Welding Gas Flow Rate . So what is the correct gas flow rate for welding? The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. A flow of 15 to 25 cfh will cover most applications. We need a lot less flow in tig welding. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. But make sure to take into account the different variables while. Be aware of the unit of measurement. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. A turbulent gas flow during welding typically. The optimal gas flow rate can vary between 10 and 35 cubic feet per hour (cfh).

from mavink.com

To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. A flow of 15 to 25 cfh will cover most applications. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. Be aware of the unit of measurement. We need a lot less flow in tig welding. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. But make sure to take into account the different variables while. The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. So what is the correct gas flow rate for welding?

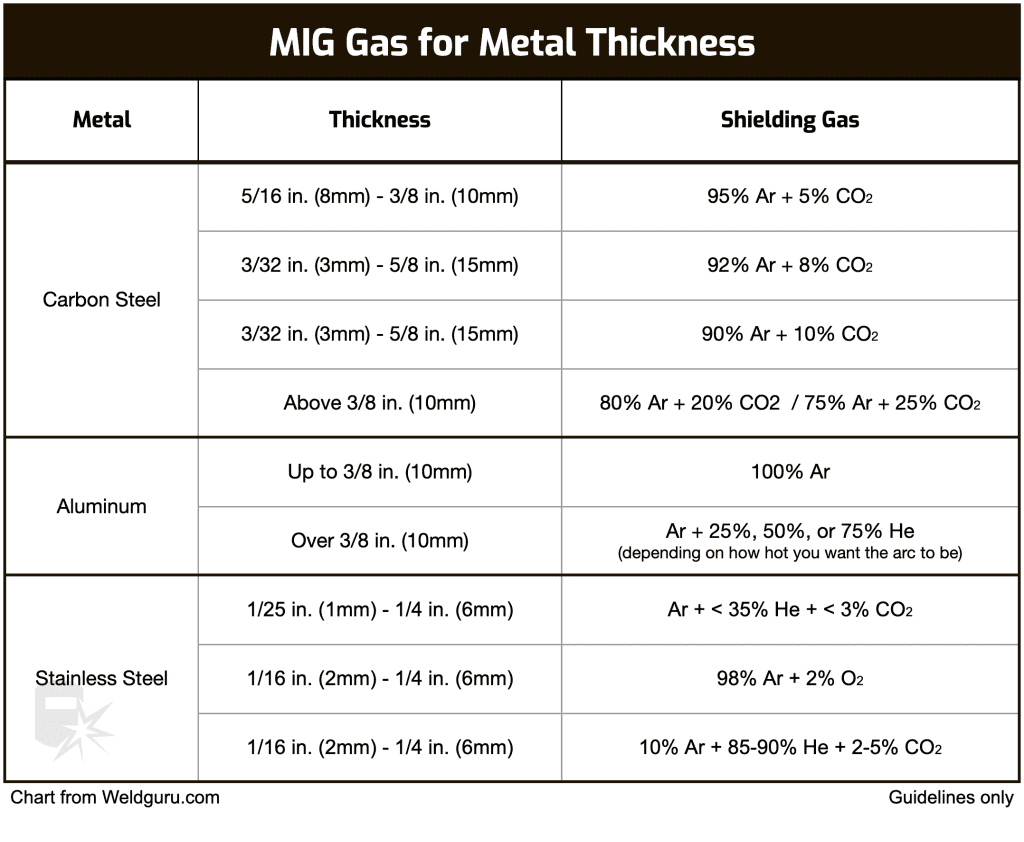

Mig Welding Gas Flow Rate Chart

Welding Gas Flow Rate The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. But make sure to take into account the different variables while. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. A turbulent gas flow during welding typically. So what is the correct gas flow rate for welding? The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. The optimal gas flow rate can vary between 10 and 35 cubic feet per hour (cfh). The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. Be aware of the unit of measurement. We need a lot less flow in tig welding. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. A flow of 15 to 25 cfh will cover most applications.

