Knurling Tool Plans . Have mercy on your lathe! In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. I’m building this mechanical project from the. There's a lot of pressure on them and if any swarf gets in there, it will grind soft. Welcome back to my manual machine shop for the finale of the knurling tool build. See the details of each part and the final assembly of the tool. Rather than engineer this one. All parts (except knurling wheels and screws). We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Knurl pins need to be very hard and a super close fit. This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans.

from www.cartertools.com

See the details of each part and the final assembly of the tool. Welcome back to my manual machine shop for the finale of the knurling tool build. Knurl pins need to be very hard and a super close fit. I’m building this mechanical project from the. There's a lot of pressure on them and if any swarf gets in there, it will grind soft. Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Rather than engineer this one. This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans. Have mercy on your lathe! In this video series i’ll be making a much improved knurling tool from my current bump knurler setup.

Make a Knurling Tool for the Taig

Knurling Tool Plans See the details of each part and the final assembly of the tool. I’m building this mechanical project from the. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Welcome back to my manual machine shop for the finale of the knurling tool build. Rather than engineer this one. This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans. All parts (except knurling wheels and screws). Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. There's a lot of pressure on them and if any swarf gets in there, it will grind soft. Knurl pins need to be very hard and a super close fit. See the details of each part and the final assembly of the tool. Have mercy on your lathe!

From www.cartertools.com

Make a Knurling Tool for the Taig Knurling Tool Plans There's a lot of pressure on them and if any swarf gets in there, it will grind soft. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. Welcome back to my manual machine shop for the finale of the knurling tool build. This is a picture of my completed “sensitive knurling. Knurling Tool Plans.

From www.pinterest.com

Knurling tool E.Riley stile Machining Metal Projects, Metal Lathe Projects, Lathe Tools, Metal Knurling Tool Plans I’m building this mechanical project from the. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. Welcome back to my manual machine shop for the finale of the knurling tool build. See the details of each part and the final assembly of the tool. This is a picture of my completed. Knurling Tool Plans.

From www.practicalmachinist.com

cut knurling tool plans? Knurling Tool Plans See the details of each part and the final assembly of the tool. Rather than engineer this one. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. I’m building this mechanical project from the. There's a lot of pressure on them and if any swarf gets in there, it will grind. Knurling Tool Plans.

From at-machining.com

Knurling Tools and Techniques A Comprehensive Guide ATMachining Knurling Tool Plans Knurl pins need to be very hard and a super close fit. All parts (except knurling wheels and screws). Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Have mercy on your lathe! There's a lot of pressure on them and if any swarf gets in there, it will grind soft. Rather. Knurling Tool Plans.

From www.youtube.com

Machining A Cut Knurl Tool & It's Theory YouTube Knurling Tool Plans In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. I’m building this mechanical project from the. Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Knurl pins need to be very hard and a super close fit. Have mercy on your lathe! This. Knurling Tool Plans.

From www.gadgetbuilder.com

Cut Knurler Knurling Tool Plans I’m building this mechanical project from the. Rather than engineer this one. This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans. Welcome back to my manual machine shop for the finale of the knurling tool build. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup.. Knurling Tool Plans.

From www.hemingwaykits.com

Sensitive Knurling Tool Knurling Tool Plans All parts (except knurling wheels and screws). Rather than engineer this one. I’m building this mechanical project from the. This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. See the details of each part and the. Knurling Tool Plans.

