Assembly Line Balancing Equations . Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. What is assembly line balancing? Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Principles of assembly line balancing: Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay.

from www.slideserve.com

Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Principles of assembly line balancing: The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. What is assembly line balancing? Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Objective is to minimize the imbalance between machines or personnel while meeting required output starts.

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free

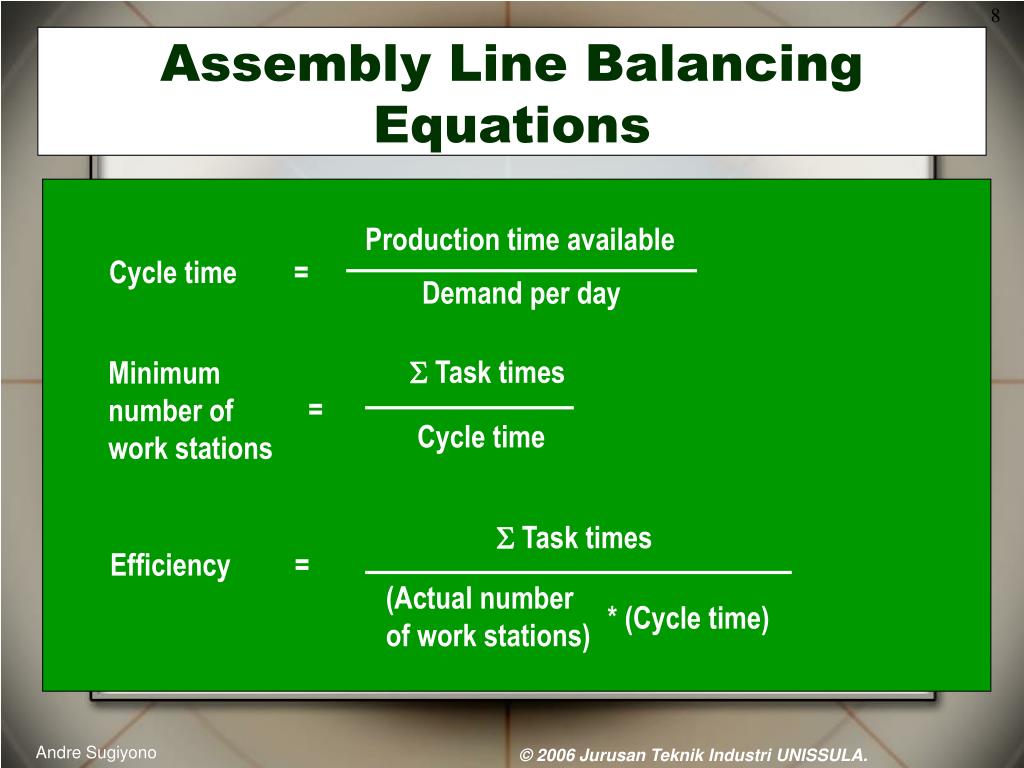

Assembly Line Balancing Equations Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. What is assembly line balancing? Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Principles of assembly line balancing: Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Assembly Line Balancing Equations Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. What is assembly line balancing? Principles of assembly line balancing: Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit. Assembly Line Balancing Equations.

From www.youtube.com

Assembly line balancing part3 Line balancing Target IES YouTube Assembly Line Balancing Equations Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Principles. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Equations Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Objective is to minimize the. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Product layout PowerPoint Presentation, free download ID526491 Assembly Line Balancing Equations Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Principles of assembly line balancing: Line balancing is done to reduce or eliminate the waiting time in the workstations of. Assembly Line Balancing Equations.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Assembly Line Balancing Equations Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. The assembly line in which the workstations have equal processing time with less or no ideal time is said to. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Equations Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Thus we can utilize the resources. Assembly Line Balancing Equations.

From www.youtube.com

Topic 04 04. Assembly Line Balancing Scaling Up YouTube Assembly Line Balancing Equations Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Principles of assembly line balancing: Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly. Assembly Line Balancing Equations.

From www.intechopen.com

Assembly Line Balancing and Sequencing IntechOpen Assembly Line Balancing Equations Thus we can utilize the resources such as manpower and machinery/equipment more effectively. What is assembly line balancing? Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from. Assembly Line Balancing Equations.

