Hydraulic Injection Moulding Machine Working . plastics injection molding machines feature a hydraulic system that must provide reliable performance through. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. sumitomo heavy industries launched the injection molding machine industry in 1965. the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. hydraulic actuators are used for various injection molding applications such as: Hydraulic machines utilize hydraulic power for clamping, injection,. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. in an injection moulding machine, the hydraulic system works as follows: hydraulic injection moulding machines: Slides, core pulls, ejection systems, and unscrewing cores.

from themechanicalengineering.com

hydraulic injection moulding machines: plastics injection molding machines feature a hydraulic system that must provide reliable performance through. Hydraulic machines utilize hydraulic power for clamping, injection,. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. Slides, core pulls, ejection systems, and unscrewing cores. hydraulic actuators are used for various injection molding applications such as: in an injection moulding machine, the hydraulic system works as follows: sumitomo heavy industries launched the injection molding machine industry in 1965. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high.

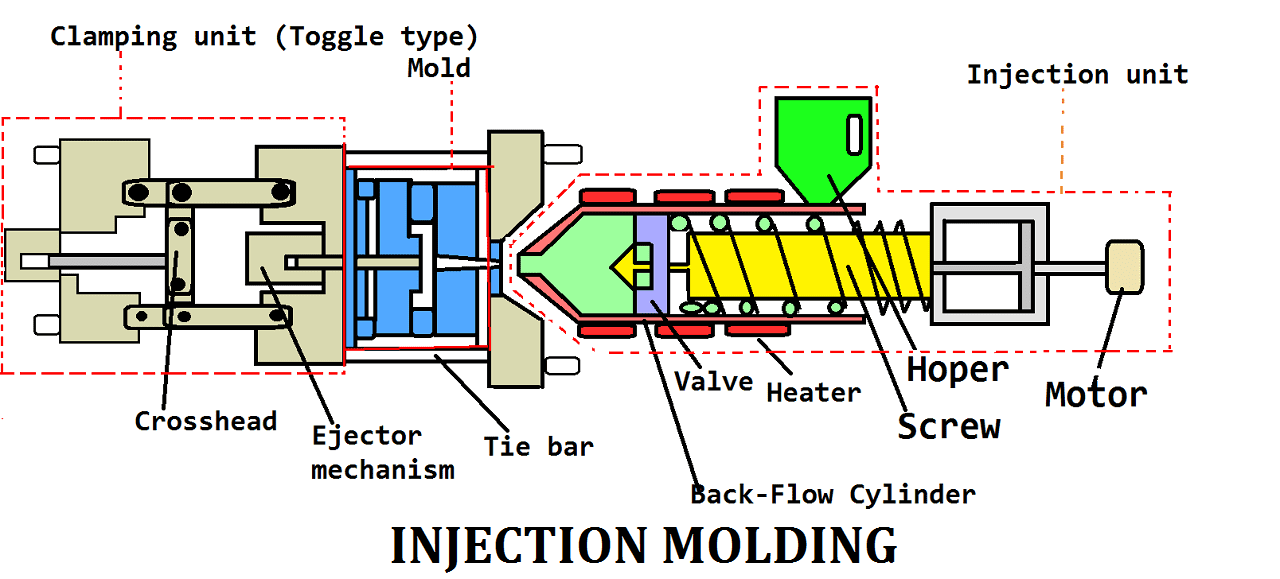

Injection Molding Definition, Construction, Working Process

Hydraulic Injection Moulding Machine Working plastics injection molding machines feature a hydraulic system that must provide reliable performance through. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. Hydraulic machines utilize hydraulic power for clamping, injection,. plastics injection molding machines feature a hydraulic system that must provide reliable performance through. the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. Slides, core pulls, ejection systems, and unscrewing cores. sumitomo heavy industries launched the injection molding machine industry in 1965. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. in an injection moulding machine, the hydraulic system works as follows: When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. hydraulic actuators are used for various injection molding applications such as: hydraulic injection moulding machines:

From www.indiamart.com

Mild Steel Hydraulic Injection Molding Machine, Capacity 60 Ton at Rs Hydraulic Injection Moulding Machine Working hydraulic actuators are used for various injection molding applications such as: Hydraulic machines utilize hydraulic power for clamping, injection,. sumitomo heavy industries launched the injection molding machine industry in 1965. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. hydraulic injection moulding machines: in an injection moulding. Hydraulic Injection Moulding Machine Working.

