Shear Cutting Blade Design . shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The guillotine (also know as the slider unit) and the swing. shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. In blanking, this forms a closed. Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. When designing blades, the following two conditions are mainly considered: two design types are common to power squaring shears:

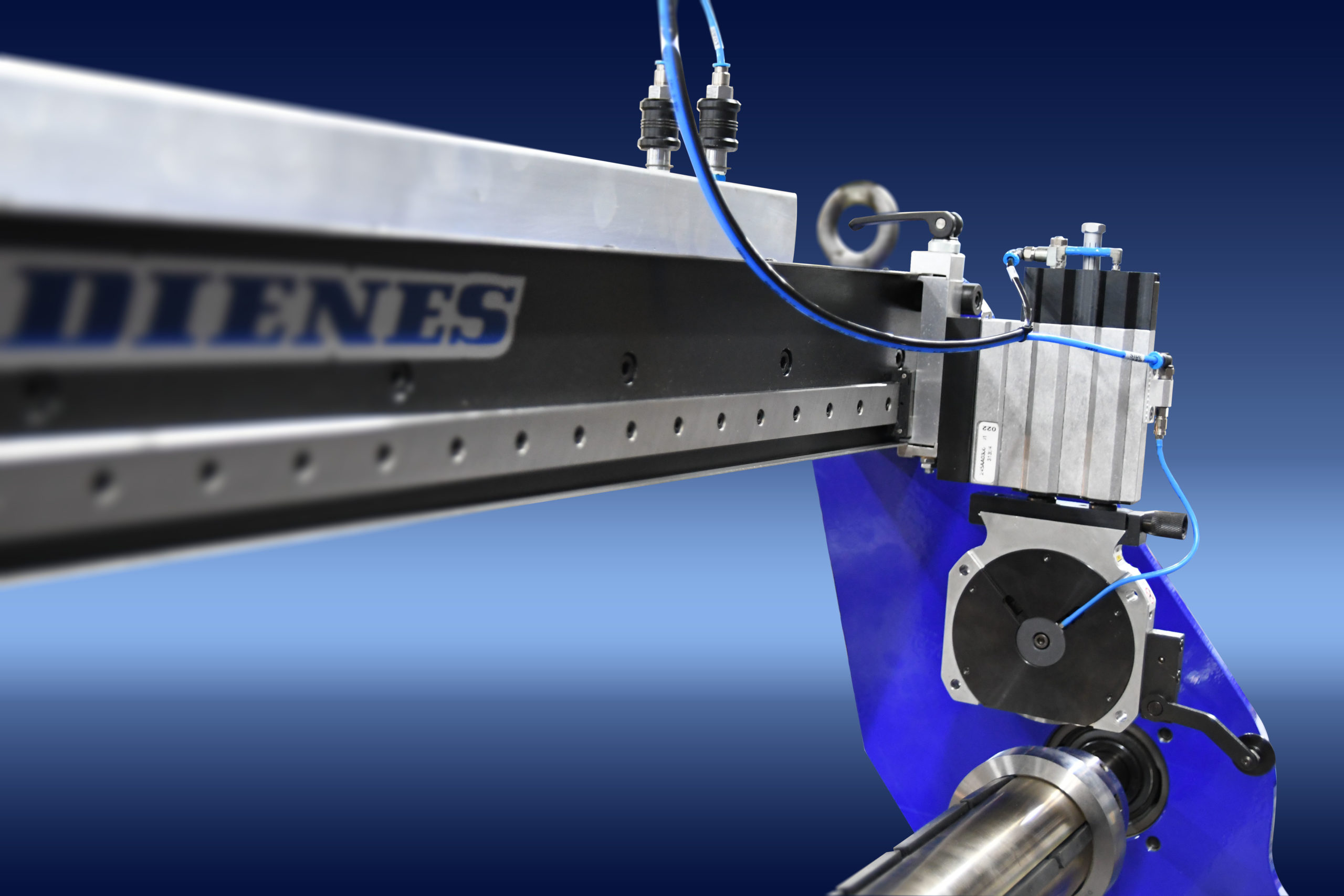

from www.dienesusa.com

When designing blades, the following two conditions are mainly considered: The guillotine (also know as the slider unit) and the swing. shear cutting is a chipless method of separating material along a cutting line (see table 2.1). shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. two design types are common to power squaring shears: Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. In blanking, this forms a closed.

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality

Shear Cutting Blade Design The guillotine (also know as the slider unit) and the swing. shear cutting is a chipless method of separating material along a cutting line (see table 2.1). shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. In blanking, this forms a closed. shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. When designing blades, the following two conditions are mainly considered: shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. The guillotine (also know as the slider unit) and the swing. two design types are common to power squaring shears: Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588.

