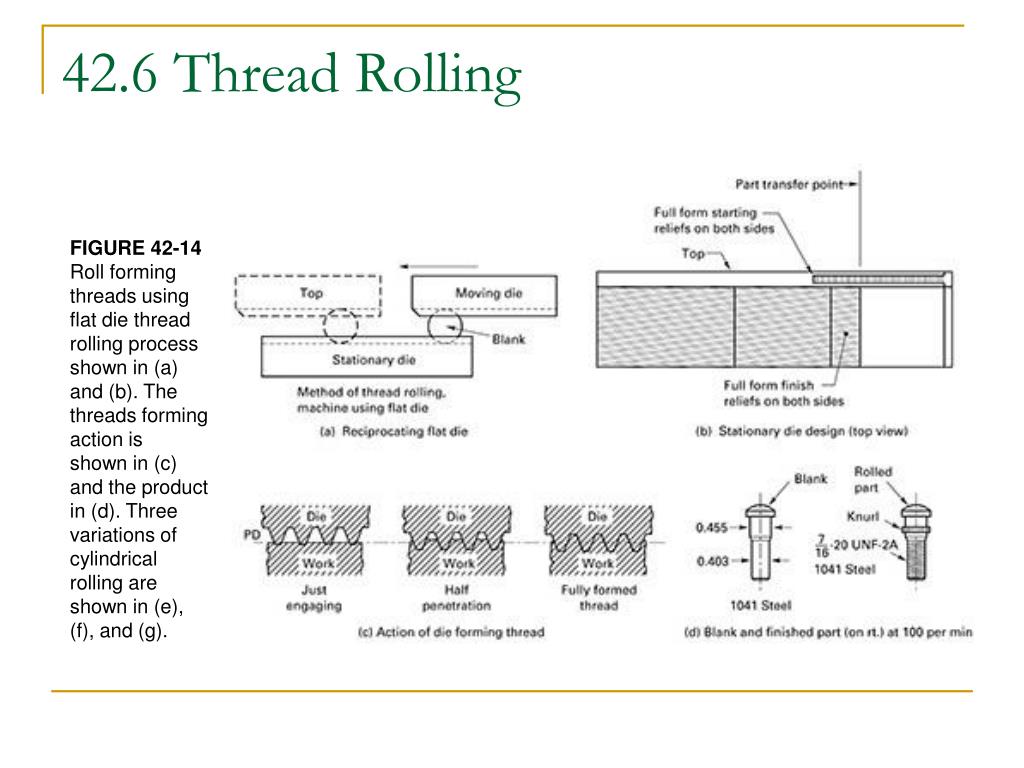

Threadrolling process using flat dies Download Scientific Diagram Thread Rolling Process Step By Step Thread rolling is not a metal cutting process. Thread rolling makes use of hardened steel cylindrical dies to shape materials; Let’s delve into each step of the process in detail: In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The dies, imprinted with the thread profile,. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Preparation before thread rolling can begin The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Thread rolling makes use of hardened steel cylindrical dies to shape materials;. Thread Rolling Process Step By Step.

From www.researchgate.net

Thread rolling machine and dies Download Scientific Diagram Thread Rolling Process Step By Step The dies, imprinted with the thread profile, penetrate the. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Let’s delve into each step of the process in detail: Preparation before thread rolling can begin Thread rolling is not a metal cutting process. Thread rolling is. Thread Rolling Process Step By Step.

From brooksforgings.co.uk

Thread Rolling Gallery Brooks Thread Rolling Process Step By Step Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Thread rolling is not. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Let’s delve into each step of the process in detail: In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Thread rolling makes use of hardened steel cylindrical dies to shape materials; Rolling changes physical properties, hardening and. The dies, imprinted with the thread profile, penetrate the.. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Preparation before thread rolling can begin Let’s delve into each step of the process in detail: The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Thread rolling makes use of hardened steel cylindrical dies to shape materials; In this “how it works” note, we explain the thread rolling process, its. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Rolling changes physical properties, hardening and. Preparation before thread rolling can begin Let’s delve into each step. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Rolling changes physical properties, hardening and. Thread rolling makes use of hardened steel cylindrical dies to shape materials; In this “how it works” note, we explain the thread rolling process, its advantages, and how we help. Thread Rolling Process Step By Step.