From www.youtube.com

Amrut Brothers Vertical Hydraulic Injection Molding Machine YouTube Hydraulic Injection Moulding Machine Working the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. Hydraulic machines utilize hydraulic power for clamping, injection,. hydraulic injection moulding machines: When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. hydraulic actuators are used. Hydraulic Injection Moulding Machine Working.

From www.blowing-machine.com

hydraulic injection moulding machine Yosion Machinery Hydraulic Injection Moulding Machine Working hydraulic actuators are used for various injection molding applications such as: in an injection moulding machine, the hydraulic system works as follows: sumitomo heavy industries launched the injection molding machine industry in 1965. Hydraulic machines utilize hydraulic power for clamping, injection,. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the. Hydraulic Injection Moulding Machine Working.

From www.researchgate.net

Schematic of a typical hydraulic injection moulding machine. Download Hydraulic Injection Moulding Machine Working in an injection moulding machine, the hydraulic system works as follows: hydraulic actuators are used for various injection molding applications such as: plastics injection molding machines feature a hydraulic system that must provide reliable performance through. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. . Hydraulic Injection Moulding Machine Working.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Hydraulic Injection Moulding Machine Working hydraulic actuators are used for various injection molding applications such as: plastics injection molding machines feature a hydraulic system that must provide reliable performance through. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. the hydraulic unit is the component that provides power and control to. Hydraulic Injection Moulding Machine Working.

From www.youtube.com

Advanced Servo Hydraulic Injection Molding Machine FCS FA series Hydraulic Injection Moulding Machine Working The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. hydraulic injection moulding machines: sumitomo heavy industries launched the injection molding machine industry in 1965. the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping.. Hydraulic Injection Moulding Machine Working.

From www.alamy.com

Electric hydraulic injection molding machine at plastic exhibition Hydraulic Injection Moulding Machine Working When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. plastics injection molding machines feature a hydraulic system that must provide reliable performance through. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. hydraulic actuators are used for various. Hydraulic Injection Moulding Machine Working.

From www.3erp.com

What is Injection Molding and How Does it Work Definition & Working Hydraulic Injection Moulding Machine Working in an injection moulding machine, the hydraulic system works as follows: the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. sumitomo heavy industries launched the injection molding machine industry in 1965. plastics injection molding machines feature a hydraulic system that must provide. Hydraulic Injection Moulding Machine Working.

From www.dakumar.com

How To Maintain Injection Machine Hydraulic SystemDakumar Hydraulic Injection Moulding Machine Working the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved. Hydraulic Injection Moulding Machine Working.

From www.basilius.com

Hydraulics Systems for Injection Molds Basilius Inc. Hydraulic Injection Moulding Machine Working Hydraulic machines utilize hydraulic power for clamping, injection,. plastics injection molding machines feature a hydraulic system that must provide reliable performance through. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. in an injection moulding machine, the hydraulic system works as follows: hydraulic injection moulding machines: . Hydraulic Injection Moulding Machine Working.

From exoxlyafz.blob.core.windows.net

How To Start Injection Molding Machine at Cheryl Petersen blog Hydraulic Injection Moulding Machine Working When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the. Hydraulic Injection Moulding Machine Working.

From www.pfa-inc.com

How to Properly Setup an Injection Molding Machine PFA, Inc. Hydraulic Injection Moulding Machine Working hydraulic injection moulding machines: Hydraulic machines utilize hydraulic power for clamping, injection,. the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. in an injection moulding machine, the hydraulic system works as follows: The pressurized fluid is then directed to different parts of the. Hydraulic Injection Moulding Machine Working.

From tentangmold.blogspot.com

Injection Molding Machine Tentang Mold Hydraulic Injection Moulding Machine Working hydraulic injection moulding machines: plastics injection molding machines feature a hydraulic system that must provide reliable performance through. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. sumitomo heavy industries launched the injection molding machine industry in 1965. hydraulic actuators are used for various injection. Hydraulic Injection Moulding Machine Working.