From d-gray-drafting-and-design.myshopify.com

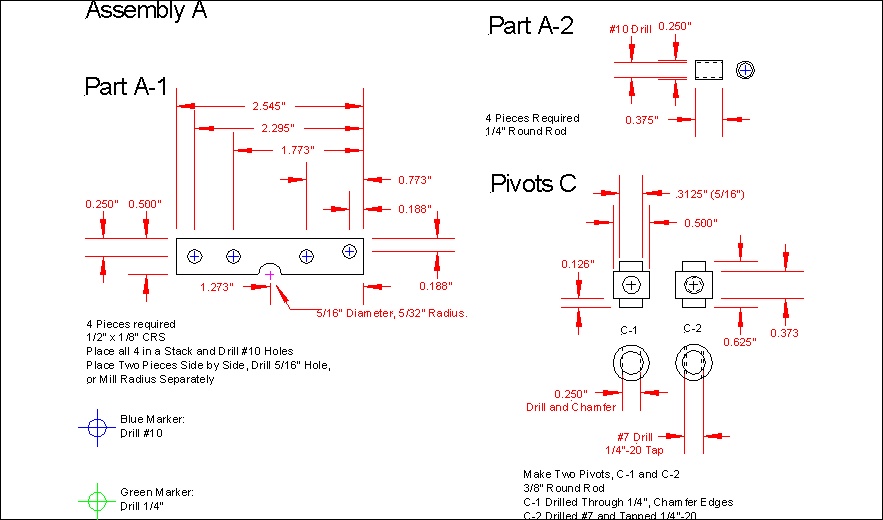

Heavy Duty Knurling Tool Drawings Only D. Gray Drafting and Design Knurling Tool Plans See the details of each part and the final assembly of the tool. Rather than engineer this one. Knurl pins need to be very hard and a super close fit. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this article, we will guide you through the. Knurling Tool Plans.

From www.youtube.com

How to knurl with a pinch type knurling tool, the basic theory, part 2 YouTube Knurling Tool Plans Welcome back to my manual machine shop for the finale of the knurling tool build. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern. Knurling Tool Plans.

From www.cartertools.com

Make a Knurling Tool for the Taig Knurling Tool Plans All parts (except knurling wheels and screws). There's a lot of pressure on them and if any swarf gets in there, it will grind soft. Knurl pins need to be very hard and a super close fit. Welcome back to my manual machine shop for the finale of the knurling tool build. Rather than engineer this one. Have mercy on. Knurling Tool Plans.

From www.practicalmachinist.com

Questions about cut knurling tool Knurling Tool Plans I’m building this mechanical project from the. Knurl pins need to be very hard and a super close fit. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. See the details of each part and the final assembly of the tool. Rather than. Knurling Tool Plans.

From www.youtube.com

Making a shop built knurling tool Part 3 YouTube Knurling Tool Plans In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as. Knurling Tool Plans.

From jeremyyoungdesign.com

Hemmingway Sensitive Knurling Tool Jeremy Young Design Knurling Tool Plans I’m building this mechanical project from the. Rather than engineer this one. Have mercy on your lathe! Knurl pins need to be very hard and a super close fit. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. There's a lot of pressure on them and if any swarf gets in. Knurling Tool Plans.

From www.homemodelenginemachinist.com

shop built knurling tool Home Model Engine Machinist Forum Knurling Tool Plans Welcome back to my manual machine shop for the finale of the knurling tool build. Rather than engineer this one. All parts (except knurling wheels and screws). I’m building this mechanical project from the. There's a lot of pressure on them and if any swarf gets in there, it will grind soft. See the details of each part and the. Knurling Tool Plans.

From www.hemingwaykits.com

Basic Knurling Tool Knurling Tool Plans There's a lot of pressure on them and if any swarf gets in there, it will grind soft. Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Rather than engineer this one. I’m building this mechanical project from the. Have mercy on your lathe! See the details of each part and the. Knurling Tool Plans.

From www.pinterest.com

Free Metalworking Project Plans A Knurling Tool Metal working projects, Metal working Knurling Tool Plans There's a lot of pressure on them and if any swarf gets in there, it will grind soft. All parts (except knurling wheels and screws). I’m building this mechanical project from the. Welcome back to my manual machine shop for the finale of the knurling tool build. See the details of each part and the final assembly of the tool.. Knurling Tool Plans.

From theminimachineshop.com

Plans Knurling Tool Plans All parts (except knurling wheels and screws). Welcome back to my manual machine shop for the finale of the knurling tool build. I’m building this mechanical project from the. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. Have mercy on your lathe! We've explored the basic principles of knurling, detailing. Knurling Tool Plans.

From www.pinterest.com

Knurling Tool by ddickey I bought the plans and got the knurler done yesterday. It was a Knurling Tool Plans Welcome back to my manual machine shop for the finale of the knurling tool build. I’m building this mechanical project from the. Have mercy on your lathe! We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this video series i’ll be making a much improved knurling tool. Knurling Tool Plans.

From thebloughs.net

Cut Knurling Tool Final Assembly Tom's Maker Site Knurling Tool Plans I’m building this mechanical project from the. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. Welcome back to my manual machine shop for the finale of the knurling tool build. There's a lot of pressure on them and if any swarf gets. Knurling Tool Plans.

From www.pinterest.com.mx

KNURLING TOOL MY WAY Machinist tools, Tools, Metal working Knurling Tool Plans I’m building this mechanical project from the. See the details of each part and the final assembly of the tool. Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Have mercy on your lathe! In this video series i’ll be making a much improved knurling tool from my current bump knurler setup.. Knurling Tool Plans.

