How To Use A Forming Tap . Roll taps, also known as form taps, hold distinct advantages over cut taps. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Roll tap advantages are inherent in the way they create the threads. 4.5k views 2 years ago. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. In today's video, our experts peter and paul go into detail about. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate.

from www.promaxxtool.com

In today's video, our experts peter and paul go into detail about. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. Roll taps, also known as form taps, hold distinct advantages over cut taps. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. 4.5k views 2 years ago. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Roll tap advantages are inherent in the way they create the threads.

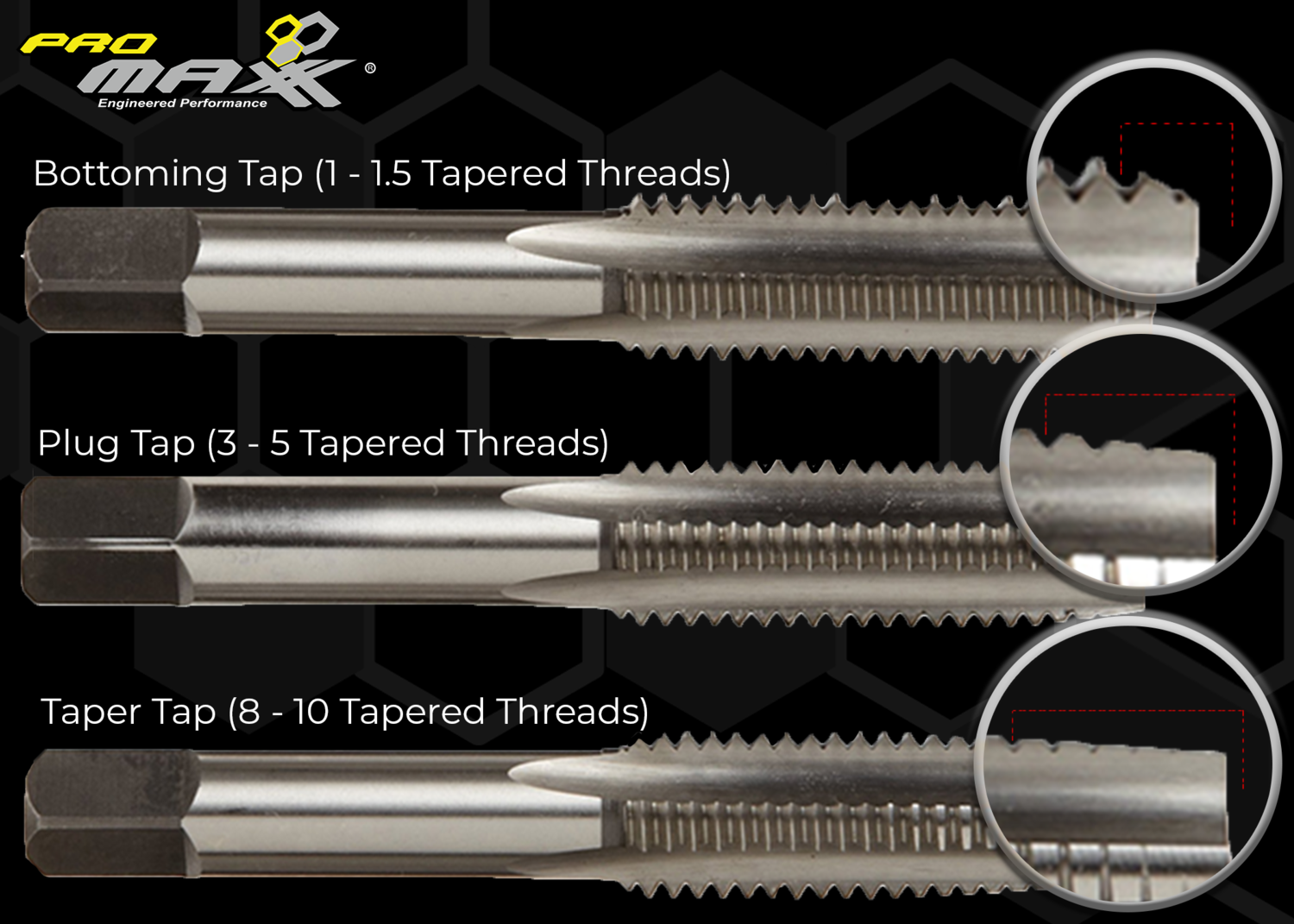

Different Types of Taps and When to Use Them ProMAXX Tool

How To Use A Forming Tap Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. In today's video, our experts peter and paul go into detail about. Roll tap advantages are inherent in the way they create the threads. 4.5k views 2 years ago. Roll taps, also known as form taps, hold distinct advantages over cut taps.

