Water Level Sensor Corrosion . icon process controls offers a range of advanced sensors designed to meet the demands of such applications. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. These unique product characteristics make the pyxis lpr applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency.

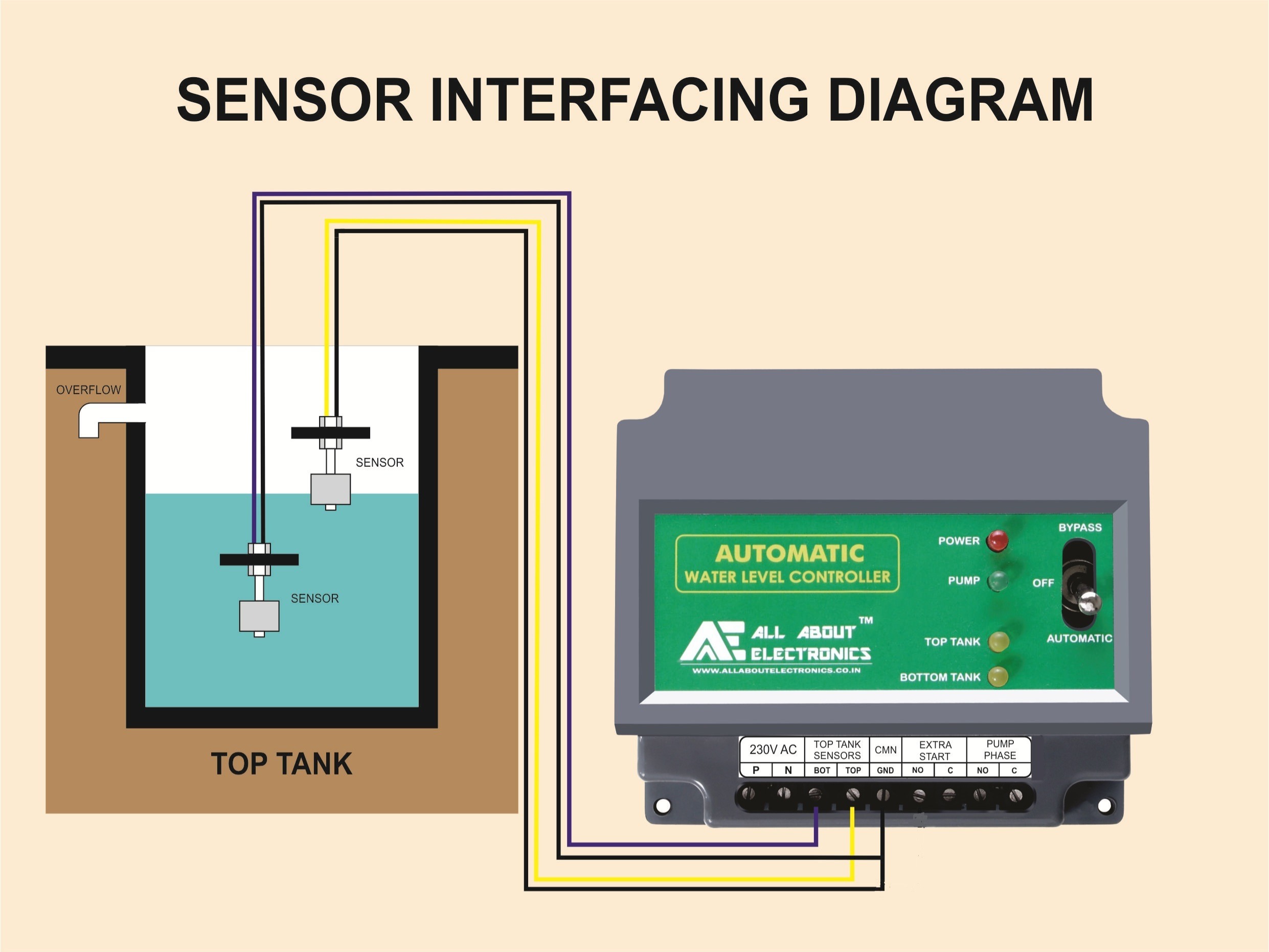

from allaboutelectronics.in

These unique product characteristics make the pyxis lpr The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. icon process controls offers a range of advanced sensors designed to meet the demands of such applications. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run.

Fully Automatic Water Level Controller with CorrosionFree Sensors

Water Level Sensor Corrosion applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. These unique product characteristics make the pyxis lpr here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. icon process controls offers a range of advanced sensors designed to meet the demands of such applications. to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency.