From www.shiniteknife.com

M2 Steel Plate Shear Cutting Blade Design for Coil Hot Rolling Mill Shear Cutting Blade Design In blanking, this forms a closed. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. two design types are common to power squaring shears: shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned.. Shear Cutting Blade Design.

From www.tfico.com

Shear Blades TFICO Shear Cutting Blade Design shear cutting is a chipless method of separating material along a cutting line (see table 2.1). With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets. Shear Cutting Blade Design.

From federalknife.com

Metal Working Shear Blades Manufacturer Federal Knife Inc. Shear Cutting Blade Design shear cutting is a chipless method of separating material along a cutting line (see table 2.1). shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. two design types are common to power squaring shears: When designing blades, the following two conditions are mainly considered: The. Shear Cutting Blade Design.

From upsilon.group

Shear Cutter Blades Upsilon industries knives and cutters Shear Cutting Blade Design The guillotine (also know as the slider unit) and the swing. shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shear cutting is the separation of workpieces by two blades. Shear Cutting Blade Design.

From www.sparkblades.com

guillotine shear blades for sheet metal cutting SparkBladesMAANSHAN Shear Cutting Blade Design two design types are common to power squaring shears: shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. When designing blades,. Shear Cutting Blade Design.

From federalknife.com

Metal cutting Shear blades for most machines makes and models • Federal Shear Cutting Blade Design shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. shear cutting is a chipless method of separating material along a cutting line (see table. Shear Cutting Blade Design.

From federalknife.com

Metal Working Shear Blades Manufacturer Federal Knife Inc. Shear Cutting Blade Design With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. shear cutting is a chipless method of separating material along a cutting line (see table 2.1). shear cutting (also known as shear slitting) is the type of slitting that uses a combination of. Shear Cutting Blade Design.

From toolnotes.com

Sheet Metal Shearing ToolNotes Shear Cutting Blade Design The guillotine (also know as the slider unit) and the swing. two design types are common to power squaring shears: Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. In blanking, this forms a closed. shear cutting (also known as shear slitting) is the type of slitting that. Shear Cutting Blade Design.

From shiniteblade.com

Shear blades,Metallurgical blade,Press brake tools,Fly shear blades Shear Cutting Blade Design shear cutting is a chipless method of separating material along a cutting line (see table 2.1). With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. The guillotine (also know as the slider unit) and the swing. shearing machine blades serve as the. Shear Cutting Blade Design.

From sendaknife.en.made-in-china.com

Professional Customized Rolling Shear Blade and Longitudinal Shear Shear Cutting Blade Design When designing blades, the following two conditions are mainly considered: shear cutting is a chipless method of separating material along a cutting line (see table 2.1). shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. Shear cutting is the separation of workpieces by two blades moving. Shear Cutting Blade Design.

From www.danieli.com

Products del service › Customer Service › DanCut Shear Blades for Shear Cutting Blade Design shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. two design types are common to power squaring shears: In blanking, this forms a closed. When designing blades, the following two conditions are mainly considered: shear cutting is a chipless method of separating material along a. Shear Cutting Blade Design.

From sendaknife.en.made-in-china.com

High Accuracy Flying Shear Cutting Blades Knives for for Matching Shear Cutting Blade Design The guillotine (also know as the slider unit) and the swing. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. two design types are. Shear Cutting Blade Design.

From www.dienesusa.com

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality Shear Cutting Blade Design shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. In blanking, this forms a closed. When designing blades, the following two conditions are mainly considered: shear cutting. Shear Cutting Blade Design.

From www.lzqtech.com

SpecialShaped Cutting Blade, Bevel Cutting Blade, Shear Knife LZQ Shear Cutting Blade Design With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. two design types are common to power squaring shears: shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. When designing blades,. Shear Cutting Blade Design.

From federalknife.com

Metal Cutting Blades & Forming Shear Blades,slitter blades Shear Cutting Blade Design The guillotine (also know as the slider unit) and the swing. shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. When designing blades, the following two conditions are. Shear Cutting Blade Design.

From masshenlite.en.made-in-china.com

Custom Hot Rolling Metal Steel Plate Shear Cutting Blades China Shear Cutting Blade Design shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. The guillotine (also know as the slider unit) and the swing. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. two design types are. Shear Cutting Blade Design.

From www.sparkblades.com

metallurgical shear blades for cutting thick steel plate mills Shear Cutting Blade Design With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. In blanking, this forms a closed. shearing machine blades serve as the cutting edge in. Shear Cutting Blade Design.

From energize-group.co.jp

CNC, Metalworking & Manufacturing 7" long Dvorak Ironworker shear blade Shear Cutting Blade Design With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. When designing blades, the following two conditions are mainly considered: shear cutting. Shear Cutting Blade Design.