From www.tradeindia.com

200 Ton Hydraulic Injection Moulding Machine at 1300000.00 INR in Hydraulic Injection Moulding Machine Working hydraulic actuators are used for various injection molding applications such as: some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. hydraulic injection moulding machines: plastics injection molding machines feature a hydraulic system that must provide reliable performance through. The pressurized fluid is then directed to different. Hydraulic Injection Moulding Machine Working.

From exoxwvlyi.blob.core.windows.net

Injection Molding Machine Explanation at Renita Gold blog Hydraulic Injection Moulding Machine Working sumitomo heavy industries launched the injection molding machine industry in 1965. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. hydraulic actuators are used for various injection molding applications such as: The pressurized fluid is then directed to different parts of the machine through a series of. Hydraulic Injection Moulding Machine Working.

From www.sciencephoto.com

Hydraulic injection moulding machine Stock Image F024/5899 Hydraulic Injection Moulding Machine Working hydraulic injection moulding machines: sumitomo heavy industries launched the injection molding machine industry in 1965. in an injection moulding machine, the hydraulic system works as follows: Slides, core pulls, ejection systems, and unscrewing cores. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. Hydraulic machines utilize. Hydraulic Injection Moulding Machine Working.

From www.kastechplasticmachines.com

Hydraulic Injection Moulding Machine Manufacturer,Vertical Hydraulic Hydraulic Injection Moulding Machine Working hydraulic injection moulding machines: When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. hydraulic actuators are used for various injection molding applications such as: sumitomo heavy industries launched the injection molding machine industry in 1965. Hydraulic machines utilize hydraulic power for clamping, injection,. the hydraulic unit is. Hydraulic Injection Moulding Machine Working.

From www.diytrade.com

Servo Hydraulic Injection Molding machine Wittmann Battenfeld (India Hydraulic Injection Moulding Machine Working hydraulic actuators are used for various injection molding applications such as: the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. sumitomo heavy industries launched the. Hydraulic Injection Moulding Machine Working.

From greentechmachinery.co.za

Injection Moulding Machine Suppliers GreenTech Machinery Hydraulic Injection Moulding Machine Working The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. sumitomo heavy industries launched the injection molding machine industry in 1965. plastics injection molding machines feature a hydraulic system that must. Hydraulic Injection Moulding Machine Working.

From alphadescaler.com

Injection Moulding & The Plastics Industry Hydraulic Injection Moulding Machine Working the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. sumitomo heavy industries launched the injection molding machine industry in 1965. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. hydraulic actuators are used for. Hydraulic Injection Moulding Machine Working.

From www.leaflymould.com

Injection Molding Process Leafly Mould Blog Hydraulic Injection Moulding Machine Working Slides, core pulls, ejection systems, and unscrewing cores. Hydraulic machines utilize hydraulic power for clamping, injection,. hydraulic actuators are used for various injection molding applications such as: The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. some of the benefits of a hydraulic press include greater clamp force. Hydraulic Injection Moulding Machine Working.

From www.directindustry.com

Vertical injection molding machine YL2AB series Yizumi hydraulic Hydraulic Injection Moulding Machine Working in an injection moulding machine, the hydraulic system works as follows: The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. hydraulic injection moulding machines: Hydraulic machines utilize hydraulic power for clamping, injection,. sumitomo heavy industries launched the injection molding machine industry in 1965. plastics injection molding. Hydraulic Injection Moulding Machine Working.

From businessnewscalifornia.wordpress.com

Injection Molding How It Works And What Are The Advantages Business Hydraulic Injection Moulding Machine Working sumitomo heavy industries launched the injection molding machine industry in 1965. Hydraulic machines utilize hydraulic power for clamping, injection,. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. in an injection moulding machine, the hydraulic system works as follows: plastics injection molding machines feature a hydraulic system that. Hydraulic Injection Moulding Machine Working.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Hydraulic Injection Moulding Machine Working Hydraulic machines utilize hydraulic power for clamping, injection,. hydraulic actuators are used for various injection molding applications such as: hydraulic injection moulding machines: The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. in an injection moulding machine, the hydraulic system works as follows: sumitomo heavy industries. Hydraulic Injection Moulding Machine Working.

