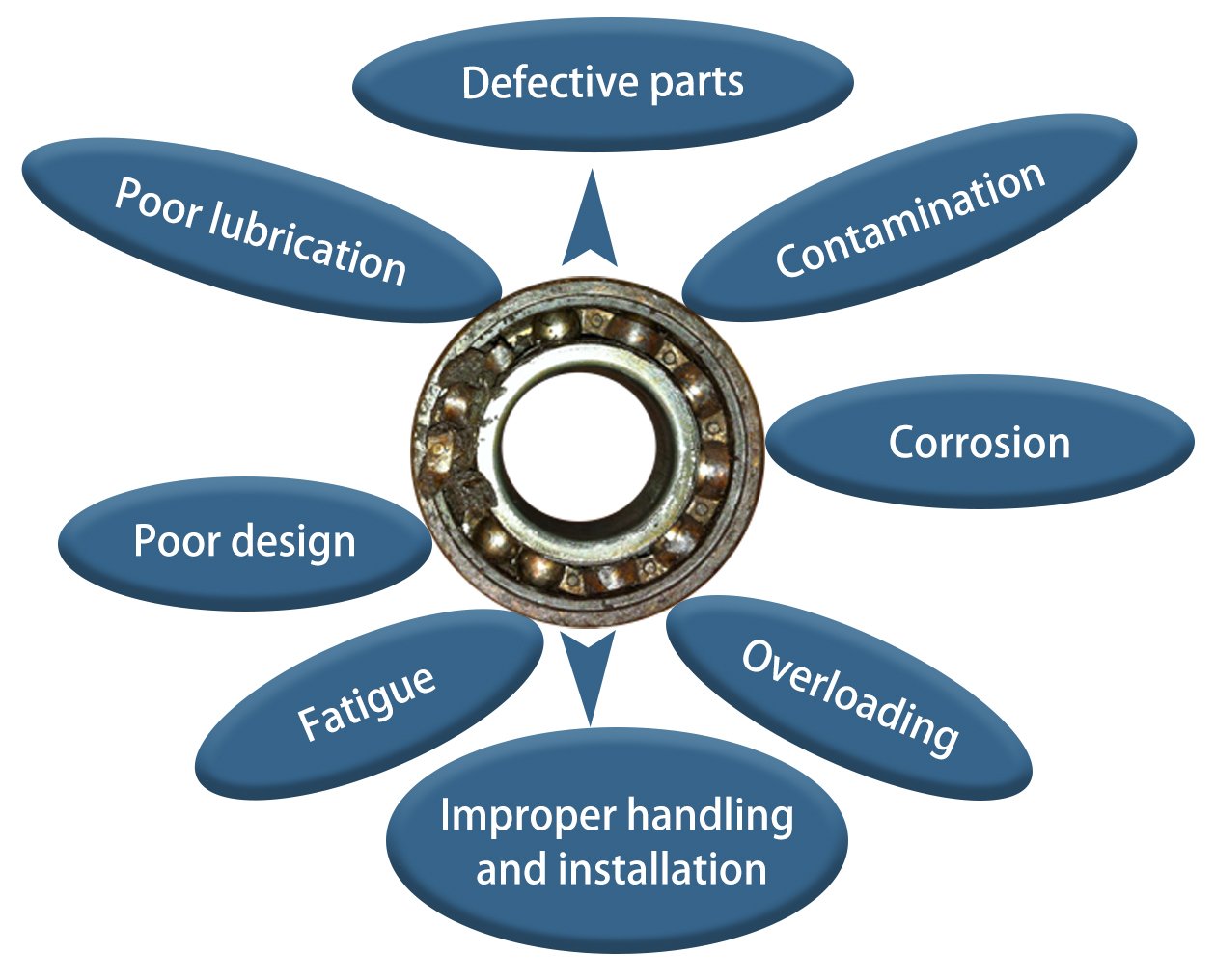

Needle Bearing Failure . Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Those listed in this guide are the most commonly identified types and causes of damage for anti. Failure analysis tpi 109 created date:. Many different factors can cause bearing damage.

from www.lily-bearing.com

Those listed in this guide are the most commonly identified types and causes of damage for anti. Many different factors can cause bearing damage. Failure analysis tpi 109 created date:. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under.

How to Prevent Bearing Failures LILY Bearing

Needle Bearing Failure Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Those listed in this guide are the most commonly identified types and causes of damage for anti. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Many different factors can cause bearing damage. Failure analysis tpi 109 created date:. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles.