From pt.slideshare.net

assembly line balancing Assembly Line Balancing Equations Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Principles of assembly line balancing:. Assembly Line Balancing Equations.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron Assembly Line Balancing Equations The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another What is assembly line balancing?. Assembly Line Balancing Equations.

From www.chegg.com

Solved Q4. Consider the assembly line balancing problem Assembly Line Balancing Equations What is assembly line balancing? Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Equations What is assembly line balancing? Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Principles of assembly line balancing: Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Alb, or simply line balancing, is. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Equations Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Assembly line balancing (alb) is a process used in. Assembly Line Balancing Equations.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing Equations Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Principles of assembly line balancing: The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Product layout PowerPoint Presentation, free download ID526491 Assembly Line Balancing Equations Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Objective is to minimize the. Assembly Line Balancing Equations.

From www.youtube.com

Operations & Supply Chain Management Assembly Line Balancing I YouTube Assembly Line Balancing Equations What is assembly line balancing? The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line. Assembly Line Balancing Equations.

From www.youtube.com

Balancing Chemical Equations 2 YouTube Assembly Line Balancing Equations Principles of assembly line balancing: Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation. Assembly Line Balancing Equations.

From www.slideshare.net

C5 process & layout Assembly Line Balancing Equations Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Principles of assembly line balancing: Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled. Assembly Line Balancing Equations.

From www.youtube.com

Assembly Line BalancingSolved ExampleOperations Management YouTube Assembly Line Balancing Equations Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Alb, or simply line balancing, is arranging the individual processing and. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Equations Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Alb, or simply line balancing, is arranging the. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Product layout PowerPoint Presentation, free download ID526491 Assembly Line Balancing Equations Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Principles of assembly line balancing: The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Assembly line balancing (alb) optimizes the mass. Assembly Line Balancing Equations.

From www.slideshare.net

Layout Assembly Line Balancing Equations What is assembly line balancing? Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Line balancing. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Equations Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Objective is to minimize the imbalance between machines or personnel while meeting. Assembly Line Balancing Equations.

From www.youtube.com

Tutorial 6 Assembly line balancing YouTube Assembly Line Balancing Equations The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. What is assembly line balancing? Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another. Assembly Line Balancing Equations.

From www.researchgate.net

Assembly line balancing problem. Download Scientific Diagram Assembly Line Balancing Equations What is assembly line balancing? Principles of assembly line balancing: Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Assembly line balancing. Assembly Line Balancing Equations.

From www.slideshare.net

Assembly Line Balancing Assembly Line Balancing Equations Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. Principles of assembly line balancing: Line balancing is done. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Equations Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Alb, or simply line balancing,. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Line Balancing Equations Principles of assembly line balancing: Thus we can utilize the resources such as manpower and machinery/equipment more effectively. Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Equations The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Objective is to minimize the imbalance between machines or personnel while meeting required output starts. What is assembly line balancing? Principles of assembly line balancing: Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Equations Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Principles of assembly line balancing: Involves task equity, sequence, capacity utilization, and flexibility. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Equations Line balancing is done to reduce or eliminate the waiting time in the workstations of an assembly line which runs in one piece flow. Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. What is assembly line balancing? Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Alb, or simply. Assembly Line Balancing Equations.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing Equations Objective is to minimize the imbalance between machines or personnel while meeting required output starts. What is assembly line balancing? Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Line balancing is done to reduce or eliminate the waiting time in the workstations of. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Equations Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal processing time to each one without any delay. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another Alb, or simply line. Assembly Line Balancing Equations.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing Equations Objective is to minimize the imbalance between machines or personnel while meeting required output starts. Alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time required at. What is assembly line balancing? Assembly line balancing (alb) optimizes the mass production process by dividing tasks into workstations and allocating equal. Assembly Line Balancing Equations.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Equations Involves task equity, sequence, capacity utilization, and flexibility to maintain workflow and efficiency. What is assembly line balancing? The assembly line in which the workstations have equal processing time with less or no ideal time is said to be a perfect one. Assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and. Assembly Line Balancing Equations.