From thegatewaymag.com

Applying Pressure The Benefits of Thread Rolling The Gateway to New Thread Rolling Process Step By Step A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Preparation before thread rolling can begin The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. The dies, imprinted with the thread profile, penetrate the. Thread rolling. Thread Rolling Process Step By Step.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Thread Rolling Process Step By Step A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Thread rolling makes use of hardened steel cylindrical dies to shape materials; Rolling changes physical properties, hardening and. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical. Thread Rolling Process Step By Step.

From www.nextgentooling.com

Thread Milling Techniques NEXT GENERATION TOOLING Thread Rolling Process Step By Step Thread rolling is not a metal cutting process. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. A common thread rolling process, used in. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Thread rolling is not a metal cutting process. Thread rolling makes use of hardened steel cylindrical dies to shape materials; Preparation before thread rolling can begin Rolling changes physical properties, hardening and. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. In this “how it works” note, we explain the. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Thread rolling is not a metal cutting process. The dies, imprinted with the thread profile, penetrate the. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Thread. Thread Rolling Process Step By Step.

From www.slideserve.com

PPT Chapter 42 Thread and Gear Manufacturing PowerPoint Presentation Thread Rolling Process Step By Step The dies, imprinted with the thread profile, penetrate the. Let’s delve into each step of the process in detail: In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Preparation before thread rolling can begin Thread rolling makes use of hardened steel cylindrical dies to shape materials;. Thread Rolling Process Step By Step.

From mech.poriyaan.in

Shape rolling operations Working Principle, Types Thread Rolling Process Step By Step The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Thread rolling is not a metal cutting process. The dies, imprinted with the thread profile, penetrate the. Rolling changes physical properties, hardening and. Thread rolling makes use of hardened steel cylindrical dies to shape materials; In this “how it works” note,. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling makes use of. Thread Rolling Process Step By Step.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material Thread Rolling Process Step By Step Thread rolling makes use of hardened steel cylindrical dies to shape materials; Preparation before thread rolling can begin Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is not a metal cutting process. The dies,. Thread Rolling Process Step By Step.

From www.powertransmission.com

Precision Thread Rolling Process for HighAccuracy Lead Screws Thread Rolling Process Step By Step In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Thread rolling is not a metal cutting process. Thread rolling. Thread Rolling Process Step By Step.

From blog.inoxmare.com

What Is the Thread Rolling Process? Blog Inox mare En Thread Rolling Process Step By Step Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Let’s delve into each step of the process in detail:. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Let’s delve into each step of the process in detail: Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is not a metal cutting process. Thread rolling makes use of hardened steel cylindrical dies to shape materials; The dies, imprinted with. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. The dies, imprinted with the thread profile, penetrate the. Preparation before thread rolling can begin. Thread Rolling Process Step By Step.

From www.researchgate.net

Finite element model of thread rolling process with two round dies Thread Rolling Process Step By Step The dies, imprinted with the thread profile, penetrate the. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. The thread rolling process the thread rolling process is a highly efficient method for producing threads on cylindrical workpieces. Let’s delve into each step of the process. Thread Rolling Process Step By Step.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Step By Step A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Preparation before thread rolling can begin Thread rolling is not a metal cutting. Thread Rolling Process Step By Step.

From www.evirtitalia.com

Thread Rolling Evirt Italia Thread Rolling Process Step By Step In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The dies, imprinted with the thread profile, penetrate the. Preparation before thread rolling can begin Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or. Thread Rolling Process Step By Step.

From www.slideserve.com

PPT ME 350 Lecture 21 Chapter 19 PowerPoint Presentation, free Thread Rolling Process Step By Step The dies, imprinted with the thread profile, penetrate the. Thread rolling is not a metal cutting process. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose. Thread Rolling Process Step By Step.

From www.slideshare.net

The Basics of Thread Rolling Thread Rolling Process Step By Step Let’s delve into each step of the process in detail: Rolling changes physical properties, hardening and. The dies, imprinted with the thread profile, penetrate the. Thread rolling is not a metal cutting process. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Thread rolling is a. Thread Rolling Process Step By Step.

From mikehardware.com

Thread Rolling Process of Screws The Basics MIKEHARDWARE Thread Rolling Process Step By Step The dies, imprinted with the thread profile, penetrate the. Let’s delve into each step of the process in detail: Thread rolling makes use of hardened steel cylindrical dies to shape materials; Thread rolling is not a metal cutting process. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile. Thread Rolling Process Step By Step.