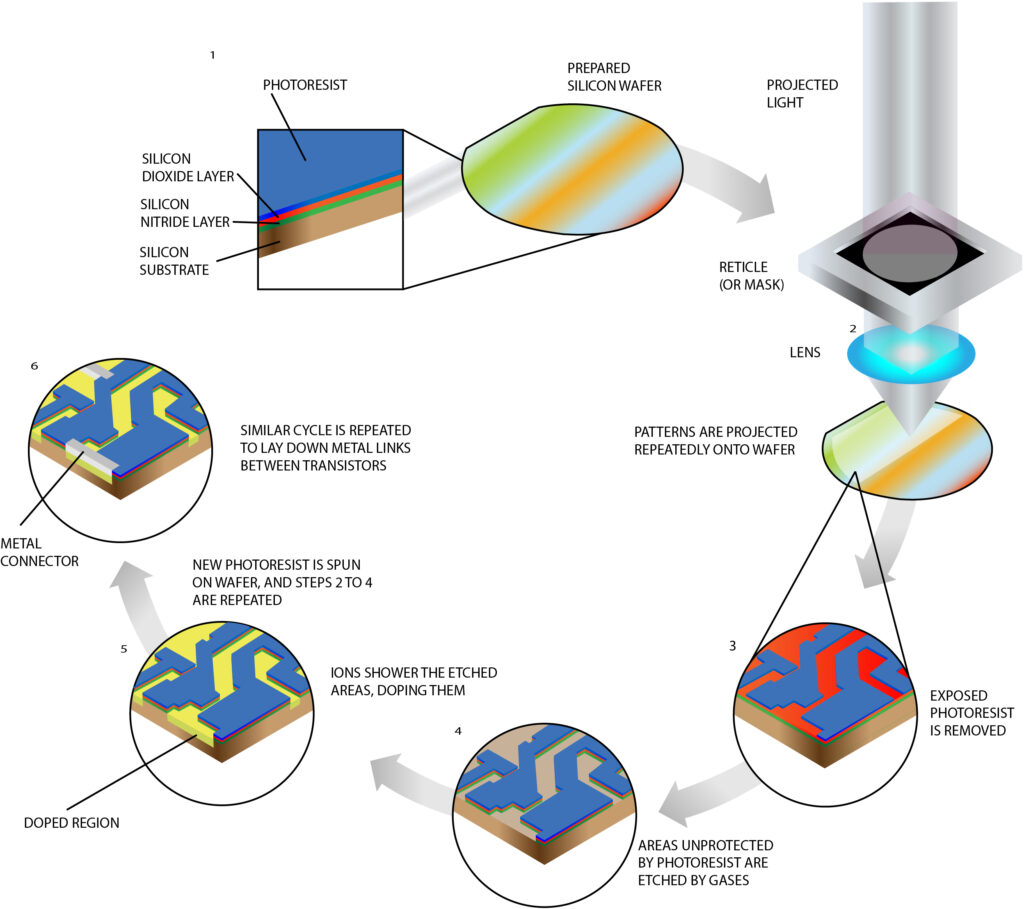

Chip Making Definition . Deposition, photoresist, lithography, etch, ionization. Microchips are made by building up layers of interconnected patterns on a silicon wafer. To make any chip, numerous processes play a role. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In this article, we will explore the semiconductor manufacturing process, including the steps. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. But have you ever wondered how these tiny chips are actually made? Let’s discuss six critical semiconductor manufacturing steps:

from techovedas.com

Microchips are made by building up layers of interconnected patterns on a silicon wafer. In this article, we will explore the semiconductor manufacturing process, including the steps. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. To make any chip, numerous processes play a role. But have you ever wondered how these tiny chips are actually made? In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Deposition, photoresist, lithography, etch, ionization. Let’s discuss six critical semiconductor manufacturing steps:

10 Fabrication Steps to Build a Semiconductor Chip techovedas

Chip Making Definition Microchips are made by building up layers of interconnected patterns on a silicon wafer. Microchips are made by building up layers of interconnected patterns on a silicon wafer. In this article, we will explore the semiconductor manufacturing process, including the steps. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. To make any chip, numerous processes play a role. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. But have you ever wondered how these tiny chips are actually made? Deposition, photoresist, lithography, etch, ionization. Let’s discuss six critical semiconductor manufacturing steps:

From www.mercurynews.com

The U.S. is bringing chipmaking home. Is California ready? Chip Making Definition Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its. Chip Making Definition.

From informacionpublica.svet.gob.gt

Inside Taiwan's 'Sacred Mountain' Of ChipMaking WIRED Chip Making Definition A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In this article, we will explore the semiconductor manufacturing process, including the steps. Let’s discuss six critical semiconductor manufacturing steps: Microchips are made by building up layers of interconnected patterns on a silicon. Chip Making Definition.