From atech-sensor.en.made-in-china.com

Corrosion Resistance 0.1Fs High Precision Level Sensor China Tank Water Level Sensor Corrosion A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. in harsh subcritical water environments, oil pipes are prone to corrosion and. Water Level Sensor Corrosion.

From sealand-equipment.en.made-in-china.com

Pressure Type Liquid Level Sensor AntiCorrosion Sewage Water Level Water Level Sensor Corrosion to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. the pyxis. Water Level Sensor Corrosion.

From wnksensor.en.made-in-china.com

420mA AntiCorrosion Water Level Sensor for Agricultural Irrigation Water Level Sensor Corrosion These unique product characteristics make the pyxis lpr here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. in industries dealing with corrosive substances, selecting the right liquid level sensor is critical. Water Level Sensor Corrosion.

From allaboutelectronics.in

Fully Automatic Water Level Controller with CorrosionFree Sensors Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. These unique product characteristics make the pyxis lpr here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in. Water Level Sensor Corrosion.

From www.alibaba.com

Ept Tech D1csd High Accuracy Level Sensor Corrosion Proof Level Sensor Water Level Sensor Corrosion The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. in harsh subcritical water environments, oil pipes are prone to corrosion. Water Level Sensor Corrosion.

From sikoflow.en.made-in-china.com

Hgl104 Septic Tank Level Indicator PTFE Submersible Corrosion Water Level Sensor Corrosion the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the. Water Level Sensor Corrosion.

From www.electronicscomp.com

AntiCorrosion Water Level Sensor with Ball Float Switch buy online at Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. the most considerable measurement. Water Level Sensor Corrosion.

From htdzsensor.en.made-in-china.com

Corrosion resistant special medium level gauge Water level sensor Water Level Sensor Corrosion Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. icon process controls. Water Level Sensor Corrosion.

From www.thanksbuyer.com

KUS550 Ultrasonic Water Level Sensor Transmitter CorrosionResistant Water Level Sensor Corrosion These unique product characteristics make the pyxis lpr A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments.. Water Level Sensor Corrosion.

From www.aliexpress.com

corrosion protection anti corrosion float switch 110V MK AAPCFS4 water Water Level Sensor Corrosion Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. the pyxis corrosion sensors. Water Level Sensor Corrosion.

From hmsensor.en.made-in-china.com

420mA AntiCorrosion Water Level Sensor (JC621R10) China Water Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. the pyxis corrosion sensors measure sample. Water Level Sensor Corrosion.

From evakw.com

Anticorrosion Type Ball Float Liquid Water Level Sensor Water Level Sensor Corrosion in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. applications include measuring atmospheric corrosivity, monitoring. Water Level Sensor Corrosion.

From gnflowmeter.en.made-in-china.com

Shanghai Gns Corrosion Resistance Level Transmitter Diffuse Silicon Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. Corrosive environments pose unique. Water Level Sensor Corrosion.

From dianyingpu2022.en.made-in-china.com

DypA07 Water Level Measurement AntiCorrosion Long Range Waterproof Water Level Sensor Corrosion the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while. Water Level Sensor Corrosion.

From hmsensor.en.made-in-china.com

AntiCorrosion Water Level Sensor China Underwater Transducer and Water Level Sensor Corrosion the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. A number of level sensors which work. Water Level Sensor Corrosion.

From sharvielectronics.com

Anti Corrosion Stainless Steel Water Level Sensor Sharvielectronics Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000. Water Level Sensor Corrosion.

From www.alibaba.com

010v Corrosion Proof Water Level Sensor 420ma Liquid Ultra Sensor De Water Level Sensor Corrosion the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. to enable. Water Level Sensor Corrosion.

From vacorda1997.en.made-in-china.com

AntiCorrosion 60GHz Radar Tank Level Sensor for Water Liquid China Water Level Sensor Corrosion A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. to enable this, sensors are now being. Water Level Sensor Corrosion.

From www.xvyanprecision.com

Corrosive Liquid Level Sensor, Fluid Level Sensor/Transducer Manufacturer Water Level Sensor Corrosion the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. These unique product characteristics make the pyxis lpr in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. icon process controls offers a range. Water Level Sensor Corrosion.

From www.indiamart.com

Anti corrosion water level sensor, 05 M at Rs 150/piece in New Delhi Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. These unique product characteristics make the pyxis lpr The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable,. Water Level Sensor Corrosion.