From www.jarviscuttingtools.com

Forming Taps Jarvis Cutting Tools How To Use A Forming Tap Roll taps, also known as form taps, hold distinct advantages over cut taps. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and. How To Use A Forming Tap.

From www.triumphtool.com

The Benefits of Form Tapping TriumphTool How To Use A Forming Tap Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Because of this, form taps do not contain any flutes, as there. How To Use A Forming Tap.

From www.jarviscuttingtools.com

Jarflo Taps Jarvis Cutting Tools How To Use A Forming Tap Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. 4.5k views 2 years ago. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Unlike most cnc cutting tools, thread forming. How To Use A Forming Tap.

From www.promaxxtool.com

Different Types of Taps and When to Use Them ProMAXX Tool How To Use A Forming Tap Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. Roll tap advantages are inherent in the way they create the threads.. How To Use A Forming Tap.

From www.youtube.com

ROLL FORM TAP YouTube How To Use A Forming Tap Roll tap advantages are inherent in the way they create the threads. Roll taps, also known as form taps, hold distinct advantages over cut taps. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Unlike most cnc cutting tools, thread forming taps, otherwise known as. How To Use A Forming Tap.

From www.universalnetworkcable.com

Thread Forming Tap Chart Universal Network How To Use A Forming Tap Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Roll tap advantages are inherent in the way they create the threads. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using. How To Use A Forming Tap.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa How To Use A Forming Tap Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. In today's video, our experts peter and paul. How To Use A Forming Tap.

From www.slideserve.com

PPT Tapping & Threading PowerPoint Presentation, free download ID How To Use A Forming Tap Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Because of this, form taps do not contain any flutes, as there. How To Use A Forming Tap.

From tamachinery.com

Threadmaster Taps Forming TA MACHINERY How To Use A Forming Tap Roll taps, also known as form taps, hold distinct advantages over cut taps. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. 4.5k views 2 years ago. Roll tap advantages are inherent in the way they create the threads. Unlike most cnc cutting tools, thread. How To Use A Forming Tap.

From www.gdandtbasics.com

How to Use the Drill Tap Wall Chart GD&T Basics How To Use A Forming Tap Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Roll tap advantages are inherent in the way. How To Use A Forming Tap.

From epictool.ca

8 Things To Know About Thread Forming Taps Epic Tool How To Use A Forming Tap Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Form taps do require different feeds and speeds and. How To Use A Forming Tap.

From grossuperior.weebly.com

Grossuperior Blog How To Use A Forming Tap Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. In today's video, our experts peter and paul go into detail about. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one.. How To Use A Forming Tap.

From www.aerospacemanufacturinganddesign.com

Manufacturing 101 Forming taps vs. cutting taps Aerospace How To Use A Forming Tap Roll tap advantages are inherent in the way they create the threads. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. 4.5k views 2 years ago. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware. How To Use A Forming Tap.

From www.harveyperformance.com

8 Unique Facts About Thread Forming Taps In The Loupe How To Use A Forming Tap In today's video, our experts peter and paul go into detail about. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using. How To Use A Forming Tap.

From fyoagrkfx.blob.core.windows.net

Difference Between Cutting And Forming Tap at Raymond Overton blog How To Use A Forming Tap In today's video, our experts peter and paul go into detail about. 4.5k views 2 years ago. Roll taps, also known as form taps, hold distinct advantages over cut taps. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Roll tap advantages are inherent. How To Use A Forming Tap.

From www.emuge-franken.se

ColdForming Taps EMUGEFRANKEN AB How To Use A Forming Tap Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Roll taps, also known as form taps, hold distinct advantages over cut taps. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using. How To Use A Forming Tap.

From china-plastic-injection-molding.com

Form Tap Drill Chart China Plastic Injection Molding How To Use A Forming Tap Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Because of this, form taps do not contain any. How To Use A Forming Tap.

From www.wikihow.com

How to Use a Tap 13 Steps (with Pictures) wikiHow How To Use A Forming Tap In today's video, our experts peter and paul go into detail about. 4.5k views 2 years ago. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Roll taps, also known as form taps, hold distinct advantages over cut taps. Roll tap advantages are inherent. How To Use A Forming Tap.