From fitwelding.com

Tig Welding Gas Flow Rate How To Achieve Perfect Gas Flow Rate? Fit Welding Gas Flow Rate Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. But make sure to take into account the different variables while. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The tig welding gas flow rate for the actual tig. Welding Gas Flow Rate.

From sophiemetcalfe.z13.web.core.windows.net

Mig Welding Gas Flow Rate Chart Welding Gas Flow Rate Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The optimal gas flow rate can vary between 10 and 35 cubic feet per hour (cfh). A turbulent gas flow during welding typically. So what is the correct gas flow rate for welding? A flow of 15 to 25 cfh will cover most applications. But. Welding Gas Flow Rate.

From resources.arcmachines.com

Tig Welding Gas Flow Rate Arc Machines Welding Gas Flow Rate A flow of 15 to 25 cfh will cover most applications. The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. A turbulent gas flow during welding typically. We need a lot less flow in tig welding. The correct gas flow rate in mig welding ranges between 15. Welding Gas Flow Rate.

From www.sevencolors.co.jp

Tig Welding Argon Gas Flow Rate sevencolors.co.jp Welding Gas Flow Rate The optimal gas flow rate can vary between 10 and 35 cubic feet per hour (cfh). The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. Gas flow rate is typically measured in either cubic feet per hour (cfh) or. Welding Gas Flow Rate.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Welding Gas Flow Rate The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. But make sure to take into account the different variables while. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the. Welding Gas Flow Rate.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Welding Gas Flow Rate Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and. Welding Gas Flow Rate.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube Welding Gas Flow Rate Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. The tig welding gas flow rate for the actual tig welding process is highly. Welding Gas Flow Rate.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) Welding Gas Flow Rate We need a lot less flow in tig welding. A turbulent gas flow during welding typically. Be aware of the unit of measurement. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. Gas flow rate is typically measured in. Welding Gas Flow Rate.

From mavink.com

Mig Welding Gas Flow Rate Chart Welding Gas Flow Rate A turbulent gas flow during welding typically. Be aware of the unit of measurement. A flow of 15 to 25 cfh will cover most applications. But make sure to take into account the different variables while. We need a lot less flow in tig welding. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To. Welding Gas Flow Rate.

From www.researchgate.net

13. Plot of Filler Dia vs Purged Gas Flow Rate in TIG Welding Welding Gas Flow Rate The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. So what is the correct gas flow rate for welding? We need a lot less flow. Welding Gas Flow Rate.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Welding Gas Flow Rate We need a lot less flow in tig welding. A flow of 15 to 25 cfh will cover most applications. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel. Welding Gas Flow Rate.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Welding Gas Flow Rate So what is the correct gas flow rate for welding? The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig. Welding Gas Flow Rate.

From www.youtube.com

Eastwood Welding Flow Meter Accurately Measure Gas Flow when Welding Welding Gas Flow Rate We need a lot less flow in tig welding. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. Be aware of the unit of measurement. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To figure out how much pressure. Welding Gas Flow Rate.

From weldinggaskeijiro.blogspot.com

Welding Gas Mig Welding Gas Flow Rate Welding Gas Flow Rate We need a lot less flow in tig welding. A turbulent gas flow during welding typically. But make sure to take into account the different variables while. The optimal gas flow rate can vary between 10 and 35 cubic feet per hour (cfh). To figure out how much pressure and the flow rate is needed for the shield gas, you. Welding Gas Flow Rate.

From reg.globaltextileexpo.com

Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool Flowmeter Welding Gas Flow Rate The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. But make sure to take into account the different variables while. Be aware of the unit of measurement. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on. Welding Gas Flow Rate.

From mavink.com

Mig Welding Gas Flow Chart Welding Gas Flow Rate The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. A turbulent gas flow during welding. Welding Gas Flow Rate.

From www.wcwelding.com

Shielding Gas Guide Welding Gas Flow Rate The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. To figure out how much pressure and the flow rate is needed for the shield gas,. Welding Gas Flow Rate.