From testoil.com

Bearing Failure and Wear What are the Causes? TestOil Needle Bearing Failure Those listed in this guide are the most commonly identified types and causes of damage for anti. Many different factors can cause bearing damage. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Bearing. Needle Bearing Failure.

From www.tundras.com

2020 Differential needle bearing failure Page 9 Toyota Tundra Forum Needle Bearing Failure The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. As. Needle Bearing Failure.

From www.hchbearingamericas.com

Ball Bearings The Causes of Bearing Failure HCH Bearings Needle Bearing Failure Many different factors can cause bearing damage. Those listed in this guide are the most commonly identified types and causes of damage for anti. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Failure analysis tpi 109 created date:. The aim of this review is to provide information on systematic failure. Needle Bearing Failure.

From www.tacomaworld.com

Front Diff passenger side needle bearing failure World Needle Bearing Failure The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Those listed in this guide are the most commonly identified types and causes of damage for anti. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Failure analysis tpi 109 created date:. Bearing failures. Needle Bearing Failure.

From www.reddit.com

Methods of Troubleshooting Bearing Failure r/MechanicalEngineering Needle Bearing Failure As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Failure analysis tpi. Needle Bearing Failure.

From pibsales.com

Bearing Damage and Failure Analysis Pibsales Needle Bearing Failure The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Many different factors can cause bearing damage. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Four of the top reasons roller bearings fail results from poor lubrication or lack. Needle Bearing Failure.

From www.bmbbearings.com

Analysis of Common Fault Causes of Needle Rolling Bearings BMB Bearings Needle Bearing Failure The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Those listed in this guide are the. Needle Bearing Failure.

From www.univbrg.com

How to Maintain Your Needle Bearings Universal Bearings Needle Bearing Failure Many different factors can cause bearing damage. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Four of the top reasons roller bearings fail results from poor lubrication. Needle Bearing Failure.

From www.lily-bearing.com

How to Prevent Bearing Failures LILY Bearing Needle Bearing Failure The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Failure analysis tpi 109 created date:. The excessive deformation and misalignment, resulting from the unbalanced loading and improper. Needle Bearing Failure.

From www.machinerylubrication.com

5 Ways to Prevent Bearing Failures Needle Bearing Failure Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. The aim of this review is. Needle Bearing Failure.

From www.youtube.com

5 COMMON TYPES OF BEARING DAMAGE YouTube Needle Bearing Failure Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Many different factors can cause bearing damage. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Those listed in this guide are the most commonly identified types and causes of damage for anti.. Needle Bearing Failure.

From ls1tech.com

Needle bearing failure, now CHE trunion kit install LS1TECH Camaro Needle Bearing Failure The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Failure analysis tpi 109 created date:. Many different factors can cause bearing damage. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Those listed in this guide are the most commonly identified types and causes of. Needle Bearing Failure.

From www.bmwlt.com

FD input pinion needle bearing failure process BMW Luxury Touring Needle Bearing Failure Many different factors can cause bearing damage. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy. Needle Bearing Failure.

From www.researchgate.net

(PDF) Failure Analysis of a Needle Roller Bearing in a Megawatt Needle Bearing Failure Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Those listed in this guide are the most commonly identified types and causes of damage for anti. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Failure analysis. Needle Bearing Failure.

From www.lily-bearing.com

How to Prevent Bearing Failures LILY Bearing Needle Bearing Failure Many different factors can cause bearing damage. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Those listed in this guide are the most commonly identified types. Needle Bearing Failure.

From www.engineeringmaintenance.info

EMS Engineering Maintenance Solutions Bearings common failures and Needle Bearing Failure Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Many different factors can cause bearing damage. Those listed in this guide are the most commonly identified types and causes of damage for anti. Failure analysis tpi. Needle Bearing Failure.

From www.tacomaworld.com

Needle Bearing Failure With Lift (How Many) Page 18 World Needle Bearing Failure Many different factors can cause bearing damage. Those listed in this guide are the most commonly identified types and causes of damage for anti. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely. Needle Bearing Failure.

From www.reddit.com

Methods of Troubleshooting Bearing Failure r/MechanicalEngineering Needle Bearing Failure As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Those listed in this guide are the most commonly identified types and causes of damage for anti. Many. Needle Bearing Failure.