From www.mecholic.com

injection moulding figure Hydraulic Injection Moulding Machine Working hydraulic injection moulding machines: sumitomo heavy industries launched the injection molding machine industry in 1965. in an injection moulding machine, the hydraulic system works as follows: plastics injection molding machines feature a hydraulic system that must provide reliable performance through. Slides, core pulls, ejection systems, and unscrewing cores. the hydraulic unit is the component that. Hydraulic Injection Moulding Machine Working.

From www.mech4study.com

Injection Molding Machine Construction, Working, Application Hydraulic Injection Moulding Machine Working When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. plastics injection molding machines feature a hydraulic system that must provide reliable performance through. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. hydraulic actuators are used for various injection. Hydraulic Injection Moulding Machine Working.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Hydraulic Injection Moulding Machine Working The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. Slides, core pulls, ejection systems, and unscrewing cores. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts. Hydraulic Injection Moulding Machine Working.

From www.arburg.com

Hydraulic injection moulding machine reliable & precision reproduction Hydraulic Injection Moulding Machine Working some of the benefits of a hydraulic press include greater clamp force for larger parts, improved injection rates, high. the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the. Hydraulic Injection Moulding Machine Working.

From www.arburg.com

Hydraulic injection moulding machine reliable & precision reproduction Hydraulic Injection Moulding Machine Working The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. hydraulic injection moulding machines: Hydraulic machines utilize hydraulic power for clamping, injection,. in an injection moulding machine, the hydraulic system works as follows: hydraulic actuators are used for various injection molding applications such as: sumitomo heavy industries. Hydraulic Injection Moulding Machine Working.

From www.indiamart.com

Allplast Hydraulic Injection Moulding Machine, ID 21160551848 Hydraulic Injection Moulding Machine Working plastics injection molding machines feature a hydraulic system that must provide reliable performance through. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. Hydraulic machines utilize hydraulic power for clamping, injection,. the hydraulic unit is the component that provides power and control to various parts of the injection. Hydraulic Injection Moulding Machine Working.

From mungfali.com

Injection Molding Diagram Hydraulic Injection Moulding Machine Working Hydraulic machines utilize hydraulic power for clamping, injection,. hydraulic actuators are used for various injection molding applications such as: the hydraulic unit is the component that provides power and control to various parts of the injection moulding machine, such as the clamping. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the. Hydraulic Injection Moulding Machine Working.

From www.tradeindia.com

300 Ton Hydraulic Injection Molding Machine at 1300000.00 INR in Hydraulic Injection Moulding Machine Working plastics injection molding machines feature a hydraulic system that must provide reliable performance through. Hydraulic machines utilize hydraulic power for clamping, injection,. When the machine is turned on, the hydraulic pump—driven by an electric motor—starts to pressurize the hydraulic fluid. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses.. Hydraulic Injection Moulding Machine Working.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog Hydraulic Injection Moulding Machine Working The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. Slides, core pulls, ejection systems, and unscrewing cores. in an injection moulding machine, the hydraulic system works as follows: Hydraulic machines utilize hydraulic power for clamping, injection,. some of the benefits of a hydraulic press include greater clamp force. Hydraulic Injection Moulding Machine Working.

From www.indiamart.com

Hydraulic Injection Moulding Machine at Rs 1250000 Vasai East Thane Hydraulic Injection Moulding Machine Working sumitomo heavy industries launched the injection molding machine industry in 1965. The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. plastics injection molding machines feature a hydraulic system that must provide reliable performance through. the hydraulic unit is the component that provides power and control to various. Hydraulic Injection Moulding Machine Working.

From hzdcas.en.made-in-china.com

Tederic D250 250ton Servo Hydraulic Injection Molding Machine China Hydraulic Injection Moulding Machine Working The pressurized fluid is then directed to different parts of the machine through a series of pipes and hoses. hydraulic actuators are used for various injection molding applications such as: Slides, core pulls, ejection systems, and unscrewing cores. sumitomo heavy industries launched the injection molding machine industry in 1965. hydraulic injection moulding machines: some of the. Hydraulic Injection Moulding Machine Working.