From www.sensorsone.com

Stop sea water level or depth sensor failures due to pitting or corrosion Water Level Sensor Corrosion the pyxis corrosion sensors measure sample water conductivity directly and compensate for the conductivity impact on the lpr measurement up to 10,000 μs/cm. A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand. Water Level Sensor Corrosion.

From www.qtmeters.com

Integrated ultrasonic level gauge sensor river water level meter anti Water Level Sensor Corrosion Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. icon process controls offers a range of advanced sensors designed to meet the demands of such applications. These unique product characteristics make the pyxis lpr The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar. Water Level Sensor Corrosion.

From www.aliexpress.com

220v AAPCFS4 corrosion protection anti corrosion Float switch water Water Level Sensor Corrosion Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. These unique product characteristics make the pyxis lpr A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. icon process controls offers a range of advanced sensors. Water Level Sensor Corrosion.

From www.aliexpress.com

High quality corrosion resistant F300 capacitive level sensor Water Water Level Sensor Corrosion in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency. to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. here we. Water Level Sensor Corrosion.

From www.homemade-circuits.com

AntiCorrosion Probes for Water Level Controller Homemade Circuit Water Level Sensor Corrosion Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan. Water Level Sensor Corrosion.

From wnksensor.en.made-in-china.com

AntiCorrosion Radar Water Level Meter Sensor Transmitter for Rod Silo Water Level Sensor Corrosion here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not cause corrosion in the long run. in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency. the. Water Level Sensor Corrosion.

From www.electronicscomp.com

AntiCorrosion Water Level Sensor with Ball Float Switch buy online at Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. to enable this, sensors. Water Level Sensor Corrosion.

From holykell.en.made-in-china.com

RS485 Stainless Steel Absolute Water Pressure Level Sensor Corrosion Water Level Sensor Corrosion The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. A number of level sensors which work with metal terminals use dc power, that, eventually, corrode as a result of the effects of. icon process controls offers a range of. Water Level Sensor Corrosion.

From robu.in

Buy AntiCorrosion Water Level Sensor with Ball Float Switch Online at Water Level Sensor Corrosion in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency. the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. icon process controls offers a range of. Water Level Sensor Corrosion.

From huadian.en.made-in-china.com

Anti Corrosion Acid Level Transmitter Submersible Water Level Sensor Water Level Sensor Corrosion to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. the most considerable measurement technique accepted by various researchers is the ultrasonic level sensor. in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency. the pyxis corrosion. Water Level Sensor Corrosion.

From www.alibaba.com

High Quality Anti Corrosion Liquid Level Sensor For Container Buy Water Level Sensor Corrosion These unique product characteristics make the pyxis lpr applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. in harsh subcritical water environments, oil pipes are prone to corrosion and even perforation, seriously. to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. The levelpro. Water Level Sensor Corrosion.

From njhjet2015.en.made-in-china.com

Corrosion Resistant Ceramic Capacitor Sensor Water Liquid Level Water Level Sensor Corrosion These unique product characteristics make the pyxis lpr icon process controls offers a range of advanced sensors designed to meet the demands of such applications. in industries dealing with corrosive substances, selecting the right liquid level sensor is critical for ensuring safety and operational efficiency. A number of level sensors which work with metal terminals use dc power,. Water Level Sensor Corrosion.

From www.snapdeal.com

Buy Best Quality Fully Automatic water level controller with Water Level Sensor Corrosion icon process controls offers a range of advanced sensors designed to meet the demands of such applications. applications include measuring atmospheric corrosivity, monitoring the tendency of cooling water to promote. Corrosive environments pose unique challenges, demanding robust and reliable sensors that can withstand harsh conditions while providing accurate measurements. in harsh subcritical water environments, oil pipes are. Water Level Sensor Corrosion.

From robu.in

Buy AntiCorrosion Water Level Sensor with Ball Float Switch Online at Water Level Sensor Corrosion The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. here we learn how to create an anti corrosive probe circuit for water level sensors, which will ensure that the water has minimum impact on the probes and does not. Water Level Sensor Corrosion.

From www.electronicscomp.com

AntiCorrosion Water Level Sensor with Ball Float Switch buy online at Water Level Sensor Corrosion to enable this, sensors are now being used in applications and environments that are not so friendly to sensors. The levelpro 100 series, cfl float level sensor, ultrapro 2000, and proscan 3 80ghz radar sensor provide reliable, accurate, and durable solutions for monitoring liquid levels in corrosive environments. the most considerable measurement technique accepted by various researchers is. Water Level Sensor Corrosion.