From exploreflex.weebly.com

What is a forming tap exploreFlex How To Use A Forming Tap 4.5k views 2 years ago. Roll taps, also known as form taps, hold distinct advantages over cut taps. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Form taps do require different feeds and speeds and they require a different starting hole size, so be. How To Use A Forming Tap.

From www.ctemag.com

Seven ways to avoid breaking taps Cutting Tool Engineering How To Use A Forming Tap Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Roll tap advantages are inherent in the way they create the threads. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away.. How To Use A Forming Tap.

From www.manufacturingguide.com

Form Tapping Find suppliers, processes & material How To Use A Forming Tap Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. 4.5k views 2 years ago. Roll taps, also known. How To Use A Forming Tap.

From www.harveyperformance.com

8 Unique Facts About Thread Forming Taps In The Loupe How To Use A Forming Tap Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Roll tap advantages are inherent in the way they create the threads. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless.. How To Use A Forming Tap.

From statezik.weebly.com

What is the difference between cutting tap and forming tap statezik How To Use A Forming Tap Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. Because of this, form taps do not contain any flutes, as there. How To Use A Forming Tap.

From proleantech.com

Thread Tap Cutting Tools A Complete Guide How To Use A Forming Tap Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some stainless. Roll taps, also known as form taps, hold distinct advantages over cut taps. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece. How To Use A Forming Tap.

From www.jarviscuttingtools.com

Cutting Taps vs. Forming Taps Difference Jarvis How To Use A Forming Tap Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. In today's video, our experts peter and paul go into detail about. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather. How To Use A Forming Tap.

From www.harveyperformance.com

8 Unique Facts About Thread Forming Taps In The Loupe How To Use A Forming Tap In today's video, our experts peter and paul go into detail about. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to. How To Use A Forming Tap.

From www.youtube.com

How a tap works YouTube How To Use A Forming Tap Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Roll taps, also known as form taps, hold distinct advantages over cut taps. In today's video, our experts peter and paul go into detail about. Because of this, form taps do not contain. How To Use A Forming Tap.

From hopmind.weebly.com

Forming taps Hopmind How To Use A Forming Tap 4.5k views 2 years ago. Roll taps, also known as form taps, hold distinct advantages over cut taps. Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Form taps, or forming taps, are also called roll taps because they roll material into. How To Use A Forming Tap.

From casalasi.weebly.com

Forming tap drill chart casaLasi How To Use A Forming Tap In today's video, our experts peter and paul go into detail about. Form taps do require different feeds and speeds and they require a different starting hole size, so be aware of that before using one. Roll tap advantages are inherent in the way they create the threads. Form taps are ideal for tapping blind holes, but can be used. How To Use A Forming Tap.

From www.youtube.com

OSG X Performer Forming Taps Series YouTube How To Use A Forming Tap Roll taps, also known as form taps, hold distinct advantages over cut taps. Roll tap advantages are inherent in the way they create the threads. 4.5k views 2 years ago. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Form taps do require different. How To Use A Forming Tap.

From sinoweihe.en.made-in-china.com

Thread Forming Tap Extrusion Taps HSS China Taps and Forming Taps How To Use A Forming Tap Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. Form taps, or forming taps, are also called roll taps because they roll material into the thread form rather than cutting excess material away. Form taps do require different feeds and speeds and. How To Use A Forming Tap.

From www.classiccarrestorationclub.com

Cutting Threads An Introduction to Using a Tap to Thread Bolt Holes How To Use A Forming Tap 4.5k views 2 years ago. Roll tap advantages are inherent in the way they create the threads. Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile. How To Use A Forming Tap.

From www.tradekorea.com

roll form taps tradekorea How To Use A Forming Tap Unlike most cnc cutting tools, thread forming taps, otherwise known as form taps, forming taps, or roll taps, work by molding the workpiece rather than cutting it. 4.5k views 2 years ago. Roll tap advantages are inherent in the way they create the threads. In today's video, our experts peter and paul go into detail about. Form taps, or forming. How To Use A Forming Tap.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types How To Use A Forming Tap Because of this, form taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Roll tap advantages are inherent in the way they create the threads. Form taps are ideal for tapping blind holes, but can be used for any tapping application in ductile material, including steel and some. How To Use A Forming Tap.