From platinumtooling.com

QUICK KNURLING TOOLS FROM HOMMEL + KELLER Platinum Tooling Knurling Tool Plans Knurl pins need to be very hard and a super close fit. Welcome back to my manual machine shop for the finale of the knurling tool build. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this video series i’ll be making a much improved knurling tool. Knurling Tool Plans.

From at-machining.com

Knurling Tools and Techniques A Comprehensive Guide ATMachining Knurling Tool Plans Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Have mercy on your lathe! Knurl pins need to be very hard and a super close fit. There's a lot of pressure on them and if any swarf gets in there, it will grind soft. See the details of each part and the. Knurling Tool Plans.

From www.practicalmachinist.com

Questions about cut knurling tool Knurling Tool Plans This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans. Have mercy on your lathe! In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. I’m building this mechanical project from the. Knurl pins need to be very hard and a super close fit. Rather than engineer. Knurling Tool Plans.

From d-gray-drafting-and-design.myshopify.com

Heavy Duty Knurling Tool Drawings Only D. Gray Drafting and Design Knurling Tool Plans Knurl pins need to be very hard and a super close fit. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. Conventional, fixed axle tools set up almost unbearable strains. Knurling Tool Plans.

From www.homemadetools.net

Knurling Tool Knurling Tool Plans I’m building this mechanical project from the. See the details of each part and the final assembly of the tool. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans. There's a lot of. Knurling Tool Plans.

From www.youtube.com

DIY Knurling Tool YouTube Knurling Tool Plans All parts (except knurling wheels and screws). See the details of each part and the final assembly of the tool. Welcome back to my manual machine shop for the finale of the knurling tool build. Rather than engineer this one. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and. Knurling Tool Plans.

From www.youtube.com

MT19 Part 1 Making a Hemingway Kits Knurling Tool for my Sieg mini lathe. By Andrew Whale Knurling Tool Plans See the details of each part and the final assembly of the tool. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth.. Knurling Tool Plans.

From thebloughs.net

Cut Knurling Tool Final Assembly Tom's Maker Site Knurling Tool Plans I’m building this mechanical project from the. See the details of each part and the final assembly of the tool. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. Rather than engineer this one. Conventional, fixed axle tools set up almost unbearable strains. Knurling Tool Plans.

From thebloughs.net

Cut Knurling Tool Final Assembly Tom's Maker Site Knurling Tool Plans Knurl pins need to be very hard and a super close fit. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. There's a lot of pressure on them and if any swarf gets in there, it will grind soft. Have mercy on your lathe! This is a picture of my completed. Knurling Tool Plans.

From jeremyyoungdesign.com

Hemmingway Sensitive Knurling Tool Jeremy Young Design Knurling Tool Plans I’m building this mechanical project from the. Rather than engineer this one. Welcome back to my manual machine shop for the finale of the knurling tool build. There's a lot of pressure on them and if any swarf gets in there, it will grind soft. See the details of each part and the final assembly of the tool. Have mercy. Knurling Tool Plans.

From www.youtube.com

How to build a big knurling tool !!! YouTube Knurling Tool Plans I’m building this mechanical project from the. See the details of each part and the final assembly of the tool. We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. In. Knurling Tool Plans.

From www.pinterest.com

Material Steel Units (mm) Below you’ll find plans for a scissortype Knurling Tool from Ken Knurling Tool Plans In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. All parts (except knurling wheels and screws). This is a picture of my completed “sensitive knurling tool” built from the hemmingway kit/plans. Rather than engineer this one. See the details of each part and. Knurling Tool Plans.

From www.cartertools.com

Make a Knurling Tool for the Taig Knurling Tool Plans See the details of each part and the final assembly of the tool. In this article, we will guide you through the process of setting up the lathe and knurling tool to achieve the desired knurling pattern and depth. I’m building this mechanical project from the. All parts (except knurling wheels and screws). Welcome back to my manual machine shop. Knurling Tool Plans.

From www.youtube.com

Tom's Techniques knurling tool in action YouTube Knurling Tool Plans See the details of each part and the final assembly of the tool. In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. Conventional, fixed axle tools set up almost unbearable strains on the spindle bearings of a light lathe. Rather than engineer this one. All parts (except knurling wheels and screws).. Knurling Tool Plans.

From www.homemadetools.net

Straight Knurling Tool Knurling Tool Plans In this video series i’ll be making a much improved knurling tool from my current bump knurler setup. All parts (except knurling wheels and screws). We've explored the basic principles of knurling, detailing the knurling operation and the equipment used, such as knurling wheels and inserts. Rather than engineer this one. This is a picture of my completed “sensitive knurling. Knurling Tool Plans.