From giodbuxra.blob.core.windows.net

Gas Flow Rate For Tig Welding at Manuel Carlton blog Welding Gas Flow Rate A turbulent gas flow during welding typically. But make sure to take into account the different variables while. We need a lot less flow in tig welding. A flow of 15 to 25 cfh will cover most applications. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness,. Welding Gas Flow Rate.

From www.youtube.com

Gas flow meter setup for welding Save gas Tips for gas leak Welding Gas Flow Rate But make sure to take into account the different variables while. A turbulent gas flow during welding typically. The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. A flow of 15 to 25 cfh will cover most applications. The optimal gas flow rate can vary between 10. Welding Gas Flow Rate.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele Welding Gas Flow Rate Be aware of the unit of measurement. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. A flow of 15 to 25 cfh will cover most applications. The optimal gas flow rate. Welding Gas Flow Rate.

From www.arccaptain.com

What is the Ideal Mig Welding Gas Flow Rate? Welding Gas Flow Rate A flow of 15 to 25 cfh will cover most applications. A turbulent gas flow during welding typically. We need a lot less flow in tig welding. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Gas flow rate is. Welding Gas Flow Rate.

From www.lazada.com.my

Manooby Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool Welding Gas Flow Rate A turbulent gas flow during welding typically. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. But make sure to take into account the different variables while. The proper flow. Welding Gas Flow Rate.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Welding Gas Flow Rate The optimal gas flow rate can vary between 10 and 35 cubic feet per hour (cfh). We need a lot less flow in tig welding. A turbulent gas flow during welding typically. But make sure to take into account the different variables while. To figure out how much pressure and the flow rate is needed for the shield gas, you. Welding Gas Flow Rate.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Welding Gas Flow Rate A flow of 15 to 25 cfh will cover most applications. The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. We need a lot less flow in tig welding. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The correct gas. Welding Gas Flow Rate.

From mavink.com

Mig Welding Gas Flow Chart Welding Gas Flow Rate A flow of 15 to 25 cfh will cover most applications. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Adequate gas flow for gmaw typically ranges from 35 to 50. Welding Gas Flow Rate.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Welding Gas Flow Rate We need a lot less flow in tig welding. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. A flow of 15 to 25 cfh will cover most applications. The optimal gas flow rate can vary between 10 and. Welding Gas Flow Rate.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele Welding Gas Flow Rate To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. So what is the correct gas flow rate for welding? Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. But make sure to take. Welding Gas Flow Rate.

From www.wire-wizard.com

Gas Flow Monitor Wire Wizard Welding Products Welding Gas Flow Rate The proper flow rate depends on many factors, including the travel speed and the amount of mill scale on the base material. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. A turbulent gas flow during welding typically. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per. Welding Gas Flow Rate.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Welding Gas Flow Rate But make sure to take into account the different variables while. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The optimal gas flow rate can vary between 10 and. Welding Gas Flow Rate.

From mavink.com

Mig Welding Gas Flow Rate Chart Welding Gas Flow Rate Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. The optimal gas flow rate can vary between 10 and 35 cubic feet per hour (cfh). The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld. Welding Gas Flow Rate.

From abbywalsh.z19.web.core.windows.net

Mig Welding Gas Flow Rate Chart Lpm Welding Gas Flow Rate But make sure to take into account the different variables while. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. We need a lot less flow in tig welding. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip. Welding Gas Flow Rate.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Welding Gas Flow Rate Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Be aware of the unit of measurement. We need a lot less flow in tig welding. So what is the correct. Welding Gas Flow Rate.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) Welding Gas Flow Rate The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. But make sure to take into account the different variables while. A flow of 15 to 25 cfh will cover most applications. We need a lot less flow in tig. Welding Gas Flow Rate.

From mavink.com

Mig Welding Gas Flow Rate Chart Welding Gas Flow Rate The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel speed of the weld head. Be aware of the unit of measurement. A flow of 15 to 25 cfh will cover most applications. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic. Welding Gas Flow Rate.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele Welding Gas Flow Rate A flow of 15 to 25 cfh will cover most applications. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. The tig welding gas flow rate for the actual tig welding process is highly specific to the material types, the material’s thickness, and the travel. Welding Gas Flow Rate.