From courses.cs.washington.edu

Chip Fabrication Chip Making Definition Let’s discuss six critical semiconductor manufacturing steps: Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. Microchips are made by building up layers of interconnected patterns on a silicon wafer. To make any chip, numerous processes play a role. A common chip is only about 1 millimeter thick and contains roughly 30. Chip Making Definition.

From loyalfoodmachine.com

Industrial Fully Automatic Potato Chips Making Machine Chip Making Definition Microchips are made by building up layers of interconnected patterns on a silicon wafer. Let’s discuss six critical semiconductor manufacturing steps: In this article, we will explore the semiconductor manufacturing process, including the steps. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. Deposition, photoresist, lithography, etch, ionization. But have you. Chip Making Definition.

From www.youtube.com

Chips Making Machine YouTube Chip Making Definition But have you ever wondered how these tiny chips are actually made? In this article, we will explore the semiconductor manufacturing process, including the steps. To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. A common. Chip Making Definition.

From techovedas.com

10 Fabrication Steps to Build a Semiconductor Chip techovedas Chip Making Definition But have you ever wondered how these tiny chips are actually made? Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. Deposition, photoresist, lithography, etch, ionization. To make any chip, numerous processes play a role. Microchips are made by building up layers of interconnected patterns on a silicon wafer. A common chip. Chip Making Definition.

From mfgbulletin.com

CNC Machine Chip Manufacturing Process MFG Bulletin Chip Making Definition In this article, we will explore the semiconductor manufacturing process, including the steps. To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: Microchips are made by building up layers of interconnected patterns on a silicon wafer. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips. Chip Making Definition.

From www.macrofab.com

How to Build a Chip Factory Reshoring American Electronics MacroFab Chip Making Definition To make any chip, numerous processes play a role. But have you ever wondered how these tiny chips are actually made? Microchips are made by building up layers of interconnected patterns on a silicon wafer. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. A common chip is only about 1 millimeter. Chip Making Definition.

From studylib.net

Making of a Chip Chip Making Definition To make any chip, numerous processes play a role. Microchips are made by building up layers of interconnected patterns on a silicon wafer. But have you ever wondered how these tiny chips are actually made? Let’s discuss six critical semiconductor manufacturing steps: In this article, we will explore the semiconductor manufacturing process, including the steps. Deposition, photoresist, lithography, etch, ionization.. Chip Making Definition.

From chenyangtech.en.made-in-china.com

Tortilla Chip Nacho Bugles Chips Making Machine Fried Snacks Food Chip Making Definition To make any chip, numerous processes play a role. In this article, we will explore the semiconductor manufacturing process, including the steps. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects. Chip Making Definition.

From www.cooker.com.tw

Vacuum Fruit and Vegetable Chips Making Machine Chip Making Definition But have you ever wondered how these tiny chips are actually made? In this article, we will explore the semiconductor manufacturing process, including the steps. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Learn about the steps in the chip fabrication. Chip Making Definition.

From www.slideserve.com

PPT Seminar On Nanotechnology PowerPoint Presentation ID1298811 Chip Making Definition Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. But have you ever wondered how these tiny chips are actually made? A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Deposition, photoresist, lithography, etch,. Chip Making Definition.

From www.powerelectronicsnews.com

Improving the SiC Wafer Process Power Electronics News Chip Making Definition Deposition, photoresist, lithography, etch, ionization. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. In modern manufacturing there are few components more crucial than semiconductors,. Chip Making Definition.

From asiatimes.com

Japan well on the way to chipmaking's vanguard Asia Times Chip Making Definition A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization. But have you. Chip Making Definition.

From www.youtube.com

Full Automatic Potato Chips Making Machine Production Line YouTube Chip Making Definition Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. But have you ever wondered how these tiny chips are actually made? Learn about the steps in. Chip Making Definition.

From scitechdaily.com

MIT Engineers Revolutionize Semiconductor Chip Technology With Atom Chip Making Definition But have you ever wondered how these tiny chips are actually made? Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. Deposition, photoresist, lithography, etch, ionization. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex. Chip Making Definition.

From www.sputtertargets.net

How Is The Chip Made? Sputtering Targets Manufacturers Chip Making Definition In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Microchips are made by building up layers of interconnected patterns on a silicon wafer. To. Chip Making Definition.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Chip Making Definition To make any chip, numerous processes play a role. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In this article, we will explore the semiconductor manufacturing process, including the steps. Let’s discuss six critical semiconductor manufacturing steps: In modern manufacturing there. Chip Making Definition.