From www.semanticscholar.org

Figure 2 from A Case Study Failure Analysis of Needle Roller Bearing Needle Bearing Failure As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Failure analysis tpi 109 created date:. Many different factors can cause bearing damage. Those listed in this guide are the. Needle Bearing Failure.

From www.youtube.com

FORD 6.0L Diesel Lifter Needle Bearing Failure How 1 Part Can Needle Bearing Failure Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Those listed in this guide are the most commonly identified types and causes of damage for anti. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles.. Needle Bearing Failure.

From www.youtube.com

Reason for Bearing Failures causes YouTube Needle Bearing Failure Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Bearing failures are more common when the. Needle Bearing Failure.

From www.youtube.com

NeoTec 892 Needle bearing failure YouTube Needle Bearing Failure Those listed in this guide are the most commonly identified types and causes of damage for anti. Many different factors can cause bearing damage. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Bearing. Needle Bearing Failure.

From www.tacomaworld.com

Needle Bearing Failure With Lift (How Many) Page 15 World Needle Bearing Failure Failure analysis tpi 109 created date:. Those listed in this guide are the most commonly identified types and causes of damage for anti. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. The aim of this review is to provide information on systematic failure analysis of bearings, identify. Needle Bearing Failure.

From fastams.com

Bearing Failure FastAMS Needle Bearing Failure Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Those listed in this guide are the most commonly identified types and causes of damage for anti. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. As shown in figure 2, the prime. Needle Bearing Failure.

From blog.emersonbearing.com

Common Causes of Bearing Failure and How to Avoid Them Needle Bearing Failure Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Those listed in this guide are the most commonly identified types and causes of damage for anti. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Many different factors can cause bearing damage. The. Needle Bearing Failure.

From feikenbearing.com

Stages of Bearing Failure Feiken Bearing Needle Bearing Failure Many different factors can cause bearing damage. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. As shown in figure 2, the prime reason roller bearings fail to. Needle Bearing Failure.

From www.bearing-news.com

Case Study Diagnosing Bearing Failure w/ LUBExpert Static & Vibration Needle Bearing Failure Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Many different factors can cause bearing damage. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. The aim of this review is to provide information on systematic failure analysis of bearings, identify. Needle Bearing Failure.

From www.youtube.com

ZBox Series 4 Needle Bearing Failure YouTube Needle Bearing Failure As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Those listed in this guide are the most commonly identified types and causes of damage for anti.. Needle Bearing Failure.

From www.slideshare.net

Koyo bearingfailurechartposter Needle Bearing Failure Failure analysis tpi 109 created date:. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals,. Needle Bearing Failure.

From www.youtube.com

Bearings & Failure Modes YouTube Needle Bearing Failure Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. Many different factors can cause bearing damage. Those listed in this guide are the most commonly identified types and causes of damage for anti. Four of the top reasons roller bearings fail results from poor lubrication or lack thereof.. Needle Bearing Failure.

From www.univbrg.com

How to Maintain Your Needle Bearings Universal Bearings Needle Bearing Failure Four of the top reasons roller bearings fail results from poor lubrication or lack thereof. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Failure analysis. Needle Bearing Failure.

From ricksfreeautorepairadvice.com

Wheel bearing failure — Ricks Free Auto Repair Advice Ricks Free Auto Needle Bearing Failure Many different factors can cause bearing damage. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Those listed in this guide are the most commonly identified types and causes of damage for anti. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to. Needle Bearing Failure.

From www.tacomaworld.com

Needle Bearing Failure With Lift (How Many) Page 19 World Needle Bearing Failure As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Failure analysis tpi 109 created date:. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. The excessive deformation and misalignment, resulting from the unbalanced loading and improper. Needle Bearing Failure.

From www.lycbearingcn.com

Analysis on the Causes of the Damage of Rolling Mill Bearings LUOYANG Needle Bearing Failure Failure analysis tpi 109 created date:. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals, or if lubricated with low. As shown in figure 2, the prime reason roller bearings fail to reach life expectancy is due to lubricant contamination from particles. Four of the top reasons roller bearings fail results from poor. Needle Bearing Failure.

From ls1tech.com

Needle bearing failure, now CHE trunion kit install LS1TECH Camaro Needle Bearing Failure Failure analysis tpi 109 created date:. The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under. The excessive deformation and misalignment, resulting from the unbalanced loading and improper assembly, are the likely cause of. Bearing failures are more common when the bearings are exposed to wet environments and corrosive chemicals,. Needle Bearing Failure.