What Surface To Weld On . Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. It can provide resistance to abrasion, erosion, or impact. This type of weld is used to deposit weld material. This is a complete guide to the different types of welds and joints found in engineering. In this guide you’ll learn: Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. As might be concluded from the name, a surface weld isn’t a join as such.

from eziil.com

In this guide you’ll learn: This is a complete guide to the different types of welds and joints found in engineering. As might be concluded from the name, a surface weld isn’t a join as such. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. It can provide resistance to abrasion, erosion, or impact. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This type of weld is used to deposit weld material. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass.

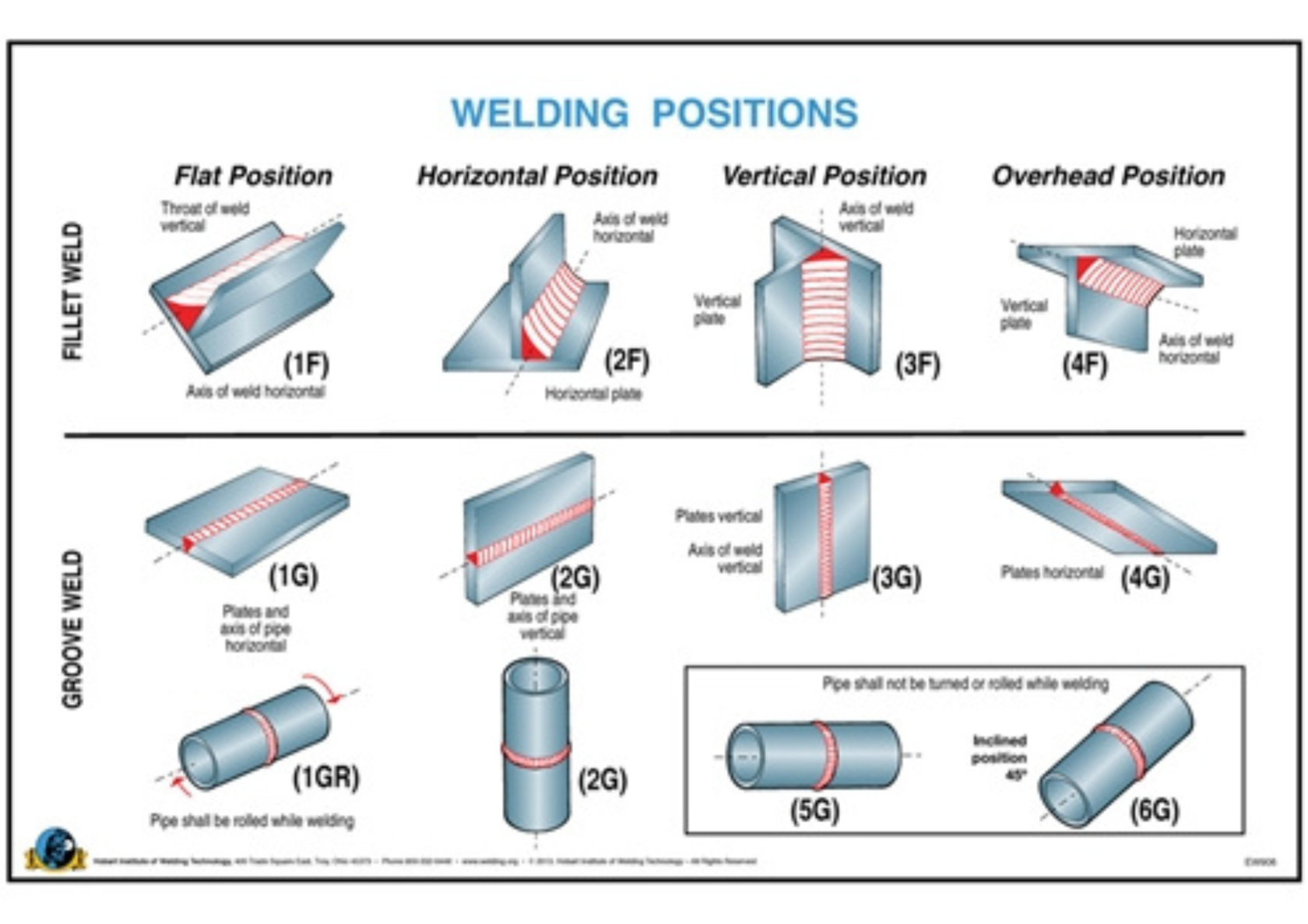

5 Types of Welding Positions 1g, 2f, 3g, 4g...

What Surface To Weld On Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. In this guide you’ll learn: This is a complete guide to the different types of welds and joints found in engineering. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. This type of weld is used to deposit weld material. It can provide resistance to abrasion, erosion, or impact. As might be concluded from the name, a surface weld isn’t a join as such.