From masshenlite.en.made-in-china.com

Custom Hot Rolled Steel Shear Blade Machine Blade for Cutting Line Shear Cutting Blade Design shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut. Shear Cutting Blade Design.

From www.shearing-blades.com

H13K Steel Plate Shear Blades Design For Rolling Mill Plant Cutting Shear Cutting Blade Design In blanking, this forms a closed. two design types are common to power squaring shears: With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588.. Shear Cutting Blade Design.

From www.zorrotz.com

Shear Blades Shear Cutting Blade Design shear cutting is a chipless method of separating material along a cutting line (see table 2.1). When designing blades, the following two conditions are mainly considered: In blanking, this forms a closed. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. The guillotine (also know as. Shear Cutting Blade Design.

From www.etmblades.com

Shear Blades ETM Blades made in Sheffield, Yorkshire, UK Shear Cutting Blade Design shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. In blanking, this forms a closed. When designing blades, the following two conditions are mainly considered: shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed.. Shear Cutting Blade Design.

From www.shearing-blades.com

Mild Steel Crop Shear Blade Design Shear Cutting Blade Design With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. shear cutting is a chipless method of separating material along a cutting line (see table. Shear Cutting Blade Design.

From www.dienesusa.com

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality Shear Cutting Blade Design The guillotine (also know as the slider unit) and the swing. When designing blades, the following two conditions are mainly considered: two design types are common to power squaring shears: Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. shear cutting is a chipless method of separating material. Shear Cutting Blade Design.

From www.shearing-blades.com

Quality Hydraulic Shear Blade & Sheet Metal Shear Blades factory from China Shear Cutting Blade Design The guillotine (also know as the slider unit) and the swing. When designing blades, the following two conditions are mainly considered: shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. With the defined geometries introduced later in this article, it creates a force on the material separating. Shear Cutting Blade Design.

From knifemaker.com

Discover Rectangular Shear Blades Shear Cutting Blade Design Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. two design types are common to power squaring shears: With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. shearing machine blades serve as. Shear Cutting Blade Design.

From www.china-prima.com

sheet metal shear blade,hydraulic shear blade,high shear blades Ma Shear Cutting Blade Design shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The guillotine (also know as the slider unit) and the swing. shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. With the defined geometries introduced later in this article, it. Shear Cutting Blade Design.

From havencut.com

Haven's DualBlade Shear Cutting Technology Haven Manufacturing Shear Cutting Blade Design shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. two design types are common to power squaring shears: When designing blades, the following two. Shear Cutting Blade Design.

From jstmt.com

Hydraulic Shear Blades Manufacturer Shear Cutting Blade Design shearing is a simple process whereby a sheet of metal is cut into smaller pieces by two knives which are positioned. When designing blades, the following two conditions are mainly considered: two design types are common to power squaring shears: shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shear. Shear Cutting Blade Design.

From www.tradeindia.com

Shear Blades Cutting Accuracy at Best Price in Kolkata Reform Shear Cutting Blade Design shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The guillotine (also know as the slider unit) and the swing. With the defined geometries introduced later in this article, it. Shear Cutting Blade Design.

From knifesol.com

Flying shear blades KnifeSol Shear Cutting Blade Design two design types are common to power squaring shears: The guillotine (also know as the slider unit) and the swing. Shear cutting is the separation of workpieces by two blades moving in opposite directions past each other (din 8588. In blanking, this forms a closed. With the defined geometries introduced later in this article, it creates a force on. Shear Cutting Blade Design.

From www.youtube.com

SHEARING PROCESS SHEARING MECHANISM SHEAR FORCE SHEAR STRENGTH Shear Cutting Blade Design In blanking, this forms a closed. With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. The guillotine (also know as the slider unit) and the swing. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets. Shear Cutting Blade Design.

From setonknife.com

Large Diameter Rotary Shear Blade Blade Manufacturer SETON Shear Cutting Blade Design two design types are common to power squaring shears: The guillotine (also know as the slider unit) and the swing. shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. In blanking, this forms a closed. When designing blades, the following two conditions are mainly considered: Shear. Shear Cutting Blade Design.

From www.iksinc.com

Metal Shear Blades Shear Blade Manufacturer IKS Shear Cutting Blade Design two design types are common to power squaring shears: shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. shear cutting (also known as shear slitting) is the type of slitting that uses a combination of top and bottom knives. shear cutting is a chipless. Shear Cutting Blade Design.

From shearbladetechnology.com

Shear Blades Shear Blade Technology Shear Cutting Blade Design With the defined geometries introduced later in this article, it creates a force on the material separating it as it goes through the cut point. shearing machine blades serve as the cutting edge in mechanical devices designed to slice through metal sheets with accuracy and speed. shearing is a simple process whereby a sheet of metal is cut. Shear Cutting Blade Design.