From www.reuters.com

What is a chip making tool? Reuters Chip Making Definition To make any chip, numerous processes play a role. Deposition, photoresist, lithography, etch, ionization. Microchips are made by building up layers of interconnected patterns on a silicon wafer. In this article, we will explore the semiconductor manufacturing process, including the steps. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. In modern. Chip Making Definition.

From www.vecteezy.com

Potato chips suspended in midair, yellow background, depicting the Chip Making Definition A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. Microchips are made by building up layers of interconnected patterns on a silicon wafer. In this. Chip Making Definition.

From taizyfoodmachines.com

What Is The Potato Chips Production Process? Chip Making Definition Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. Microchips are made by building up layers of interconnected patterns on a silicon. Chip Making Definition.

From www.youtube.com

Amazing! Fully automatic potato chips making machine in big food Chip Making Definition In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Microchips are made by building up layers of interconnected patterns on a silicon wafer. In. Chip Making Definition.

From www.indiamart.com

Fully Automatic Chips Making Plant at Rs 600000/piece Crisp Making Chip Making Definition Microchips are made by building up layers of interconnected patterns on a silicon wafer. But have you ever wondered how these tiny chips are actually made? To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or.. Chip Making Definition.

From www.researchgate.net

LED chip process method. Download Scientific Diagram Chip Making Definition But have you ever wondered how these tiny chips are actually made? Let’s discuss six critical semiconductor manufacturing steps: A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. To make any chip, numerous processes play a role. In modern manufacturing there are. Chip Making Definition.

From www.slideserve.com

PPT Chip Manufacturing Process PowerPoint Presentation, free download Chip Making Definition In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. In this article, we will explore the semiconductor manufacturing process, including the steps. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Learn about. Chip Making Definition.

From www.toshiba-clip.com

Toshiba Clip How to make semiconductors, the brains of everything Chip Making Definition To make any chip, numerous processes play a role. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. In this article, we will explore. Chip Making Definition.

From www.potatochipprocessing.com

How about the potato chips manufacturing process? Chip Making Definition But have you ever wondered how these tiny chips are actually made? In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. Deposition, photoresist, lithography, etch, ionization. To make any chip, numerous processes play a role. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of. Chip Making Definition.

From www.oxfordlearnersdictionaries.com

chip noun Definition, pictures, pronunciation and usage notes Chip Making Definition In this article, we will explore the semiconductor manufacturing process, including the steps. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. Microchips are made by building up layers of interconnected patterns on a silicon wafer. To make any chip, numerous processes. Chip Making Definition.

From animalia-life.club

Semiconductor Chip Chip Making Definition To make any chip, numerous processes play a role. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. Microchips are made by building up layers of interconnected patterns on a silicon wafer. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. A common. Chip Making Definition.

From china-shuliymachine.en.made-in-china.com

Fully Automatic 500kg/H Potato Chips Making Machine Potato Chips Chip Making Definition A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In this article, we will explore the semiconductor manufacturing process, including the steps. But have you ever wondered how these tiny chips are actually made? Let’s discuss six critical semiconductor manufacturing steps: Microchips. Chip Making Definition.

From www.siasat.com

Chips for chipmaking machines affected, say TSMC, Intel Chip Making Definition A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. But have you ever wondered how these tiny chips are actually made? Learn about the. Chip Making Definition.

From laser-tec.org

How A Chip Is Born Poster LASERTEC Chip Making Definition Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. To make any chip, numerous processes play a role. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization. In this article, we will explore the semiconductor manufacturing process, including the steps. But have you ever wondered how these tiny chips. Chip Making Definition.

From english.vov.vn

The opportunity for a chipmaking industry in Vietnam Chip Making Definition A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects that make up its complex circuitry. In modern manufacturing there are few components more crucial than semiconductors, also sometimes referred to as microchips or. Deposition, photoresist, lithography, etch, ionization. To make any chip, numerous processes play a role. Let’s. Chip Making Definition.

From www.vecteezy.com

Potato chips suspended in midair, yellow background, depicting the Chip Making Definition In this article, we will explore the semiconductor manufacturing process, including the steps. Let’s discuss six critical semiconductor manufacturing steps: But have you ever wondered how these tiny chips are actually made? Microchips are made by building up layers of interconnected patterns on a silicon wafer. Deposition, photoresist, lithography, etch, ionization. Learn about the steps in the chip fabrication process. Chip Making Definition.

From www.youtube.com

fully automatic chips making machine YouTube Chip Making Definition To make any chip, numerous processes play a role. In this article, we will explore the semiconductor manufacturing process, including the steps. Learn about the steps in the chip fabrication process and what it’s like working in a cleanroom. A common chip is only about 1 millimeter thick and contains roughly 30 different layers of components and wires called interconnects. Chip Making Definition.