From www.dreamstime.com

Welding Robot with Welding Torch in Motion, Creating a Weld on Metal What Surface To Weld On As might be concluded from the name, a surface weld isn’t a join as such. This type of weld is used to deposit weld material. In this guide you’ll learn: This is a complete guide to the different types of welds and joints found in engineering. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing.. What Surface To Weld On.

From www.hardfacingfty.com

Surfacing Welding WALDUN What Surface To Weld On As might be concluded from the name, a surface weld isn’t a join as such. This is a complete guide to the different types of welds and joints found in engineering. In this guide you’ll learn: Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. It. What Surface To Weld On.

From www.researchgate.net

Comparison of weld surface and crosssection formation for different What Surface To Weld On In this guide you’ll learn: This is a complete guide to the different types of welds and joints found in engineering. It can provide resistance to abrasion, erosion, or impact. As might be concluded from the name, a surface weld isn’t a join as such. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper. What Surface To Weld On.

From welditu.com

Main Types of Welds Used in Welding WelditU What Surface To Weld On It can provide resistance to abrasion, erosion, or impact. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. As might be concluded from the name, a surface weld isn’t a join as such. This type of weld is used to deposit weld material. Removing any mill scale, chemicals, contaminants, and coatings. What Surface To Weld On.

From www.mdpi.com

Applied Sciences Free FullText Material Flow Behavior on Weld Pool What Surface To Weld On This type of weld is used to deposit weld material. It can provide resistance to abrasion, erosion, or impact. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. In this guide you’ll learn: As might be concluded from the name, a surface weld isn’t a join as such. Once the material is cut and beveled,. What Surface To Weld On.

From www.youtube.com

Weld removal on a flat steel surface YouTube What Surface To Weld On Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. This type of weld is used to deposit weld material. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This is a complete guide to the different types of welds and joints. What Surface To Weld On.

From weldguru.com

Parts of A Weld Weld Components with Diagram Weld Guru What Surface To Weld On This is a complete guide to the different types of welds and joints found in engineering. In this guide you’ll learn: Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity,. What Surface To Weld On.

From www.reddit.com

Surface weld pad ( 6010 whip on 1/4) for welding course. 2 weeks into What Surface To Weld On Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This is a complete guide to the different types of welds and joints found in engineering. In this guide you’ll learn: This type of weld is used to deposit weld material. It can provide resistance to abrasion, erosion, or impact. Removing any mill scale, chemicals, contaminants,. What Surface To Weld On.

From ktagage.com

NACE Surface Finish Weld Replica For Examining Welds What Surface To Weld On In this guide you’ll learn: Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This is a complete guide to the different types of welds and joints found in engineering. As might be concluded from the name, a surface weld isn’t a join as such. Removing any mill scale, chemicals, contaminants, and coatings from the. What Surface To Weld On.

From www.researchgate.net

Irregular weld surface Download Scientific Diagram What Surface To Weld On Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This type of weld is used to deposit weld material. As might be concluded from the name, a surface weld isn’t a join as such. This is a complete guide to the different types of welds and joints found in engineering. In this guide you’ll learn:. What Surface To Weld On.

From www.researchgate.net

weld surface finishing Download Table What Surface To Weld On As might be concluded from the name, a surface weld isn’t a join as such. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. This is a complete guide to the different types of welds and joints found in engineering. Other types of welds include flange welds, plug welds, slot welds,. What Surface To Weld On.

From www.pinterest.com

Student SMAW E6010 Surface Weld on a 5"x7" plate. Welding, Plates, Weld What Surface To Weld On Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. It can provide resistance to abrasion, erosion, or impact. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. In this guide you’ll learn: This type of weld is. What Surface To Weld On.

From www.hera.org.nz

Notice Surface imperfections on welds made with flux cored arc What Surface To Weld On This is a complete guide to the different types of welds and joints found in engineering. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. It can provide resistance to abrasion, erosion,. What Surface To Weld On.

From www.hardfacingfty.com

Surfacing Welding WALDUN What Surface To Weld On It can provide resistance to abrasion, erosion, or impact. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. This is a complete guide to the different types of. What Surface To Weld On.

From www.sonomavalleyhighschoolart.com

Types of Welds & Joints SVHS ART & CAREER TECH What Surface To Weld On As might be concluded from the name, a surface weld isn’t a join as such. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. This type of weld is used to deposit weld material. It can provide resistance to abrasion, erosion, or impact. In this guide you’ll learn: This is a. What Surface To Weld On.

From www.youtube.com

Babbitt Surface Welding YouTube What Surface To Weld On This is a complete guide to the different types of welds and joints found in engineering. This type of weld is used to deposit weld material. It can provide resistance to abrasion, erosion, or impact. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Other types of welds include flange welds,. What Surface To Weld On.

From www.thefabricator.com

5 steps for proper weld preparation What Surface To Weld On This type of weld is used to deposit weld material. As might be concluded from the name, a surface weld isn’t a join as such. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. It can provide resistance to abrasion, erosion, or impact. This is a. What Surface To Weld On.

From www.machinemfg.com

The Ultimate Guide to Surfacing Welding Techniques MachineMFG What Surface To Weld On Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. As might be concluded from the name, a surface weld isn’t a join as such. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps. What Surface To Weld On.

From weldingmastermind.com

How to Weld Aluminum The Ultimate Guide Welding Mastermind What Surface To Weld On This type of weld is used to deposit weld material. In this guide you’ll learn: Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This is a complete guide to the different. What Surface To Weld On.

From www.youtube.com

Fidur Technology Strip Surface Welding I Kjellberg YouTube What Surface To Weld On This type of weld is used to deposit weld material. As might be concluded from the name, a surface weld isn’t a join as such. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This is a complete guide to the different types of welds and joints found in engineering. It can provide resistance to. What Surface To Weld On.

From savree.com

Flange Welds and NDT Explained saVRee What Surface To Weld On In this guide you’ll learn: This is a complete guide to the different types of welds and joints found in engineering. This type of weld is used to deposit weld material. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. Once the material is cut and beveled, it’s time to prepare the surface for the. What Surface To Weld On.

From weldguru.com

Porosity in Welding What is it? And How to Prevent It What Surface To Weld On Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. It can provide resistance to abrasion, erosion, or impact. This is a complete guide to the different types of welds and joints found in engineering. Once the material is cut and beveled, it’s time to prepare the. What Surface To Weld On.

From mewelding.com

Types of Welds What Surface To Weld On As might be concluded from the name, a surface weld isn’t a join as such. It can provide resistance to abrasion, erosion, or impact. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. This type of weld. What Surface To Weld On.

From www.youtube.com

Welding A Shaft Keyway and Carbide Precipitation YouTube What Surface To Weld On This type of weld is used to deposit weld material. This is a complete guide to the different types of welds and joints found in engineering. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld. What Surface To Weld On.

From eziil.com

5 Types of Welding Positions 1g, 2f, 3g, 4g... What Surface To Weld On Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. As might be concluded from the name, a surface weld isn’t a join as such. In this guide you’ll learn: This is a complete guide to the different. What Surface To Weld On.

From flow3d.co.kr

Fig. 3. Weld morphologies of crosssection and upper surface for the What Surface To Weld On Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. This is a complete guide to the different types of welds and joints found in engineering. This type of weld is used to deposit weld material. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld. What Surface To Weld On.

From www.researchgate.net

The weld surface of the different conditions, i.e. experiment number What Surface To Weld On Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. This type of weld is. What Surface To Weld On.

From www.slideserve.com

PPT Welding Representation PowerPoint Presentation, free download What Surface To Weld On Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. It can provide resistance to abrasion, erosion, or impact. This type of weld is used to deposit weld material. Removing any mill scale, chemicals, contaminants, and coatings from. What Surface To Weld On.

From weldingpros.net

Hardfacing Welding Overview Hard Surface Welding Surfacing What Surface To Weld On As might be concluded from the name, a surface weld isn’t a join as such. Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This type of weld is used to deposit weld material. In this guide. What Surface To Weld On.

From www.researchgate.net

WELD SURFACE FINISHING Download Table What Surface To Weld On Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. It can provide resistance to abrasion, erosion, or impact. In this guide you’ll learn: Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. This type of weld is used to deposit weld. What Surface To Weld On.

From www.youtube.com

Fidur Surface Welding I Kjellberg YouTube What Surface To Weld On Other types of welds include flange welds, plug welds, slot welds, seam welds, surfacing. In this guide you’ll learn: It can provide resistance to abrasion, erosion, or impact. As might be concluded from the name, a surface weld isn’t a join as such. This type of weld is used to deposit weld material. Removing any mill scale, chemicals, contaminants, and. What Surface To Weld On.

From weldingofwelders.com

What Causes Pinholes in Welding? Welding of Welders What Surface To Weld On It can provide resistance to abrasion, erosion, or impact. In this guide you’ll learn: This is a complete guide to the different types of welds and joints found in engineering. As might be concluded from the name, a surface weld isn’t a join as such. This type of weld is used to deposit weld material. Other types of welds include. What Surface To Weld On.

From www.slideserve.com

PPT Welding Symbols PowerPoint Presentation, free download ID2242556 What Surface To Weld On Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. It can provide resistance to abrasion, erosion, or impact. This is a complete guide to the different types of welds and joints found in engineering. As might be concluded from the name, a surface weld isn’t a join as such. Other types. What Surface To Weld On.

From www.slideserve.com

PPT Fusion Welding PowerPoint Presentation, free download ID5733048 What Surface To Weld On Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. This type of weld is used to deposit weld material. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions. As might be concluded from the name, a surface. What Surface To Weld On.

From welditu.com

Guide to Welding Joint Types and Parts WelditU What Surface To Weld On As might be concluded from the name, a surface weld isn’t a join as such. This is a complete guide to the different types of welds and joints found in engineering. It can provide resistance to abrasion, erosion, or impact. This type of weld is used to deposit weld material. Other types of welds include flange welds, plug welds, slot. What Surface To Weld On.